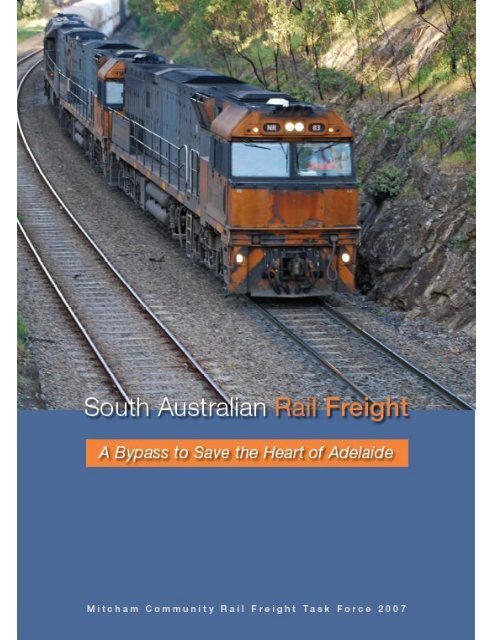

Rail Freight Task Force - Final Report (7737 kb) - City of Mitcham

Rail Freight Task Force - Final Report (7737 kb) - City of Mitcham

Rail Freight Task Force - Final Report (7737 kb) - City of Mitcham

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DisclaimerThe <strong>Rail</strong> <strong>Freight</strong> <strong>Task</strong> <strong>Force</strong> <strong>Report</strong> has been prepared with funding and assistance from <strong>Mitcham</strong>Council. The <strong>Report</strong> is the result <strong>of</strong> collaboration between members <strong>of</strong> the <strong>Rail</strong> <strong>Freight</strong> <strong>Task</strong> <strong>Force</strong>and various community representatives and aims to provide an alternative perspective on railfreight through the Adelaide area.The information provided in the <strong>Report</strong> provides a general overview <strong>of</strong> the issues surrounding railfreight transport in the <strong>Mitcham</strong> Council (and/or surrounding) area. The <strong>Report</strong> is not intended as apanacea for current rail transport problems but <strong>of</strong>fers an informed perspective from the <strong>Rail</strong> <strong>Freight</strong><strong>Task</strong> <strong>Force</strong>. Findings and recommendations made in the <strong>Report</strong> are based on the informationsourced and considered by the <strong>Rail</strong> <strong>Freight</strong> <strong>Task</strong> <strong>Force</strong> during the period <strong>of</strong> review and should notbe relied on without independent verification. Readers are encouraged to utilise all relevantsources <strong>of</strong> information and should make their own specific enquiries and take any necessary actionas appropriate before acting on any information contained in this <strong>Report</strong>.

CONTENTSEXECUTIVE SUMMARY....................................................................................................................................31. BACKGROUND INFORMATION ............................................................................................................6Importance <strong>of</strong> the <strong>Rail</strong>way System.......................................................................................................6How Much <strong>Freight</strong> Moves Through the Adelaide Hills.......................................................................7Historical Basis and Existing Patterns <strong>of</strong> Use ....................................................................................7Ownership and Control <strong>of</strong> <strong>Rail</strong>ways.....................................................................................................7Australian Government <strong>Rail</strong> Funding...................................................................................................7AusLink ...................................................................................................................................................8AusLink Projects....................................................................................................................................8<strong>Rail</strong> Infrastructure ..................................................................................................................................8<strong>Rail</strong> <strong>Freight</strong> Operators ...........................................................................................................................82. CURRENT PROBLEMS AND OBJECTIONS EXPRESSED BY THE COMMUNITY ..........................103. RAILWAY NOISE ..................................................................................................................................11<strong>Rail</strong>way Noise – Contributing Factors ...............................................................................................12<strong>Rail</strong> Noise Effects and Intrusion .........................................................................................................14Health Effects <strong>of</strong> <strong>Rail</strong>way Noise..........................................................................................................16<strong>Rail</strong>way Noise Reduction Methods.....................................................................................................16Environmental Noise Regulation - Suggested Criteria ....................................................................17Air Pollution ..........................................................................................................................................184. RAILWAY SAFETY AND PROTECTION..............................................................................................19<strong>Freight</strong> Trains Are Too Long and Too Heavy ....................................................................................19Curvature Too Sharp for <strong>Freight</strong> Trains with Long Wagons ...........................................................195. ACCIDENTS ..........................................................................................................................................20Inadequate Clearances ........................................................................................................................20Tunnels..................................................................................................................................................20Weak Structures...................................................................................................................................20Derailments...........................................................................................................................................216. ROAD TRAFFIC DELAYS.....................................................................................................................23Incident <strong>Report</strong>s...................................................................................................................................23Usual Level Crossing Delay Times.....................................................................................................24Blocking <strong>of</strong> Emergency Vehicle Access............................................................................................257. OPTIONS FOR EXISTING RAIL CORRIDOR.......................................................................................26Long-Term Future <strong>of</strong> Existing Track ..................................................................................................278. TRACK CORRIDOR UPGRADE - ALIGNMENT FOR FREIGHT TRAFFIC ........................................29Page 1

9. ALTERNATIVE USES ...........................................................................................................................30Suggested Future Use <strong>of</strong> the Existing <strong>Rail</strong> Corridor ........................................................................3010. BYPASS ROUTE FEASIBILITY............................................................................................................31Background ..........................................................................................................................................31Proposed Route....................................................................................................................................31Economics ............................................................................................................................................33Regional Considerations.....................................................................................................................34Other Considerations...........................................................................................................................35Inland <strong>Rail</strong> Proposal.............................................................................................................................36CONCLUSIONS ...............................................................................................................................................37REFERENCES .................................................................................................................................................38APPENDIX 1 ....................................................................................................................................................39Terms <strong>of</strong> Reference..............................................................................................................................39APPENDIX 2 ....................................................................................................................................................41Timelines <strong>of</strong> South Australian <strong>Rail</strong>ways............................................................................................41APPENDIX 3 ....................................................................................................................................................42Australian <strong>Rail</strong> Track Corporation (ARTC) ........................................................................................42APPENDIX 4 ....................................................................................................................................................43<strong>Rail</strong>way Noise .......................................................................................................................................43APPENDIX 5 ....................................................................................................................................................45Ownership, Investors, Users, Stakeholders......................................................................................45APPENDIX 6 ....................................................................................................................................................46Track Modifications by Deviation Number taken from the Peregrine <strong>Report</strong> (SAR 1975):...........46Existing <strong>Rail</strong>way Rectification Works by Deviation & Curve Number............................................48APPENDIX 7a ..................................................................................................................................................51<strong>Freight</strong> Train Traffic Daily Survey 1, taken at Millswood Station ....................................................51APPENDIX 7b ..................................................................................................................................................52<strong>Freight</strong> Train Traffic Weekly Survey 2, 2006 – Millswood Station...................................................52APPENDIX 8 ....................................................................................................................................................54Running Costs......................................................................................................................................54APPENDIX 9 ....................................................................................................................................................55Cant Deficiency ....................................................................................................................................55APPENDIX 10 ..................................................................................................................................................62<strong>Rail</strong> Safety Act ......................................................................................................................................62MEMBERSHIP OF THE RAIL FREIGHT TASK FORCE ................................................................................65ACKNOWLEDGEMENTS................................................................................................................................66

