Ceramics

Ceramics

Ceramics

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

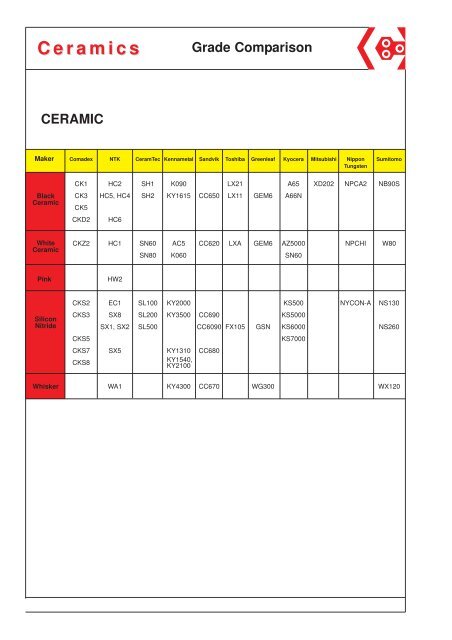

cutting speedHardness<strong>Ceramics</strong>GRADEComadex Ceramic Cutting Tool is an inorganic materials, die-pressed and sintered using veryfine and pure raw materials. These are oxide, carbide and nitride with high purity and finemicrostructure.CERMETSince the Comadex ceramics is prepared by HIP process toDIAcondense completely,it is highly wear resistant and very strong against the fracture.TiC-TiCN system PVD Coating PCBNCharacteristics-High cutting speed based on high strength at high temperature.-Capable CXF31 of diffecult cutting. CTF91CBN1-Precise cutting and superior surface roughness on workpiece due to stablethermo-chemical properties.-Longer tool life due to excellent wear resistance.CXF32CTF92CBN2PCDPKD1PKD2Physical CXF33 PropertiesCTF93PKD3Materials Grade Composition Color Density Hardness Toughness Heat Transfer(g/cm³) (Hv) (MN/m 2/3 ) (cal/cm. sec.CK1 Al2O3+TiC Black 4.2 2100 4.0 0.08CK8 Al2O3+TiCN Black 4.6 2300 4.8 0.08CERAMICCKD2 TiC+Al2O3 Black 4.6 2200 4.5 0.07CKZ2 Al2O3+ZrO2 White 4.0 1800 4.5 0.07Application of Ceramic GradeCKS2 Si3N4 Black 3.2 1600 5.0 0.06CKS3 Si3N4 Gray 3.1 1600 6.0 0.05CKS5 Si3N4 Gray 3.1 1700 6.0 0.05HighAl2O3-TiC system (CK Series)CKS7 Si3N4 Brown 3.5 1750 6.5 0.05Si3N4 (CKS Series)Cermet (CXF Series)Coated WCCarbide (WC)LowLowFeedHigh43

<strong>Ceramics</strong>Grade Application Applications and Characteristics and Characteristics of <strong>Ceramics</strong> (I) (II)Grade Application CharacteristicsCK Series (Al2O3 -Hardened +TiC, steelTiCN)-Excellent wear resistantCK1 -Finish and medium cutting for steel and -High thermal shock resistanceCK1CKcast-ironCK1 Series shows excellent thermal shock resistance and wear resistance. It is general purpose machininggrade for hardened steel and -Hardened difficult steelcutting. It can be used for finish -Superior and wear medium resistant cutting for softCK8cast iron without interruption. -Heat treated hardened steel and alloy steel -Alternative to CBNCK3-Finish and Medium cutting for ductile-High thermal shock resistantSKD CKD2 cast-iron-Usable with coolantCK3 was developed for extremely -Finish for hardened hardened steel steel and high hardness alloyd steel. It is a Al-TiCNgrade with micrograin structure.-Finish/Medium/rough cutting for cast iron -Toughened by ZrO2CKZ CKZ2-finish/Medium cutting for steel-High chemical stabilityCKD Series (TiC + Al2O3 )CKD2-Rough and interrupted cutting for cast iron-High toughness and thermal schock-Rough cutting for roll turning cast iron and resistantCKS2CKD2 is TiC major (70%) steel Al-TiC grade for medium and finish -Well cut of balanced ductile wear cast resistance iron. It and showsexcellent wear resistance -Milling and strong for cast edge ironeven for finish cutting toughness for cast iron. It is recommendedusing coolants.-High speed cutting for cast iron with heavy -High toughness and thermal shock resistantCKSSeriesCKS3CKS5interruptionCKS Series (Si3N4 )CKS2-High speed cutting for cast iron withinterruption-Excellent toughness and wear resistant-High speed cutting and severe interruption-Pure silicon nitride grade-Superior wear resistant at extremely highWell known grade for general -High speed purpose milling machining for cast iron of rough and medium cutting speed cutting of cast iron withinterruption. It shows excellent -Rough wear and interrupted resistance cutting during for cast milling iron operation -Good termal of cast shock iron. resistance and goodCKS3-Cutting for Ni-base alloytermal conductivityCKS7 -Ductile cast iron-Excellent wear resistant against the longIt was designed for high cutting speed of cast iron with heavy interruption.chip for Ni-base alloy-Needs cutting fluidsCKS5The edge hardness was improved for extremely high cutting speed for cast iron cutting with normalinterruption.CKS7CKS7 is a composite with addition of TiN into Si3N4. It shows excellent wear resistance of edge duringcutting for long chip forming work piece and Ni-Based Alloy. It can be used also for cast ironcutting but coolant recommended.CKZ (Al2O3+ZrO2 )CKZ2CKZ2 is a Al2O3 grade, which was toughened by Zirconia. This is the most stable grade and can beused for general rough, medium and finish cutting for cast iron with normal interruption.65

