Aerospace Tooling and Equipment

Aerospace Tooling and Equipment

Aerospace Tooling and Equipment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Aerospace</strong> <strong>Tooling</strong><strong>and</strong> <strong>Equipment</strong>

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Pages1 Crimping <strong>Equipment</strong> 21.1 <strong>Tooling</strong> available by Product Family 21.2 Premium CERTI-CRIMP <strong>and</strong>CERTI-CRIMP II Tools 5 H<strong>and</strong> Tools 6 Power Assist Options 101.3 SDE Premium Crimp <strong>Tooling</strong> 13 SDE H<strong>and</strong> Tools 14 Power Assist Options 171.4 Tools for MIL Indent Crimping 181.5 Power Assist <strong>Equipment</strong> 20 Battery Tool 1.5 t 20 Battery Tool 4 t 21 SDE Electric Terminator withCERTI-CRIMP Adapters 22 626 <strong>and</strong> Micro PneumaticTool System 231.6 Hydraulic <strong>Equipment</strong> 281.7 Insertion / Extraction Tools 381.8 H<strong>and</strong> Tool Control Gauges 391.9 Service <strong>and</strong> Calibration 402 Wire Processing <strong>Equipment</strong> 412.1 Stripping Machines 412.2 Cutting <strong>and</strong> Stripping Machines 422.3 4/8 Indent Stripper Crimperwith Touch Sensor 432.4 AM03 Universal Stripper Crimper 442.5 Micrograph Cross-SectionLaboratories 45 Micrograph Laboratory 45 Portable Micrograph Laboratory 463 Test <strong>Equipment</strong> 473.1 High Voltage Test <strong>Equipment</strong> 473.2 Cable Test Systems 514 Appendix - Useful Information 524.1 Wire Range Limits 524.2 Computing CMA 534.3 Wire Range <strong>and</strong> Colour Codes 544.4 Terminal Styles 57For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe1

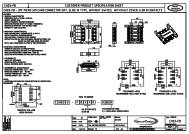

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1 Crimping <strong>Equipment</strong>1.1 <strong>Tooling</strong> available by Product FamilyInsulated TerminalsH<strong>and</strong> ToolsPower ToolsConnector/TerminalStyleWire Range(AWG)PremiumCERTI-CRIMP<strong>and</strong>CERTI-CRIMP IISDEPremium DiesBatteryTool 1.5 tBatteryTool 4 tHydraulic<strong>Equipment</strong>626PneumaticToolElectricTerminatorSection 1.2 Section 1.3 Section 1.5 Section 1.5 Section 1.6 Section 1.5Sections1.3, 1.5PIDGPLASTI-GRIPPIDGSTRATO-THERMwith TEFLON orPEEK InsulationTERMINYLAMPLI-BONDTerminals <strong>and</strong>SplicesTerminals <strong>and</strong>Splices (Radiationresistant)Terminals <strong>and</strong>Splices (Insulationrestricting nylon)Spare Wire capsSplicesTerminalsTerminals <strong>and</strong>SplicesTerminalsTerminals <strong>and</strong>Splices26 to 24 X X X22 to 18 X X X X X16 X X X X14 X X X X X12 to 10 X X X X X24 to 14 X X12 to 10 X X26 to 14 X X12 to 10 X X22 to 14 X X12 to 10 X X26 to 24 X X22 to 14 X X X12 to 10 X X8 X X26 to 24 X X X22 to 14 X X X X X12 to 10 X X X X X8 X X X6 X4 to 4/024 to 16 X X X X14 X X X X12 to 10 X X X X8 X6 X4 to 4/08 X X6 to 4/0TEFLON is a trademark of E.I. DuPont deNemours <strong>and</strong> Co.2For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Un-Insulated TerminalsH<strong>and</strong> ToolsPower ToolsConnector/TerminalStyleWire Range(AWG)PremiumCERTI-CRIMP SDE<strong>and</strong> Premium DiesCERTI-CRIMP IIBatteryTool 1.5 tBatteryTool 4 tHydraulic<strong>Equipment</strong>626PneumaticToolElectricTerminatorSOLISTRANDCOPALUMSTRATO-THERMTerminals & SplicesTerminals(with <strong>and</strong> withoutinsulation support)Section 1.2 Section 1.3 Section 1.5 Section 1.5 Section 1.6 Section 1.526 to 24 X X22 to 18 X X X12 to 10 X X X8 to 6 X X X4 to 2 X0 to 600 MCM X16 to 10 X8 X X6 to 500 MCM X22 to 14 X X X12 to 10 X X X8 to 2/0 XTERMI-FOIL 8 XAMPOWER 1/0 to 1500 MCM XSections1.3, 1.5ContactsH<strong>and</strong> ToolsPower ToolsConnector/TerminalStyleWire Range(AWG)PremiumCERTI-CRIMP<strong>and</strong>CERTI-CRIMP IISDEPremiumDiesMIL Indent<strong>Tooling</strong>BatteryTool 1.5 tBatteryTool 4 tHydraulic<strong>Equipment</strong>626PneumaticToolElectricTerminatorSection 1.2 Section 1.3 Section 1.4 Section 1.5.1 Section 1.5 Section 1.6 Section 1.5Sections1.3, 1.5Screw-machinedContactsXAMPLIMITE Size 22 DF 28 to 22 X XD-SUBSize 20 DF 28 to 20 X X X XAMPMODU IV 26 to 20 X X X XLocking Clip 26 to 22 X X X XAMPMODU Mini T<strong>and</strong>em Spring 32 to 28 X X X XMTE Pin 32 to 22 X X X XShort Point 32 to 20 X X X XCommercial 30 to 14 X X X XUniversal 24 to 14 X X X XMATE-N-LOK Universal II 24 to 14 X X X XMini Universal 20 to 16 X X X XMini Universal II 26 to 16 X X X XMR Connector Contacts 26 to 18 X X X XCPC Type II X X X XType III+ 30 to 14 X X X XFor more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe3