EXECUTIVE SUMMARYThe <strong>Rail</strong> <strong>Freight</strong> <strong>Task</strong> <strong>Force</strong> (RFTF) was initiated by the <strong>City</strong> <strong>of</strong> <strong>Mitcham</strong> in mid 2006, in responseto growing concerns from residents affected adversely by the movement <strong>of</strong> freight trains along theAdelaide Hills Line. The group is comprised <strong>of</strong> elected members <strong>of</strong> Council and communityrepresentatives, a number <strong>of</strong> whom have pr<strong>of</strong>essional expertise in the area <strong>of</strong> railway engineeringand operations.The RFTF determined to examine all relevant issues from a viable and constructive perspective.That is, wherever possible it would present all feasible solutions to current problems and identifythose solutions which are in the best interests <strong>of</strong> not only the affected residents, but all partiesassociated with the rail freight industry.Over the last ten years, rail freight has increased in length, weight and frequency. In a societywhich is looking to encourage rail freight over road freight, the wider community generally sees thisexpansion as a positive. However, the passage <strong>of</strong> heavy freight though a major city, a section <strong>of</strong>which includes tunnels, tight curves and steep gradients, naturally is accompanied by the very realproblems <strong>of</strong> noise, health, safety and traffic delays.In many cases it is suspected that rail track ‘cant’ elevations are falling outside <strong>of</strong> balanced speed‘cants’, thus increasing rail head wear and noise at the interface. In addition, where there is railwear there is also wheel wear. ‘Cant’ deficiencies which exceed 75 mm are not only a danger forderailment but force larger loads on to the outer wheels and flanges.An upgrading <strong>of</strong> the Adelaide Hills Line would not only be a massive and ongoing expense (asidentified in number <strong>of</strong> reports), but would only ever partially address the problems mentionedabove.With the broad and long-term picture in mind, the RFTF is proposing and has mapped a newfreight train bypass to the north <strong>of</strong> Adelaide. The new corridor, running from Murray Bridge in theeast to Mallala in the west, would travel though relatively unpopulated, much straighter and flattercountry than the present route. It could also have the added advantage <strong>of</strong> allowing a parallel roadfreight carriageway, which could reduce both road and rail freight movements into the Adelaidemetropolitan area.The proposed bypass <strong>of</strong>fers enormous long-lasting benefits to both residents <strong>of</strong> the widercommunity as well as to those in the rail freight industry.Considering the importance <strong>of</strong> rail freight to both the South Australian and Federal Governments, itwould seem reasonable for SA to see some real response to these issues.

For the residents <strong>of</strong> the Adelaide Hills and the city, a rail freight bypass will mean:(1) An improved quality <strong>of</strong> life where freight train noise, most especially ‘wheel squeal’, will be nomore than an unpleasant memory(2) Peace <strong>of</strong> mind – eliminating the possibility <strong>of</strong> freight train derailments with potentially toxicspills in built-up areas(3) Minimising major delays for commuters and emergency services at crucial railway crossings(4) Cleaner air, especially in certain topography <strong>of</strong> the Adelaide Hills where toxic diesel fumestend to collect(5) The potential for the existing corridor to once more become a dual track passenger service,fast, efficient and reliable, extending from Adelaide to Belair. A service could also beextended to the rapidly expanding Mt Barker. Such a rail service has many spin-<strong>of</strong>f benefits,including reducing the number <strong>of</strong> cars travelling to the city thereby reducing pollution andtraffic congestion(6) An opportunity to boost tourism to Strathalbyn and Victor Harbor by providing a rail link fromAdelaide Station to the Steam Ranger Heritage <strong>Rail</strong>way terminal at Mount Barker. (It isacknowledged that this would need to happen in conjunction with the long-term plan tostandardise the Adelaide metropolitan rail system)For the Australian <strong>Rail</strong> and Track Corporation (ARTC) and the owner-operators <strong>of</strong> the freight trains,it means:(1) A time saving <strong>of</strong> approximately one and a half hours for those trains not needing to accessAdelaide. The flatter, straighter track will allow for faster, safer train speeds(2) A saving <strong>of</strong> fuel. Less energy would be required to haul loads over the flatter, straighterterrain(3) Fewer locomotives will be needed to haul the loads(4) Minimising rail crossing delays(5) Minimising the chance <strong>of</strong> derailment with its attendant damage and clean up costs(6) Less expensive on-going maintenance on the Adelaide Hills Line which was never originallybuilt to take the weight and volume <strong>of</strong> modern freight services(7) No more expensive noise-monitoring or noise reducing devices and strategies to reducewheel squeal(8) The potential for longer, heavier and higher stacking currently prohibited by the tight curves,steep gradients and tunnels <strong>of</strong> the Adelaide Hills Line (it is noted there is still a problem withthe Footscray tunnel near Melbourne)(9) An opportunity to create regional employment at a new national rail freight reconfigurationyard which could be developed near MallalaPage 4

The RFTF believes that the likely costs for the proposed bypass are feasible and need not beprohibitive, and that the long-term benefits will soon outweigh the impact <strong>of</strong> the initial capital outlay.The RFTF needs the support <strong>of</strong> all interested parties if these proposed objectives are to be met.It needs the goodwill and long-term vision <strong>of</strong> both Federal and State Governments, and welcomesconstructive and positive comments from all members <strong>of</strong> the community.At this point in time we are at the very least asking for a thorough and unbiased examination <strong>of</strong> theattached report. In particular the evaluation <strong>of</strong> the proposed bypass, as well as a realistic costing <strong>of</strong>the project, is imperative. We also believe there could be considerable economic benefits to theState and Federal economies, coupled with significant regional development opportunities fortowns along the route.A bygone era - Sleeps Hill Viaduct, circa 1890 - Courtesy National <strong>Rail</strong>way MuseumPage 5

1. BACKGROUND INFORMATIONImportance <strong>of</strong> the <strong>Rail</strong>way System1.1 It should be recognised that the Australian <strong>Rail</strong>way System is a very important part <strong>of</strong> theeconomy, due to Australia's reliance on exports and imports particularly to and from South EastAsia. Consequently there is a growing need for an expanded and more adaptable rail system. <strong>Rail</strong>and sea freight are recognised as the most efficient way in which to move large loads quickly andefficiently over long distances. The Australian freight task is growing rapidly and is set to double by2020 (Standing Committee on Transport and Regional Services 2007), including the rail freightsector (Fig. 1.1).Figure 1.1(Source: National Transport Commission 2004)1.2 The Australian coastline does not have many deep-sea ports and this is especially so in areasother than the east coast <strong>of</strong> the continent. Ports near productive cities lack sufficient depth andcapacity and cannot cater well for larger ships now in use (SCTRS 2007). The ports <strong>of</strong> Darwin andPerth (more correctly Fremantle) and their proximity to South East Asian Markets compared withEast Coast cities, makes them increasingly important destinations for imports and for the export <strong>of</strong>Australian made goods and bulk commodities transported by rail.1.3 The Adelaide Hills line is therefore an important link from the East Coast to the north and the west.Consequently most freight movements by rail to the Asian markets will travel though the AdelaideHills rail corridor.The proposed Inland <strong>Freight</strong> Line connecting Brisbane and Melbourne is set to increase railconnectivity between the eastern capitals (ARTC 2001c). This link will increase movements <strong>of</strong>freight throughout the national rail network including the Adelaide Hills line. Already, some 80% <strong>of</strong>all Melbourne-Perth freight is carried through the heart <strong>of</strong> Adelaide with no need to stop (ARTC2001b, Auslink 2007). This raises the question – Is this intrusion absolutely necessary?Page 6

