ASPECT4 Logistics A Presentation of Release 9.1

ASPECT4 Logistics A Presentation of Release 9.1

ASPECT4 Logistics A Presentation of Release 9.1

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ASPECT4</strong> <strong>Logistics</strong><br />

A <strong>Presentation</strong> <strong>of</strong><br />

<strong>Release</strong> <strong>9.1</strong><br />

The release <strong>9.1</strong> <strong>of</strong> <strong>ASPECT4</strong> <strong>Logistics</strong> contains many functional<br />

improvements to the commerce-related parts <strong>of</strong> the system.<br />

Many development projects ensures a smooth change-over to<br />

<strong>ASPECT4</strong> <strong>Logistics</strong> for customers previously running the commerce<br />

module <strong>of</strong> <strong>ASPECT4</strong>. The major part <strong>of</strong> the features relate<br />

to outgoing logistics, e.g. price and discount addition, dynamic<br />

rearrangement and transport management. For incoming<br />

logistics the enhancements include a cockpit for receiving supplier<br />

invoices. Some <strong>of</strong> the general improvements is the ability<br />

to implement alternative cost prices – and the opportunity to<br />

design your own screen display in eXposer.

2<br />

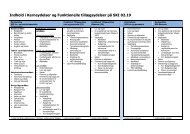

Contents<br />

About <strong>ASPECT4</strong> <strong>Logistics</strong> <strong>Release</strong> <strong>9.1</strong> .......................... 3<br />

Outgoing <strong>Logistics</strong><br />

Dynamic Rearrangement ............................................ 4<br />

Set up Dynamic Rearrangement .............................. 4<br />

Simulate Ability to Deliver ....................................... 5<br />

Dynamic Rearrangement and Order Processing .......... 6<br />

Log <strong>of</strong> Rearrangements ........................................... 7<br />

Manual Reprioritising <strong>of</strong> Orders ................................ 7<br />

Dynamic Rearrangement and Time ........................... 7<br />

Sales Prices and Discounts ......................................... 8<br />

Definitions ............................................................ 8<br />

Master Records ...................................................... 8<br />

Company Parameters ............................................. 9<br />

Other .................................................................. 12<br />

Master Data Maintenance ....................................... 12<br />

Rules and Restrictions ........................................... 15<br />

Functions ............................................................. 15<br />

Transport Management ............................................. 17<br />

How Do Transport Requirements Occur? .................. 18<br />

Planning a Transportation ....................................... 19<br />

Completing a Transportation ................................... 20<br />

Blanket Orders ........................................................ 23<br />

What is a Blanket Order Agreement ........................ 24<br />

Relationship between Blanket Order Agreements<br />

and Blanket Orders ........................................... 24<br />

Customer-agreed Minimum Stocks .......................... 24<br />

Distributing a Blanket Order Agreement Line<br />

to Periods ......................................................... 24<br />

Availability on Derived Orders ................................. 25<br />

Availability on Internal Trade .................................. 26<br />

Improved Call-<strong>of</strong>f Management ............................... 26<br />

Improved Folllow-up Options on Order Hierarchies .... 27<br />

Integration to Sales Budget .................................... 27<br />

e-Export ................................................................. 27<br />

Receiving Delivery Proposal via Adaptor DELFOR ......... 28<br />

Prerequisites and Delimitations ............................... 28<br />

Minor enhancements – outgoing <strong>Logistics</strong> ................... 29<br />

Copying order lines ............................................... 29<br />

Entry <strong>of</strong> a numerical customer number .................... 29<br />

EAN number as customer item number .................... 29<br />

Selection by status ................................................ 29<br />

Wholesaler Group ................................................. 29<br />

Price Setting Customer .......................................... 29<br />

Allocating pallets and packages ............................... 30<br />

Extended control code scanning .............................. 30<br />

Customs Tariff on Pr<strong>of</strong>orma Invoices ....................... 30<br />

KID Number on Invoice ......................................... 30<br />

Inward bound <strong>Logistics</strong><br />

Cockpit for Receiving Invoices ................................... 31<br />

Cockpit for Capacity Overview ................................... 32<br />

Check against Accumulated Capacity .......................... 33<br />

Changed Control <strong>of</strong> Breakdown <strong>of</strong> Sales Plan ............... 33<br />

Material Check in Fine Planning .................................. 34<br />

Backward Dating in Fine Planning ............................... 34<br />

Selection by Production Model Groups ........................ 34<br />

Missing Data for POPX-TS .......................................... 34<br />

Max size <strong>of</strong> Data Queues ........................................... 35<br />

Function Groups in Connection with<br />

Company Parameters A9145 and A9141 ................. 35<br />

Workflow for Approval <strong>of</strong> Supplier Invoices ................. 35<br />

Cross-Disciplinary Enhancements<br />

New Standard Cost Methods ...................................... 37<br />

Product Configuration during Sales Order Registration .. 37<br />

Configuration <strong>of</strong> Item Set .......................................... 38<br />

Item Number and Name ........................................... 38<br />

Copying in Relation to Item Features .......................... 40<br />

Print Options in 'Calculate Costs for<br />

Purchase Items' (9231) ............................................ 40<br />

Restructured Financial Interface ................................ 40<br />

Technical Enhancements<br />

STFE Processing under eXposer ................................. 41<br />

Shortcut F4 ............................................................. 42<br />

External Documents in DocManager ........................... 42<br />

Call <strong>of</strong> PC Applications by using Shortcuts ................... 42<br />

Implementation<br />

Implementing <strong>Release</strong> <strong>9.1</strong> ......................................... 43<br />

Preparation ............................................................. 43<br />

Receiving and Installing Packages .............................. 43<br />

Environment Setup .................................................. 44<br />

Upgrading Test Environment ...................................... 44<br />

Upgrading Operating Environment .............................. 45<br />

Upgrading Test/Operating Environment ....................... 46<br />

Comments .............................................................. 46<br />

Triggers .................................................................. 46

About <strong>ASPECT4</strong> <strong>Logistics</strong><br />

<strong>Release</strong> <strong>9.1</strong><br />

This new release <strong>of</strong> <strong>ASPECT4</strong> <strong>Logistics</strong> contains many functional<br />

improvements to the commerce-related parts <strong>of</strong> the<br />

system. Many development projects have been carried<br />

out in order to ensure a smooth change-over to <strong>ASPECT4</strong><br />

<strong>Logistics</strong> for customers previously running the commerce<br />

module <strong>of</strong> <strong>ASPECT4</strong>.<br />

The major part <strong>of</strong> the innovative features relate to outgoing<br />

logistics, e.g. price and discount addition, dynamic rearrangement,<br />

and transport management. For incoming<br />

logistics the enhancements include a cockpit for receiving<br />

supplier invoices.<br />

One <strong>of</strong> the general improvements is the ability to implement<br />

alternative cost prices. Besides, you now have the<br />

opportunity to design your own screen display in eXposer –<br />

read about combo boxes, field groups and radio groups in<br />

the chapter introducing technical improvements.<br />

We are proud to announce that the first cockpits developed<br />

are now included in the standard system. We hope that<br />

you will all benefit from them.<br />

This release description is distributed electronically, only. If<br />

you need to have a paper edition, please print this file.<br />

If you have not already upgraded to release 9.0, we recommend<br />

that you upgrade directly to release <strong>9.1</strong>.<br />

For all <strong>of</strong> you who are already running release 9.0, we recommend<br />

that you upgrade to release <strong>9.1</strong> to benefit from<br />

the enhancements described in this document.<br />

3

The purpose <strong>of</strong> dynamic rearrangement in <strong>ASPECT4</strong> <strong>Logistics</strong><br />