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Coaxial ConnectorsH<strong>and</strong> ToolsPower ToolsConnector/TerminalStyleWire Range(AWG)PremiumCERTI-CRIMP<strong>and</strong>CERTI-CRIMP IISDEPremium DiesBatteryTool 1.5 tBatteryTool 4 tHydraulic<strong>Equipment</strong>626PneumaticToolElectricTerminatorSection 1.2 Section 1.3 Section 1.5 Section 1.5 Section 1.6 Section 1.5Sections1.3, 1.550 Ohm BNC 26 to 24 X X X X50 Ohm SMB 22 to 18 X X X XRaychem SplicesH<strong>and</strong> ToolsPower ToolsConnector/TerminalStyleWire Range(AWG)PremiumCERTI-CRIMP<strong>and</strong>CERTI-CRIMP IISDEPremium DiesBatteryTool 1.5 tBatteryTool 4 tHydraulic<strong>Equipment</strong>626PneumaticToolElectricTerminatorSection 1.2 Section 1.3 Section 1.5 Section 1.5 Section 1.6 Section 1.5Sections1.3, 1.5MiniSeal 26 to 12 X XDuraSeal 26 to 12 X X4For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.2 Premium CERTI-CRIMP <strong>and</strong> CERTI-CRIMP II H<strong>and</strong> ToolsDesigned to exactingspecificationsRatchet control providescomplete crimping cycleFor most military, UL <strong>and</strong> CSAapplicationsManufactured using the highestquality materialsRequires minimum skillRepairableCalibrated; recalibrationrecommended every 6 monthsor 5,000 cyclesProduced under a QualityManagement System certifiedto ISO 9001CERTI-CRIMP H<strong>and</strong> Tools aretop-of-the-line, premium, h<strong>and</strong>operatedtools for crimping abroad array of terminals, contacts<strong>and</strong> special wiring devices availablefrom Tyco Electronics. They aredesigned to exacting specificationsto produce consistent, high-qualityterminations. A potential servicelife of over 50,000 cycles is possible,depending on operator care.Other features include insulationcrimp adjustment for differentinsulation thicknesses, a locatorfor properly positioning <strong>and</strong> supportingthe terminal or contact inthe tool, a wire stop, <strong>and</strong> colorcoding <strong>and</strong>/or wire size informationon the head of the tool or on theh<strong>and</strong>les.All CERTI-CRIMP H<strong>and</strong> Tools featurethe reliable ratchet control.The ratchet will not release untilthe h<strong>and</strong>les are fully closed <strong>and</strong>the dies bottomed. This helpseliminate partial crimps.CERTI-CRIMP H<strong>and</strong> Tools are wellsuited for low production runs,prototype work, <strong>and</strong> repairs almostany application requiring consistent,highly-reliable terminations.CERTI-CRIMP H<strong>and</strong> Tools aredesigned to meet all featurerequirements listed on applicableTyco Electronics ApplicationSpecifications.(Check appropriate product catalogsfor qualification to militaryspecifications, UL recognition <strong>and</strong>CSA certification.)Calibration:Recommended every 6 month or 5000 crimp cycles.See section 1.9 of this catalogue for your nearest calibration centre.Produced under a Quality Management System.Certified to ISO 9001.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe5