How Much <strong>Freight</strong> Moves Through the Adelaide Hills1.4 Estimates vary as to exactly how much freight is currently being transported through the AdelaideHills. ARTC estimated a volume <strong>of</strong> about 4 million tonnes in 2003-4 (ARTC 2005a). Auslink refersto 5 million tonnes carried in 2004-5 (Auslink 2007). Data collected by the RFTF shows that thisfreight is carried by some 88 movements per week on the Hills freight line (See Appendix 7). Bothfreight tonnage and train numbers continue to grow each year.1.5 The recently approved Penola Pulp Mill has signed a $70 million deal with Flinders Ports totransport 750,000 tonnes <strong>of</strong> pulp per year to Port Adelaide (The Advertiser, 5 Sept 2007). All <strong>of</strong>this will be carried on the Hills <strong>Freight</strong> Line - increasing tonnage on the line by between 15-19%.Historical Basis and Existing Patterns <strong>of</strong> Use1.6 The first attempts to build railways in Australia were by private companies, based in the extantcolonies <strong>of</strong> New South Wales, Victoria and South Australia. The first line opened in South Australiain 1854 as a horse-drawn line, while the first steam-powered line opened in Victoria in 1854. Theprivate companies, soon in financial difficulties, were taken over by the respective Governments,as railway development was in the public interest. Despite advice from London to adopt a uniformgauge, different gauges were adopted in different states and even within states, which has causedongoing problems right up to the present day. (Refer Appendix 2, Timeline <strong>of</strong> SA <strong>Rail</strong>ways)Ownership and Control <strong>of</strong> <strong>Rail</strong>ways1.7 In the latter part <strong>of</strong> the nineteenth century, the establishment <strong>of</strong> an Australian Federation from thesix colonies was debated. One <strong>of</strong> the points <strong>of</strong> discussion was the extent to which railways wouldbecome a federal responsibility. A vote to make it so was narrowly lost. Instead the newconstitution allowed "the acquisition, with the consent <strong>of</strong> a State, <strong>of</strong> any railways <strong>of</strong> the State onterms arranged between the Commonwealth and the State" (Section 51 xxxiii) and "railwayconstruction and extension in any State with the consent <strong>of</strong> that State" (Section 51 xxxiv). TheAustralian Government was, however, free to provide funding to the states for rail upgradingprojects under Section 96 ("the Parliament may grant financial assistance to any State on suchterms and conditions as the Parliament thinks fit").1.8 Attempts to rectify the gauge inconsistencies are ongoing and by no means unified. Such problemshave led to many lines being taken out <strong>of</strong> use. Governments and private interests continue tosquabble about who should pay to remedy the problem.Australian Government <strong>Rail</strong> Funding1.9 While successive Australian Governments have provided substantial funding for the upgrading <strong>of</strong>roads, since the 1920s they have not regularly funded investment in railways except for its ownrailway, the Commonwealth <strong>Rail</strong>ways (later to become the Australian National <strong>Rail</strong>waysCommission and privatised in 1997). They have considered the funding <strong>of</strong> railways owned by StateGovernment to be a State responsibility.1.10 Australian Governments have, however, made loans to the States for gauge standardisationprojects from the 1920s to the 1970s. From the 1970s to 1996, the Australian Government hasprovided grant funding to the States for various rail projects. The Keating Government's OneNation program, which was announced in 1992, was notable for the standardisation <strong>of</strong> theAdelaide to Melbourne line in 1995. Significant Australian Government funding was also madeavailable for the Alice Springs to Darwin <strong>Rail</strong>way, which was completed in 2004. It should be notedthat this investment also involved ARTC being given (not sold) the single line freight route thoughthe Adelaide Hills by the Government <strong>of</strong> South Australia.Page 7

Funding is now being made available for rail freight though the Australian <strong>Rail</strong> Track Corporationand the AusLink land transport funding program.AusLink1.11 Under the AusLink program, introduced in July 2004, the Australian Government has provided theopportunity for rail freight to gain access to funds on a similar basis to that <strong>of</strong> roads. AusLinkestablished a defined National Network (superseding the former National Highway system) <strong>of</strong>important road and rail infrastructure links and their internodal connections (Auslink 2007).1.12 Australian Government land transport funding is focused on the National Network, including thefollowing rail corridors, connecting at one or both ends to State Capital Cities such as:• Sydney to Adelaide, via Cootamundra, Parkes, Broken Hill and Crystal Brook• Melbourne to Adelaide via Geelong• Adelaide to Perth - Trans-Australian <strong>Rail</strong>way• Adelaide to Darwin - Port Augusta-Darwin lineAusLink Projects1.13 <strong>Rail</strong> funding has been announced for the following projects in South Australia at this date:• $2.5 million for the upgrading and strengthening <strong>of</strong> the Murray River Bridge at Murray Bridge• $8 million for crossing loop extensions at Jamestown and Mingary between Crystal Brookand Broken Hill at Yarrabandia, and Matakana between Broken Hill and Parkes<strong>Rail</strong> Infrastructure1.14 In the case <strong>of</strong> the interstate network and the non-urban railways <strong>of</strong> New South Wales (theAustralian Government-owned Australian <strong>Rail</strong> Track Corporation ARTC) and Western Australia(WestNet <strong>Rail</strong>), construction and maintenance <strong>of</strong> network infrastructure is consolidated into nonpr<strong>of</strong>itgovernment bodies. This is intended to provide access to new and existing players.The ARTC is the prime mover <strong>of</strong> construction and maintenance <strong>of</strong> the track systems in SouthAustralia. (Refer Appendix 3)<strong>Rail</strong> <strong>Freight</strong> Operators1.15 The major freight operators on the rail networks (excluding integrated mining railways) are:• Pacific National - interstate network and branch lines in New South Wales, Victoria andTasmania• Queensland <strong>Rail</strong> - Queensland• Australian <strong>Rail</strong>road Group (Queensland <strong>Rail</strong>) - Western Australian lines• Genesee & Wyoming (GWA – US) – South Australian linesPage 8

1.16 Other rail freight operators include:• Southern Shorthaul <strong>Rail</strong>road• South Spur <strong>Rail</strong> Services• Patrick <strong>Rail</strong> Operations• Specialised Container Transport• <strong>Freight</strong>Link• Silverton <strong>Rail</strong>1.17 Licensing <strong>of</strong> personnel with nationally recognised credentials facilitates the transfer <strong>of</strong> those peoplefrom one state or operator to another, as traffic demands.<strong>Freight</strong> train passing through Belair Station, 2006 – Courtesy R MarshallPage 9

2. CURRENT PROBLEMS AND OBJECTIONS EXPRESSED BY THE COMMUNITY2.1 The effects <strong>of</strong> this rail traffic on metropolitan Adelaide are the main concerns <strong>of</strong> this report. Thefollowing concerns are paramount to The <strong>Rail</strong> <strong>Freight</strong> <strong>Task</strong> <strong>Force</strong> research:• <strong>Freight</strong> trains are extremely noisy• <strong>Freight</strong> Trains pass though heavily populated residential areas• <strong>Freight</strong> trains operate at any time <strong>of</strong> day or night, peak period or early mornings(Refer Appendix 7)• <strong>Freight</strong> trains are long and likely to get longer• <strong>Freight</strong> trains cause pollution problems• Large traffic delays at level crossings, the cost borne by the community• Level crossings frustrate future and current planning <strong>of</strong> suburban growth areas• Local public transport systems are affected adversely by freight traffic movements• Future growth <strong>of</strong> the suburban public transport system is prevented beyond Belair• Improvements to passenger services to Belair are limited by having only one track• Increasing heavier freight traffic will exacerbate all <strong>of</strong> the problems above<strong>Freight</strong> train snaking through Eden Hills, 2007 - Courtesy S McCarthy-LinehanPage 10

3. RAILWAY NOISE3.1 It is acknowledged that rail freight is more efficient than road transport. <strong>Freight</strong> trains can carry theequivalent <strong>of</strong> 35 road trains though the Adelaide Hills. Almost all freight train traffic bound for thewest or east currently travels though the Adelaide Hills <strong>Rail</strong>way System Corridor and some <strong>of</strong> themost densely populated suburbs <strong>of</strong> Adelaide itself.3.2 It was reported in 2003 that 25 freight trains per week would be achieved by 2013. However, over80 trains per week were achieved by 2006 just 3 years later. By the end <strong>of</strong> 2006, there were up to18 trains per day as surveyed by the RFTF, far beyond what was reasonably expected by thecommunity.3.3 This is a quality <strong>of</strong> life issue for at least 100,000 residents living in the vicinity <strong>of</strong> the tracks. Theseinclude workers, retirees, elderly citizens, hospital patients and young families. Trains movethrough residential areas at all hours <strong>of</strong> the night and day (Fig. 3.1), disrupting sleep and causingmajor loss <strong>of</strong> amenity.3.4 Future train numbers will only increase as the advantages <strong>of</strong> the Darwin port facilities becomeavailable to industry and food transporters from South East Asia. The same will result from Perth’sclose proximity to Singapore and Malaysia and will mean more rail traffic heading east to where thepopulation is greatest.3.5 The Adelaide Hills part <strong>of</strong> the railway corridor will become more densely populated as the searchfor a better quality <strong>of</strong> life attracts people to the hills zone and beyond, and as a consequence <strong>of</strong> theimposition <strong>of</strong> the urban growth boundary. Estimates <strong>of</strong> the numbers affected by noise and safetyshow that as many as 100,000 people are directly affected between Adelaide and Nairne.3.6 The existing corridor cannot cope. Problems <strong>of</strong> noise, pollution and potentially unsafe movementswill get worse with increased rail freight traffic. There will be rail corridor safety issues relating tothe type <strong>of</strong> goods carried and the increased possibility <strong>of</strong> derailments.3.7 Future upgrading <strong>of</strong> the existing line to cater for higher speeds, heavier loads and longer trains willbecome imperative. This is likely to be controversial due to the unavoidable impact upon significantremnant bushland <strong>of</strong> the Adelaide Hills Corridor.3.8 The demands <strong>of</strong> a consumer driven society and consequent growth in rail freight traffic willnecessitate a major upgrading <strong>of</strong> the Adelaide Hills line and corridor in the near future, which willaffect road traffic and further residential developments nearby.3.9 The primary sources <strong>of</strong> railway noise are wheel squeal, locomotive noise, horn sounding andvibration. The majority <strong>of</strong> complaints received by the SA Environmental Protection Authority (EPA)relate to wheel squeal (NTC 2004).Page 11