is to ensure that customers are served with goods to<br />

the best ability and in a prioritised order. Any change in the<br />

business’ supply situation will also be reflected directly on<br />

the sales orders by their delivery dates being changed automatically<br />

according to defined parameters.<br />

Dynamic rearrangement will allocate sales orders based on<br />

the supply situation, i.e. based on stockholding and<br />

planned receipts from purchase and production. Dynamic<br />

rearrangement does not solve any tasks in connection with<br />

improving the company’s supply situation.<br />

Dynamic rearrangement n <strong>ASPECT4</strong> <strong>Logistics</strong> is implemented<br />

for normal sales orders, i.e. firm orders. It functions<br />

within one warehouse area and not across warehouse areas.<br />

The below new applications in <strong>ASPECT4</strong> <strong>Logistics</strong> deal with<br />

dynamic rearrangement:<br />

6360 Display Arrangements<br />

6260 Continuous Rearrangements<br />

6263 Stop Continuous Rearrangements<br />

6264 Rearrange All Items<br />

6190 Work with Order Priorities<br />

Set up Dynamic Rearrangement<br />

Setting up dynamic rearrangement is a comprehensive<br />

task. In order to apply dynamic rearrangement, you must<br />

carry out settings within the following fields:<br />

• Setup <strong>of</strong> system parameters<br />

• Setup <strong>of</strong> triggers<br />

• Application setup for order processing<br />

• Start <strong>of</strong> applications required for using dynamic<br />

rearrangement<br />

System Parameters for Dynamic<br />

Rearrangement<br />

The system parameter REDISP is new in <strong>ASPECT4</strong> <strong>Logistics</strong><br />

and is aimed at managing dynamic rearrangement.<br />

As it appears from this system parameter, you can apply<br />

three different elements for prioritising customer orders: A<br />

customer grouping, a priority, or an order registration time<br />

stamp. If you apply a customer grouping for the prioritising<br />

<strong>of</strong> customers (e.g. A/B/C customers), you must also<br />

specify the customer group for the classification.<br />

4<br />

Dynamic Rearrangement<br />

OUTGOING LOGISTICS<br />

If you prioritise the customers on a first-come basis, exclusively,<br />

you only apply the time stamp as the priority.<br />

As you will see from the parameters, you can also control<br />

the maximum number <strong>of</strong> splits for an order line (corresponding<br />

to the number <strong>of</strong> part deliveries). And you can<br />

control that a particular minimum percentage <strong>of</strong> an order<br />

line must be deliverable for the delivery to be <strong>of</strong> interest<br />

altogether.<br />

Besides, we recommend that you use a special setup to<br />

control which orders to include in the arrangement. A typically<br />

setup could be:<br />

For purchase and production orders, you will normally include<br />

confirmed purchase orders and production orders<br />

(possibly controlled by status). For stocked items, all locations<br />

and all consignments should be marked as included.<br />

The below system parameters are new parameters resulting<br />

from implementing dynamic rearrangement:<br />

DISPBASE: Arrangement based on (system values)<br />

REDIAARS: Cause <strong>of</strong> rearrangement (system values)<br />

REDILBGR: Log limit for rearrangement (excludes causes<br />

from the log).

Triggers<br />

Dynamic rearrangement is based on triggers to the follow-<br />

ing files:<br />

• Stockholdings (LABEREG)<br />

• Sales order lines (ORDLREGS)<br />

• Purchase order lines (ORDLREGI)<br />

• Production order lines (PROLREG)<br />

You set up triggers via application 'Work with Event Descriptions'<br />

(9188) and application 'Work with Onward Processing'<br />

(9189). Below we describe a typical setup <strong>of</strong> these<br />

applications.<br />

Example <strong>of</strong> setup in 'Work with Onward Processing' (9189):<br />

The specific setup <strong>of</strong> for example the file LABEREG may<br />

look like this:<br />

The general overview <strong>of</strong> which triggers are added to the<br />

files is provided by the application 'Work with Event Descriptions'<br />

(9188):<br />

Activating Rearrangement in Order Processing<br />

In order to apply dynamic rearrangement in order processing,<br />

the following parameters must be set up in for example<br />

'Work with Firm Order Lines' (6524):<br />

Code value <strong>of</strong> 'Check available holding' must be 3.<br />

So far, you have only had the code options 0 and 1. If you<br />

select 3, the arrangement screen will appear if the order<br />

either cannot be delivered directly from stock or the delivery<br />

time <strong>of</strong> the order line is later than the delivery time <strong>of</strong><br />

the item.<br />

Items with an arrangement code smaller than 7 will not be<br />

included in the arrangement.<br />

Active Applications for Dynamic Rearrangement<br />

The application 'Implement Onward Processing' (9272)<br />

must be active, and so must the application 'Continuous<br />

Rearrangement' (6260). We recommend that you manage<br />

this via application 'Work with Job Definitions' (9176).<br />

Simulate Ability to Deliver<br />

The ability to deliver can be viewed in application 'Display<br />

Arrangement' (6360). Specify the item number, customer<br />

number, and warehouse area. If you apply only the time <strong>of</strong><br />

registration as the priority in the arrangement, the customer<br />

number is <strong>of</strong> no significance. If the customers have been<br />

prioritised either by a customer group <strong>of</strong> by their priority,<br />

the delivery situation depends on the customer’s priorities.<br />

5

An arrangement screen may look like this:<br />

It appears that the delivery time is 7 days and that the enquiry<br />

is for 500 pieces. 50 pieces can be delivered from<br />

stock. 200 pieces can be delivered when items purchased<br />

have arrived on 17.10. The rest can be delivered according<br />

to the item’s standard delivery time <strong>of</strong> 7 days, i.e. on<br />

17.10.<br />

Managing Planned Receipts<br />

As always in <strong>ASPECT4</strong> <strong>Logistics</strong>, a precise management <strong>of</strong><br />

the dates <strong>of</strong> expected receipts is significant to the credibility<br />

<strong>of</strong> the arrangement overviews. The significance is even<br />

greater when you apply the dynamic rearrangement facility.<br />

A planned receipt is always at least one day ahead. Hereby<br />

you have provided for time to handle the goods.<br />

Managing Delivery Times<br />

The procurement time <strong>of</strong> an item is stored in the purchase<br />

information. If this information is not available, the system<br />

will get the standard delivery time stored in the item’s<br />

sales information. Based on experience it is difficult to keep<br />

supplier delivery times updated even if they can easily be<br />

maintained in <strong>ASPECT4</strong> <strong>Logistics</strong>. If a purchase order has<br />