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>H<strong>and</strong> ToolsCERTI-CRIMP IIStraight Action H<strong>and</strong> Tools(SAHT) Dies close in a straight line Contact locator <strong>and</strong> support Wire stop Insulation crimp adjustment(4 positions) Ejects crimped contact Approx. weight 0.59 kg[1.3 lb]Heads are compatible with:BatteryKitsMicroPneumaticPneumatic6-26ElectricTerminatorDouble Action HT Yes Yes Yes NoHeavy Head HT Yes No Yes NoCERTI-CRIMP IIStraight Action HTCERTI-CRIMP IIStraight Action HTLarge DieYes Yes Yes YesYes No Yes YesDouble ActionH<strong>and</strong> Tool (DAHT) Dies travel in arc-like path Locator on tools forFASTON, MATE-N-LOK,PIDG <strong>and</strong> PLASTI-GRIPterminals Insulation adjustment ontools for FASTON,MATE-N-LOK, PIDG <strong>and</strong>PLASTI-GRIP terminals Approx. weight 0.54 kg[1.2 lb]Battery Tool forCERTI-CRIMP II,Straight Action (SAHT) <strong>and</strong>Double Action (DAHT) Light weight <strong>and</strong> fullymobile power assist option Compatible with allst<strong>and</strong>ard die setsHeavy Head H<strong>and</strong> Tool(HHHT) Designed to terminatemost large coaxial cable<strong>and</strong> heavy-gage wire Dies close in a straight line Locator <strong>and</strong> wire stopwhen applicable Insulation adjustment ontools for AMPLI-BOND,PIDG <strong>and</strong> PLASTI-GRIPterminals Approx. weight 0.95 kg[2.1 lb]626 <strong>and</strong> Micro PneumaticTool for CERTI-CRIMP II,Straight Action (SAHT) <strong>and</strong>Double Action (DAHT) Effortless crimping for abroad range of terminals Either bench-mounted orh<strong>and</strong>held for working incramped quarters6For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Premium CERTI-CRIMP <strong>and</strong> CERTI-CRIMP IITerminal to Tool ReferenceInsulated Terminals Sleeve Wire Range Insulation RangeTerminal Type Style Colour / Stripe mm² AWG Diameter [mm]H<strong>and</strong> ToolType <strong>and</strong> P/NDAHTHHHTYellow 0.1-0.4 26-22 2.08 max 46121White 0.16-0.65 24-20 2.54 max 47907-1Red 0.26-0.96 22-18 3.18 max 47386Terminals <strong>and</strong> SplicesGreen 0.5-1.42 20-16 HD 3.81 maxBlue 1.04-2.62 16-14 4.32 max47387Yellow / Black 1.04-2.62 16-14 HDYellow 2.62-6.64 12-106.35 max 59239-4PIDGTerminals <strong>and</strong> Splices(Radiation Resistant)Translucent / White 0.16-0.65 24-20 2.54 max 47907-1Translucent / Red 0.26-0.96 22-18 3.18 max 47386Translucent / Blue 1.04-2.62 16-14 4.32 max 47387Translucent / Black 1.04-2.62 16-14 HD6.35 max 59239-4Translucent / Yellow 3.0-5.0 12-10Yellow / Black 0.15 26 0.66-1.446121Yellow / Blue 0.24 24 0.79-1.4Red / Green 0.38 22 0.97-1.4Terminals <strong>and</strong> Splices(InsulationRestricting Nylon)Red / Red 0.6 20 1.17-2.79Red / White 0.96 18 1.42-2.79Blue / Blue 1.42 16 1.6-3.3Blue / Green 2.15 14 1.98-3.3Yellow / Yellow 3.37 12 2.41-5.08Yellow / Brown 6.11 10 3.02-5.08473864738759239-4Spare Wire Caps(Nylon)Red 0.3-0.85 22-18 3.15 max 47386Blue 1.4-2.0 16-14 3.78 max 47387Yellow 3.0-6.0 12-10 5.33 max 59239-4Terminals & Butt Splice Yellow 0.1-0.41 26-22 2.03 max 46121Butt Splice45160Red 0.26-1.65 22-16 4.32 maxParallel Splice 45449PLASTI-GRIPButt Splice45575-1Blue 1.04-2.62 16-14 5.46 maxParallel Splice 45450Butt Splice12-1059489Yellow 2.62-6.647.62 maxParallel Splice 16-14 HD 59270For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe7

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Premium CERTI-CRIMP <strong>and</strong> CERTI-CRIMP IITerminal to Tool ReferenceInsulated Terminals Sleeve Wire Range Insulation RangeH<strong>and</strong> ToolType <strong>and</strong> P/NDAHTTerminal Type Style Colour / Stripe mm² AWG Diameter [mm]HHHTCERTI-CRIMP IIPLASTI-GRIPTerminalsRed 0.26-1.65 22-16 5.08 max 47386Blue 1.04-2.62 16-14 6.35 max 47387Yellow 2.62-6.64 12-10 7.62 max 59239-4Red9.14 maxButt Splice Red 6.64-10.5 86.35 max69959AMPLI-BOND Red 9.58 maxBrown 0.25-0.4 24-22 0.89-1.9 576778Grey 0.6 20 1.14-2.03 576779PIDGSTRATO-THERMwith PTFE orPEEK InsulationTerminals(thin-wall insulation)Brown 0.25-0.4 24-22 0.89-1.91901611-1Grey 0.6 20 1.14-2.031.0 18576780Orange1.2 16 1.4-2.675767811.0-1.2 18-16 1901600-1Beige2.0 145767822.3-3.183.0 12 576783Black 5.0 10 2.6-5.44 576784Uninsulated Terminals - no insulation supportWire RangeH<strong>and</strong> ToolType <strong>and</strong> P/NTerminal Type Terminal Style mm 2 AWG0.1-0.41 26-220.2-0.6 24-20DAHTHHHT693630.26-1.65 22-16SOLISTRANDTerminals <strong>and</strong> Splices(except Flat Tongue Terminals)1.04-2.62 16-14499352.62-6.64 12-101.65-4.17 14-12 495926.64-10.50 8 69355For Battery Tool Kit with Adapter for CERTI-CRIMP II options see Section 1.58For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Premium CERTI-CRIMP <strong>and</strong> CERTI-CRIMP IITerminal to Tool ReferenceTerminals Wire Range Insulation RangeH<strong>and</strong> ToolType <strong>and</strong> P/NTerminal Type Terminal Style mm² AWG Diameter [mm] CERTI-CRIMP IIAMPLIMITE D-SubAMPMODUSize 20 DFSize 22 DF0.08-0.24 28-24 0.76-1.000.2-0.6 24-20 1.27-1.520.09-0.15 28-260.2-0.39 24-2291503-10.76-1.27 91520-1MODU IV0.12-0.24 26-241.02-1.52 91517-11.32-0.38 220.12-0.51 26-20 1.22 max91516-10.2-0.6 24-20 1.75 maxLocking Clip 0.12-0.38 26-22 0.97-1.57 91533-1Mini TANDEM SPRINGRecptacleMTE Pin0.03-0.09 32-28 1.52-0.64 1901786-1SHORT POINT Recept.MTE Pin0.12-0.38 26-22 0.91-1.42 91531-1MATE-N-LOKMR ConnectorCPC M SeriesSHORT POINTReceptacleCommercialUniversalUniversal IIMini-UniversalMini-Universal IIMR Contacts0.03-0.09 32-280.64-1.52 91518-10.12-0.38 26-220.2-0.6 24-20 0.64-1.52 91551-10.05-0.38 30-22 0.89-1.491515-10.05-0.6 30-20 1.02-1.910.2-0.6 24-201.52-2.54 91512-10.81-0.96 180.5-2.1 20-14 2.54-3.3 91504-10.2-0.38 24-220.51-0.96 20-182.54 max 91510-10.51-0.96 20-181.2-2-1 16-143.30 max 91500-10.51-0.96 20-1891508-15.08 max1.2-2.1 16-14 91506-10.5-0.96 20-18 2.0-3.01.42 16 2.49-3.20.12-0.24 26-24 1.19-1.600.32-0.38 22 1.5-1.750.32-0.6 22-20 1.5-2.010.81-0.96 18 2.11-2.390.5-0.89 20-18 2.0-3.21.42 16 2.49-3.20.12-0.38 26-220.5-0.96 20-1891536-191529-191522-191594-11.27-2.79 91526-1Type II Terminal PN Specific 91539-1Type III+0.05-0.38 30-22 0.89-1.491515-10.05-0.6 30-20 1.02-1.910.2-1.6 24-202.03-2.54 91523-11.81-1.42 18-160.2-0.6 24-20 1.14-1.7891505-11.81-1.42 18-16 2.03-2.540.81-1.42 18-161.94-2.14 142.03-2.54 91519-1For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe9