<strong>Ceramics</strong>Recommended cutting conditionGrade Choice for WorkpieceMachining Grade Workpiece Cutting Velocity(V) Feed(f) Depth(D)Type Grade CKZ2 CK1 Style CKD2 (m/min) CKS2, (mm/rev) CKS3 CKS7(mm)Workpiece -Gray cast Iron (FC) CK3 Rough 150~800 CKS5 0.2~0.5 3~6GRAY CASTGRAYIRON -Malleable (FCMB) Finish 200~1,200 0.3~0.5 0.1~0.5CAST -Ductile cast Iron (FCD)Cast Iron CHILLED CK1 CAST IRON IRON Rough 30~1000.1~0.20.5~1.5-Chilled cast ironDUCTILE CAST IRON Finish 50~200 0.05~0.15 0.1~0.5MILDCK8STEEL -Carbon steel Rough 150~400 0.2~0.5 2~5-Alloy steel Finish 200~800 0.05~0.2 0.1~0.5CARBON STEEL-Bearing steelSTEELALLOY STEEL Rough 20~100 0.1~0.2 0.5~1.5-Hard steel (HRC 45 >)FORGED STEELFinish 40~200 0.05~0.5 0.1~0.5CKD2Rough 100~400 0.1~0.2 1~2Turning Steel HEAT TREATED -DUCTILE STEEL CAST IRONFinish 200~800 0.05~0.25 0.1~0.5HIGH SPEED STEELRough 200~700 0.2~0.4 2~5-GRAY CAST IRON (fc)HIGH CKZ2 MANGANESE STEEL Finish 300~1,200 0.05~0.3 0.1~0.5Rough 200~400 0.2~0.4 2~4STAINLESS -STEEL (HRC 45 < )Finish 300~1,200 0.05~0.3 0.1~0.5HEAT RESISTANT STEEL -Gray cast iron (FC) Rough 150~1,100 0.3~0.8

<strong>Ceramics</strong>110Shape 3Champfer specificationToleranceC(1) Mono type 80°DEHLRSTVW75°55°35°ødSymbolAFCHEGJK*L*M*N*U*EødEwidthsd (mm) m (mm) S (mm)±0.025 ±0.005 ±0.025±0.013 ±0.005 ±0.025±0.025 ±0.013 ±0.025±0.013 ±0.013Insert Tip±0.025±0.025 ±0.025 ±0.025±0.025 ±0.025 ±0.13±0.05 ±0.05 ±0.13±0.05~ ±0.13 ±0.13 ±0.025 horning±0.05~ ±0.13 ±0.025 ±0.025±0.05~ ±0.13 ±0.08~ ±0.18 ±0.13±0.05~ ±0.13 ±0.08~ ±0.18 ±0.025±0.08~ ±0.25 ±0.13~ ±0.38 ±0.13CDSKTd (mm)Class MInscibed circle (mm) d (mm) m (mm)6.350 ±0.05 ±0.089.525 ±0.05 ±0.0812.700 ±0.08 ±0.1315.875 ±0.10 ±0.1519.050 ±0.10 ±0.15degree 25.400 ±0.13 ±0.18m (mm)6.350 ±0.05 ±0.119.525 ±0.05 ±0.1112.700 ±0.08 ±0.1515.875 ±0.10 ±0.1819.050 ±0.10 ±0.18ISOASAChampfer degree (°C) Champfer Width (mm) Horning (µm)E : 20G : 30TURNING02 : 0.1004 : 0.20S1N2G3N450 : 2.5060 : 3.000 : No Horning2 : 20S1N2G3N4MILLINGS1N2K3N4(2) Double typeInsert TypeTip1st chamfer width2ndchamferwidth2 Relief angle 4 Type of insertBCDENPO5°7°15°20°0°11°Other normal clearanceInscribedcircleover 6.35NFRSymbolhorning1st chamferdegreeInscribed circle2nd chamfer(included 7.938)degreeunder 5.556ELSType70° - 90°70° - 90°SymbolInscribedcircleover 6.35HBA D40°-60°1st Champfer degree (°C) 1st Champfer Width (mm) 2nd Champfer Width (mm) Xdegree (°C)GKTHorning (µm)W : 10X : 155 : 1.50Specialdesign6 : 2.00MXP3 : 0.20 X 2540°-60°X4 : 0.10 X 30W2 : 205 : 50109