been confirmed at a time later than the item’s delivery<br />

time, the dynamic rearrangement facility will automatically<br />

extend the delivery time for that item.<br />

Dynamic Rearrangement and<br />

Order Processing<br />

If an order line cannot be completely delivered from stock,<br />

and if it must not be delivered at a time later than the<br />

standard delivery time, you apply the same arrangement<br />

screen as displayed above under "Simulate ability to deliver".<br />

In order to provide a true picture <strong>of</strong> an order line’s<br />

delivery situation, we have introduced a new status code:<br />

25 = Available. An order line can have status 25 if it is<br />

available either against stock or against a stock receipt<br />

(purchase or production).<br />

You have a number <strong>of</strong> options for the order processing in<br />

the screen display:<br />

1. Best possible. If you select this option in our example,<br />

the order line will be split into three order lines according<br />

to the delivery situation. All order lines will have<br />

02.10 as the requested delivery date. If the goods can<br />

6<br />

be delivered at an earlier date, the order lines will automatically<br />

be moved in time correspondingly.<br />

2. You agree with the customer that all 500 must be delivered<br />

on 17.10. This is achieved by marking 'Delivery'<br />

next to the date 17.10. An order line will be created<br />

with 17.10 as the delivery date and 17.10 as requested<br />

delivery date (an order line will never attempt to deliver<br />

prior to requested delivery date).<br />

3. You agree with the customer that 50 pieces must be delivered<br />

now and the rest on 17.10. This is achieved by<br />

entering 50 next to 02.10 and marking 17.10 for the<br />

rest. The arrangement screen will then appear as shown<br />

below. It will result in two order lines with the delivery<br />

dates 02.10 and 17.10, respectively. Requested delivery<br />

date is set to the same date as the delivery date.<br />

4. Many other combinations may be agreed with the customer.<br />

Only the maximum number <strong>of</strong> splits must not be<br />

exceeded, and a delivery must fulfil at least the percentage<br />

from the system parameter REDISP (except for the<br />

last delivery).<br />

What Happens to the Order if Something is Changed?<br />

Let us assume that the above example has been created as<br />

an order. Now, if there is a stock adjustment <strong>of</strong> -50, the<br />

following events will occur:<br />

1. The order line with delivery on 02.10 can no longer be<br />

delivered. It will therefore be split into two order lines.<br />

The original order line is reduced to 0, and a new order<br />

line <strong>of</strong> 50 on 17.10 is created. This is caused by the fact<br />

that it was agreed with the customer that 50 pieces<br />

must be delivered on 02.10 and the first possible delivery<br />

date is 17.10.<br />

2. The order line for 17.10 is kept unchanged.<br />

You may imagine many scenarios <strong>of</strong> events. We recommend<br />

that you simulate any relevant scenario in order to<br />

clarify how the arrangement will react in particular situations.<br />

Basically, the following rules apply:<br />

• An order will never attempt to deliver prior to requested<br />

delivery date.<br />

• An order line will never be split into a lager number than<br />

that <strong>of</strong> the system parameter REDISP. If an order line<br />

has been split manually in the arrangement screen, the<br />

split lines can be split again, still considering the number<br />

<strong>of</strong> splits allowed in the system parameter REDISP.<br />

• An order line will never allow deliveries below the percentage<br />

<strong>of</strong> the smallest delivery, cf. system parameter<br />

REDISP (except for the last delivery).

Order Entry via EDI or BusinessConnector<br />

If orders are received electronically, they will be processed<br />

according to the 'Best possible' option.<br />

Procured items and direct deliveries<br />

Procured items and direct deliveries are not included in the<br />

rearrangement processing in the usual way. For the order<br />

policies IS, IO, PO, and IG, order lines are automatically<br />

created in status 30, meaning 'prioritised'. This means that<br />

they are actually not included in the rearrangement and<br />

thereby they do not risk being split.<br />

Log <strong>of</strong> Rearrangements<br />

The changes made by dynamic rearrangement are <strong>of</strong><br />

course being logged. You can work with this log via application<br />

'Work with Rearrangement Log' (6135). The log<br />

shows what changes have been made to the order lines.<br />

Based on the log you may choose to select, for example,<br />

that you must send a new confirmation to the customer.<br />

Manual Reprioritising <strong>of</strong> Orders<br />

If you need to override the automatic allocation <strong>of</strong> items,<br />

you can override via application 'Work with Order Priorities'<br />

(6190). By selecting an order line in the application, its<br />

status can be changed to 30, which is 'prioritised'.<br />

Log <strong>of</strong> rearrangements<br />

Dynamic rearrangement may be disturbed by the use <strong>of</strong><br />

reservations and allocations in the order processing. We<br />

therefore recommend that these options are removed from<br />

the order processing applications, i.e. do not allocate items<br />

until they are picked from stock. We also recommend that<br />

you restrict access to application 'Work with Order Priorities'<br />

(6190).<br />

Dynamic Rearrangement and Time<br />

The fact that time passes cannot be perceived by the trigger<br />

settings on the files. Therefore, once a day you must<br />

reallocate all items. This is performed via application 'Reallocate<br />

All Items' (6264).<br />

7

To provide an overview <strong>of</strong> the sales price and discount addition<br />

in <strong>ASPECT4</strong> <strong>Logistics</strong> we have chosen to include in<br />

this document a full description <strong>of</strong> the opportunities <strong>of</strong><br />

managing prices and discounts. Thus not only new features<br />

are described below.<br />

Managing sales prices and discounts implies:<br />

• Management <strong>of</strong> price information and conditions.<br />

• Communication <strong>of</strong> price information and conditions.<br />

• Retrieval <strong>of</strong> current prices and prices conditions when<br />

creating orders.<br />

• Documentation <strong>of</strong> divergences, if any.<br />

Facilities for the above-mentioned tasks include:<br />

• An item may appear on various price lists.<br />

• A price list my appear in various currencies.<br />

• Price lists may be limited in time.<br />

• Customers can be connected to a particular price list.<br />

• A price list may be limited to one particular customer.<br />

• Both prices and discounts can be processed.<br />

• Quantity-dependent prices and discounts can be processed.<br />

• Feature-dependent prices can be processed.<br />

• Separate financial posting <strong>of</strong> the individual price elements.<br />

Definitions<br />

In <strong>ASPECT4</strong> <strong>Logistics</strong> there are several concepts in the field<br />

<strong>of</strong> 'Sales Prices and Discounts'.<br />

Below you will find a definition <strong>of</strong> some <strong>of</strong> them.<br />

Price - (basic price) is the basis on which the sales price is<br />

determined.<br />

The basis can be modified by addition/deduction (corrections)<br />

and/or by granted discounts.<br />

Discount - is the amount/percentage by which the sales<br />

price is reduced when determining the net price.<br />

A discount will always be specified and will appear as a<br />

specified amount in quotations, order confirmations and invoices.<br />

Price discounts in currency differ from price discounts in<br />

percentage by being absolute variables as opposed to relative<br />

percentages.<br />

Correction - is an addition or deduction by which the basic<br />

price is modified.<br />

The correction will not appear as a specified amount in<br />

quotations, order confirmations and invoices.<br />

Price corrections in currency differ from price corrections in<br />

percentage by being absolute variables added or deducted<br />

as opposed to relative percentages.<br />

8<br />

Sales Prices and Discounts<br />

Total discount - is a discount granted for the entire order.<br />

It will be specified on the sales order header and will be<br />

initiated with the value from the customer master records.<br />

It will be calculated as a percentage <strong>of</strong> the order total,<br />

however adjusted for the prices, discounts, corrections,<br />

and order lines that have been deselected from total discount<br />

calculation.<br />

Chain discount - is a discount that can be granted in several<br />

levels.<br />

Discount agreements can exist in a random number <strong>of</strong> levels.<br />

Thus it can be established when one agreement "replaces"<br />

another agreement, and when the found agreement<br />

is an "addition" to other agreements.<br />

Discount calculation have many details, one <strong>of</strong> which is the<br />

"level" <strong>of</strong> net amount on which to base the discount calculation;<br />

for example: one discount agreement triggering 10<br />

% discount and a second discount agreement triggering a<br />

further 5 %. In this case the discount will be granted from<br />

the net amount that was already subject to discount calculation.<br />

Master Records<br />

Customer File<br />

Customer master records include the following fields on<br />

which sales price fixing and discount are based:<br />

Price Setting Customer No - provides the opportunity <strong>of</strong><br />

controlling price fixing and discount by the number specified<br />

here. Thus the price addition control is flexible for each<br />

customer (not tied to customer or debtor). The pricing customer<br />

number may be applied in case <strong>of</strong> a wholesale society<br />

determining the price.<br />

Price List Number – is used for determining which price the<br />

customer must pay when purchasing. If the field value is 0<br />

(zero), the customer will buy at basic sales prices, and if it<br />

is 1 (one), the customer will buy at price list prices. The<br />

normal situation is 1.<br />

Line Discount Code – determines whether the customer is<br />

entitled to a price discount.<br />

Quantity Discount Code - determines whether the customer<br />

is entitled to a quantity discount.<br />

Discount Group – is the price and discount group to which<br />

the customer belongs. It provides the opportunity <strong>of</strong> connecting<br />

customers to a common price list. It was applied<br />

before the pricing customer concept was introduced.<br />

Total Order Discount Percent – for customer.