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Power Assist Options for CERTI-CRIMP IIStraight Action H<strong>and</strong> ToolsCERTI-CRIMP II Tool Adapter can be used with thefollowing tools Battery Tool 626 or Micro Pneumatic Electric TerminatorBattery Tool Heads can be removed from H<strong>and</strong>Tools, or the head only is available as a [-3] option.Example P/N 91503-1; h<strong>and</strong>les can be removed oralternatively P/N 91503-3 (head only) can bepuchased <strong>and</strong> used in the shown Power-Assistoptions.626 or Micro Pneumatic Tool withCERTI-CRIMP II Tool AdapterCERTI-CRIMP II ToolAdapter for 626 or MicroPneumatic ToolP/N 1583527-1For more information on the 626 <strong>and</strong> MicroPneumatic System see Section 1.5Battery Tool Kit with Adapter forCERTI-CRIMP II H<strong>and</strong> ToolEU Power Plug P/N 1213805-4GB Power Plug P/N 1213805-6These tools have the st<strong>and</strong>ard retract switch coveredover to best ensure complete crimp cycle.The switch is fully functional with the cover removed.Electric Terminator withCERTI-CRIMP II Tool AdapterCERTI-CRIMP IITool AdapterP/N 1213660-1for Electric TerminatorFor more information on the Electric Terminator seeSection 1.510For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Power Assist Options for Double Action <strong>and</strong>Heavy Head H<strong>and</strong> Tools626 or Micro Pneumatic ToolCrimping Head forLarge Tool Holder (LTH)Crimping Head forSmall Tool Holder (STH)Crimping Heads for 626 or Micro Pneumatic ToolLarge Tool Holder LTH P/N 356302-1Small Tool Holder STH P/N 356303-1DAHT Adapter to MicroPneumatic H<strong>and</strong> ToolHHHT Adapter to MicroPneumatic H<strong>and</strong> ToolAdapters to Micro Pneumatic ToolDAHT Adapter P/N 1213563-1HHHT Adapter P/N 525432-1HHHT = Heavy Head H<strong>and</strong> ToolDAHT = Double Action H<strong>and</strong> ToolFor more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe11

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>626 or Micro Pneumatic Terminal to Tool Reference ToolTerminal TypePIDGTerminals <strong>and</strong> SplicesPLASTI-GRIP TerminalsWire RangeCrimping Headsmm² AWG 626 (LTH) 626 (STH) Micro1.3-2.0 HD 16-14 HD679300-13.0-6.0 12-100.12-0.3 26-22 314537-10.3-1.3 22-16 31470-31.3-2.0 16-14 314269-1PLASTI-GRIPButt Splices0.3-1.3 22-16 314868-11.3-2.0 16-14 314869-10.9-8.0 ECV 18-8Closed End SpliceInsulated0.9-6.0 CES 18-100.3-2.0 22-14 354422-10.3-1.3 VS 22-16 217205-10.3-6.0 EC 22-10 354422-2PIDG STRATO-THERMTerminals <strong>and</strong> Splices0.3-6.0 22-10 217206-10.3-6.0 22-10 679301-18.0 8 1338757-1SOLISTRANDUninsulatedTerminals <strong>and</strong> Splices13.0 6 1338758-10.3-3.0 22-14 189989-10.3-1.3 22-16 314516-11.3-2.0 16-14 314517-12.0-3.0 14-12 314518-112For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.3 SDE Premium Crimp <strong>Tooling</strong>SDE (St<strong>and</strong>ard Die Envelope) is a new, flexibleapproach to crimp tooling, that allows use of the samedies on tooling across a range of application platforms.Dies are interchangeable in tools from portable h<strong>and</strong>tools - manual or battery-powered - to pneumatic h<strong>and</strong>tools <strong>and</strong> electric bench terminators. It is a family oftools that you can take from bench to production orinto the field, without the need for dies fitted to eachkind of tool.You can be sure your dies will fit your long-term needs,because they are completely compatible with all toolsin the SDE system. They move with you as your needsgrow.Fast FactsThese versatile h<strong>and</strong> tools are ideallysuited for R&D, networking applications,<strong>and</strong> on-site maintenance work.• User-adjustable ratchet control fora complete crimping cycle• Emergency ratchet release• Angled head, providing a comfortableh<strong>and</strong> <strong>and</strong> wrist position• Over 100 interchangeable SDE diesets to crimp a broad range ofconnectors• Able to h<strong>and</strong>le multiple wire <strong>and</strong>terminal sizes in one die set• Precision construction of durablehigh-carbon steel• Extra strength pivot pins for maximumdurability• Engineered <strong>and</strong> manufactured usingprocesses independently certified tointernationally recognized qualityst<strong>and</strong>ards ISO-9001:2000 <strong>and</strong>Telecommunications IndustrySt<strong>and</strong>ard TL 9000.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe13

