Viega ProPress System - Pacific Energy Sales

Viega ProPress System - Pacific Energy Sales

Viega ProPress System - Pacific Energy Sales

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

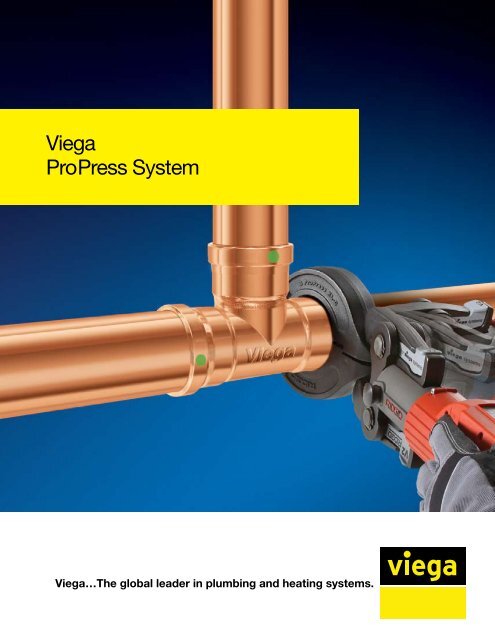

Speed• Speeds installation time dramaticallywith press connections completedin as little as five seconds.The fastest, most reliable,flameless way to join copper tubing...around the world. +The <strong>ProPress</strong> <strong>System</strong>, pioneered inEurope by <strong>Viega</strong>, is sweeping NorthAmerica. In commercial, industrialand residential installations, the<strong>ProPress</strong> <strong>System</strong> is the fastest,most reliable, flameless way tojoin copper tubing.Much faster than soldering• Safer - no flame• Cleaner - no solder,no flux• Convenient - one tool, one sourceof fittings• Over 25 years of provenperformance worldwide• Highest quality• Patented Smart Connect feature- only <strong>Viega</strong> fittings have it• Wide selection of sizes, types• Meets/exceeds industrystandards• Guaranteed reliabilityReliability• Consistent press connectionsmean water-tight and gas-tightjoints every time.• Patented Smart Connect featureidentifies unpressed connectionsso they are not left behind.=“<strong>ProPress</strong> is the best investment I havemade in the past 5 years. It has paidfor itself job after job.”Rick Williams,Aquanaut Plumbing“The time savings of <strong>ProPress</strong> isincredible. That coupled with no leaks,unlike the 1 to 3% we used to get withsoldering, has significantly increasedour productivity.”Larry Lee,East Coast Mechanical, Inc.Results• Thousands of professionals areusing the <strong>ProPress</strong> <strong>System</strong> toimprove installation time, avoidleaks and provide a professionallooking job.<strong>Viega</strong> 1-800-976-98194www.viega.com

<strong>ProPress</strong> 1/2" to 2" fittingsWe’re not only the fastest,but no one offersmore fitting choicesthan <strong>Viega</strong> <strong>ProPress</strong>.<strong>ProPress</strong> XL-C (copper) 2 1/2" to 4" fittingsOur speed and reliability has made the <strong>Viega</strong> <strong>ProPress</strong> <strong>System</strong>the industry standard for copper press systems. Also, <strong>Viega</strong><strong>ProPress</strong> fittings and valves are available in the widest varietyof configurations and sizes from 1/2" to 4", for any commercial,industrial or residential applications.<strong>ProPress</strong> XL (bronze) 2 1/2" to 4" fittingsNote: XL fittings may not be available in all areas.<strong>ProPress</strong>G 1/2" to 2" fuel gas fittings<strong>ProPress</strong> and <strong>ProPress</strong>G valves<strong>Viega</strong> 1-800-976-98196www.viega.com

Orange County Choppers ®World Headquarters“Soldering all the fittings in this job would have taken toolong - I would estimate the <strong>ProPress</strong> system saved mycrew at least ten days of work.”Larry Krug,Orange County Sheet Metal,Newburgh, N.Y.<strong>Viega</strong> 8 1-800-976-98197www.viega.com