Item File<br />

Item master records include the following fields on which<br />

sales price fixing and discount are based:<br />

Discount Group for the item when selling.<br />

The discount group specified in the sales item’s master<br />

records is used when adding corrections and discounts.<br />

Besides, it is possible to connect the item to a number <strong>of</strong><br />

supplementing item discount groups. These groups will<br />

only be applied when calculating discount (not when calculating<br />

corrections). The calculation sequence is specified in<br />

the system parameter RABATVAR.<br />

Line Discount Code – indicates whether a price discount is<br />

granted on the item.<br />

Quantity Discount Code - indicates whether a quantity discount<br />

is granted on the item.<br />

Company Parameters<br />

Below you will find the company parameters influencing<br />

sales prices and discounts.<br />

Discount Agreement (RABATAFT)<br />

Level: The level <strong>of</strong> the discount agreement. 0 is the highest<br />

level, 9 is the lowest.<br />

Discount Agreement Id: The entry basis. The discount<br />

agreement Id is applied when posting chain discount.<br />

Discount Basis: A discount that has been manually granted<br />

to a particular order line will always override any other discount<br />

calculation. This means that for example a collective<br />

discount will not be added to the line as well. However, the<br />

quantity on the line can be part <strong>of</strong> the total quantity basis<br />

applied when determining the collective discount rates for<br />

the entire agreement.<br />

Collective Discount: When calculating discounts at a group<br />

level, it must be specified whether the discount only applies<br />

to the individual order line or whether it comprises all<br />

order lines on the order belonging to the current item discount<br />

group and discount agreement.<br />

Unit Type: The type indicates whether the unit on the current<br />

agreement is a unit <strong>of</strong> quantity or a unit <strong>of</strong> amount<br />

(currency code).<br />

If it is a unit <strong>of</strong> quantity, the order quantity will be converted<br />

to the specified unit when calculating the discount.<br />

If it is a currency code, the gross amount <strong>of</strong> the order line<br />

will be used when searching for amount limits. If an agreement<br />

in order currency has not been created, an agreement<br />

in system currency may be applied. See the system<br />

parameter SALGPRIS.<br />

Unit: The unit (alternative unit) in which quantity limits are<br />

specified in connection with discounts in the current agreement.<br />

If the unit is a currency code, the limits specified are<br />

amount limits in the current currency. Please note that if it<br />

is a currency code, the gross amount <strong>of</strong> the order line will<br />

be used when searching for amount limits.<br />

Info on Next Quantity Limit: A percentage controlling notification<br />

<strong>of</strong> a further discount potential. If a further discount<br />

is possible and if the current quantity basis differs less than<br />

the specified percentage from the next quantity limit, the<br />

assistant dealing with the order will be notified. Notification<br />

will occur when the line processing has been completed or<br />

on request. If the value is 0, there will be no automatic information.<br />

Manual Discount: A discount that has been granted manually<br />

on a particular order line will always override any other<br />

discount calculation. This means that for example a collective<br />

discount will not be added to the line as well. However,<br />

the quantity on the line can be part <strong>of</strong> the total quantity<br />

basis applied when determining the collective discount<br />

rates for the entire agreement.<br />

Sequence Number: This is the calculation sequence number<br />

for the discount agreement. When calculating sales discounts,<br />

the individual discount agreements will be processed<br />

in the sequence specified here.<br />

Next Sequence Number: If a discount has been granted in<br />

the current discount agreement, discount can be suppressed<br />

in one or more succeeding discount agreements.<br />

If the next sequence number is greater than zero (and<br />

greater than the current calculation sequence number),<br />

subsequent discount will continue from the sequence number<br />

specified here.<br />

9

Price and Discount Groups for Customers<br />

(RABATKUN)<br />

Possible Alternative Price Group: Alternative price group is<br />

applied when searching in the price list after an unsuccessful<br />

search via the primary customer price/discount group.<br />

Hereby it is possible to use different groups when searching<br />

prices and searching discounts, respectively. This is relevant<br />

if you have rather many discount potentials, but only<br />

few price lists.<br />

If the field is blank, the alternative cost group is not included<br />

in the search.<br />

Discount Level Information (RABATNIV)<br />

Processing Code: The processing code determines how the<br />

discount must be granted.<br />

The discount can be granted irrespective <strong>of</strong> other discount<br />

potentials within the current discount level or, as an alternative,<br />

it can replace other groups that would produce a<br />

lower rate.<br />

Besides, you can specify whether the discount should be<br />

granted when a manual price has been entered on the order<br />

line.<br />

10<br />

Discount Groups for Items (RABATVAR)<br />

Total Disc on Items in Group: Must lines on items in this<br />

group be included when calculating total discount (invoice<br />

discount)?<br />

EDI Discount Code: The associated discount code submitted<br />

via EDI.<br />

Sales Pricing (SALGPRIS)<br />

Select by check mark the combinations to be applied in the<br />

sales pricing:<br />

Sales Price by CustNo-ItemNo<br />

Sales Price by CustGrpN-ItemNo<br />

Sales Price by Blank-ItemNo<br />

Complete Feature/Option Spec: Sales pricing <strong>of</strong> feature<br />

items with complete feature/option specification.<br />

Addition/Deduction Features: Sales pricing <strong>of</strong> feature items<br />

with addition/deduction for the feature determining the<br />

price.

Sales Price Corr in Currency: The code determines if and<br />

how sales price correction in currency is applied. Valid<br />

codes are:<br />

0: Sales price correction in currency is not applied<br />

1: Sales price correction in currency is applied<br />

2: Sales price correction in currency is applied if a sales<br />

price correction in percent does not exist<br />

Sales Price Correction %: The code determines if and how<br />

sales price correction in percent is applied. Valid codes are:<br />

0: Sales price correction in percent is not applied<br />

1: Sales price correction in percent is applied<br />

2: Sales price correction in percent is applied if a sales<br />

price correction in currency does not exist<br />

Sales Discount in Currency: The code determines if and<br />

how sales discount in currency is applied. Valid codes are:<br />

0: Sales discount in currency is not applied<br />

1: Sales discount in currency is applied<br />

2: Sales discount in currency is applied, if sales discount in<br />

percent does not exist<br />

Sales Discount %: The code determines if and how sales<br />

discount in percent is applied. Valid codes are:<br />

0: Sales discount in percent is not applied<br />

1: Sales discount in percent is applied<br />

2: Sales discount in percent is applied, if sales discount in<br />

currency does not exist<br />

Basic Correction Number: This number will be applied if<br />

there is no sales price correction for the current sales order<br />

header priority.<br />

Select by check mark the combinations to be applied when<br />

searching for sales price corrections and sales price discounts.<br />

Discount Search in System Currency: When searching for<br />

sales discounts where the discount is subject to specified<br />

amount limits, the search will primarily be for discount limits<br />

specified in order currency. If such limits do not exist,<br />

by selecting this field you request to alternatively search<br />

for limits in system currency.<br />

Please note: In order to avoid that discounts are in this<br />

case granted on the basis <strong>of</strong> both agreements in order currency<br />