Figure 3.1 - Total Number <strong>of</strong> <strong>Rail</strong> Movements throughGoodwood Junction876Trains per Week5432101 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24Hour <strong>of</strong> Day(Source: RFTF Survey December, 2006)<strong>Rail</strong>way Noise – Contributing Factors3.10 Wheel Squeal - Wheel squeal noise is attributed to the contact between the tapered wheel flangesand the rail head. This occurs mostly on curves but can occur along straight track sections.The ‘problem’ <strong>of</strong> wheel squeal is caused by the interaction <strong>of</strong> the wheel/rail interface whenrollingstock traverses the track. It gives rise to a loud high-pitched squeal.The following elements, singularly or in combination, may affect the presence and level <strong>of</strong> wheelsqueal:• The wagon wheels• The railway track• Those parts <strong>of</strong> the train which control or are controlled by the movement <strong>of</strong> wheel over railARTC initially assumed that the extreme curvatures found on the Hills track were the cause <strong>of</strong> themajority <strong>of</strong> wheel squeal problems. The high numbers <strong>of</strong> sharp curves through the Adelaide Hillsare a result <strong>of</strong> historical engineering limitations and are present in few other parts <strong>of</strong> the Australian<strong>Rail</strong> Network.Attempts to address the problem were made using ‘oiler system’ detection equipment. Trialscommenced in 2000 (NTC 2004). Due to lack <strong>of</strong> effectiveness the trial has now been discontinued.It has been reported that straight sections <strong>of</strong> rail track produced high pitched squeals and that notall wheels squeal. To better monitor wheel noises a system <strong>of</strong> electronic surveillance was set up byARTC and acoustic monitoring consultants VIPAC at Heathfield.The device installed at Heathfield is known as "<strong>Rail</strong>Squad". It is a data logger and bar-code readerand consists <strong>of</strong> several microphone arrays for approach, passing and going directions to identifyelectronic tags on every wagon with other data. If a ‘squealer’ is noted, it is logged and flagged upPage 12

to three trips before the system sends an email to the operator. A computer program can identifyup to 30 bogie types and is capable <strong>of</strong> typing groups for later identification.The data logger can also give information on:• Wheel number• Owner• Weight carried• Speed• Temperature• Date and timeThe South Australian Environmental Protection Authority (EPA) - Noise Branch is directlyresponsible for overseeing this operation. Once an irregularity is detected, the relevant operator isautomatically contacted and advised. This enables that operator to rectify the problem. At aninstallation cost <strong>of</strong> $500,000, the success <strong>of</strong> this system has yet to be demonstrated. To this reportdate, monitoring data has not been sighted.The EPA has also instigated a plan known as the Environmental Improvement Program (EIP),which requires all operators to put forward an operating plan for reducing the incidence <strong>of</strong> noiseprogressively from their equipment using this track.<strong>Rail</strong> Gauge – <strong>Rail</strong> gauge has been tightened through the installation <strong>of</strong> concrete sleepers, whichprovide a more consistent gauge, less subject to swelling and movement <strong>of</strong> wooden sleepers. Inaddition, anecdotal evidence suggests that since recent derailments, insurers <strong>of</strong> the railway haveasked for a reduction in rail gauge tolerances. The standard gauge width <strong>of</strong> 1435mm is slightlywider on curves to permit an easier path for wheel flanges to turn on sharper curves. In the past,wider tolerances were used on curves compared to the present. Hence increased noise from morefrequent contact between wheel flange and rail head is now occurring. While this results inincreased safety against derailment, it may also coincide with an increase in wheel noise.Wheel Drag and ‘Slip-Stick’ Effects - <strong>Rail</strong> carriage axle sets consist <strong>of</strong> wheels left and rightconnected by a rigid axle with no differential movement possible. When traversing a curve, theouter wheel must travel a greater distance than the inner wheel and the wheel experiencing thelightest load, as affected by speed and cant, will drag along the rail.On some <strong>of</strong> the sharper curves on the Hills railway, the lighter loaded wheels could actually ‘drag’up to 2 metres in track length.This ‘drag’ distance was addressed by early rail operators through the use <strong>of</strong> oilers, and bygrinding rail line heads and wheel flanges to make them smoother to reduce friction and heat.Cant Deficiency - Cant deficiency results when there is insufficient curve banking or tilt for the trainspeed. Balanced cant is achieved when the train mass balances centrifugal forces on curves(ARTC 2005b).On some curves cant deficiencies will result in wheels not ‘tracking’ properly, causing high wearand loud squeals. On the straight there is no banking and therefore no cant deficiency.Page 13

3.11 Locomotive Noise - Large freight trains moving through the Adelaide Hills may be pulled by up to 5locomotives. Many freight locomotives still in use date from the 1950s and 60s, and as they powerup to negotiate the steep inclines <strong>of</strong> the Adelaide Hills line, they produce high levels <strong>of</strong> lowfrequency noise. This noise can easily penetrate homes over distance and become increasinglyobtrusive (NTC 2004).Horn sounding by locomotives is a problem for residents living adjacent to tracks, particularlyaround level crossings. Horns are designed to be very loud and intrusive, but their use isconsidered to be primarily a safety issue as trains may need to announce their approach to levelcrossings and track maintenance crews.Vibration caused by the movement <strong>of</strong> heavy locomotives and rolling stock along the track is notonly an intrusive problem for residents, but it can also damage buildings. Many houses,particularly through Adelaide's inner southern suburbs, are built in very close proximity to the Hillsfreight line.Problems may also occur with rolling stock noise and general haulage noises from draw-barcoupling, rail breaks, and loose equipment.Some <strong>of</strong> these problems have been partially overcome by the installation <strong>of</strong> fully welded andtensioned track along with concrete sleeper and ballast arrangements and maintenance providedby the ARTC. Concrete sleepers however do not absorb as much vibration as wooden sleepers(NTC 2004).<strong>Rail</strong> Noise Effects and Intrusion3.12 There has always been noise associated with locomotives and carriages on the Adelaide Hills<strong>Rail</strong>way Line. However the number <strong>of</strong> complaints has increased since the introduction <strong>of</strong> standardgauge (NTC 2004), and as freight volumes have increased, particularly over the last 10 years.Intrusive noise relates to high frequency, very loud squealing together with juddering and rumbling.The intensity <strong>of</strong> these noises may be such that no locomotive exhaust or engine sounds can beheard above them. These intrusive noises will drown out normal conversation within residences asfar away as 700 metres from the track, while some individuals have to block their ears until it issafe again to listen.3.13 The RFTF was informed by the EPA that sound levels up to 115 dB(A) are now recorded atHeathfield. This is well above acceptable Australian Standards <strong>of</strong> exposure for humans. TheNSW government recommends railway noise levels in homes should not exceed 40dB(A) indaytime and 35dB(A) at night (STA 2003).3.14 Earlier versions <strong>of</strong> diesel-electric freight locomotives, singly or in multiples hauling heavy loads onthe extreme gradients found only on this section <strong>of</strong> Australian railroads, produce some deafeningexhaust noise. Historically, freight trains hauling large loads across the Mount L<strong>of</strong>ty range(Adelaide Hills) produced only minor carriage wheel noise. In recent years there appears to havebeen a steady build-up <strong>of</strong> noise, some from the more powerful locomotives but by far the mostnoise emanating from wagon wheel squeal. The wagon wheel squeal has caused a major outcryfrom residents in the adjacent suburbs <strong>of</strong> Goodwood, Unley, <strong>Mitcham</strong>, Panorama, Eden Hills,Bellevue Heights, Coromandel Valley, Blackwood, Glenalta, Belair, Aldgate, Bridgewater,Heathfield and even Nairne.This represents a distance <strong>of</strong> some 55km <strong>of</strong> rail corridor causing loss <strong>of</strong> amenity to residents.Page 14