<strong>ProPress</strong> vs.Sweat time comparisonTo compare labor times between copper sweatand press applications, a typical restaurantrestroom installation was used. The installationwould include the plumbing fixtures: five tanktype water closets, one flushometer urinal,four lavatories, one water heater. A total of 53copper fittings in sizes ranging from 1/2" to 1"were estimated. MCAA* calculator was utilizedin the labor estimate.<strong>ProPress</strong>6.21MCAA labor hoursSweat25.54MCAA labor hoursThe results of this estimate show that thereis a dramatic savings in time when utilizingPress technology versus soldering. The timesavings translates into jobs being completedquicker and on time or ahead of schedule.Approximate difference of75%Labor Savings*MCAA is the Mechanical Contractors Association of America. (Site source)<strong>Viega</strong> 1-800-976-98198www.viega.com9

<strong>Viega</strong> 12 1-800-976-981911www.viega.com

Here’s how to identify the best press fittings.<strong>ProPress</strong> 1/2" to 2" fittings.Unpressed connection withthe Smart Connect featureallows liquids and/or air topass by the sealing elementduring pressure test.EPDMsealFittingbeadCoppertubing<strong>ProPress</strong>fittingPressed connection is pressed in front of,on top of, and behind the seal making agas-tight and water-tight seal. The SmartConnect feature is sealed during pressing.<strong>ProPress</strong> XL-C (copper)2 1/2" to 4" fittings.EPDMsealSeparatorringStainless steelgrip ringThe stainless steel grip ringis pressed on top, forcingthe grip ring teeth againstthe tube, making a highstrengthconnection.<strong>ProPress</strong>XL-C fittingFittingbeadCoppertubing<strong>Viega</strong> 1-800-976-981912www.viega.com 13

<strong>Viega</strong> 1-800-976-981913www.viega.com

PatentedSmart Connectfeature:The exclusive <strong>Viega</strong> Smart Connectfeature with the yellow spots for<strong>ProPress</strong>G, gives the installerthe ability to identify unpressedfittings during pressure testing...saving time and improving safety.The unpressed connection allowsair to flow past the seal. The finalpressure test should be completedin accordance with local codes.1Identify an unpressedconnection duringpressure testing whenair flows past the sealingelement.R & D <strong>System</strong>s, Minneapolis, MNThis medical research company needed to replace an outdatedsteam boiler. This system serves a new 80,000 sq. ft. additiondisrupted during the retrofit. Due to the critical nature of work,2Upon identificationthe “press‚ toolis used to press thefitting, making a permanentleak‐proof connection.Look for the yellow dots.3<strong>ProPress</strong>connections arefast, flamelessand more reliable.UnpressedPressed<strong>Viega</strong> 16 1-800-976-981915www.viega.com

steam generator with a new gas-fired high-pressureand an existing building where work could not bethey required a fail-safe mechanical system.Marine Terminal Loft Condos, Milwaukee, WIThe Marine Terminal building in the historic Milwaukee Third Wardrequired a complete retrofit of an old warehouse into 84 condos,which involved installation of gas and water lines in tight spaces.Avoiding flames was also a major concern.<strong>Viega</strong> 1-800-976-981916www.viega.com 17