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>SDE H<strong>and</strong> ToolsPRO-CRIMPER IIIH<strong>and</strong> ToolPart No. 354940-1The PRO-CRIMPER III H<strong>and</strong> Toolcombines the versatility of generalpurpose service tools with thereliability <strong>and</strong> ease of use of manypremium grade tools. It is ideallysuited for R&D prototyping, networkingapplications, <strong>and</strong> commercial,industrial, <strong>and</strong> institutionalmaintenance work.The precision design <strong>and</strong> manufacturingtechniques that go into thistool ensure reliable, repeatable performance.The new h<strong>and</strong>les <strong>and</strong> headdesign result in increased usablelifecycle.Versatile. As part of the SDE familyof tools, the system accommodatesdozens of interchangeable dies in anever-exp<strong>and</strong>ing range, includingthose for open-barrel contacts <strong>and</strong>terminals. Many die sets have multiplecavities for crimping more thanone wire or terminal size at the sametime.Dependable. The tool is constructedof durable high-carbon steel withextra strength pivot pins, for maximumreliability <strong>and</strong> long-life precision.Locators are included withpin-<strong>and</strong>-socket style tools. They helpproperly locate the contact in thedie set, provide a wire stop, <strong>and</strong>help minimize contact rotation <strong>and</strong>bending during crimping.Convenient. User convenience <strong>and</strong>comfort features are evident throughout.User-adjustable ratchet controlis provided for complete crimpcycling that helps eliminate partialcrimps. An emergency ratchetrelease allows the user to open thetool jaws at any time during the crimpcycle. To reduce h<strong>and</strong>le force, thelinkage was designed to match theforces required to crimp our largestinsulated terminal. The result is dramaticallyless h<strong>and</strong> force than comparabletools. The angled head <strong>and</strong>specially designed h<strong>and</strong>les providecomfortable operation.Quality. Every tool crimps with precision,because every tool incorporatesthe traditional quality of allTyco Electronics products.SDE DAH<strong>and</strong> ToolPart No. 1213745-1This tool is specifically designed forclosed barrel SDE dies. It incorporatesall the convenient operationalfeatures of the SDE family.• Excellent mechanical advantage,enhancing user comfort• Adjustable ratchet withemergency releaseSDE PEW 12H<strong>and</strong> ToolPart No. 9-1478240-0The unique geometry of this toolresults in a comfortable, easy-touseh<strong>and</strong>le design that isunmatched in the market.• Easy accessibility for space-constrainedapplications• Large crimp jaw arc, minimizing“roll” in open barrel applications• User-adjustable ratchet control<strong>and</strong> emergency ratchet release• Compatible with over 100 interchangeableSDE dies14For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>SDE Premium Crimp <strong>Tooling</strong>Terminal to Tool ReferencePart NumberProductFamilyCatalogNumberTyco ElectronicsProductRG/U CableWire SizeTerminationType/StyleP/N 354940-1withSDE Die SetSDE Die SetOnlyRD 316, 180, 195, Belden 8218 “O”/Commercial — 58539-150 OhmBNC <strong>and</strong> TNC“O”/Commercial 58433-1 58435-158, 62, 59Hex/Commercial 58433-2 58436-1Belden 9248, 9114 “O”/Commercial — 58539-1174, 188, 316, 179, 161, 187 “O”/Commercial 318450-1 318450-262, 59 “O”/Commercial — 58435-1Belden 9907, 89907, Comm/Scope 2104 “O”/Commercial 318452-1 318452-2174, 188, 316, 179, 161, 187 Hex/Commercial — 58436-362, 59, Belden 9104, 9112 “O”/Commercial & Military — 58537-150 Ohm BNCBelden 8281, 9141Hex/Commercial — 58436-2“O”/Commercial & Military — 58538-1180, 195, Belden 8218, 9248, 9114 “O”/Commercial — 58539-158 “O”/Military — 220189-375 OhmBNC <strong>and</strong> TNC62, 59 “O”/Commercial — 58536-16, Belden 8281 “O”/Commercial — 58538-1CoaxialConnector8207475 Ohm BNC“O”/Commercial 318451-1 318451-2179, 161, 187Hex/Commercial 58531-2 58425-262, 59 Hex/Commercial 58531-1 58425-1Double Braid 59, Belden 8281, 9141 Hex/Commercial 58531-3 58425-3Belden 9248, 9114 “O”/Commercial — 58536-1Belden 8218 “O”/Commercial — 58174-150 <strong>and</strong> 75 Ohm BNC 6, Belden 8281 “O”/Commercial — 58538-150 Ohm N58, 62, 59 Hex/Commercial 58433-2 58436-18, 213, 11, 216, 9, 214 Hex/Commercial 58501-1 58485-1Miniature UHF 58 Dual Crimp 58506-3 220196-150 Ohm SMB174, 316, 188, 179, 161, 187,RD 316, 188 Double BraidHex/Commercial 58500-1 58489-1Hex/Military 58499-1 58483-1178, 196, 174, 316, 188, 179, 161, 187 Hex/Commercial — 58046-150 <strong>and</strong> 75 OhmConsumer BNC58, 62, 59 “F” / “O” 58558-1 58558-2174, 316, 188, 179, 161, 187 “F” / “O” 58559-1 58559-258, 6, 7, 6.6, 8.2, 9.8[0.259, 0.324, 0.384] Dia.Hex/Commercial 58621-1 58621-2Series FCATV PlugsBraid-Pic BraidTermination58, 6,7,7.4, 8.7 [0.290, 0.343] Dia.59,69.1 [0.360] Dia.Hex/Commercial 58622-1 58622-2Hex/Commercial 58663-1 58663-258, 62, 59 — — 220195-1For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe15