and agreements in system currency, the discount<br />

rules should be defined to the effect that the agreement in<br />

system currency is made subject to the non-existence <strong>of</strong><br />

an agreement in order currency. This can be achieved by<br />

specifying a 'Next Sequence Number' in system parameter<br />

RABATVAR.<br />

You should also be aware that conversion between currencies<br />

will always be at the current rate and therefore discount<br />

limits converted into order currency may vary from<br />

time to time.<br />

11

Sales Management (MODUL-3)<br />

Price List Used: Select to apply the price list system.<br />

Customer Object Type: Whether the ordering customer or<br />

the paying customer must determine the price setting. In<br />

case you apply price setting customer, you must select ordering<br />

customer.<br />

Price Setting Date: Whether the order entry date or the delivery<br />

date must function as the default price setting date.<br />

Collective Discount Used: Whether collective discount is applied<br />

at item discount group level.<br />

Other<br />

In the feature file you must specify whether the feature or<br />

the option must determine the sales price (J/N).<br />

Master Data Maintenance<br />

Basic Prices - Sale<br />

12<br />

These items <strong>of</strong> information make up the basis on which the<br />

sales price is determined. The basis can be modified by addition/deduction<br />

and/or by granted discounts.<br />

Price List Identification: This is the "pointer" onto the price<br />

list that can be created from a customer/order. The price<br />

list identification includes:<br />

• Customer Identification Type<br />

• Customer Identification<br />

• Item Number<br />

• Cost Variant Type<br />

• Currency<br />

Customer Identification Type is used in order to define<br />

which kind <strong>of</strong> customer identification is applied:<br />

O = Object (customer number)<br />

G = Group (customer price/discount group)<br />

I = No customer identification (blank)<br />

Customer identification may be:<br />

Customer Number<br />

Customer Price/Discount Group<br />

Blank<br />

Item Identification: It is a basic condition that the sales<br />

prices can always exist per item number. Additional specification<br />

may even be required if the business is selling feature<br />

items. Therefore the item identification includes:<br />

• Item Number<br />

• Cost Variant Type (1, 2, or 3)<br />

• Variant (5 fields <strong>of</strong> 5 characters each)<br />

In this structure there are three types <strong>of</strong> item identification:<br />

- Pricing irrespective <strong>of</strong> feature<br />

(fields for feature being blank).<br />

- Pricing with comlete feature/option specification<br />

( in the relevant fields for feature/options you must have<br />

the option for the feature determining the price; the remaining<br />

fields must be blank).<br />

- Pricing with addition/deduction per feature<br />

(for each feature determining the price you must specify<br />

feature and option, respectively, in the first two fields;<br />

the remaining fields must be blank).<br />

From Date: The date from which the price list is effective.<br />

This makes it possible to have several versions <strong>of</strong> the<br />

"same" price list at the same time. When setting the price,<br />

either delivery date or order entry date is decisive for the<br />

choice <strong>of</strong> price list. This price setting date is stored and<br />

maintained on the order line.<br />

To Date: The date from which the price list is no longer effective.<br />

A price list is effective until a new one takes effect<br />

or until the price list expires. Expired price lists thus function<br />

as if they do not exist, irrespective <strong>of</strong> their From Date.

Unit Price: Price per sales unit (per sales price specification).<br />

May be corrected by addition or deduction. Likewise,<br />

different kinds <strong>of</strong> discounts may influence the final net price.<br />

Price Correction Possible: Whether the found sales price<br />

may be corrected by addition/deduction.<br />

Sales Price Discount Possible: Whether a sales price discount<br />

may be granted on the found sales price. A sales<br />

price discount is a discount with a quantity limit equalling<br />

zero.<br />

Quantity Discount Possible: Whether a quantity discount<br />

may be granted on the found sales price. A quantity discount<br />

is a discount with a quantity limit not equalling zero.<br />

Total Discount Possible: Whether the order line may be included<br />

when calculating the basis <strong>of</strong> a total discount.<br />

Price Correction in Currency<br />

The information in this file is about additions or deductions,<br />

if any, by which the basic price can be corrected. Addition/<br />

Deduction are common terms describing situations <strong>of</strong> deviation,<br />

which are always relating to and applying to an entire<br />

sales order voucher.<br />

Additions or deductions may be commercially based or<br />

may be the result <strong>of</strong> an achieved customer service, e.g.<br />

addition for prompt delivery.<br />

Price corrections in currency differ from price corrections in<br />

percent by being additions or deductions <strong>of</strong> absolute<br />

amounts as opposed to relative percentages.<br />

Correction Number: Which addition or deduction to calculate<br />

in the particular situation. The order priority on the<br />

sales order header is applied when calculating.<br />

Price List Identification: This is the "pointer" onto the price<br />

list that can be created from a customer/order.<br />

The price list identification includes:<br />

• Customer Identification Type<br />

• Customer Identification<br />

• Item Number<br />

• Cost Variant Type<br />

• Currency<br />

Customer Identification Type is used in order to define<br />

which kind <strong>of</strong> customer identification is applied:<br />

O = Object (customer number)<br />

G = Group (customer price/discount group)<br />

I = No customer identification (blank)<br />

Customer identification may be:<br />

Customer Number<br />

Customer Price/Discount Group<br />

Blank<br />

Item Identification: This includes:<br />

• Item Identification Type<br />

• Item Identification<br />

Item identification type is used in order to define which<br />

kind <strong>of</strong> item identification is applied:<br />

O = Object (item number)<br />

G = Group (discount group for item when selling)<br />

I = No item identification (blank)<br />

Item identification may be:<br />

Item number<br />

Discount group for item when selling<br />

Blank<br />

Quantity Limit: The corrections apply to purchases from<br />

and including this quantity limit (ordered sales units).<br />

When buying a sales unit quantity below the lower quantity<br />

limit, quantity correction is not applied.<br />

Valid From Date: The date from which the price list is effective.<br />

This makes it possible to have several versions <strong>of</strong><br />

the "same" price list at the same time. When setting the<br />

price, either delivery date or order entry date is decisive<br />

for the choice <strong>of</strong> price list. This price setting date is stored<br />

and maintained on the order line.<br />

Expiry Date: The date from which the price list is no longer<br />

effective. A price list is effective until a new one takes effect<br />

or until the price list expires. Expired price lists thus<br />

function as if they do not exist, irrespective <strong>of</strong> their From<br />