No one can press connect more applicationsthan <strong>Viega</strong> <strong>ProPress</strong> and <strong>ProPress</strong>G.Only the <strong>Viega</strong> <strong>ProPress</strong> <strong>System</strong>soffer hundreds of engineeredcopper and bronze press fittings inconfigurations from 1/2" to 4" forfluids and gas. Both <strong>Viega</strong> <strong>ProPress</strong>and <strong>ProPress</strong>G offer the exclusiveSmart Connect feature - to quicklyidentify unpressed fittings.Type of ServiceFluids<strong>System</strong> Operating ConditionsSpecialty SealsFactory Installed<strong>ProPress</strong> w/EPDMColor-Shiny BlackSpecialty SealsField InstalledFKM Color-Dull Black*Specialty SealsFactory Installed<strong>ProPress</strong>G w/HNBRColor-YellowHot and Cold Potable Water 32°F – 250°F, max. 200 PSI YES NO NOPotable Water <strong>System</strong> Flushing Compliant with major plumbing codes YES NO NOChilled Waterwith corrosion inhibitorsHydronic Heating0°F – 250°F, max. 200 PSIEthylene Glycol – 50% max. concentrationPropylene Glycol – 50% max. concentration0°F – 250°F, max. 200 PSIEthylene Glycol – 50% max. concentrationPropylene Glycol – 50% max. concentrationYES YES NOYES YES NOLow Pressure Steam Max. 15 PSI NO YES NORainwater/Greywater 32°F – 250°F, max. 200 PSI YES YES YESFire Sprinkler 32°F – 250°F, max. 175 PSI YES NO NOHeating Fuel Oil -40°F – 150°F Ambient, max. 125 PSI NO NO YESDiesel Fuel Compliant with NFPA 30 and 30A NO NO YESProcess PipingPropylene Glycol 0°F – 250°F, 200 psi 100% max. concentration YES YES NOEthylene Glycol 0°F – 250°F, 200 psi 100% max. concentration YES YES NOButylene Glycol 0°F – 250°F, 200 psi 100% max. concentration YES YES NOPure Grain Alcohol NO NO NOLiquid Nitrogen NO NO NOGasesCompressed Air with less than25mg/m 3 oil content0°F – 160°F Ambient, max. 200 PSI YES YES YESCompressed Air with more than25mg/m 3 oil content0°F – 160°F Ambient, max. 200 PSI NO YES YESCarbon Dioxide CO2 dryNitrogen N2ArgonCorgon0°F – 250°F Ambient, max. 140 PSI0°F – 250°F Ambient, max. 160 PSI0°F – 250°F Ambient, max. 140 PSI0°F – 250°F Ambient, max. 160 PSI0°F – 250°F Ambient, max. 140 PSI0°F – 250°F Ambient, max. 160 PSI0°F – 250°F Ambient, max. 140 PSI0°F – 250°F Ambient, max. 160 PSIArgonmac - K (welding gas) 0°F – 250°F Ambient, max. 140 PSI YES NO NOVacuum Max. 29.2 inches of Mercury YES YES NONatural Gas, Liquid Propane Gas,Mixed Fuel Gases, Manufactured -40°F – 160°F Ambient, max. 125 PSI NO NO YESFuel Gases, Liquid Butane GasOxygen O2(non-medical) -40°F – 160°F Ambient, max. 125 PSI YES NO YES*Notes: FKM sealing elements not compatible with XL-C fittings.†Warning: All systems are recommended to be clearly labeled with the fluid or gas being conveyed. For further information please see the<strong>Viega</strong> technical bulletin TB-PIPELABELING. Consult the <strong>Viega</strong> Technical Support Department for information on applications not listed andapplications outside the temperature and pressure ranges listed above.YESNOYESNOYESNOYESNONONONONONONONONONOYESNOYESNOYESNOYES<strong>Viega</strong> 1-800-976-981918www.viega.com

<strong>Viega</strong> 20 1-800-976-981919www.viega.com

<strong>ProPress</strong> maximizesproductivity withthe tightest distancebetween fittings.“We prefer it for newconstruction becauseit presents the mostprofessional image possible.”Mike Fitzgerald,East Coast Mechanical Inc.Mandalay Bay Hotel Tower, Las Vegas, NVThis resort complex used over 60,000 <strong>Viega</strong> <strong>ProPress</strong> fittings forpotable, hydronic, chilled water systems; collection mains; risers; boilerrooms for swimming pools and spas on the property.“We have installed over100,000 fittings to datewithout a single leak.”Mike Haggerty, President,Haggerty & Company<strong>ProPress</strong> and<strong>ProPress</strong>G 1/2" – 2"TubingdiameterMinimum distancebetween fittingsinches (mm)Ford Motor Company, Livonia, MIFord chose the <strong>ProPress</strong> <strong>System</strong> for a fire protection systeminstalled in their Livonia transmission plant. The job involved2 miles of copper tube and thousands of <strong>Viega</strong> fittings.1/2" 0" (0)3/4" 0" (0)1" 0" (0)1 1/4" 7/16" (10)1 1/2" 5/8" (15)2" 3/4" (20)<strong>ProPress</strong> XL-C (Copper)2 1/2" – 4"2 1/2" 5/8" (15)3" 5/8" (15)4" 5/8" (15)<strong>ProPress</strong> XL (Bronze)2 1/2" – 4"Pentagon, Washington D.C.<strong>Viega</strong> systems are successfully installed and operating inmany government facilities such as the Pentagon and theLibrary of Congress among others.2 1/2" 0" (0)3" 0" (0)4" 0" (0)<strong>Viega</strong> 1-800-976-981920www.viega.com 21