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>SDE Premium Crimp <strong>Tooling</strong>Terminal to Tool ReferenceProductFamilyCatalogNumberTyco ElectronicsProductCable orWire SizeP/N 354940-1withSDE Die SetSDE Die SetOnlyFSMA <strong>and</strong> ST-Style (S.S.)Connectors (504XXX Series only)ST-Style FC Type, D4 <strong>and</strong>AMP SC Connectors3.0 mm Jacket Dia. 58551-1* 58552-13.0 mm Jacket Dia. 58433-4* 58424-1ST-Style (Ceramic) Connectors 3.8 mm Jacket Dia. — * 503890-182164 <strong>and</strong> 296355FC Type <strong>and</strong> AMP SC Connectors(Next Generation)3.0 mm Jacket Dia. 503911-1** 503910-1Fiber OpticConnectorsFSD, FSD MC <strong>and</strong> RSD Connectors;FSD Breakout KitLightCrimp XTC Connectors(Ceramic/Polymer/S.S.)DUALAN <strong>and</strong> LDD 58519-1* 58510-13.0 mm Jacket Dia. 503568-1* 503567-1LightCrimp SC (Ceramic) Connectors 3.0 mm Jacket Dia. 503699-1* 503698-11307099LightCrimp Plus AMP SC 3.0 mm Jacket Dia. 492623-1*** 492622-1LightCrimp Plus ST-Style 3.0 mm Jacket Dia. 492782-1*** 492783-1— Multimate Contacts1 mm Plastic Fiber,2.2 mm Jacket Dia.217211-1 217211-2Request catalog for detailed product information.* Tool Frame Part No. 58532-1** Tool Frame Part No. 58588-1*** Tool Frame Part No. 58532-2SDE Premium Die-Sets for PIDG <strong>and</strong> PLASTI-GRIP TerminalsPart Number Description AWG / mm 2 /other91963-2PIDG, PLASTI-GRIP Terminals & Splices - equivalent crimp to 47387Qualifications: Mil-T-7928; LUL RSE 024 pt6 <strong>and</strong> EE6161Marks the applied product with a two dot indent code.16-14 / 1.5-2.520-16 / 0.6-1.5 HD91964-2PIDG, PLASTI-GRIP Terminals <strong>and</strong> Splices - equivalent crimp to 47386Qualifications: Mil-T-7928; LUL RSE 024 pt6 & EE6161Marks the applied product with a two dot indent code.22-16 / 0.4-1.591965-2PIDG, PLASTI-GRIP Terminals & Splices - equivalent crimp to 59239-4Qualifications: Mil-T-7928; LUL RSE 024 pt6 <strong>and</strong> EE6161Marks the applied product with a two dot indent code.12-10 / 4.0-6.0Only the most popular options are listed here, please use our online search by terminal PN to find the right tool for yourapplication, <strong>and</strong> contact us where information is unclear or missing - there may well be something available for yourrequirement.16For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Power Assist Options for SDE Premium <strong>Tooling</strong>SDE 626 Pneumatic Tool• P/N 1213855-1Complete all pneumatic unit• P/N 679304-1SDE Head onlyFor more information on the 626 Systemsee Section 1.5SDE Battery Tool Kits• P/N 1725837-4SDE Shoulder DiesOPEN head (EU Power Plug)• P/N 1725837-6SDE Shoulder DiesOPEN head (UK Power Plug)For more information on the Battery Tool Kitssee Section 1.5SDE Electric Terminator• P/N 1490076-2Portable Bench-top Unit with SDE Head <strong>and</strong>Foot Switch• P/N 1673663-2Adapter only for SDE DiesFor more information on the Electric Terminatorsee Section 1.5For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe17