3.15 Despite frequent requests from residents, local politicians, business people, schools, hospitals andretirement establishments along the way, there has been no real outcome from rail operators,government transport authorities or rail regulators.3.16 ARTC as the owner and maintainer <strong>of</strong> the Hills rail line, have been proactive in attempting toresolve the noise problem, but it continues to affect residents.Track maintenance Shepherds Hill Tunnel, 2007 - Courtesy S McCarthy-LinehanPage 15

Health Effects <strong>of</strong> <strong>Rail</strong>way Noise3.17 Loud noise damages hearing. People exposed to noise for extended periods either in the workplace or other constant noise locations could accumulate progressive hearing loss. Noise sufficientto cause hearing loss is not <strong>of</strong>ten found in the environment while noise from discos, powerequipment, power saws, edge trimmers, and sporting activities like shooting can result inaccumulative hearing loss. People are unaware they are going deaf until they have pr<strong>of</strong>ounddeafness which may occur later in life.3.18 Environmental noise may cause annoyance, sleep loss, difficulties in communicating and stress. Itmay lead to significant effects on quality <strong>of</strong> life, mental health, aggression, introversion, tiredness,accidents and poor work performance or increased consumption <strong>of</strong> medications. Further noise andsleep loss leads to heart disease, digestive system and circulation problems and other diseasesassociated with long term stress. The effects <strong>of</strong> noise can add to pre-existing levels <strong>of</strong> stress orother diseases.3.19 The RFTF understands that no fixed criteria or regulations are currently in legislation in SouthAustralia that provide a basis for measuring if rail track noise is in contravention <strong>of</strong> acceptablehealth levels.<strong>Rail</strong>way Noise Reduction Methods3.20 There are many ways in which noise from railways can be minimised and reduced. A smallreduction in decibels will significantly reduce the noise intensity. Some <strong>of</strong> the following can easilybe trialled by laboratory research.1) The <strong>Rail</strong> Track:a) Experiment with different sleeper materialsb) Use thicker elastomeric / neoprene pads between rail and sleeper at problem locationsc) Provide more permanent noise barriers to an appropriate height from the track. This workson Melbourne freeways, Eastern and Western Ring Road Bypasses and several freewaysin Sydney. It begs the question, “Why do roads require sound barriers when railways donot?”d) Add a surface layer <strong>of</strong> finer size ballast. Raise ballast height to rail level on the shoulderse) Lubrication <strong>of</strong> <strong>Rail</strong>s - although this has proved unsuccessful in trials on the Hills Line (NTC2004)f) Reduce cant deficiency to appropriate levels. Where cant elevations fall outside <strong>of</strong>balanced speed cants, this leads to increased rail head wear and increased noise at theinterface. In addition, if there is rail wear there is also wheel wear. (Refer Appendix 9)2) The Wheels:a) Provide sound attenuating barriers or skirt height barriers on each side <strong>of</strong> a wagon close tothe wheel down to rail level. This relies upon the fact that wheel noise is translatedhorizontally outwards from the contact point <strong>of</strong> wheel and rail, at interface levelb) Experiment with different wheel materials, different hardness <strong>of</strong> rail or wheel rimc) Ensure that both side wheels on each bogie are at least close in diameterd) Experiment with rail head geometry and wheel contact surfaces applied to curves toaffect/limit the slip-stick effects between inner and outer wheelsPage 16

3) Other Parts Controlling Wheel/<strong>Rail</strong> Interface:a) Lubricate bogie pivots to allow free rotationb) Apply load cell technology to each wagon to ensure that the centre <strong>of</strong> gravity is centralwhen loaded, so that ‘skate boarding’ will not occur or is reduced (Refer Appendix 9)c) Reduce wagon length <strong>of</strong> flat-top. Excessively long wagon length in combination with cantdeficiencies may result in increased weight on the inner rail, thus causing a turning effect <strong>of</strong>front and rear bogies. The USA has at least 4 different flat top lengths. For a 22m bogie thecentre <strong>of</strong> gravity is 320mm <strong>of</strong>f the centre line <strong>of</strong> the track.Further research may discover additional options.Environmental Noise Regulation - Suggested Criteria3.21 The Australian Standard relating to noise exposure is AS 1055 [1997].3.22 The first standard specifically relating to railway noise was released in May 2002, AS 2377 -'Acoustics - Methods for the measurement <strong>of</strong> railbound vehicles'(NTC 2004).3.23 The Australian Standard for occupational exposure to noise states that levels above 85dB pose anunacceptable risk to hearing. Over long periods repeated exposure to noise between 75 and 85dBmay be damaging to the hearing <strong>of</strong> some people (NOHSC 2000).3.24 The NSW government recommends railway noise levels in homes should not exceed 40dB(A) indaytime and 35dB(A) at night (STA 2003).3.25 The Environmental Protection Agency (USA) recommended that overall outdoor noise should belimited to an average <strong>of</strong> 55 dB(A) to prevent noise annoyance (Goodlee 1992).3.26 Standards are even tighter in Europe. German and British laws state a maximum <strong>of</strong> 55 dB(A) forurban residential areas while suburban residential areas require some 5dB(A) less and rural,recreational and hospital areas should be 10 dB(A) less.3.27 Whichever <strong>of</strong> the above parameters are decided upon, an over-riding SA EPA requirement mustspecify to which hours <strong>of</strong> each day <strong>of</strong> the week the criteria shall apply, and with expressrequirements for further reductions during night times.3.28 Noise effects should also be considered cumulatively. Appropriate criteria could be based on theaccumulated noise by hours per day at various noise levels. This would account for rail trafficnumbers at appropriate times during the day or night.3.29 An initiative by the SA EPA, Noise Abatement Section, intends to implement as part <strong>of</strong> thelicensing agreement a requirement for rail operators to show how the operator intends to reducerolling stock noise. An Environmental Improvement Program will be set up to enable noise fromvarious sources on the train to be progressively reduced as part <strong>of</strong> the licence requirements.Page 17

Air Pollution3.30 <strong>Freight</strong> train traffic is polluting the corridor and adjacent suburbs with diesel exhaust fumes, wheeland brake dust.3.31 At certain times <strong>of</strong> the night and day, especially during temperature inversions when layers <strong>of</strong> airare trapped at ground level, exhaust gases cannot disperse, causing choking fumes. This couldpose a health risk, especially to those suffering respiratory conditions. It is also a significantamenity problem for nearby residents.3.32 Confined topography in some areas <strong>of</strong> the Adelaide Hills exacerbates the problem.3.33 Diesel powered locomotives produce a number <strong>of</strong> emissions, including nitrogen oxides (NOx),particulate matter, carbon monoxide (CO) and carbon dioxide (CO 2 ).3.34 At present no emission standards apply to locomotives in Australia and any measures undertakenare entirely voluntary (NTC 2004).3.35 As far as the RFTF is aware, no air-borne particulate sampling has been carried out.3.36 Conclusion: <strong>Freight</strong> train diesels are unhealthy and pose an increasing health hazard which islikely to get worse with faster, heavier and more frequent traffic unsuited to the Hills corridor.Air pollution from freight train passing through Belair Station, 2006 – Courtesy R MarshallPage 18