<strong>Viega</strong> 1-800-976-981921www.viega.com

<strong>Viega</strong> <strong>ProPress</strong> coppersolderless press fittingsystem for NFPA13 wet ordry fire sprinkler systems.Proven under fire, <strong>Viega</strong> <strong>ProPress</strong> fittings for fire controlsystems have exceeded all four sequential severe firetests at UL Labs in accordance with UL852 for steelpiping systems. The fittings were also tested to physicalperformance requirements of UL213, which covers allrubber gasketed fittings.The wood crib fire test in progress, just beforesprinkler activation.• Flameless - no soldering or flammable gases• Faster connections - joins copper pipe in seconds• Patented Smart Connect feature - only <strong>Viega</strong> fittingshave it• Long life - no deterioration, never gets brittle• No down time - installs wet or dry• Corrosion resistant - no need for protective painting• Professional appearance - no burn marks or rust• Continuous flow - no corrosion buildup that couldclog sprinkler heads• Versatile - commercial, industrial andresidential applications• UL listed and FM approved for fire sprinkler systems,for use with type K, L and M copper tube in NFPA 13,13D and 13R fire sprinkler systemsFittings available in sizes from 1/2"- 2" for 1/2" and 3/4"sprinkler heads.<strong>Viega</strong> 1-800-976-981922www.viega.com

<strong>Viega</strong> 24 1-800-976-981923www.viega.com

Yosemite National Park uses <strong>Viega</strong> <strong>ProPress</strong>for fire sprinkler systems.Yosemite National Park decided to renovate ten historicalcabins with updates to their electrical systems and their firesprinkler systems. Park officials would not allow any form ofopen flame within 50' of the structures. Contractors, ControlFire from Bakersfield, CA, chose to use the <strong>Viega</strong> <strong>ProPress</strong>system for the renovations because it is a fast, flameless,solderless system. Theupdates were alsoscheduled during the heightof forest fire season, theneed for a safe and easy wayto install a sprinkler systemwas of high importance.Villa Amorosa protects its winerywith <strong>Viega</strong> <strong>ProPress</strong>.<strong>Viega</strong> <strong>ProPress</strong> was the system ofchoice for fire protection at the VillaAmorosa Winery in Calistoga, CA.Fairbanks Mechanical Contractorsinstalled the fire sprinkler system, aswell as the domestic and hydronicwater systems in the winery.Fairbanks Mechanical was one ofthe first contractors in NorthernCalifornia to use <strong>Viega</strong> systemsback in spring 2000.<strong>Viega</strong> 1-800-976-981924www.viega.com 25

<strong>Viega</strong> 26 1-800-976-981925www.viega.com

<strong>Viega</strong> hybrid technologycombines two innovative systems.<strong>Viega</strong> hybrid technology combines two proven systems- <strong>ProPress</strong> copper press system and PureFlow PEXPress fittings and <strong>Viega</strong>PEX tubing. Together, the twosystems improve efficiency and capitalize on the uniqueproperties of each material.“<strong>Viega</strong>’s PEX and <strong>ProPress</strong> combinationsystem works great and helps us provideexceptional quality.”Jack O’BrienDirector Field Services, Harris Companies“<strong>Viega</strong> products beat all others when it comesto speed and reliability. No leaks. Done.”Charlie McCarthyDesign Engineer, Donovan & SonsForward-thinking plumbing and mechanical contractorsare adopting <strong>Viega</strong> hybrid technology to reduceinstallation time, improve reliability and provide thehighest quality plumbing solutions.Quick and easy copperto PEX connections.Combining <strong>Viega</strong>’s PureFlow and <strong>ProPress</strong> systemsallows contractors to stay ahead of schedule withproven reliability.Manifold connectionsmade easy.The <strong>ProPress</strong> manifold’s modular technology designenables contractors to build manifolds to anyconfiguration with fewer parts and unmatched speed.Hybrid fittings makethe difference.<strong>ProPress</strong> and PureFlow fittings combine to connectvarious diameters of <strong>Viega</strong>PEX or FostaPEX withcopper tubing.<strong>Viega</strong> 1-800-976-981926www.viega.com 27