<strong>Ceramics</strong>TURNING5 Cutting edge length 6 ThicknessDiameter ofinscribedcircle3.969 5 03 02 04 03 03 06Thickness4.762 Specification 6 Dimension 04 03 (mm) 05 04 04 08Ceramic Stock(mm) ISO ASA6.35 over 5.65 underISO5.556ASA7d05 03t r09CK106 05CK805CKD209CKZ2 CKS2 CKS3 CKS5 CKS76.350 2 (8) 06 04 11 07 06 06 11 1.59 01 - 2CNGN 090304 CNGN 321 9.525 3.18 0.47.938 0 07 05 13 09 08 07 132.38 02 - 3CNGN 9.525 090308 CNGN 3 322 09 06 0.83.18 03 2 416 11 09 09 163.97 T3 - 5CNGN 12.700 090312 CNGN 4 323 12 08 1.2 22 15 12 12 224.76 04 3 6CNGN 15.875 090404 CNGN 5 331 9.525 15 4.76 10 0.4 27 19 16 15 27 5.56 05 - -CNGN 19.050 090408 CNGN 6 332 19 13 0.8 33 23 19 19 33 6.35 06 4 -CNGN22.225090412 CNGN7333221.238 27 22 22 38 7.94 07 5 -25.400 8 25 44 31 25 25 44 9.52 09 6 -CNGN 120304 CNGN 421 12.70 3.18 0.431.750 0 31 54 38 32 31 55 12.70 12 8 -CNGN 120308 CNGN 422 0.8 12ASA (Inch)6.35 over 5.56 underCNGN 120312 CNGN 423 1.20408CNGN 120416 5 CNGN 6 434 71.6 10 453627Metricr R W V t D C S TCNGN 120404 CNGN 431 12.70 4.76 0.4 E 0 4 0CNGN 120408 CNGN 432 0.8 CNGN 120408 CNGN 433 1.2 CNGN 120420 CNGN 435 2.0CNGN 120424 CNGN 436 2.4 CNGN 120432 CNGN 438 3.2CNGN 120604 CNGN 441 12.70 6.35 0.4CNGN 120608 CNGN 442 0.8 4536E8N9CNGN 120612 CNGN 443 1.2 CNGN 120616 CNGN 444 1.6CNGN 120704 CNGN 451 12.70 7.94 0.4CNGN 120708 CNGN 452 0.8 CNGN 1207127CNGNNose-radius45381.2Landangle9Relifangle10Chamfer specCNGN 120716 CNGN 454 1.6 Corner roundness ISO ASADetailed edge preparationCNGN 120720 CNGN 455 2.0 (mm)is refer to page 9CNGN 160608 CNGN 542 15.875 6.35 0.8Sharp nose 00 OCNGN 160612 CNGN 543 1.2 CNGN 160616 0.2 CNGN 54402 Y 1.6 CNGN 160620.4 CNGN 54504 1 2.0A - 45°CNGN 1607080.8CNGN 5520815.87527.94 0.8 B - 5°CNGN 160712 CNGN 553 1.2 D - 60° C - 7° 1.2 12 3CNGN 160716 CNGN 554 1.6 D - 15° CNGN 1607201.6CNGN 55516 42.0 E - 75°E - 20° CNGN 190612 2.0 CNGN 64320 19.0556.35 1.2 F - 25° A - 3°CNGN 190616 2.4 CNGN 64424 6 1.6 F - 85°G - 30°CNGN 1906322.8CNGN 64828 73.2 N - 0°CNGN 190712 CNGN 653 19.05 7.94 1.2 P - 90°P - 11°3.2 32 8CNGN 190716 CNGN 654 1.6 CNGN 190720 CNGN 655 2.0 CNGN 190724 CNGN 656 2.4CNGN 250724 CNGN 856 25.40 7.94 2.4 dCNGN 250924 CNGN 866 25.40 9.52 2.4 80°1211

<strong>Ceramics</strong>CNGX80°TURNINGDrd80° tSpecification Dimension (mm) Ceramic StockrtISO ASA d t r D CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7CNGA 090304 CNGA 321 9.525 3.18 0.4 3.81CNGASpecification090308 CNGA 322Dimension (mm)0.8Ceramic StockCNGAISO090312ASACNGA 323d t r1.2CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7CNGX 120708 CNGX 452 12.70 7.94 0.8CNGA 090404 CNGA 331 9.525 4.76 0.4 3.81CNGX 120712 CNGX 453 1.2 CNGA 090408 CNGA 332 0.8CNGX 120716 CNGX 454 1.6 CNGA 090412 CNGA 333 1.2CNGA 120304 CNGA 421 12.70 3.18 0.4 5.16 CNGA 120308 CNGA 422 0.8 CNGA 120312 CNGA 423 1.2 CNGA 120404 CNGA 431 12.70 4.76 0.4 5.16 CNGA 120408 CNGA 432 0.8CNGA 120412 CNGA 433 1.2DNGNCNGA 120416 CNGA 434 1.6CNGA 120420 CNGA 435 2.0CNGA 120424 CNGA 436 2.4CNGA 120432 CNGA 438 3.2CNGA 120604 CNGA 441 12.70 6.35 0.455°5.16CNGA 120608 CNGA 442 0.8rCNGA 120612 CNGA 443 1.2CNGA 120616 CNGA 444 1.6ddCNGA Specification 120704 CNGA 451 Dimension 12.70 (mm) 7.94 0.4 5.16Ceramic StockCNGA ISO 120708 ASA CNGA 452 d t r 0.8CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7DNGN CNGA 150404 120712 DNGN CNGA 431 453 12.70 4.76 0.4 1.2 DNGN CNGA 150408 120716 DNGN CNGA 432 454 0.8 1.6 DNGN CNGA 1504120720 DNGN CNGA 433 455 1.2 2.0 DNGN CNGA 1504160608 DNGN CNGA 434 542 15.875 6.35 1.6 0.8 6.35 DNGN CNGA 150604 160612 DNGN CNGA 441 543 12.70 6.35 0.4 1.2 DNGN CNGA 150608 160616 DNGN CNGA 442 544 0.8 1.6 DNGN CNGA 150612 160620 DNGN CNGA 443 545 1.2 2.0 DNGN CNGA 150616 160708 DNGN CNGA 444 552 15.875 7.94 1.6 0.8 6.35 DNGNCNGA150704160712DNGNCNGA45155312.70 7.94 0.41.2 DNGN 150708 DNGN 452CNGA 160716 CNGA 5540.8 1.6 DNGN 150712 DNGN 453 1.2 CNGA 160720 CNGA 555 2.0DNGN 150716 DNGN 454 1.6 CNGA 190608 CNGA 642 19.05 6.35 0.8 7.93 DNGN 150720 DNGN 455 2.0 CNGA 190612 CNGA 643 1.2 DNGN 190608 DNGN 542 15.875 6.35 0.8CNGA 190616 CNGA 644 1.6 DNGN 190608 DNGN 543 1.2CNGA 190712 CNGA 653 19.05 7.94 1.2 7.93DNGN 190608 DNGN 544 1.6CNGA 190716 CNGA 654 1.6 DNGN 190708 DNGN 552 15.875 7.94 0.8CNGA 190720 CNGA 655DNGN 190712 DNGN 553 0.82.0DNGNCNGA190716190724DNGNCNGA5546560.82.41413t