4. RAILWAY SAFETY AND PROTECTION4.1 The SA EPA plans to monitor compliance with Environmental Improvement Programs amongstthose operators who are signatories. Noise is a concern along with safety, air pollution andemergency threat situations, such as derailed wagons containing dangerous chemicals, as well asnuclear and other radioactive material and equipment destined for nuclear power plants inAustralia or overseas.<strong>Freight</strong> Trains Are Too Long and Too Heavy4.2 The freight trains are too long for the existing Adelaide Hills track alignment. Currently trainlengths <strong>of</strong> up to 1500 metres are permitted, with 23 tonne axles allowable and usually hauled bytwo or more diesel DC electric locomotives.4.3 Auslink states that 5Mt <strong>of</strong> freight used the Hills rail corridor in 2004-5 (Auslink 2007).4.4 Based on the RFTF traffic surveys, the average number <strong>of</strong> freight trains is approximately 75 perweek (3900 per annum).4.5 Some crossing loops (parking for bypassing) are presently too short to be adequate for this trainlength. There is also a shortage <strong>of</strong> loops so that when a train fails to reach the next waiting area allother trains in the system are held up (ARTC 2001a). Work needs to be done urgently to addressthis problem.4.6 Conclusion: Within a short time there will be newer, larger AC-Diesel locomotives capable <strong>of</strong>hauling even heavier loads (more than 35% extra) and freight train lengths will increase to 1800metres or more. This means the Adelaide Hills corridor will be even more inappropriate for freighttrains.Curvature Too Sharp for <strong>Freight</strong> Trains with Long Wagons4.7 The 1500 metre long freight trains are also a problem for the Adelaide Hills Track system sincemost curves are banked with what is known as cant deficiency. This ‘cant’ is required for all railwaycurves and is simply stated as the amount <strong>of</strong> banking required for each curve radius to permit abalance <strong>of</strong> centrifugal force (due to speed) against the wagon’s weight.4.8 An example <strong>of</strong> curvature deficiencies on the Hills line can be seen between Shepherds Hill Roadand the exit at Belair National Park Tunnel where there are 28 curves. On 8 curves the radii are200 metres or less, with two at 190 metres radii.4.9 A balanced cant should be 203mm for the current posted speed <strong>of</strong> 60 km/h and 149mm for 50km/h posted speed. However, the actual values used are 100mm and 60mm respectively. Thisresults in a cant deficiency <strong>of</strong> 203-100=103mm and 149–60=89mm respectively.4.10 Cant deficiencies should not exceed 75mm, although different criteria apply depending on the type<strong>of</strong> train (ARTC 2005b). High cant deficiencies throughout the Hills freight line results in excessivelyhigh rail and wheel wear (especially flanges). It is also possible that much <strong>of</strong> the wheel squealcould be attributed to this phenomenon. Cant deficiencies also create safety concerns where trainweights are not evenly distributed on the track for a given speed.4.11 Conclusion: The engineering envelopes are approaching or have potentially exceeded recognisedlimits <strong>of</strong> safety on this track. Alignment geometry and safety is a concern for potential derailment.Page 19

5. ACCIDENTSInadequate Clearances5.1 The height clearance required for normal operations is 4.9 - 6.1 m, and bridges and tunnels requirethis clearance to be negotiated safely especially when cargo items could come loose on a freighttrain.5.2 Height clearance is also an important issue when double stacked wagons are the norm for freightarriving from Perth and Darwin. These lines permit this extra freight height to be used whichexceeds structural clearances given above, until it arrives at the Adelaide terminal. Due to the Hillsrestriction reloading <strong>of</strong> freight must take place at Dry Creek, losing 32 hours <strong>of</strong> transit time.Consequently, because <strong>of</strong> the Adelaide Hills height restrictions, nearly twice as many trains arerequired to cross South Australia in both directions (SCTRS 2007).5.3 Width clearances are also inadequate. Loose freight items can become dangerous when lateralwidth safety factors are jeopardised. A serious incident occurred in Eden Hills in 2005, when loosefreight on a passing freight train collided with a passenger train (ATSB 2005).Tunnels5.4 Adelaide Hills line tunnels in their current form are incapable <strong>of</strong> taking high loads or double stackedvehicles.5.5 It is not feasible to attempt enlargement <strong>of</strong> these tunnels without severe disruption to freight trains,local traffic and residents. Replacement or enlargement <strong>of</strong> these structures is a major and difficultengineering feat which would cause major economic upheaval both to operators, local businessand road traffic generally. Due to their age and form <strong>of</strong> construction Hills tunnels do not havestructural adequacy for enlargement which makes the job even more difficult.Weak Structures5.6 Since its conversion to standard gauge the Adelaide-Melbourne rail line, including the Hills line, islaid on concrete sleepers through to the border in order to cater for modern heavier and longerfreight trains. Other infrastructure, however, has not been upgraded. A number <strong>of</strong> tunnels werebuilt from the 1860’s onwards, usually <strong>of</strong> weak materials including locally made brick and earlyreinforced concrete. Many <strong>of</strong> these tunnels, as well as bridges and other structures, are overduefor replacement or upgrade.5.7 Conclusion: Tunnels and bridges are inadequate for this corridor and would be prohibitivelyexpensive to repair or replace.Page 20

Derailments5.8 There have been several derailments on the Hills <strong>Rail</strong>way since 1990.5.9 In June 1990 the Melbourne Express Passenger train was derailed near Belair Station. Damagecosts were given as $50,000. Derailment was caused by steel plates laid on the track. Thisoccurred before conversion <strong>of</strong> the rail line to standard gauge.5.10 In October 2002, after standardisation <strong>of</strong> the rail gauge, a freight train derailed at Glenalta causingdamage estimated at $300,000.5.11 In November 2004, a freight train derailed at Glenalta near the suburban station. Eleven wagonsleft the line and plunged into residential properties nearby. The estimated damage was $2,000,000.5.12 These derailments were investigated by the Australian Transport Safety Bureau InvestigationTeam (ATSB). However, anecdotal evidence confirms that another serious derailment occurred onthe up track side <strong>of</strong> Eden Hills Station after standardisation. While the station platform wassignificantly damaged and was consequently demolished, the Willowie Street Bridge remarkablywas not affected. The incident was made worse because the locomotive driver was unaware that awagon at the rear <strong>of</strong> the train had derailed.What can be learned from these derailments?5.13 Most have been along the Glenalta stretch <strong>of</strong> standard gauge track. The track lies on the top <strong>of</strong> aridge <strong>of</strong> relatively steep grading in the railway, with a nominal slope <strong>of</strong> 1 in 45.5.14 Since speed is well known to cause instability it is worth looking at the Adelaide Hills <strong>Rail</strong>way tosee what speeds are posted. These are given on the ARTC web site (www.artc.com.au) as"posted speeds" <strong>of</strong> 60km/h dropping to 55km/h under the main road bridge at the Belair end.These are not considered high speeds. In fact these speeds are probably the maximum that canever be used along this section. For balanced design the cant should be around 60mm. Howeverthe cants in this line are 35 - 45mm showing they are 25 - 15mm below the speed value used. Thisis not a cause for concern, since normal practice allows for cants to be deficient by up to 75mmbelow the balanced speed values. Concern would be justified when cant deficiencies exceeded75mm as they do in other sections <strong>of</strong> this railway. (Refer Appendix 9, Tables for curves 6 and 28)5.15 Alignment <strong>of</strong> tracks may be a source <strong>of</strong> danger when tight curves are present. In this section <strong>of</strong>track however curve radii <strong>of</strong> 600 metres or more are not considered sharp or dangerous at theabove speeds. However, the danger comes when the curvature sharpens up after several gentlecurves. The driver, who may not be familiar with the track or is not warned ahead <strong>of</strong> time, could runinto trouble in this situation.5.16 The Glenalta derailment was found to be the result <strong>of</strong> inappropriate loading <strong>of</strong> wagons. While thefront and rear <strong>of</strong> the train was loaded, the centre wagons had no freight load, thus creating a majorimbalance. The ATSB determined that the derailment was caused by dynamic braking <strong>of</strong> thelocomotives on the down hill run. This was followed, apparently, by a delay in wheel braking in therear wagons. The rear wagons carrying a large proportion <strong>of</strong> weight then tried to over-run the front<strong>of</strong> the train and succeeded in lifting the centre wagons <strong>of</strong>f the track and derailed them.5.17 Hence the apparent cause <strong>of</strong> the accident was due to poor loading practices by the operator.Elsewhere in this report the RFTF has identified that wheel squeal and similar noise can beproduced by incorrect loading practices.Page 21