<strong>Viega</strong> Internal Recirculation <strong>System</strong>... another hybrid innovation.<strong>Viega</strong>’s new Internal Recirculation <strong>System</strong> is aninside lying recirculation system, which uses thesupply riser to insulate the internal recirculation piping.A 3/8" <strong>Viega</strong>PEX return line is inside the riser andis insulated by warm water. This type of installationcompletely eliminates the need for an outside returnpipe, creating an energy savings of 20 to 30 percentover a conventional circulation system.“Not only are the materialssavings significant, butI would estimate wesaved at least an hour ofinstallation time per room.”Brian DwyerDwyer Plumbing<strong>Viega</strong> 1-800-976-981927www.viega.com

Saves time, space,materials and energy.• Reduces penetrations and core drilling• Minimizes insulation on return lines• Lowers heat loss on return lineProfessional appearance.• Compact design• Requires fewer fittings and supportsHot water recirculation<strong>Viega</strong>PEX line is connecteddirectly to the top of the riser.The specially designed fittingallows for recirculation flowthrough the internal line.Proven press technology.• No solder or flame6th Floor5th Floor4th Floor6th Floor5th Floor4th FloorBranch lines to eachfloor feed directly off riser,either in <strong>Viega</strong>PEX,FostaPEX or Copper.3rd Floor2nd Floor1st Floor3rd Floor2nd Floor1st FloorInternal recirculationreturn line keeps riserhot without requiringadditional insulation orseparate core drilled.Thermostatic ValveBall ValveCirculation PumpCheck ValveHot SupplyRecirculation Line (return)Hot WaterSourceInternal recirculation lineconnects directly to thereturn line for the hot watersource; no additionalmaterials needed.<strong>Viega</strong> 1-800-976-981928www.viega.com

Zero Lead… Zero ProblemThanks to <strong>Viega</strong>, contractors acrossthe country have been installinglead-free plumbing systems for 10+years. There’s no need to worry aboutnew lead-free legislations being setacross the United States. Californiaand Vermont may have been at theforefront in lead-free legislation, but<strong>Viega</strong> <strong>ProPress</strong> copper and stainlessproducts, already meet theirlead-free requirements.Because copper and stainless isnaturally lead-free, all <strong>Viega</strong> <strong>ProPress</strong>copper and stainless productsinherently comply with new Zero Leadlegislations. The <strong>ProPress</strong> Bronze1/2" – 2" products that did not alreadycomply with new lead-freerequirements have been manufacturedutilizing <strong>Viega</strong>’s new Zero Lead siliconbronze alloy. These alloys haveexcellent resistance to corrosionand dezincification.When specifying <strong>Viega</strong> products,look for the following markings:<strong>Viega</strong> 30 1-800-976-981929www.viega.com

• Labeling and installationinstructions of compliant productswill contain a notice stating, “Thisproduct contains Zero Lead”.• <strong>ProPress</strong> Zero Lead bronzeproducts will be marked withNSF 61-G, and copper productswill continue to be marked NSF-61.• <strong>Viega</strong>’s Zero Lead listing can bedownloaded at the NSF Web site:NSF Certified Products -Plumbing and Related Products(www.nsf.org/Certified/Plumbing)We remain committed to providingour customers with clean, safe,healthy drinking water deliverysystems. You can be confidentthat when you are specifying <strong>Viega</strong>products, you are getting productsthat meet and exceed the moststringent lead-free requirements.Additional information can be found at zeroleadfacts.comZero Lead identifies <strong>Viega</strong> products meeting the lead-free requirements of California and Vermont law, effective January 1, 2010, as testedand listed against NSF-61, Annex G.<strong>Viega</strong> 1-800-976-981930www.viega.com 31

180°RIDGID is a registered trademark of Ridge Tool Company.<strong>Viega</strong> 1-800-976-981931www.viega.com