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.4 Tools for Mil Indent CrimpingTurrets - accurately position Contacts in the ToolPart Number DescriptionP/N 601967-2Turret TH1A [M22520/1-02] for ARINC ContactsP/N 601967-3Turret TH163 [M22520/1-04] for MS27490; MS27655P/N 601967-4Turret TH4 [M22520/1-03] for MS17803; MS21097;OSI2814 ContactsP/N 601967-5Universal Head UH2-5 [M22520/1-05]AF8P/N 601967-1Base Tool (AF8) without TurretP/N 2031846-1Pneumatic AF8 (WA27F) without TurretFeatures 4/8 indent Crimp to Military st<strong>and</strong>ard M22520/1-01 Ratchet mechanism ensures complete crimp cycle 8 Position Dial select Indent Depth control Many Turrets available Ergonomic non-slip h<strong>and</strong>lesP/N 601967-6Turret TP45 [M22520/1-06]for OSI2814 type M size 16 & 22P/N 601967-7Turret TP85 [M22520/1-07]for MS18232; MS18233 ContactsP/N 601967-8Turret TH199S [M22520/1-08]for MS3343; MS90460; MS90461 ContactsP/N 1-601967-2Single Position Head TP465 [M22520/1-11]for M39029Partial listing only. For the full range please visit our online H<strong>and</strong> Tool Catalogue atwww.tooling.tycoelectronics.com/europe/catalogue.aspthen go to the Tools for Screw-machined Contacts section.DMC is a trademark of Daniels Manufacturing Corp.18For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Tools for Mil Indent CrimpingPositioners - accurately position Contacts in the ToolPart Number DescriptionP/N 601966-2Positioner K1S [M22520/2-02]for TERMI-BLOK ContactP/N 601966-3Positioner K60S [M22520/2-03]for MS3343; MS90461 ContactsP/N 601966-4Positioner K41 [M22520/2-06]for Size 22 ContactsAFM8P/N 601966-1Base Tool (AFM8) without PositionerP/N 2031845-1Pneumatic AFM8 (WA22) without PositionerFeatures4/8 indent Crimp to Military st<strong>and</strong>ard M22520/2-01Ratchet mechanism ensures complete crimp cycle8 Position Dial select Indent Depth controlMany Positioners availableErgonomic non-slip h<strong>and</strong>lesP/N 601966-6Positioner K13-1 [M225202/2-08]for ARINC size 20 ContactsP/N 1-601966-1Positioner K339 [M22520/2-16]for M39029/17 ContactsP/N 1-601966-3Positioner K40 [M22520/2-07]for MS27490; MS27655 ContactsP/N 1-601966-4Positioner K43 [M22520/2-10]for MS27490; MS27491; MS27492 <strong>and</strong> more ContactsP/N 1-601966-6Positioner K370 [M22520/2-12]for ARINC COAXICON size 15 ContactsP/N 966254-1Positioner K42 [M22520/2-09]for ARINC size 22 ContactsPartial listing only. For the full range please visit our online H<strong>and</strong> Tool Catalogue atwww.tooling.tycoelectronics.com/europe/catalogue.aspthen go to the Tools for Screw-machined Contacts section.DMC is a trademark of Daniels Manufacturing Corp.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe19

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.5 Power Assist <strong>Equipment</strong>Battery Tool 1.5 tTyco Electronics only recommends the use of h<strong>and</strong>tools for prototyping, service <strong>and</strong> repair, as continueduse can cause operators to experience RSI(Repetitive Strain Injury).We are continually adding to our power-assist rangeto minimise this risk. All electric, all pneumatic <strong>and</strong>now battery powered options. With the vastimprovement of battery life <strong>and</strong> small motor power,the practicality <strong>and</strong> convenience of battery poweredtools is now well known.These tools have the st<strong>and</strong>ard retract switch coveredover to best ensure complete crimp cycle. The switchis fully functional with the cover removed.All Battery tools come together with a battery charger<strong>and</strong> will be supplied in a durable plastic case.Battery Tool Kit with Adapter for HHHTEU Power Plug P/N 1901235-4GB Power Plug P/N 1901235-6Battery Tool Kit with Adapter for DAHTEU Power Plug P/N 1213840-4GB Power Plug P/N 1213840-6For HHT <strong>and</strong> DAHT, heads can be removed fromh<strong>and</strong> tools <strong>and</strong> used with the above kits.Typical C-Head SAHT DiesMoving DieInsulation AdjustmentSpacersBattery Tool Kit with Adapter for C-Head SAHTStationary DieEU Power Plug P/N 1213819-2GB Power Plug P/N 1213819-5LocatorHHHT = Heavy Head H<strong>and</strong> ToolDAHT = Double Action H<strong>and</strong> ToolSAHT = Straight Action H<strong>and</strong> ToolsDie Holding Screw20For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Battery Tool 4 tOver 100 Crimps per chargeCompact only 356 mm long <strong>and</strong> weighs 160 kg (3.4lbs)Kits are supplied in a durable carry case <strong>and</strong> include:• Battery tool• 4 t Latched Head• Battery Charger 230 V• Two BatteriesSpares:• Battery P/N 1725839-1• Battery Charger EU Power Plug P/N 1725840-2• Battery Charger GB Power Plug P/N 1725840-5Crimping Tool (with Battery Installed)Length356 mm [14 in]Width60 mm [2 3/8 in]Depth80 mm [3 1/8 in]Mass Weight (w/Battery)1.6 kg [3.4 lb]Sound Level75 dB(A) at 1 mVibration