<strong>Ceramics</strong>ENGN DNGATURNING55°75°DrdtrtSpecification Dimension (mm) Ceramic StockdISO ASA d t r D CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7DNGASpecification 150404 DNGA 431 Dimension 12.70 4.76 (mm) 0.4 5.16 Ceramic StockDNGA ISO 150408 ASA DNGA 432 d t r 0.8 CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7ENGN DNGA 130404 150412ENGN DNGA 43143312.70 4.76 0.4 1.2 ENGN DNGA 130408 150416ENGN DNGA 432434 0.8 1.6 ENGN DNGA 130412 150602ENGN DNGA 4334402 12.70 6.351.2 0.2 5.16 ENGNDNGA130416150604ENGNDNGA4344411.60.4 ENGN 130420 ENGN 435DNGA 150606 DNGA 44062.00.6 ENGN 130704 ENGN 451 12.70 7.94 0.4 DNGA 150608 DNGA 442 0.8 ENGN 130708 ENGN 452 0.8 DNGA 150612 DNGA 443 1.2 ENGN 130712 ENGN 453 1.2 DNGA 150616 DNGA 444 1.6 ENGN 130716 ENGN 454 1.6 DNGA 150704 DNGA 451 12.70 7.94 0.4 5.16 ENGN 130720 ENGN 455 2.0 DNGA 150708 DNGA 452 0.8 DNGA 150712 DNGA 453 1.2 DNGA 150716 DNGA 454 1.6DNGA 150720 DNGA 455 2.0DNGA 190608 DNGA 542 15.875 6.35 0.8 5.16 DNGA 190612 DNGA 543 1.2 DNGA 190616 DNGA 544 1.6 DNGA 190708 DNGA 552 15.875 6.35 0.8 5.16DNGA 190712 DNGA 553 1.2DNGA 190716 DNGA 554 1.6DNGX55°rdt16Specification Dimension (mm) Ceramic StockISO ASA d t r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7DNGX 120708 10.00 7.94 0.8DNGX 120712 1.2 DNGX 120716 1.6 DNGX 150708 DNGX 452 12.70 7.94 0.8DNGX 150712 DNGX 453 1.2 DNGX 150716 DNGX 454 1.6 15

<strong>Ceramics</strong>TURNINGRNGA RBGNdDt5°dtSpecification Dimension (mm) Ceramic StockISO ASA d t r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7RBGN Specification 090300 RBGN 320Dimension 9.525 3.18 (mm) Ceramic StockRBGN ISO 100700 ASA d 10.00t 7.94D CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7RNGA RBGN 120300 120400RNGA RBGN 420 43012.70 12.70 3.184.76 5.16 RNGARBGN120400120600RNGARBGN430440 12.704.766.35RNGA 120600 RNGA 440 6.35RBGN 120700 RBGN 450 12.70 7.94 RNGA 120700 RNGA 450 7.94 RNGNRPGNdtSpecification Dimension (mm) Ceramic StockISO ASA d t r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7RNGN 060200 RNGN 210 6.35 2.38RNGN 060300 RNGN 220 3.18 11°dRNGN 060400 RNGN 230 3.18 tRNGN 080700 8.00 7.94 RNGN 090300 RNGN 320 9.525 3.18 RNGN 090400 RNGN 330 4.76 RNGN Specification 100700 Dimension 10.00 7.94 (mm) Ceramic StockRNGN ISO 120300 ASA RNGN 420 d 12.70t 3.18r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7RPGN RNGN 090300 120400RPGN RNGN 3204309.525 3.184.76 RPGN RNGN 090400 120600RPGN RNGN 330440 4.766.35RPGN RNGN 120300 120700RPGN RNGN 42045012.70 3.187.94 RPGN RNGN 120400 12J700RPGN 430 12.00 4.767.94 RPGN RNGN 120600 150700RPGN RNGN 440550 15.875 6.357.94 RPGN RNGN 120700 190600RPGN RNGN 450640 19.05 7.946.35 RPGN RNGN 150700 190700RPGN RNGN 550650 15.875 7.94 7.94 RPGN RNGN 190700 250700RPGN RNGN 65085019.05 25.40 7.94 7.94 RPGN RNGN 250900 250900RPGN RNGN 85086025.40 9.52 9.521817