5.18 Given the considerable length <strong>of</strong> trains currently used (and the longer freight trains anticipated inthe future), it seems elementary to have appropriate electronic device to warn the driver <strong>of</strong> theconditions at the rear, perhaps not for every wagon bogie in the train, but at least for unladen ones.Train security is essential at all times, especially given that speeds, loads and lengths are likely toincrease in the future.5.19 While drivers control the speed <strong>of</strong> the trains, they have no control over the condition andengineering constraints <strong>of</strong> the track. The only safeguards to prevent derailments are well-designedrailways with gentle curves and proper cant values which allow for balanced speeds.5.20 Conclusion: Modern fast freight trains do not belong on a poorly designed antiquated track system.The track system should have sufficient safety margins to allow drivers a chance to recover fromminor discrepancies in driving technique.The RFTF believes that the existing Hills railway is outdated for rail freight and not upgradeable tosafe and modern standards.<strong>Freight</strong> train derailment between Coromandel and Eden Hills stations, 1988 – Courtesy P HartPage 22

6. ROAD TRAFFIC DELAYSIncident <strong>Report</strong>s6.1 The following list <strong>of</strong> level crossing delays (Table 6.1) is on public record. These are railway faultsaffecting road level crossings, and where Road Traffic gives way to <strong>Rail</strong> Traffic Controls. These areonly for faults which are reported as a result <strong>of</strong> rail failures observed by and affecting the public.These do not include delays from regular maintenance operations.Table 6.1 - LEVEL CROSSING DEVICE FAILUREPeriod Aug 2002 - Aug 2007Crossing LocationNumber <strong>of</strong> call outsGOODWOOD / Leader St 10GOODWOOD / Victoria St 14UNLEY / Cross Rds 17HAWTHORN / Hilda Tce 4HAWTHORN / Angas Rd 3HAWTHORN / Grange Rd 10Lower MITCHAM / Wattlebury Ave 6PANORAMA / Barretts Rd 5BLACKWOOD / Main Rd 23BLACKWOOD / Brighton Pde 12GLENALTA / Main Rd 17ALDGATE / Cricklewood Rd 8ALDGATE / Yatina Ave 2BRIDGEWATER / Kain Rd 2BRIDGEWATER / Bridgewater Rd 4BALHANNAH /Onkaparinga Valley Rd 3BALHANNAH / Junction Rd 3LITTLEHAMPTON / Hallett Rd 2NAIRNE / North <strong>Rail</strong>way Tce 3NAIRNE / Lower Nixon St 3NAIRNE / Bartley St 3TOTAL 154Average Call-out Rate = 30 per year(Source: SA Government Traffic Management Centre August 2007)The above shows that problems can occur with road traffic controls at level crossings. Whendevice failures occur, road traffic delay times can be considerable, especially at peak road traffictimes.6.2 Some incident response times can be up to half a day. Most calls from the public seem to be madeby mobile phone as ‘Incident <strong>Report</strong>s’ and typically describe boom gates stuck down; visible andaudible signals flashing but no trains in sight, etc.6.3 It should also be noted that The <strong>Rail</strong>ways Safety Act requires any train incident to be immediatelyattended to. This involves stopping the train within the shortest possible time. Due to the longlength <strong>of</strong> freight trains they may need to stop across a level crossing for considerable periods <strong>of</strong>time. This happens <strong>of</strong>ten in the Adelaide Hills where alternative road routes are not possible. Thiscan mean long delays for road traffic, including emergency vehicles.Page 23

Usual Level Crossing Delay Times6.4 It should be noted that this discussion about level crossing delays does not include regular railwaymaintenance and rebuilding which can cause considerable delays and re-routing <strong>of</strong> traffic on to<strong>of</strong>ten confusing Adelaide Hills back roads.6.5 The RFTF has surveyed some Adelaide Hills crossings and found typical delay times for roadtraffic as follows. For example, the average delay described below is from signal operation start tostop, at Glenalta Level Crossing, Main Road (an arterial road and the only practical route foremergency services).1. TransAdelaide single vehicle delay, about 50 seconds2. <strong>Freight</strong> train, about 5 - 7 minutes6.6 The effects on road traffic vary depending on time <strong>of</strong> day. At peak periods there can be road trafficvolumes up to 1100 vehicles per hour both ways at the Glenalta Crossing. In a normal working daythis swells to approximately 18,000 vehicles per day in both directions (Transport SA 2006).6.7 An average figure for freight train traffic is 13 every twenty four hours.(Refer: RFTF Survey <strong>of</strong> weekly traffic Appendix 7)Table 6.2 - Glenalta Level Crossing Time DelaysActionDailyPeakHourRoad Traffic through crossing 36,000 2200<strong>Rail</strong> Traffic 13 1-2Delay time (@ 7 min per train) 91 7No. <strong>of</strong> road traffic vehicles delayed 2275 257Accumulated Delay time in hours ( @ 7 mins closure ) 265 33(Source: RFTF Survey Feb 2007)Note: The above observations and calculations relate only to a single level crossing.6.8 Clearly, the faster the gates operate the less delay times for road traffic. A similar time delay islikely to operate at the (arterial) Main Road Level Crossing in Blackwood, at Cross Road in UnleyPark, and the other eight level crossings, with more or less time delay depending on location andtrain speed. It would be therefore quite reasonable to predict a cost to road traffic and the generalpublic for the Hills <strong>Rail</strong>way <strong>of</strong> $16-$32,000,000 per year (assuming a working year <strong>of</strong> 240 days),attributed to <strong>Rail</strong> <strong>Freight</strong> Traffic on this line.6.9 For a city the size <strong>of</strong> Adelaide with level crossings at almost every rail traffic intersection, railwaydelays are costly.6.10 Conclusion: Delays at level crossings cause the public considerable economic losses.Page 24

Blocking <strong>of</strong> Emergency Vehicle AccessEmergency vehicles are blocked in much the same way as other vehicles at level crossings. Itshould be noted that when emergency services are similarly detained, the consequences arepotentially very serious, especially in the Adelaide Hills where alternative routes are <strong>of</strong>tenunavailable. Emergency vehicles are held up not only by the level crossing gates, but also by thetraffic congestion they create.<strong>Freight</strong> train blocks Cross Road traffic, 2007 - Courtesy R MarshallPage 25

7. OPTIONS FOR EXISTING RAIL CORRIDOR7.1 The Hills corridor was surveyed in the late 1870's after considerable discussion and seeking themost feasible route though the Mount L<strong>of</strong>ty ranges from the Adelaide Plain. Early alternative plansincluded taking the line via ‘The Gap’ where Truro now sits, tunnelling though the ranges, or goingsouth over the lower southern ranges.7.2 The needs for a railway line are simple and basically unchanged. Grades not exceeding about 2-3% (or 2 -3 metres rise in 100 metres) allow for steel wheels gripping steel rails most <strong>of</strong> the timewithout slip.7.3 Similarly curves were considered sharp if they were less than 40 metres radius, provided wagonswere 14 metres or less in length. Today’s wagons can be 29 metres long for which the absoluteminimum curve radii should be 90 metres. These minimum radii presuppose very slow trainspeeds.7.4 The Hills line has grades around 2% and curves as sharp as 190 metres with posted speeds <strong>of</strong>50km/h. Between Adelaide and Murray Bridge there are about 30 curves with radii around 200metres and posted speeds <strong>of</strong> 50km/h. In fact over this distance there are a total <strong>of</strong> 200 curves,making this one <strong>of</strong> the most curvilinear tracks in the world (See Fig. 7.1).7.5 In addition, there are 19 bridges under or over the railway line, along with 7 tunnels <strong>of</strong> almost2.5km <strong>of</strong> total length. The construction efforts in the 1880's must have been enormous.All <strong>of</strong> this costly construction effort produced just 96km <strong>of</strong> railway.Adelaide O’Bahn, circa 1984 – Courtesy R HuntPage 26

