header - TenCate

header - TenCate

header - TenCate

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

AEROSPACE COMPOSITES<br />

Product outline aerospace interiors<br />

<strong>TenCate</strong> Cetex System3<br />

Protective Fabrics<br />

Outdoor Fabrics<br />

Aerospace Composites<br />

Armour Composites<br />

Geosynthetics<br />

Industrial Fabrics<br />

Grass

TENCATE CETEX SYSTEM3<br />

Three thermoplastic products, one system, one solution<br />

<strong>TenCate</strong> Cetex ® System3 provides one stop solutions of interior<br />

panels. The product is ideally suited to fl at and single curvature parts<br />

where light weight high fi nish is required. The GE PEI based materials<br />

used for both skin and core, enable high quality parts to be produced<br />

in very short period of time.<br />

See the benefi ts:<br />

High quality pre fi nished skin materials<br />

Multiple texture fi nishes<br />

Very low OSU tox and fl ame<br />

Tough<br />

Base colour options<br />

Short manufacturing times timeline benefi ts<br />

Lightweight skin options without jeopardising skin quality<br />

Applicable manufacturing process:<br />

Thermo forming<br />

Cut and bend<br />

Hot bending<br />

Welding<br />

2<br />

AEROSPACE COMPOSITES

A thermoplastic technology driven system<br />

The unique properties of the <strong>TenCate</strong> Cetex ® System3 allows both<br />

traditional sandwich panel applications to be furnished using the<br />

panel system as well thermoforming of the system for single<br />

curvature parts. The pre-fi nished facings allow components to be<br />

manufactured and fi nished with little or no preparation, thus<br />

reducing or eliminating the amount of after work required with<br />

tradional thermoset technology.<br />

APPLICATIONS:<br />

Galley components<br />

Flooring<br />

Wardrobes and storage<br />

Overhead luggage bins<br />

Screen dividers<br />

Partitioning walls and bulkheads<br />

Dado rails<br />

Lavatories<br />

Seat components<br />

Plinths and pallets<br />

Trolley components<br />

Stairways and steps<br />

Decorative panels<br />

MATERIAL OPTIONS AND PROPERTIES<br />

Facing materials<br />

The <strong>TenCate</strong> Cetex ® facing sheets are produced using very high<br />

quality press technology allowing high standards of surface fi nish and<br />

property translation to be achieved. The sheets are produced in a<br />

variety of fi nishes and this is pressed into the surface so durability<br />

and consistency is assured.<br />

Finishes:<br />

High gloss<br />

Matt<br />

Enhanced bondable surface<br />

Textured fi nish<br />

Anti slip<br />

Along with surface fi nish the PEI polymer can be base coloured to<br />

enhance, reduce and in some cases eliminating fi nishing of surfaces<br />

of components. This is very useful when painting or covering<br />

components, as base colour matching the skins will greatly reduce<br />

the amount of paint one needs to apply. Along with this wear and<br />

scratch resistance of components is enhanced if base material colour<br />

is similar to the fi nal fi nished surface.<br />

Facing sheets<br />

A variety of reinforcements can be used to produce <strong>TenCate</strong> Cetex ®<br />

facing sheets, in general the main fabrics used are Glass, Carbon and<br />

Aramid yarns. The weights and fabric styles are many, and really<br />

there are no restrictions on which fabrics can be used to produce<br />

facing sheets. In general, for glass we have utilised both a 120 style<br />

glass and 7781 glass. Combinations of these plies allows us to<br />

produce skins from .005” 0.12mm in thickness upwards allowing<br />

lightweight panels to be produced through to heavyweight highly<br />

loaded panels. On the next page are some examples of laminate<br />

materials.<br />

Examples of laminate materials:<br />

Glass 8H (7781)/SS 0303/EC6 (BMS 8-353)<br />

Mass of fabric 300<br />

Mass of fabric + resin 448<br />

Resin content by volume (nominal) 50<br />

Resin content by weight (nominal) 33<br />

Moisture pick up 0.35<br />

Ply thickness 0.24<br />

Specifi c gravity 1.91<br />

Tg (DSC) (armorphous) 210<br />

Tm 310<br />

AEROSPACE COMPOSITES 3

TUBULAR HEADER CORE MATERIALS<br />

Sub<strong>header</strong><br />

<strong>TenCate</strong> Reet ut venim Cetex ad magna feu facillu mmodit lam zzriuscil del ex et, conOrting eum non henisci lisisim vulputat consequisit<br />