<strong>Ceramics</strong>SNGN SNGNTURNING75°rdtrtSpecification Dimension (mm) Ceramic StockdISO ASA d t r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7Specification Dimension (mm)SNGN 060304 SNGN 221 6.35 3.18 0.4Ceramic StockISO ASA d t r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SNGN 060308 SNGN 222 0.8SNGN 190608 SNGN 642 19.05 4.76 0.8SNGN 090304 SNGN 321 9.525 3.18 0.4 SNGN 190612 SNGN 643 1.2 SNGN 090308 SNGN 322 0.8 SNGN 190616 SNGN 644 1.6 SNGN 090312 SNGN 323 1.2 SNGN 190620 SNGN 645 2.0SNGN 090404 SNGN 331 9.525 4.76 0.4SNGN 190624 SNGN 646 2.4SNGN 090408 SNGN 332SNGN 190712 SNGN 653 19.05 7.94 1.20.8SNGNSNGN190716090412SNGNSNGN6543331.61.2 SNGNSNGN190720090416SNGNSNGN6553342.01.6 SNGN SNGN 190724 090420SNGN SNGN 656 335 2.4 2.0 SNGN SNGN 190732 120304SNGN SNGN 658 421 12.70 3.18 3.2 0.4SNGN SNGN 250720 120308SNGN SNGN 854 42225.40 7.94 2.0 0.8 SNGN SNGN 250724 120312SNGN SNGN 856 423 2.4 1.2 SNGN SNGN 250732 120404SNGN SNGN 858 431 12.70 4.76 3.2 0.4 SNGN SNGN 250924 120408SNGN SNGN 866 4325.40 9.52 2.4 0.8 SNGN SNGN 250932 120412SNGN SNGN 868 433 3.2 1.2 SNGN SNGN 3812R 120416 SNGN 43438.10 12.70 0.4 1.6 SNGN 120420 SNGN 435 2.0 SNGN 120424 SNGN 436 2.4 SNGN 120432 SNGN 438 3.2 SNGN 120604 SNGN 441 12.70 6.35 0.4SNGN 120608 SNGN 442 0.8SNGN 120612 SNGN 443 1.2 SNGN 120616 SNGN 444 1.6 SNGN 120708 SNGN 452 12.70 7.94 0.8 SNGN 120712 SNGN 453 1.2 SNGN 120716 SNGN 454 1.6 SNGN 120720 SNGN 455 2.0 SNGN 120724 SNGN 456 2.4 SNGN 120732 SNGN 458 3.2 SNGN 150408 SNGN 532 15.875 4.76 0.8SNGN 150412 SNGN 533 1.2 SNGN 150416 SNGN 534 1.6 SNGN 150420 SNGN 535 2.0SNGN 150424 SNGN 536 2.4 SNGN 150708 SNGN 552 15.875 7.94 0.8 SNGN 150712 SNGN 553 1.2 SNGN 150716 SNGN 554 1.6 SNGN 150720 SNGN 555 2.0 2019

<strong>Ceramics</strong>SPGNSNGNTURNINGrdtSpecification Dimension (mm) 11°Ceramic Stockr dtISO ASA d t r D CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SNGASpecification 090304 SNGA 321 Dimension 9.525 3.18 (mm) 0.4 3.81Ceramic StockSNGA ISO 090308 ASA SNGA 322 d t r 0.8 CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SPGN SNGA 060304 090312SPGN SNGA 221323 6.35 3.18 0.4 1.2SPGN SNGA 060308 090404SPGN SNGA 222331 9.525 4.760.80.4 3.81SPGN SNGA 090304 090408SPGN SNGA 3213329.525 3.18 0.4 0.8 SPGN SNGA 090308 090412SPGN SNGA 322333 0.8 1.2 SPGN SNGA 090312 090416SPGN SNGA 323334 1.2 1.6 SPGN SNGA 090404 090420SPGN SNGA 3313359.525 4.76 0.4 2.0SPGN SNGA 090408 120304SPGN SNGA 332421 12.70 3.180.80.4 5.16SPGN SNGA 090412 120308SPGN SNGA 333422 1.2 0.8SPGN SNGA 090416 120312SPGN SNGA 334423 1.6 1.2SPGNSNGA090420120404SPGNSNGA335431 12.70 4.762.00.4 5.16 SPGN 120304 SPGN 421 12.70SNGA 120408 SNGA 4323.18 0.40.8 SPGN 120308 SPGN 422 0.8 SNGA 120412 SNGA 433 1.2 SPGN 120312 SPGN 423 1.2 SNGA 120416 SNGA 434 1.6 SPGN 120404 SPGN 431 12.70 4.76 0.4SNGA 120420 SNGA 435 2.0SPGN 120408 SPGN 432 0.8 SNGA 120424 SNGA 436 2.4SPGN 120412 SPGN 433 1.2 SNGA 120432 SNGA 438 3.2SPGN 120416 SPGN 434 1.6 SNGA 120604 SNGA 441 12.70 6.35 0.4 5.16SPGN 120420 SPGN 435 2.0SNGA 120608 SNGA 442SPGN 120424 SPGN 4360.82.4SPGNSNGA120432120612SPGNSNGA4384433.21.2SPGN SNGA 120604 120616SPGN SNGA 44144412.70 6.35 0.4 1.6SPGN SNGA 120608 120708SPGN SNGA 442452 12.70 7.940.80.8 5.16 SPGN SNGA 120612 120712SPGN SNGA 443453 1.2 1.2 SPGN SNGA 120616 120716SPGN SNGA 444454 1.6 1.6 SPGN SNGA 120708 120720SPGN SNGA 45245512.70 7.94 0.8 2.0SPGN SNGA 120712 150408SPGN SNGA 453532 15.875 4.761.20.8 6.35SPGN SNGA 120716 150412SPGN SNGA 454533 1.6 1.2 SPGN SNGA 120720 150416SPGN SNGA 455534 2.0 1.6SPGN SNGA 150408 150420SPGN SNGA 53253515.875 4.76 0.8 2.0SPGN SNGA 150412 150424SPGN SNGA 533536 1.2 2.4 SPGN SNGA 150416 150708SPGN SNGA 534552 15.875 7.941.60.8 6.35SPGNSNGA150420150712SPGNSNGA5355532.01.2 SPGNSNGA150424150716SPGNSNGA5365542.41.6 SPGN 150708 SPGN 552 15.875 4.76SNGA 150720 SNGA 5550.82.0SPGN 150712 SPGN 553 1.2SNGA 190608 SNGA 642 19.05 6.35 0.8 7.94 SPGN 150716 SPGN 554 1.6SNGA 190712 SNGA 643 1.2 SPGN 150720 SPGN 555 2.0SNGA 190716 SNGA 644 1.6SNGA 190720 SNGA 645 2.0SNGA 190724 SNGA 646 2.42221