Long-Term Future <strong>of</strong> Existing Track7.6 The advantages to industry and other commercial enterprises <strong>of</strong> rail are obvious. While road freightmay <strong>of</strong>fer some time advantages over rail, particularly for refrigerated freight, rail is considered farmore efficient. When one considers that 40 large 200 tonne B-double trucks are needed to carrythe equivalent load <strong>of</strong> a single freight train, it is easy to understand why railways have acompetitive advantage.7.7 Economics are also an important driving factor for commercial operations. If cost comparisons aremade between truck and train for most bulk freight movements, road freight cannot compete onprice per tonne. If the costs to the community <strong>of</strong> road damage are included there is no comparison.7.8 The RFTF believes rail growth will continue well into the future. However, with growing haste forproduct delivered on time and to cost there will be a need for the Adelaide Hills <strong>Rail</strong>way to performover and above its current capability and at twice the speed. It appears that if the previous 3-4years growth rate in rail freight is repeated, the need for a faster rail service will make the existingAdelaide Hills <strong>Rail</strong>way obsolete in a short period <strong>of</strong> time.7.9 The RFTF has examined an upgrade to the Adelaide Hills line which allows for track speeds todouble the existing posted speeds. Information researched on locomotive power shows thathauling trains <strong>of</strong> much greater weight and length will soon be a possibility though the Hills using thelatest AC powered engines. However, any upgrade completed in the next year will soon be out <strong>of</strong>date and out <strong>of</strong> step with continuing demands for greater speed and more powerful engines.7.10 All this does not address the current issues <strong>of</strong> noise and amenity loss to the community. It does,however, invite careful consideration to the RFTF's proposed bypass alignment which aims tomeet future rail needs longer term.<strong>Freight</strong> train Sleeps Hill, circa 1950 - Courtesy National <strong>Rail</strong>way MuseumPage 27

Figure 7.1Page 28

8. TRACK CORRIDOR UPGRADE - ALIGNMENT FOR FREIGHT TRAFFIC8.1 The following is a brief description <strong>of</strong> a proposed maximum possible upgrade on the existing trackcorridor between Adelaide and Murray Bridge.8.2 When referring to the ‘maximum possible upgrade’ which allows posted speeds to be double thecurrent speeds, it should be noted that with unlimited finances almost anything can be achieved.Within the bounds <strong>of</strong> serious consideration the RFTF believes the following will demonstrate theproposed engineering works needed for such an upgrade will cause major physical disruption andwill be economically prohibitive.8.3 As mentioned previously many <strong>of</strong> the existing structures are incapable <strong>of</strong> being upgraded tocurrent freight standards. Their demolition or abandonment would be more appropriate to allow fora new deviated route on a better alignment. Since speed and low maintenance would be the maincriteria for any new route, the next main consideration should surely be the overall cost <strong>of</strong> theupgrade compared with a new alternate route, such as the proposed RFTF Bypass.8.4 The main object <strong>of</strong> the upgrade exercise is to provide a dedicated corridor for high speed freighttrain traffic, suited to future freight delivery demands. Speeds proposed are above 100 km/h, andalthough wheel squeal noise may be reduced, general noise will be significantly increased unlessnew developments are used to suppress noise from locomotives and wagons. It follows that thecorridor would have its own exclusive right <strong>of</strong> way.8.5 The main benefits would be to eliminate or reduce curve numbers, widen and increase the trackclearances so that higher speeds than are now possible can be used with safety. Elimination <strong>of</strong> alllevel crossings is taken as a necessity.8.6 It should be noted that the problems <strong>of</strong> noise or pollution are not solved by this scenario.8.7 The RFTF recognise that the cost <strong>of</strong> the upgrade would largely need to be borne by the freightoperators and consumers <strong>of</strong> rail-freighted products. This provides yet another reason why theproposed RFTF Bypass Route (discussed later) is the preferred option.8.8 The RFTF is indebted to a previous study undertaken by South Australian <strong>Rail</strong>ways in 1975 - ThePeregrine <strong>Report</strong> (SAR 1975). This study was commissioned for a proposed new city at Monartonear Murray Bridge. Upgrade issue are also discussed in the ARTC Operational and EngineeringStudies <strong>Report</strong> (ARTC 2001a).8.9 The main criteria carried into this freight study shows the size <strong>of</strong> the upgrade needed to complywith current and future standards for freight traffic with regard to speed and accessibility forcrossing loops and other infrastructure.8.10 In the opinion <strong>of</strong> the RFTF, the costs <strong>of</strong> this upgraded route alignment are likely to be as high as400% greater than the costs <strong>of</strong> the RFTF Bypass alignment.(Refer: track modifications by deviation number, Appendix 6)Page 29

9. ALTERNATIVE USESSuggested Future Use <strong>of</strong> the Existing <strong>Rail</strong> Corridor9.1 The relocation <strong>of</strong> rail freight movements away from the current Adelaide Hills route via theproposed northern bypass would create a number <strong>of</strong> exciting and very real opportunities for anexpanded public transport service.9.2 The current rail corridor from the <strong>City</strong> <strong>of</strong> Adelaide to Belair could be converted back to a twin trackpassenger line. It is considered that this would be most efficiently carried out when the proposedconversion <strong>of</strong> metropolitan rail system to standard gauge takes place, as to replace the existingstandard gauge line with broad gauge would be a retrograde step.9.3 A dual passenger line would once again allow TransAdelaide the opportunity to provide proper andappropriate scheduling <strong>of</strong> commuter trains, something which has not been possible in the currentsingle line scenario.9.4 Once a reliable and sustainable timetabling frequency could be established, it would then befeasible to reopen the current suburban stations which were made ‘redundant’ by the then StateGovernment when the existing freight line was standardised some twelve years ago. These‘redundant’ stations, namely Hawthorn, Clapham and Millswood could also be complimented bythe construction <strong>of</strong> possible new stations along the route.9.5 Associated expansion <strong>of</strong> “Park n Ride” facilities would encourage many more commuters to utilisepassenger trains, an imperative for the future with rising fuel costs, climate change considerations,air pollution and an inadequate, congested, and rapidly deteriorating public road system.9.6 The Adelaide Hills line from Belair to Mount Barker could then be upgraded to a passenger servicewhich would facilitate the reopening all <strong>of</strong> the existing railway stations along the route as it oncedid. As part <strong>of</strong> a quickly growing Adelaide Hills town, Mount Barker residents would undoubtedlyprovide substantial patronage for such an expanded service.9.7 It would then also be possible for tourists to catch a train at Adelaide <strong>Rail</strong>way Station to link up withthe Steam Ranger Heritage <strong>Rail</strong>way at Mt Barker.9.8 There may also be an opportunity to upgrade the current line from Mount Barker to Victor Harbor toa dual gauge line thereby allowing commuter trains to once more service the southern towns <strong>of</strong>Strathalbyn, Goolwa, Port Elliott and Victor Harbor, whilst still accommodating the Steam RangerHeritage <strong>Rail</strong>way.9.9 The opportunities previously mentioned are not exhaustive. Another option could be the creation <strong>of</strong>an O’Bahn system. This would enable the purpose built vehicles to travel the track and thendeviate from the route via public roads as the Adelaide O’Bahn currently does.9.10 Electrification <strong>of</strong> the conventional rail system is another future option. This would bring SouthAustralia into line with most other states in Australia. Electrification <strong>of</strong> selected Adelaide suburbanlines was announced in the 2007 budget. Alternatively, this electrification could also be combinedwith purpose built O’Bahn vehicles, thereby eliminating exhaust pollution in built up areas. It isworth noting that electric buses are now widely used in many cities throughout the world wherethey operate efficiently and effectively.9.11 Additionally, the opportunity to create public walking trails and bicycle tracks alongside any futurepublic transport system should not be ignored.Page 30