Quality Function Deployment for Environment

Quality Function Deployment for Environment

Quality Function Deployment for Environment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

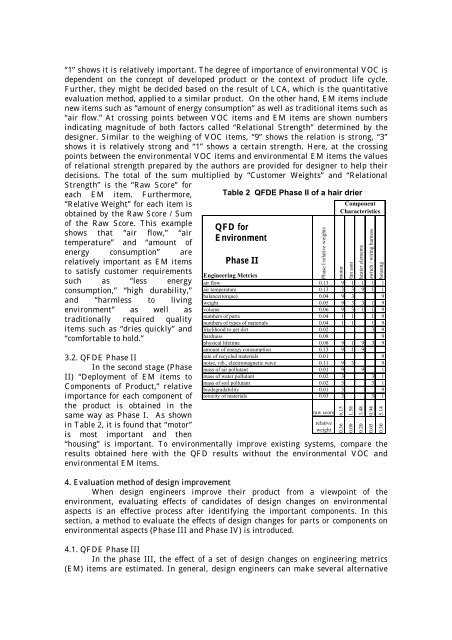

“1” shows it is relatively important. The degree of importance of environmental VOC isdependent on the concept of developed product or the context of product life cycle.Further, they might be decided based on the result of LCA, which is the quantitativeevaluation method, applied to a similar product. On the other hand, EM items includenew items such as “amount of energy consumption” as well as traditional items such as“air flow.” At crossing points between VOC items and EM items are shown numbersindicating magnitude of both factors called “Relational Strength” determined by thedesigner. Similar to the weighing of VOC items, “9” shows the relation is strong, “3”shows it is relatively strong and “1” shows a certain strength. Here, at the crossingpoints between the environmental VOC items and environmental EM items the valuesof relational strength prepared by the authors are provided <strong>for</strong> designer to help theirdecisions. The total of the sum multiplied by “Customer Weights” and “RelationalStrength” is the “Raw Score” <strong>for</strong>each EM item. Furthermore,“Relative Weight” <strong>for</strong> each item isobtained by the Raw Score / Sumof the Raw Score. This exampleshows that “air flow,” “airtemperature” and “amount ofenergy consumption” arerelatively important as EM itemsto satisfy customer requirementssuch as “less energyconsumption,” “high durability,”and “harmless to livingenvironment” as well astraditionally required qualityitems such as “dries quickly” and“com<strong>for</strong>table to hold.”3.2. QFDE Phase IIIn the second stage (PhaseII) “<strong>Deployment</strong> of EM items toComponents of Product,” relativeimportance <strong>for</strong> each component ofthe product is obtained in thesame way as Phase I. As shownin Table 2, it is found that “motor”is most important and thenTable 2 QFDE Phase II of a hair drierQFD <strong>for</strong><strong>Environment</strong>Phase IIComponentCharacteristicsEngineering Metricsair flow 0.13 9 1 1 1 1air temperature 0.13 3 3 9 1 1balance(torque) 0.04 9 3 9weight 0.05 9 3 3 1 9volume 0.06 9 3 1 1 9numbers of parts 0.04 1 1 1 9numbers of types of materials 0.04 1 1 1 9likelihood to get dirt 0.02 3 9hardness 0.08 9physical lifetime 0.08 9 1 9 3 9amount of energy consumption 0.13 9 1 9rate of recycled materials 0.01 9noise, vib., electromagnetic wave 0.11 9 3 9mass of air pollutant 0.01 9 9 1mass of water pollutant 0.02 3 3 1mass of soil pollutant 0.02 3 3 1biodegradability 0.01 3 9toxicity of materials 0.03 3 3 1“housing” is important. To environmentally improve existing systems, compare theresults obtained here with the QFD results without the environmental VOC andenvironmental EM items.4. Evaluation method of design improvementWhen design engineers improve their product from a viewpoint of theenvironment, evaluating effects of candidates of design changes on environmentalaspects is an effective process after identifying the important components. In thissection, a method to evaluate the effects of design changes <strong>for</strong> parts or components onenvironmental aspects (Phase III and Phase IV) is introduced.4.1. QFDE Phase IIIIn the phase III, the effect of a set of design changes on engineering metrics(EM) items are estimated. In general, design engineers can make several alternativePhase I relative weightsraw scorerelativeweightmotorfan asmheater elementsswitch / wiring harnesshousing6.151.583.480.945.140.360.090.200.050.30