<strong>Ceramics</strong>TNGN SNGXTURNING60°drrdttSpecification Specification Dimension Dimension (mm) (mm) Ceramic Ceramic Stock StockISO ISO ASA ASA d d t t r r CK1 CK1 CK8 CK8CKD2 CKD2CKZ2 CKZ2CKS2 CKS2CKS3 CKS3 CKS5 CKS5 CKS7 CKS7TNGN SNGX 110304 120708TNGN SNGX 221 4526.3512.70 3.187.94 0.4 0.8 TNGN SNGX 110308 120712TNGN SNGX 222 453 0.8 1.2 TNGN SNGX 160304 120716TNGN SNGX 321 4549.525 3.18 0.4 1.6 TNGN 160308 TNGN 322 0.8TNGN 160312 TNGN 323 1.2TNGN 160404 TNGN 331 9.525 4.76 0.4 TNGN 160408 TNGN 332 0.8 TNGN 160412 TNGN 333 1.2 TNGN 160416 TNGN 334 1.6 TNGN 160704 TNGN 351 9.525 6.35 0.4 TNGN 160708 TNGN 352 0.8 TNGN 160712 TNGN 353 1.2 TNGN 160716 TNGN 354 1.6 SCGNTNGN 160720 TNGN 355 2.0TNGN 160724 TNGN 356 2.4TNGN 220404 TNGN 431 12.70 4.76 0.4 TNGN 220408 TNGN 432 0.8 TNGN 220412 TNGN 433 1.2 TNGN 220416 TNGN 434 1.6TNGN 220420 TNGN 435 2.07°r dTNGN 220432 TNGN 438 3.2 t TNGN 220608 TNGN 442 12.70 6.35 0.8TNGN 220612Specification TNGN 443 Dimension 1.2(mm) Ceramic StockTNGN 220616 ISO TNGN 444 ASA d t 1.6 r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7TNGNSCGN220708120404TNGNSCGN45243112.7012.707.944.760.80.4TNGN 220712 TNGN 453SCGN 120408 SCGN 4321.20.8 TNGN 220716 TNGN 454SCGN 120412 SCGN 4331.61.2 TNGN 270608 TNGN 542 15.875 6.35 0.8SCGN 120416 SCGN 434 1.6TNGN 270612 TNGN 543 1.2 TNGN 270616 TNGN 544 1.6TNGN 440924 TNGN 866 25.40 9.52 2.4TNGN 440932 TNGN 868 3.2TNGN 440948 TNGN 8612 4.82423