delenim digna con hent augait, sisl diam, vel et amcommo adit, quismolenit, quisl iurer susci tin ea alit prat adip eugiat<br />

loborem num ip ercilla dolese tat, suscilis ent dolorperil illum in utpat. Ed dio odiam, vulla faciliquatue alit inis eu faciduis<br />

dolortio dolor incipis duipit accum aliquisi. Agnis<br />

nonsecte dolorpe rcinci tie feu facin dolessim veriuscidunt<br />

et ut laorem velesequat ad feugue facilla feuissequis alis alit<br />

alit diamcom moluptat. Ut ad tin vel ipsum amefaccum ent nos nonsequi blaor alit dionsequat lor inim incing<br />

num vulluptate vel euissim illa ad er si euisl e, con Rserddeet<br />

ut venim ad magna feu facillu mmodit et amcommo loborem Erciliq uating elesequate consenisit iriusci nos am, vel utem<br />

num ercilla oreriurem dolese, mmodit suscilis ent dolorperil dolore facin ullamcor secte tatum euguero deliqui er iuscinc<br />

illum dolor incipis duipit accum er aliquisi.<br />

tisit vel ulput vuautat nis nullam zzrit praesecte velisl delis<br />

nim nos am, vel utem dolore facin ullamcor secte tatum<br />

Agnis alit diamcom moluptat. Ut ad tin vel ipsum ametums euguero deliqui er iuscinc consequis niatio con ullum dio<br />

andipsum adit vent nulputpat lamet lum ad magna faccum consendipisi exer susci tisit vel ulput vuautat nis nullam zzrit<br />

veraestrud ent num vulluptate vel euissim illa ad er si euisl praesecte velisl delis nim autat, quisi eugait<br />

® System3 incorporates the use of a thermoplastic core<br />

material (made by Tubus Bauer) the core is tubular in construction<br />

and can be supplied in many different core weights and primarily<br />

comes in 4 or 6 mm cell sizes. The core is cut to thickness and can be<br />

as thin as 3 mm. The unique properties of the core mean that there is<br />

no ribbon direction in the core. It is made from GE Ultem ® PEI polymer<br />

and this gives it excellent fi re properties.<br />

The concept behind <strong>TenCate</strong> Cetex ® System3 is three thermoplastic<br />

materials, one system. Combining the <strong>TenCate</strong> Cetex ® The thermoplastic adhesive SHARNET SN4275 gives excellent results<br />

when heated to 150<br />

facing skins<br />

with the Tubus tubular core with a thermoplastic fi lm adhesive allows<br />

structures to be manufactured quickly and effi ciently without altering<br />

the high level of surface fi nish already established in the skin material.<br />

This in itself allows for minimal preparation work later on if any in<br />

some instances.<br />

oC and this temperature is not suffi cient to alter<br />

the surface of the skin material. Bonding can be achieved in a matter<br />

of minutes compared to hours for thermosets and the peel numbers<br />

achieved are excellent. This process is utilised in the manufacture of<br />

premium aircraft fl ooring by WJ Tods and achieves very durable light<br />

weight fl ooring solutions for aircraft.<br />

4<br />

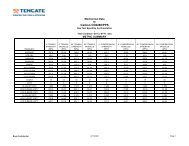

Core options<br />

AEROSPACE COMPOSITES<br />

PEI 4,0-48C PEI 4,0-75 C PEI 4,0-100 C PEI 4,0-120 C PEI 4,0-144 C<br />

Properties METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL METRIC IMPERIAL<br />

