Product information LED Spot - Dr. Hönle AG

Product information LED Spot - Dr. Hönle AG

Product information LED Spot - Dr. Hönle AG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

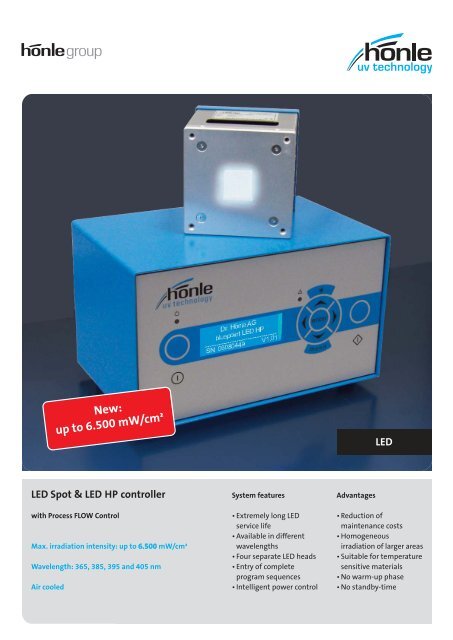

New:up to 6.500 mW/cm²<strong>LED</strong><strong>LED</strong> <strong>Spot</strong> & <strong>LED</strong> HP controllerwith Process FLOW ControlMax. irradiation intensity: up to 6.500 mW/cm²Wavelength: 365, 385, 395 and 405 nmAir cooledSystem features• Extremely long <strong>LED</strong>service life• Available in differentwavelengths• Four separate <strong>LED</strong> heads• Entry of completeprogram sequences• Intelligent power controlAdvantages• Reduction ofmaintenance costs• Homogeneousirradiation of larger areas• Suitable for temperaturesensitive materials• No warm-up phase• No standby-time

<strong>LED</strong> <strong>Spot</strong> & <strong>LED</strong> HP controller with Process FLOW ControlThe <strong>LED</strong> <strong>Spot</strong> has been developed for all applications requiringa most intensive UV irradiation on a larger area. Thanksto its high intensity and the possibility to program completeprocess sequences, e.g. exposure series with different intensitiesand holding times, shortest cycle and machinethroughput times can be realized, especially in fully automatedproduction lines.The typical service life of a <strong>LED</strong> is longer than 20.000 hours*.The <strong>LED</strong>s can be switched on and off as often as necessary.They do not require a warm-up or cooling phase.The emitted wavelengths are available in 365/385/395/405 nm +/- 10 nm. It is thus possible to adapt the <strong>LED</strong> headto any application in question.The square light emitting aperture has a size of20 mm x 20 mm. Depending on the selected intensity/homogeneity it can be increased considerably by changingthe distance to the substrate. The resulting irradiation fieldcan then be divided into four segments, which can be activatedindependently from each other.The integrated fan provides adequate cooling even for continuousoperation.ApplicationsThe <strong>LED</strong> <strong>Spot</strong> controlled by the <strong>LED</strong> HP controller is appropriatefor various applications, such as• Bonding, fixing or encapsulating of components in theelectronic, optical or medical sector• Fluorescence stimulation for materials testing andpicture processing• High-intensive UV irradiation in the chemical, biologicaland pharmaceutical sector<strong>LED</strong> <strong>Spot</strong> activationThe irradiation time can be adjusted for each <strong>LED</strong> segmentseparately in range between 0.1 and 999.9 seconds or cancharged to continious operations.The operating states and the actual temperatures of the <strong>LED</strong>segments as well as the irradiation times can be seen on thedisplay at one glance. The electric <strong>LED</strong> power can also beadjusted between 10 % and 100 % in 1 %-steps.The unit registers the <strong>LED</strong> operating hours as well as theunit s operating hours.Due to the application the <strong>LED</strong> HP contoller offers differentmodes of power control. In the standard power-mode avalue between 10% and 100% is forced, according to whichthe <strong>LED</strong> capacity gets adjusted. The ConstPower modeallows an almost constant optical output. In this mode theintensity of irradiation is kept constant over a broad temperaturerange. For a short time irradiation with longer pausesbetween separate irradiation cycles the optical output canbe maximised in the PeakPower mode.

InterfacesThe <strong>LED</strong> HP contoller has the following interfaces:• PLC inputs: 4x <strong>LED</strong> on (can be assigned to 1 ore more<strong>LED</strong>-Segments), start "Process FLOW Control" (PFC),polling input for PFC• PLC outputs: 4x status <strong>LED</strong> segment (<strong>LED</strong> on, <strong>LED</strong> off, <strong>LED</strong>error, <strong>LED</strong> warning), 1x status unit (unit on, unit error, PFCis running, …)• <strong>Dr</strong>y contact with selectable function (cf. PLC outputs)• RS 232 interface for programming the operating parameters,for operating the unit with PLC or PC, for transferringprogram sequences or for downloading the update of theoperating software• Foot switch• Release safety circuit• Safety code in order to protect the unit againstunauthorised useFurther FeaturesAll parameter settings can be filed in six memory locationsand reloaded when needed. The language for the menutexts can be selected between German, English, French orItalian.Process FLOW ControlWith the <strong>LED</strong> HP contoller, complete process sequences canbe programmed. They can be entered through the controlsystem or by transferring a text file compiled on PC.The following sequences can be programmed:• Exposure series with different intensities• Activation of external handling components• Holding times• Conditional commanding depending on extern controlsignalsAdvantages of the <strong>LED</strong> technology<strong>LED</strong>s do not emit IR radiation. Due to the inferior temperatureload of the substrate, even temperature-sensitivematerials can be irradiated. The different spectra availableguarantee a safe and fast curing. As <strong>LED</strong>s do not require awarm-up phase, <strong>LED</strong> heads can be switched on and offwithout any problems: they are immediately ready foroperation.Moreover, the following features characterise the <strong>LED</strong> HPcontroller:• Large and clear display with all relevant <strong>information</strong>• Intelligent power control (for each <strong>LED</strong> head separately)• Temperature compensation of the <strong>LED</strong>• Entry of complete program sequences

Technical data<strong>LED</strong> service lifeadjustment range of timerwavelengths in nmtypical intensity in mW/cm² **> 20.000 hours*0,1 – 999,9 sec.or continuous operation365 385 395 405550 4.000 6.500 6.500power supply 90 V – 264 V,47 Hz – 63 Hzmax. input current2,4 Apower input200 Wdimensions <strong>LED</strong>-head without ca. 100 x 93 x 93 mmconnectors (H x B x T)* typical time for usage under standard environment conditions** measured with Hönle <strong>LED</strong> sensors for UV meterMore Hönle <strong>LED</strong>-Unitswater cooled types - wavelength available 365/385/395/405 nm<strong>LED</strong> <strong>Spot</strong><strong>LED</strong> Powerline<strong>LED</strong> point source - wavelength available 365/385/400 nm<strong>LED</strong> headCuring <strong>Dr</strong>yingBonding Potting Measuringaladin eleco-efd eltosch grafix hönle mitronic panacol raesch uv-technik speziallampenprintconcept<strong>Dr</strong>. Hönle <strong>AG</strong> UV Technology, Lochhamer Schlag 1, 82166 Gräfelfing/München, GermanyPhone: +49 89 85608-0, Fax: +49 89 85608-148. www.hoenle.deOperating parameters depend on production characteristics and may differ from the foregoing <strong>information</strong>.We reserve the right to modify technical data. © Copyright <strong>Dr</strong>. Hönle <strong>AG</strong>. Updated 03/14.