<strong>Ceramics</strong>TURNINGTPGN TNGA60°60°ddDrrt11°tSpecification Specification Dimension Dimension (mm) (mm) Ceramic Ceramic Stock StockISO ISO ASA ASA d d t t r r CK1D CK8 CK1 CKD2 CK8 CKD2 CKZ2 CKZ2 CKS2 CKS2 CKS3 CKS3 CKS5 CKS5 CKS7 CKS7TPGN TNGA 110304 090304TPGN TNGA 221 221 6.35 6.353.183.180.4 0.4 2.26 TPGN TNGA 110308 090308TPGN TNGA 222 222 0.8 0.8 TPGN TNGA 160304 160304TPGN TNGA 321 3219.525 9.5253.183.180.4 0.4 3.81 TPGN TNGA 160308 160308TPGN TNGA 322 322 0.8 0.8 TPGN TNGA 160312 160312TPGN TNGA 323 323 1.2 1.2 TPGN TNGA 160404 160404TPGN TNGA 331 3319.525 9.5254.764.760.4 0.4 3.81 TPGN TNGA 160408 160408TPGN TNGA 332 332 0.8 0.8 TPGN TNGA 160412 160412TPGN TNGA 333 333 1.2 1.2 TPGN TNGA 160416 160416TPGN TNGA 334 334 1.6 1.6 TPGNTNGA160704160704TPGNTNGA3513519.5259.5257.947.940.40.4 3.81TPGN 160708 TPGN 352TNGA 160708 TNGA 3520.80.8TPGN 160712 TPGN 353 1.2TNGA 160712 TNGA 353 1.2TPGN 160716 TPGN 354 1.6TNGA 160716 TNGA 354 1.6TPGN 160720 TPGN 355 2.0TNGA 160720 TNGA 355 2.0TPGN 160724 TPGN 356 2.4TNGA 160724 TNGA 356 2.4TPGN 220404 TPGN 431 12.70 4.76 0.4 TNGA 220404 TNGA 431 12.70 4.76 0.4 5.16 TPGN 220408 TPGN 432 0.8 TNGA 220408 TNGA 432 0.8 TPGN 220412 TPGN 433 1.2 TNGA 220412 TNGA 433TPGN 220416 TPGN 4341.21.6 TPGNTNGA220420220416TPGNTNGA4354342.01.6 TPGN TNGA 220432 220420TPGN TNGA 438435 3.2 2.0TPGN TNGA 220608 220432TPGN TNGA 44243812.70 6.35 0.8 3.2TPGN TNGA 220612 220404TPGN TNGA 443442 12.70 6.351.20.8 5.16TPGN TNGA 220616 220408TPGN TNGA 444443 1.6 1.2TPGN TNGA 220708 220408TPGN TNGA 45244412.70 7.94 0.8 1.6TPGN 220712 TPGN 453 1.2TPGN 220716 TPGN 454 1.6TPGN 270608 TPGN 542 15.875 6.35 0.8TPGN 270612 TPGN 543 1.2TPGN 270616 TPGN 544 1.6 2625

<strong>Ceramics</strong>TURNINGWNGAVNGNr20°80°ddt35°DtSpecificationSpecificationDimension (mm)Dimension (mm)Ceramic StockCeramic StockISOISO ASAASA ddttrrDCK1CK1CK8CK8CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7VNGN 160404 VNGN 331 9.525 4.76WNGA 080404 WNGA 431 12.70 4.76 0.40.45.16 VNGN 160408 VNGN 332WNGA 080408 WNGA 432 0.80.8 VNGN 160412 VNGN 333WNGA 080412 WNGA 4331.21.2 VNGN 220404 VNGN 431 9.525 4.76 0.4VNGN 220408 VNGN 432 0.8 VNGN 220412 VNGN 433 1.2VNGA35°rdtSpecification Dimension (mm) Ceramic StockISO ASA d t r D CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7VNGA 160404 VNGA 331 9.525 4.76 0.4 3.81 VNGA 160408 VNGA 332 0.8 VNGA 160412 VNGA 333 1.2 VNGA 220404 VNGA 431 12.70 4.76 0.4 5.16VNGA 220408 VNGA 432 0.8 VNGA 220412 VNGA 433 1.2 2827

<strong>Ceramics</strong>MILLINGSNKN SEAN45°ddtt20°abaaSpecification Dimension (mm) Ceramic StockSpecification Dimension (mm) Ceramic StockISO ASA d t a CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7ISO ASA d t a b CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SEAN 1203 AFTN SEAN 42 AFTN 12.70 3.18 2.0 SNKN 1204 ENTN SNKN 43 ENTN 12.70 4.76 1.4 1.0 SNKN 1504 ENTN SNKN 53 ENTN 15.875 4.76 1.4 1.0 SPKN SEKN45°ddt11° t20°abaSpecification Specification Dimension Dimension (mm) (mm) Ceramic Ceramic Stock StockISO ISO ASA ASA d d t t a ab CK1 CK1 CK8 CK8 CKD2 CKD2CKZ2 CKZ2 CKS2 CKS2 CKS3 CKS3CKS5 CKS5CKS7CKS7SPKN SEKN 12041203 ENTN AFTNSPKN SEKN 43 ENTN 42 AFTN12.70 12.70 3.18 3.18 1.4 2.0 1.0 SPKN SEKN 1504 1504 ENTN AFTNSPKN SEKN 53 ENTN 53 AFTN 15.875 15.875 4.76 4.76 1.4 2.0 1.0 TEKNSNCNdt20°aabadtSpecification Dimension (mm) Ceramic StockISO Specification ASA d Dimension t a(mm) CK1 CK8 CKD2 CKZ2Ceramic CKS2 Stock CKS3 CKS5 CKS7TEKN 1603 ISO PDTR TEKN 32 ASA PDTR 9.525 d 3.18 t 1.75 a CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7TEKN SNCN 22041204 PDTRENTN TEKN SNCN 43 PDTR 43 ENTN 12.70 12.70 4.76 4.76 1.75 1.0 3029

ab<strong>Ceramics</strong>ROLLMILLINGTURNINGCDH TNCNLTdWD10,5aathSpecificationSpecificationDimensionDimension(mm)(mm)CeramicCeramicStockStockISOISOASAASAddttDaCK1CK1CK8CK8CKD2CKD2CKZ2CKZ2CKS2CKS2CKS3CKS3CKS5CKS5CKS7CKS7CDHTNCN1206001204 ANTCDHTNCN2243 ANT12.7012.706.354.763.182.6 CDH 120900 CDH 23 12.70 9.525 3.18 CDH 191200 CDH 32 19.05 12.70 6.35 CDH 191900 CDH 33 19.05 9.525 6.35 CDH 251200 CDH 42 25.40 12.70 6.75 CDH 251900 CDH 43 25.40 19.05 6.75 TPKNCDH 320900 CDH 515 31.75 9.525 9.92 CDH 321900 CDH 53 31.75 19.05 9.92 dF - Seriest11°aSpecification Dimension (mm) Ceramic StockISO ASA d t a b CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS76°TPKN 1603 PDTR TPKN 32 PDTR 9.525 3.18 0.7 1.3 tTPKN 2204 PDTR TPKN 43 PDTR 12.70 4.76 0.7 1.3 dDSpecification Dimension (mm) Ceramic StockISO L W T D h a CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7F 13941 32.0 19.05 12.0 6.5 6.0 120° F 10537 44.5 25.4 14.2 6.5 7.0 140° 3231