Date.<br />

Price Correction: Addition (positive) or deduction (negative)<br />

per sales unit. If the item identification type is item<br />

number, the corrections are per sales price specification;<br />

otherwise they apply to one sales unit. The corrections are<br />

made for the found basic price.<br />

Sales Price Discount Possible: Whether a sales price discount<br />

may be granted on the found sales price. A sales<br />

price discount is a discount with a quantity limit equalling<br />

zero.<br />

13

Quantity Discount Possible: Whether a quantity discount<br />

may be granted on the found sales price. A quantity discount<br />

is a discount with a quantity limit not equalling zero.<br />

Total Discount Possible: Whether the order line may be included<br />

when calculating the basis <strong>of</strong> a total discount.<br />

Price Correction in Percent<br />

The information in this file serves the same purpose as the<br />

information in the file <strong>of</strong> price correction in currency. Here,<br />

however, addition and deduction are expressed by a percentage.<br />

The data structure is the structure described in the section<br />

about price lists, except for:<br />

Currency is not in the record.<br />

Price Correction is replaced by Percentage Correction.<br />

Price Discounts in Currency<br />

The information in this file is about discounts deducted<br />

from (added to) the sales price when determining the net<br />

14<br />

price. Discounts are always specified individually and appear<br />

specified on quotations, order confirmations, and invoices.<br />

Discounts in currency differ from discounts in percent by<br />

being deductions <strong>of</strong> absolute amounts as opposed to relative<br />

percentages.<br />

The data structure is the structure described in the section<br />

about price lists, except for:<br />

Discount Agreement is added in the record.<br />

Correction Number is not in the record.<br />

Price Correction is replaced by Unit Discount.<br />

Sales Price Discount Possible is not in the record.<br />

Quantity Discount Possible is not in the record.<br />

Price Discounts in Percent<br />

The information in this file serves the same purpose as the<br />

information in the file <strong>of</strong> sales price discounts in currency.<br />

Here, however, the discount is expressed by a percentage.<br />

The data structure is the structure described in the section<br />

about price corrections, except for:<br />

Currency is not in the record.<br />

Unit Discount is replaced by Discount Percentage.

Rules and Restrictions<br />

This chapter describes the precedence <strong>of</strong> the price/discount<br />

elements that were introduced in the preceding sections.<br />

Calculation Sequence<br />

Calculations are made individually, i.e. not inter-dependent,<br />

in the following steps:<br />

1. Basic prices - sale<br />

2. Price correction in currency / Price correction in percent<br />

3. Price discounts in currency / Price discounts in percent<br />

In the company file (SALGPRIS) you must specify whether<br />

you apply price correction in currency, price correction in percent,<br />

price discounts in currency, price discounts in percent.<br />

If you apply price correction and/or discounts in both currency<br />

and percent, please also specify the search sequence<br />

for them. It is a rule that the 'first found' will be applied for<br />

the price calculation.<br />

Search Sequence<br />

In each <strong>of</strong> the above-mentioned steps, information from only<br />

one record will be applied. The general search sequence is:<br />

1. Customer number - Item number<br />

2. Customer number - Item discount group<br />

3. Customer number - Blank<br />

4. Customer price/discount group - Item number<br />

5. Customer price/discount group - Item discount group<br />

6. Customer price/discount group - Blank<br />

7. Blank - Item number<br />

8. Blank - Item discount group<br />

9. Blank - Blank<br />

In case <strong>of</strong> item features, a complete feature/option specification<br />

is searched first and then addition/deduction per<br />

feature is searched.<br />

By editing the company parameter SALGPRIS, the search<br />

sequence can be limited compared to the above.<br />

Validity<br />

Within the above-mentioned nine search steps, valid information<br />

will be found in respect to a price setting date. The<br />

valid record is characterized by being the latest 'Valid From<br />

Date' that must not, however, be later than the price setting<br />

date – and the 'To Date' must not be earlier than the<br />

price setting date.<br />

Restrictions in Sales Price Corrections and Discounts<br />

In the individual calculation steps there may be a restriction<br />

to the subsequent calculation <strong>of</strong> addition, deduction, or<br />

discounts. The option No (N) in this connection will always<br />

take precedence over a subsequent Yes (J) in later calculation<br />

steps.<br />

Please also note the following circumstances:<br />

• If the option 'N' was selected for line discounts on the<br />

price agreement, this will apply to all discount groups.<br />

• If a discount has been specified at item number level,<br />

discounts will not be retrieved at an item group level.<br />

• If just one <strong>of</strong> several discount options at an item group<br />

level has the option 'N' for 'Total Discount', this will override<br />

any other discount groups’ total discount specification.<br />

Functions<br />

Work with Price Lists<br />

You can work with basic prices, price corrections, and price<br />

discounts. You can make queries for "complete" price lists<br />

where gross price, gross price after price correction, and<br />

net price will appear once you have entered a customer<br />

number, item number, feature option, quantity, price setting<br />

date, and correction number, if any.<br />

Working with price lists includes a copy facility. You can<br />

copy to another validity date or to another price list identification.<br />

You can adjust prices by using a specified index. Besides,<br />

you can adjust sales prices based on standard cost price,<br />

simulation price, or basic sales price. When based on standard<br />

cost price or basic sales price, you can even choose<br />

between new or current prices. When adjusting prices, you<br />

can apply the item’s pr<strong>of</strong>it percentage, index, or constant<br />

addition. And you can define rules for rounding <strong>of</strong>f.<br />

Print Price Lists<br />

By defining a number <strong>of</strong> parameters, you will have the opportunity<br />

to print price lists with a user-defined layout. In<br />

addition to printing the price list onto paper, you can print<br />

it to a file that you can send to a CD ROM catalogue, to a<br />

printing company, or to other reprocessing business.<br />

Work with Sales Orders<br />

The price lists are used for suggesting a unit price for the<br />

individual item line when creating an order in case there is<br />

no special agreement for the item-customer combination.<br />

The pricing is made according to the following precedence<br />

rules:<br />

• Manually entered price and discount<br />

• Special agreement price and discount<br />

• Price list price, corrections, and discount<br />

• Basic sales price<br />

When processing an order, you are able to correct the customer<br />

price/discount group and the price setting date for<br />

an order line.<br />

The order processing is able to find price list, sales price<br />

correction, and sales price discount based on any corrected<br />

order line information such as price setting date, ordered<br />

quantity etc.<br />

Furthermore, the order processing includes a facility for redetermining<br />

price list price, sales correction, and sales<br />

price discount. The functioning <strong>of</strong> this facility is analogous<br />

to default order line, i.e. price setting date is changed to<br />

entry/delivery date and customer price/discount group is<br />

changed to the group according to the customer master information.<br />

15

In addition, the order processing has a facility for restarting<br />

pricing. The functioning <strong>of</strong> this facility is similar to that<br />

<strong>of</strong> a new order line, i.e. the pricing is carried out according<br />

to the precedence rules mentioned above.<br />

On the individual order line you can work with discount<br />

lines. Basically, the discount lines being documented here,<br />

are the discount lines found in connection with pricing, but<br />

they can be edited.<br />

For each effected discount potential there will be a line<br />

showing rate and discount basis. Discount lines can be edited,<br />

and new discount lines can be created.<br />

IMPORTANT: Calculation <strong>of</strong> net discount basis is made in<br />

line number order.<br />

If at least one line is edited, the price discount code on the<br />

sales order line will be 'R' (manual editing at discount line<br />

level). In this case, discount lines will not be updated automatically<br />

even if the sales order line information is adjusted.<br />

Display Customer Agreements<br />

In 'Next Level' <strong>of</strong> customer master data (application 6128)<br />

you will see a list <strong>of</strong> customer agreement elements.<br />

Display customer agreements<br />

16<br />

The following record types are included in the list:<br />

• Basic price<br />

• Correction in percent<br />

• Correction in currency<br />

• Discounts in percent<br />

• Discounts in currency<br />

• Total discount<br />

• Bonus<br />

Via 'Fixed Selections' you can select for each type which<br />

agreement types to display (O/G/I) or if no records should<br />

be displayed for the type.<br />

Furthermore, you can specify an 'At Date', which will enable<br />

you to distinguish between historical, current, and future<br />

agreements. This parameter is always set at current<br />

date when starting the program.<br />

Financial Reporting<br />

The financial sales reporting comprises the following item<br />

sale transactions:<br />

• Sales at basic sales price<br />

• Sales price correction<br />

• Total discount<br />

• Line discount (trade discounts)<br />

• Sales price difference (difference between basic price<br />

and basic sales price)