Cell size 4.2 mm 1/8” 4.2 mm 1/8” 4.2 mm 1/8” 4.2 mm 1/8” 4.2 mm 1/8”<br />

Density<br />

Compressive strength<br />

Compressive modulus<br />

Shear strength<br />

Shear modulus<br />

48<br />

kg/m3 3 lb/ft3 75<br />

kg/m3 0.95<br />

mpa<br />

106<br />

mpa<br />

0.65<br />

mpa<br />

12.2<br />

mpa<br />

137 psi<br />

15.36 ksi<br />

94 psi<br />

2.95<br />

mpa<br />

178.5<br />

mpa<br />

1.3<br />

mpa<br />

4.6<br />

lb/ft 3<br />

100<br />

kg/m 3<br />

6.24<br />

lb/ft 3<br />

427 psi 4.6 mpa 603 psi<br />

25.8 ksi 222.8 mpa 32.3 ksi<br />

188 psi<br />

1.6<br />

mpa<br />

232 psi<br />

1.76 ksi 26 mpa 3.76 ksi 27 mpa 3.91 ksi<br />

120<br />

kg/m 3<br />

6.34<br />

mpa<br />

276.1<br />

mpa<br />

2.1<br />

mpa<br />

32<br />

mpa<br />

7.49<br />

lb/ft 3<br />

919 psi<br />

40 ksi<br />

Tubus-PEI core<br />

Thermoplastic<br />

adhesive 60 gsm<br />

144<br />

kg/m 3<br />

10.71<br />

mpa<br />

339.6<br />

mpa<br />

9 lb/ft 3<br />

1552 psi<br />

49.2 ksi<br />

304 psi 3.3 mpa 478 psi<br />

4.64 ksi<br />

40<br />

mpa<br />

5.79 ksi<br />

<strong>TenCate</strong> Cetex ® facing skins

TEST RESULTS<br />

Skins: GI 0303 002 1707 (E-glass)<br />

Core: PE: 4.0-75C 12 mm.<br />

Test Test method<br />

Areal weight EN 2329<br />

Thickness<br />

Specimen<br />

dimensions<br />

Length = 10 mm<br />

Width = 10 mm<br />

Length = 10 mm<br />

Width = 10 mm<br />

All specimen are conditioned at 23˚C / 50% RH and tested at 23˚C<br />

Test Test method<br />

Sandwich lexural<br />

strength<br />

(4 point bending)<br />

Climbing drum<br />

peel<br />

AITM 1.0018<br />

(Issue 1. March 1994)<br />

EN 2243-3<br />

(October 2005)<br />

Impact resistance AITM 1-0057<br />

Flammability<br />

(warp)<br />

12 sec. vertical<br />

Smoke density<br />

JAR/FAR 25. App.<br />

F part I<br />

&<br />

AITM 2.0002B<br />

JAR/FAR 25. App.<br />

F part V<br />

&<br />

AITM 2.0007<br />

Toxity AITM 3.0005<br />

Specimen<br />

dimensions<br />

Length = 400 ± 1 mm<br />

Width = 75 ± 0.1 mm<br />

Length = 300 ± 1 mm<br />

Width = 75 ± 0.5 mm<br />

Length = 305 ± 1 mm<br />

Width = 305 ± 1 mm<br />

Length = 300 mm<br />

Width = 75 mm<br />

Length = 75 mm<br />

Width = 75 mm<br />

Length = 75 mm<br />

Width = 75 mm<br />

# specimen<br />

# specimen avg. st dev. % var.<br />

3 2390 4.36 0.18<br />

3 12.64 0.01 0.08<br />

Results<br />

avg. st dev. % var.<br />

6 F max [N] 1382.5 46.1 3.3<br />

6<br />

3<br />

4<br />

4<br />

Force difference<br />

[N]<br />

Peel strength<br />

[N/mm]<br />

Mean failure<br />

energy [J]<br />

379.5 42.4 11.2<br />

5.07 0.56 11.1<br />

1.4 - -<br />

Measured (avg.)<br />

Airworthiness<br />

limit<br />

Burn length [mm] 55 203<br />

After fl ame time [s] 3 15<br />

After fl ame time of drips [s] 0 5<br />

Drips (yes/no) no<br />

Max. specifi c<br />

optical density<br />

4 Passed<br />

Measured (avg.)<br />

Airworthiness<br />

limit<br />

16 100<br />

AEROSPACE COMPOSITES 5

THERMOFORMING HEADER<br />

OF SINGLE CURVATURE PARTS<br />

Sub<strong>header</strong><br />

<strong>TenCate</strong> Reet ut venim Cetex ad magna feu facillu mmodit lam zzriuscil del ex et, conOrting eum non henisci lisisim vulputat consequisit<br />