<strong>Ceramics</strong>RBGX LNJROLL TURNINGtTWdLT5°Specification Dimension (mm) Ceramic StockSpecification Dimension (mm) Ceramic StockL W T r CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7d D t T CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7LNJ 5464RBGX 06T25.40 15.88 9.526.0 3.0 5.0 3.01.6 LNJ 5568RBGX 12T31.75 15.88 9.5212.0 6.0 9.0 6.03.2LNJ 6588RBGX 16T31.75 19.05 12.7016.0 8.0 13.0 8.03.2 LNJ 6688RBGX 20T38.10 19.05 12.70 3.220.0 10.0 15.0 10.0 RBGX 26T 26.0 14.0 15.0 1.0 RCGXtTad7°Specification Dimension (mm) Ceramic Stockd t T a CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7RCGX 060400 6.35 4.76 4.57 120° RCGX 060600 6.35 6.20 RCGX 060700 7.94 7.70 RCGX 090700 9.52 7.94 7.70 120° RCGX 120700 12.70 7.94 7.70 120° RCGX 151000 15.88 10.0 9.77 120° RCGX 191000 19.05 10.0 9.77 120° RCGX 251200 25.4 12.0 11.85 140° 3433

<strong>Ceramics</strong>GROOVINGSGF SYBFR0,4RSLLWT6.35 6.35Specification Dimension (mm) Ceramic StockSpecification Dimension (mm)L W T S CK1Ceramic StockCK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SYBF 3228L W H28.58 3.175R CK16.350 2.692CK8CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SGF 0525SYBF 402825.4 5.0 7.5 0.8 3.962 6.350 2.692 SGF 0625SYBF 482825.4 6.0 7.5 0.8 4.775 6.350 3.657 SGF 6325SYBF 552825.4 6.35 7.5 0.8 5.537 6.350 3.657 SGF 1425SYBF 642825.4 14.0 7.5 0.8 6.350 8.559 5.130 SGF 0515SYBF 712815.0 5.0 7.5 0.87.137 8.559 5.130 SGF 6315SYBF 792815.0 6.35 7.5 0.8 7.924 8.559 5.130 SYBF 8728 8.737 8.559 6.985 SYBF 9528 9.525 8.559 6.985 SGRSYBRR0,4SFULLRADIUSTWH10°5° 5°90°WTL45°±30°L5° 5°6.35 6.355°Specification Dimension (mm) Ceramic StockSpecificationLDimensionW T(mm)CK1 CK8 CKD2 CKZ2CeramicCKS2StockCKS3 CKS5 CKS7SGR 4712L W T12.70 4.762 4.749 S CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SYBR 3228SGR 551928.58 3.175 6.350 2.69219.05 5.557 6.35 SYBR 4028SGR 63193.962 6.350 2.6926.350 SYBR 4828SGR 71194.775 6.350 3.6577.142 SYBR 5528SGR 79255.537 6.350 3.65725.40 7.937 8.559 SYBR 6428SGR 87256.350 8.559 5.1308.732 SYBR 7128SGR 95257.137 8.559 5.1309.525 SYBR 7928SGR 63257.924 8.559 5.13025.40 6.350 7.96 SYBR 8728SGR 06258.737 8.559 6.9856.00 SYBR 9528SGR 05259.525 8.559 6.9855.00 3635

d<strong>Ceramics</strong>Special GROOVING insertsSNMX SSRRtdWTLR5°90°Specification Dimension (mm) Ceramic StockL W T R CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7Specification Dimension (mm) Ceramic StockSSR 4713 13.462 4.762 4.724 2.387 d t R CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7SSR 3515 15.875 3.571 4.749 1.778 SNMX 121006R 12.70 10.0 6 SSR 6319 19.05 6.350 4.775 3.175 SNMX 121009R 9 SSR 9519 19.05 9.525 6.350 4.749 SNMX 121012R 12 SSR 1225 25.40 12.70 7.772 6.35 SNMX 121015R 15 SNMX 121020R 20 SNMX 121025R 25 SNMX 121030R 30 SNMX 121040R 40 SNMX 121050R 50 GVGN90°αTLSpecification Dimension (mm) Ceramic StockL α d T CK1 CK8 CKD2 CKZ2 CKS2 CKS3 CKS5 CKS7GVGN 38320 32 38° 14.238 7.94 GVGN 38335 33.5 38° 13.28GVGN 36340 34 36° 13.593837

COMADEXComadex Cutting Tools b.v.Raphaelstraat 1H7031 BA Wehl, HollandTel: +31(0) 314-690 990Fax: +31(0) 314-681 280E-mail : info@comadex.nlwww.comadex.nl