<strong>Viega</strong> <strong>ProPress</strong> <strong>System</strong>s offersthe right tools and jawsfor any pressing application.The <strong>ProPress</strong> <strong>System</strong> is the result of a joint effort by two ofthe world’s most recognized names in plumbing – Ridgidand <strong>Viega</strong>. Together, <strong>Viega</strong> fittings and Ridgid tools haverevolutionized the industry with their fast, flameless, solderlesspress technology. The Ridgid tools, jaws, actuators and ringsare system matched to the <strong>Viega</strong> fittings for a trouble-freeconnection every time. These two leaders continue to advancepress technology, with features like the new 180° swivel for 1/2"to 2" fittings, making it even easier to press in tight spaces.<strong>Viega</strong> fittings and Ridgid tools have combined innovationand quality making <strong>ProPress</strong> the premier press system forcontractors around the world.Patented 180° swivel now availablefor 1/2" to 4" fittings and valves.• Ball-tip actuator swivels 180° with 1/2" to 4" pressing rings.• Same tools and jaws for copper and stainless steel fittings.• Provides increased flexibility in tight spaces.• Over 20% reduction in actuator jaw weight forincreased comfort.• Exclusive identification clip to quickly identify the properactuator jaw.<strong>Viega</strong> 1-800-976-981932www.viega.com

<strong>Viega</strong> 34 1-800-976-981933www.viega.com

Tools and jaws recommended for <strong>ProPress</strong>,<strong>ProPress</strong>G and <strong>ProPress</strong> Stainlessstandard fittings and valves.Three pressing tool options:RP210-B – Battery powered Tool (1/2" to 1 1/4")RP 330-B – <strong>ProPress</strong> Copper and <strong>ProPress</strong> Stainless1/2" to 4"RP 330-C – <strong>ProPress</strong> Copper and <strong>ProPress</strong> Stainless1/2" to 4"Actuator and ring kits – 1/2" to 2"V1 Kit – Includes C1 Actuator (use with RIDGID 100-Btool), V1 Actuator (use with RIDGID RP 330-B and RP330-C tools) and 1/2", 3/4", 1" and 1 1/4" Pressing RingsV2 Kit – Includes V2 Actuator, 1 1/2" and 2" PressingRings for use with RIDGID RP 330-B and RP 330-C toolsTools and jaws recommended for<strong>ProPress</strong> XL-C (copper) and<strong>ProPress</strong> XL-S (stainless) fittings.XL-C (copper) and XL-S (stainless) fittings are onlycompatible with XL-C Pressing Rings and V2 Actuator.Press with either RIDGID RP 330-B or RP 330-CPress Tools.<strong>ProPress</strong> 2 1/2" to 4" XL-C (copper) and XL-S (stainless)fittings must be installed with <strong>ProPress</strong> XL-C ringsand V2 actuator jaw. Any deviation will result in animproper connection.Tools and jaws recommended for<strong>ProPress</strong> XL (bronze) fittings.XL (bronze) fittings are only compatible with XLPressing Rings and R2 Actuator. Press with eitherRIDGID RP 330-B or RP 330-C Press Tools.<strong>ProPress</strong> 2 1/2" to 4" XL (bronze) fittings must be installedwith <strong>ProPress</strong> XL-rings and R2 actuator jaw. Any deviationwill result in an improper connection.<strong>Viega</strong> 1-800-976-981934www.viega.com 35

<strong>Viega</strong>301 N. Main, 9th FloorWichita, KS 67202Phone: 1-800-976-9819Fax: 1-800-976-9817www.viega.cominsidesales@viega.com©2010, <strong>ProPress</strong> ® , PureFlow ® , Smart Connect ® , Climate Panel ® , Climate Mat ® ,Climate Trak ® , FostaPEX ® , MANABLOC ® , MINIBLOC ® , Radiant Wizard ® , Seapress ® ,S-no-Ice ® , <strong>Viega</strong> ® , XL ® , and XL-C ® are registered trademarks of <strong>Viega</strong>. <strong>ProPress</strong>G ,ProRadiant ® , Polyalloy , PlumbingCAD , SC Feature , <strong>Viega</strong>PEX and Zero Lead are trademarks of <strong>Viega</strong>. RIDGID ® is a registered trademark of Ridge Tool Company.724582_PP_SYSTEM_BR_USA_0110