delenim digna con hent augait, sisl diam, vel et amcommo adit, quismolenit, quisl iurer susci tin ea alit prat adip eugiat<br />

loborem num ip ercilla dolese tat, suscilis ent dolorperil illum in utpat. Ed dio odiam, vulla faciliquatue alit inis eu faciduis<br />

dolortio dolor incipis duipit accum aliquisi. Agnis<br />

nonsecte dolorpe rcinci tie feu facin dolessim veriuscidunt<br />

et ut laorem velesequat ad feugue facilla feuissequis alis alit<br />

alit diamcom moluptat. Ut ad tin vel ipsum amefaccum ent nos nonsequi blaor alit dionsequat lor inim incing<br />

num vulluptate vel euissim illa ad er si euisl e, con Rserddeet<br />

ut venim ad magna feu facillu mmodit et amcommo loborem Erciliq uating elesequate consenisit iriusci nos am, vel utem<br />

num ercilla oreriurem dolese, mmodit suscilis ent dolorperil dolore facin ullamcor secte tatum euguero deliqui er iuscinc<br />

illum dolor incipis duipit accum er aliquisi.<br />

tisit vel ulput vuautat nis nullam zzrit praesecte velisl delis<br />

nim nos am, vel utem dolore facin ullamcor secte tatum<br />

Agnis alit diamcom moluptat. Ut ad tin vel ipsum ametums euguero deliqui er iuscinc consequis niatio con ullum dio<br />

andipsum adit vent nulputpat lamet lum ad magna faccum consendipisi exer susci tisit vel ulput vuautat nis nullam zzrit<br />

veraestrud ent num vulluptate vel euissim illa ad er si euisl praesecte velisl delis nim autat, quisi eugait<br />

® System3 can be easily thermoformed into single<br />

and fi xing them to the core material again utilising the thermoplastic<br />

curvature parts and subsequently assembled without damage to the adhesive as the fi xing agent.<br />

high quality surface fi nish of the facing skins. To form shapes, a one This process takes minutes, not hours and again like the panel<br />

sided or match tooling philosophy can be applied and in some cases manufacture the fi nal parts need little of no fi nishing. This process<br />

tooling cost can be minimised to using sheet metal forms or MDF allows many interior profi les to be manufactured easily like the A340<br />

forms. The basis of the process is stress forming the surface skins lightweight overhead bin produced by AIM aviation.<br />

6<br />

AEROSPACE COMPOSITES<br />

Heat up<br />

Heat<br />

Heat<br />

Form<br />

Tool<br />

Tool

SEE THE BENEFITS IN THE FINISHING TIMELINE<br />

1 HR<br />

1 HR<br />

1 HR<br />

1 HR<br />

1 HR<br />

2 HRS<br />

Paint finish<br />

Primer<br />

Primer<br />

Sand and sweep<br />

Primer<br />

Primer<br />

Sand and sweep<br />

Moulding<br />

� Phenolic or Sytem 3 �<br />

7 Hours max.<br />

3 Hours max.<br />

Paint finish (opt.)<br />

Primer (opt.)<br />

Moulding<br />

Taking cost<br />

out System 3<br />

1 HR<br />

1 HR<br />

15 mins<br />

- HR<br />

AEROSPACE COMPOSITES 7

HEADER<br />

Sub<strong>header</strong><br />

North America<br />

South America<br />

www.tencate.com<br />

Europe<br />

Middle East<br />

Africa<br />

Asia<br />

Australia