Transport Management<br />

The purpose <strong>of</strong> the transport solution in <strong>ASPECT4</strong><br />

<strong>Logistics</strong> is to manage the internal task <strong>of</strong> planning<br />

transportation, executing despatch, and following<br />

up on the progress compared to the planning.<br />

The transport solution in <strong>ASPECT4</strong> <strong>Logistics</strong> is exclusively<br />

aimed at the transportation <strong>of</strong> firm orders<br />

(normal sales and stock movement orders).<br />

It does not include the route management or dossier<br />

accounting that is usually associated with a<br />

transportation task. And it does not include any<br />

new facilities controlling return goods. If you wish<br />

to have these aspects covered by your IT solution,<br />

you must integrate with <strong>ASPECT4</strong> Transportation.<br />

As a result <strong>of</strong> the above facts, this description<br />

covers the following functions:<br />

• How do transport requirements occur?<br />

• Automatic creation<br />

• Manual creation<br />

• Planning a transportation<br />

• Rebooking<br />

• Booking list (Communication with carrier)<br />

• Taking trip numbers<br />

• Completing a transportation<br />

• Feedback <strong>of</strong> what to transport<br />

• Creation <strong>of</strong> freight dockets and package labels<br />

• Print <strong>of</strong> freight dockets<br />

• Print <strong>of</strong> package labels<br />

• Creation <strong>of</strong> transport purchase orders<br />

• Reversal <strong>of</strong> freight purchase<br />

• Following up on transport<br />

• Freight statistics<br />

• Freight variances<br />

The flow chart illustrates a typical transport process<br />

<strong>of</strong> a business.<br />

There may be deviations from this flow chart<br />

without the basic functionality being changed. For<br />

example, the elements "Preparation <strong>of</strong> documents"<br />

and "Loading" may be parallel processes.<br />

Picking <strong>of</strong> items does not appear in the flow<br />

chart, but the picking process is expected to be<br />

parallel to the first processes up till "Preparation<br />

<strong>of</strong> documents".<br />

Despatch<br />

journals<br />

Dialogue with<br />

customer<br />

Transport planning<br />

Monitoring<br />

transport<br />

requirements<br />

Redistribution<br />

needs<br />

yes<br />

Move<br />

requirements to<br />

other route/date<br />

Booking <strong>of</strong><br />

carrier<br />

Recording <strong>of</strong><br />

special costs <strong>of</strong><br />

transport<br />

Need to<br />

rebook?<br />

nej<br />

Preparation <strong>of</strong><br />

documents<br />

Loading<br />

Report transport<br />

complete<br />

Invoice<br />

registration<br />

Match on<br />

amount?<br />

no<br />

Approval <strong>of</strong><br />

invoice<br />

End<br />

yes<br />

no<br />

Booking list<br />

Delivery note<br />

Package labels<br />

EDI freight docket<br />

+ documents for<br />

carrier<br />

Freight docket<br />

overview<br />

Transport<br />

purchase<br />

order<br />

17

How do Transport Requirements Occur?<br />

In principle, transport requirements may occur in many<br />

ways. Basically, there is a requirement when one or more<br />

items <strong>of</strong> goods must be moved from our warehouse to a<br />

consignee. The next question is: When do we know the<br />

precise requirement, i.e. the quantity to be transported to<br />

the customer and the time when is must be transported.<br />

The answers may be many and they undoubtedly vary between<br />

companies.<br />

Fully aware that a precise transport requirement may occur<br />

at many different times in different companies, we also<br />

know that a number <strong>of</strong> <strong>ASPECT4</strong> users will demand C-solutions<br />

within this area.<br />

Automatic Creation<br />

In <strong>ASPECT4</strong> <strong>Logistics</strong> we have chosen to establish that a<br />

transport requirement may occur when a despatch journal<br />

is created. The despatch journal is the job that controls the<br />

picking <strong>of</strong> items from stock. If you only select stocks for<br />

picking that are allocated, you can be quite sure that the<br />

planned transport requirement will have to be fulfilled. It is<br />

a condition that picking is made against order or against<br />

customer (same customer number and delivery address).<br />

The automatic transport requirement will arise when you<br />

place the trigger program ZTRGTRAL on the file RUTHREG.<br />

The trigger program will control that a transport requirement<br />

is created corresponding to the despatch journal (the<br />

picking job). The transport requirement is created on the<br />

date <strong>of</strong> the despatch, and therefore we recommend that<br />

you are very precise when you select the method for fixing<br />

the date in the despatch journal. Furthermore, the transport<br />

requirement is separated from the order by route<br />

number, warehouse, and delivery method.<br />

Many other variants <strong>of</strong> the occurrence <strong>of</strong> a transport<br />

requirement can be imagined. Some variants can be subject<br />

to a development cooperation, others will require Csolutions<br />

to be developed.<br />

Naturally, transport requirements will also start from sales<br />

orders. Some new fields have been added to the sales orders<br />

in order to support the transport management. The<br />

new fields are:<br />

• Transport requirements (e.g. crane, size <strong>of</strong> truck etc.)<br />

• Time <strong>of</strong> delivery<br />

• Trip number<br />

Add to this that the despatch planning is already based on<br />

the delivery models appearing from the route calendars in<br />

application 'Work with Route Calendars' (9174). The arrival<br />

time at the customer’s is calculated on the basis <strong>of</strong> partly<br />

the number <strong>of</strong> days en route to the customer and partly<br />

the route calendar <strong>of</strong> the delivery method. Selection <strong>of</strong> carrier<br />

is controlled solely by the transport planning, i.e. a selection<br />

<strong>of</strong> carrier, if any, on the fixed order is not considered.<br />

18<br />

An automatically created transport requirement may include<br />

the following information:<br />

• Customer number and delivery address<br />

• Despatch journal number<br />

• Number <strong>of</strong> pallets, packages, volume, gross weight and<br />

net weight<br />

• Transport requirements, customer requirements, and<br />

time (hour) <strong>of</strong> delivery<br />

• Length, width, and height (the greater ones from the<br />

items)<br />

• Status code (following the status code from the despatch<br />

journal)<br />

During the lifetime <strong>of</strong> a transport requirement, information<br />

such as the below will be added:<br />

• Number <strong>of</strong> despatch units picked<br />

• Freight provision<br />

• Booking list to carrier printed<br />

The transport requirements are grouped in transport<br />

headers that are created automatically when a new transport<br />

requirement is created. The key to a collection <strong>of</strong><br />

transport requirements (a transport header) is: date,<br />

route, warehouse, and delivery method.<br />

The header contains information such as:<br />

• Number <strong>of</strong> orders, order lines<br />

• Summed-up despatch units<br />

• Warehouse area (exit place) (defaulted by system parameter<br />

Route)<br />

• Departure time (hour) (defaulted by system parameter<br />

Route)<br />

• Carrier/Responsible (defaulted by system parameter<br />

Route)<br />

• Summed-up number <strong>of</strong> pallets, packages, volume, gross<br />

weight and net weight<br />

• Status<br />

00 = Created<br />

30 = Picking started<br />

60 = Picking completed<br />

80 = Delivery notes, freight dockets, and package labels<br />

printed<br />

Manual creation<br />

From time to time, companies working with transport planning<br />

will typically experience a need to create a transport<br />

requirement manually. Most <strong>of</strong>ten the case will be about<br />

items that are not to be picked from stock. In order to be<br />

able to create manually, you simply open a number <strong>of</strong><br />

fields that are normally not enabled. This will allow you to<br />

enter the precise transport information.

Planning a Transportation<br />

The planning task partly consists <strong>of</strong> optimising transports,<br />

partly <strong>of</strong> communicating with the carriers, and partly <strong>of</strong><br />

taking trip numbers (will not be applied in all companies).<br />

Rebooking<br />

As we have described, the creation <strong>of</strong> despatch journals<br />

will trigger the creation <strong>of</strong> a transport requirement. If you<br />

have additional requirements for your transport, e.g. an attempt<br />

to drive full loads only, you will <strong>of</strong>ten have to rebook<br />

your transport requirements.<br />

Or you may wish to have only one car per transport. In<br />

this case you will have to move some <strong>of</strong> the transport requirements<br />

to other date/route combinations. It is not a<br />

must that the routes must exist as master data. This allows<br />

you to for example move a number <strong>of</strong> transport requirements<br />

to a quite new and unknown route that will only occur<br />

this one time due to a special transport requirement.<br />

This method will also be the one to apply if you have several<br />

transports to the same area that you need to divide<br />

onto several cars.<br />

It is a general rule that if you have moved a transport requirement<br />

to for example another route, an additional<br />

matching transport requirement (same order) will be<br />

planned for the same route.<br />

In the application 'Work with Transport Planning' (6191)<br />

the rebooking function is named 'Move line'.<br />

Booking List<br />

The communication with the carriers is processed via a<br />

booking list. The booking list is the document that covers<br />

the carrier’s need for information, i.e. the details required<br />

to get a suitable number <strong>of</strong> vehicles to solve the transport<br />

task. The booking list can be printed via application 'Print<br />

Booking List' (6293). Please note that the booking list cannot<br />

be printed to paper unless you apply DocManager.<br />

The booking list contains information about which transports<br />

have been booked on a trip. For each transport requirement<br />

you will see the delivery address and the expected<br />

gross weight and the expected volume. These data<br />

have been computed on the basis <strong>of</strong> the freight information<br />

on the item’s sales information. Besides, the delivery time<br />

(hour), special transport requirements, and customer requirements<br />

appear.<br />

Trip Numbers<br />

Many companies wish to gather the trips on trip numbers.<br />

You can take a common trip number for the transport requirements<br />

gathered on a trip (combination <strong>of</strong> date/route/<br />

warehouse/delivery method). The trip number is also updated<br />

on the associated invoice order where it can be<br />

used, among other things, for a combined print <strong>of</strong> the delivery<br />

notes belonging to the trip. The trip number may<br />

also be applied in connection with a follow-up on the actual<br />

freight costs. A trip number is assigned by the voucher<br />

number series TU.<br />

Taking a trip number is not a must for applying the transport<br />

planning in <strong>ASPECT4</strong> <strong>Logistics</strong>. Only if you want to<br />

have a combined print <strong>of</strong> delivery notes for the trip, you<br />

have to take a trip number.<br />

19

The booking list shows which transports have been booked for a trip.<br />

Completing a Transportation<br />

To complete a transportation, you record what has been<br />

packed for the transport and you communicate to the interested<br />

parties by submitting freight dockets, package labels,<br />

freight docket summary, and delivery notes. Besides,<br />

you must create the transport purchase order.<br />

Feed-back on What to Transport<br />

A transport requirement is directly connected with the picking<br />

task – one transport requirement per despatch journal.<br />

Therefore, it is natural to record the number <strong>of</strong> despatch<br />

units per transport requirement. The purpose <strong>of</strong> this type<br />

<strong>of</strong> registration is to have the correct number <strong>of</strong> despatch<br />

units (pallets, packages, batch etc.) for the freight docket<br />

and for generating packages and package labels.<br />

To control the different despatch units, we have created a<br />

new system parameter called 'Package types number<br />

fields' (FRTPANT). The system parameter allows you to create<br />

up to 10 different despatch units. Typical despatch<br />

units are: pallet, package, batch or the like. When you<br />

have completed picking for a despatch journal, the completion<br />

<strong>of</strong> the journal will provide a field where you can enter<br />

the number <strong>of</strong> despatch units, cf. those created under the<br />

system parameter 'Package types number fields' (FRTPANT).<br />

The alternative to recording the number <strong>of</strong> packages in<br />

connection with completing a despatch journal is to record<br />

20<br />

the number <strong>of</strong> packed despatch units directly in the transport<br />

planning, application 'Work with Transport Planning'<br />

(6191). On the system parameter 'Package types number<br />

fields' (FRTPANT) you can also specify an item number to<br />

be invoiced when the despatch unit is recorded (e.g. invoicing<br />

<strong>of</strong> EUR pallets when recording number <strong>of</strong> EUR pallets).<br />

The above-mentioned recording <strong>of</strong> the number <strong>of</strong> despatch<br />

units must not be confused with the "pick and pack" function<br />

in <strong>ASPECT4</strong> <strong>Logistics</strong>. The above-mentioned sort <strong>of</strong><br />

registration is general and does not control which items/<br />

contents are in the individual packages. The registration<br />

task in connection with this type <strong>of</strong> general feedback requires<br />

far less resources than does the corresponding registration<br />

<strong>of</strong> which contents are in the individual packages.<br />

Creation <strong>of</strong> Freight Dockets and Package Labels<br />

In connection with despatching the picked items, freight<br />

dockets and package labels must usually be generated.<br />

The principle <strong>of</strong> generating freight dockets requires one<br />

freight docket per delivery address per customer. This ensures<br />

that several orders for the same customer on the<br />

same delivery address will be collected in one freight<br />

docket. Hereby, the actual freight costs are kept at a minimum.<br />

Via the reference structure you can trace the freight<br />

docket by the order or vice versa.<br />

Freight dockets are assigned a number from the system<br />

parameter 'Freight docket numbers – building' (FRAGTMSK).<br />

This parameter controls partly the length <strong>of</strong> the freight<br />

docket number, partly the number assignment for the variable<br />

part <strong>of</strong> the freight docket number. The building <strong>of</strong><br />

freight docket numbers may vary between carriers.<br />

When freight dockets are generated, packages are generated,<br />

as well. Basically, one package number is generated<br />

per despatch unit reported back on the transport jobs collected<br />

on the freight docket. If the carrier is able to trace<br />

the individual packages, one package will be generated per

despatch unit reported back (example: 7 pallets on the<br />

freight docket will result in 7 package numbers and thereby<br />

7 unique package labels). The supplier field KULEARB4B<br />

will control this process.<br />

The freight docket contains information that can be added<br />

manually if required, e.g. transport instruction, COD<br />

amount, insurance amount and insurance category, policy<br />

number, payer, transport code, delivery instruction. Manual<br />

entry must be performed via application 'Work with Freight<br />

Dockets' (6192).<br />

Technical information about the freight docket:<br />

• Freight docket number is taken according to the information<br />

stored in system parameter 'Freight docket numbers<br />

– building' (FRAGTMSK).<br />

• Consignor address for the freight docket is defaulted<br />

from the warehouse <strong>of</strong> the transport. The address <strong>of</strong> the<br />

warehouse address number is applied. If it does not exist,<br />

the address is taken from section 0010 in the Gen-<br />

eral Files.<br />

• Carrier is defaulted from the transport header.<br />

• The below data are suggested from the system parameter<br />

'Freight docket information default' (FRBRV):<br />

• Consignor’s GAN number<br />

• Transport instruction<br />

• Freight payer code<br />

• Transport code<br />

• Delivery instruction<br />

• Package type<br />

• Quantity and package type are suggested from the<br />

transport lines.<br />