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>SDE Electric Terminator with CERTI-CRIMP Tool AdaptersThis all electric portable bench-top Terminator is fast,effortless <strong>and</strong> ideal for low to medium volume production.P/N 167377-2 Electric TerminatorP/N 679304-1 SDE Head AdapterP/N 1213860-1 CERTI-CRIMP II Straight Action Head AdapterP/N 1901556-1 C-Head SAHT AdapterP/N 1673664-1 Optional Foot SwitchMain powered unit - nor air requiredSwitchable 110 V or 240 V supplyCycle CounterTwo stage crimp cycle optionDimensions [mm] 390 x 260 x 200Weight 13 kgPIDG <strong>and</strong> STRATO-THERM Die Sets for Electric Terminatorwith C-Head SAHT AdapterColor AWG Die SetBrown 24-22 P/N 576711Grey 20 P/N 576720Orange 18 P/N 576715Orange 16 P/N 576714White / Beige 14 P/N 576716White / Beige 12 P/N 576742Black 10 P/N 57672322For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>626 <strong>and</strong> Micro Pneumatic Tool SystemMaximize your productivity whileminimizing your effort - replaceyour manual h<strong>and</strong> tools with the626 Pneumatic Tool System.Terminating wires from0.12–13.0 mm 2 [26–6 AWG] hasnever been easier. And you cancontinue to use most, if not all, ofyour existing Tyco Electronicscompatible crimp heads <strong>and</strong> diesets.The 626 System WorksWhere <strong>and</strong> HowYou Need ItUsing 626 adapters, tools previouslyrestricted to prototype or limitedproduction applications can nowbe used in low to medium benchproduction <strong>and</strong> harness assemblyoperations.Because the 626 crimp head canbe rotated to any angle, you canAdapter HoldersPart No. 189928-1Part No. 356304-1 (w/ratchet)Fast FactsEffortless crimping for a broadrange of terminals, either benchmountedor h<strong>and</strong>-held for workingin cramped quarters.• Lightweight tool eliminatesphysical force required by h<strong>and</strong>tools• H<strong>and</strong>- or foot-switch operation• Termination wire range from0.12–13.0 mm 2 [26–6 AWG], pluscoaxial <strong>and</strong> fiber optic cable• Works with existing TycoElectronics compatible crimpheads <strong>and</strong> die sets• Ratchet control option providescomplete crimp cycle, eliminatingpartial crimps• Use rotating head assembly toreach difficult termination locations• Engineered <strong>and</strong> manufacturedusing processes independentlycertified to internationallyrecognized quality st<strong>and</strong>ardsISO-9001:2000 <strong>and</strong> TelecommunicationsIndustrySt<strong>and</strong>ard TL 9000The powerful 626 Pneumatic ToolSystem makes crimping as easy aspressing a h<strong>and</strong> or foot switch.Besides reducing operator fatigue,this means you do not have todesign your production bencharound your tool.Include the fully adjustable BenchMount Assembly with the footswitch, <strong>and</strong> you are completelyfree to concentrate on aligningthe wire <strong>and</strong> terminal. Now you cancrimp faster <strong>and</strong> with fewer mistakes.Certi-Crimp II,SAHT AdapterPart No. 1583527-1Heavy Head H<strong>and</strong> ToolAdapter,Part No. 525432-1also work on those difficult terminationsin confined equipmentcabinets or enclosures.Looking for the complete crimpcycle control provided by themechanical ratchet in premiumCERTI-CRIMP h<strong>and</strong> tools? Theavailable 626 System ratchet toolholders produce a complete crimpcycle by simply pressing a switch.Dies will fully bottom before youcan open the jaws to release thecrimped product.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe23

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>626 <strong>and</strong> Micro Pneumatic Tool System626 Pneumatic System Power UnitProtect Your ToolInvestmentOutside DiameterLength45 mm [1.8 in]225 mm [8.88]for foot actuated unit230 mm [9.00 in]for h<strong>and</strong> actuated unitThe 626 System’s power unitworks with a variety of adapters<strong>and</strong> tool holders, so you can continueto work with your existingcrimp heads <strong>and</strong> die sets.Grip SpanMassAir PressureMicro Pneumatic System Power Unit55 mm [2.19 in] over button/h<strong>and</strong>le0.60 kg [1.32 lbm]for foot actuated unit600-700 kPa [90-100 psi]Air Displacement 0.00018 m 3 [11.14 in 3 ]Air Supply HoseCycle TimeOutside DiameterLengthGrip SpanMass3.05 m [10 ft] long4.8 mm [3/16 in] I.D.with 1/8 in NPT fitting0.7-0.8 s (for 16-14 AWG[1.3-2 mm 2 ] PIDG Terminals)45 mm [1.8 in]146.5 mm [5.75 in]55 mm [2.19 in] over button/h<strong>and</strong>le0.70 kg [1.5 lbm]Big Return in a MicroPackageDoes your crimping applicationdem<strong>and</strong> even more accessibility<strong>and</strong> flexibility than the 626 Systemoffers?The Micro Pneumatic Tool Systemterminates wires in the 0.12-2 mm 2[26-14 AWG] range,* but with asmaller <strong>and</strong> lighter power unit.Weighing in at only 0.7 kg [1.5 lb]<strong>and</strong> just 146.5 mm [5.75 in] long, theh<strong>and</strong>-actuated Micro System iscompatible with three differenthead systems.* With the exception of theSOLISTRAND tool head combination,which crimps 0.3-2 mm 2[22–10 AWG] combinations.Air Pressure600 - 700 kPa [90-100 psi]Die InterchangeabilityAir Displacement 0.00018 m 3 [11.14 in 3 ]Air Supply HoseCycle Time3.05 m [10 ft] long4.8 [3/16 in] I.D.with 1/8 in NPT fitting0.7-0.8 s (for 16-14 AWG)[1.3-2 mm 2 ] PIDG Terminals)For the ability to change diesquickly when needs change,whether from one terminal type toanother or from tool to tool whenworkload <strong>and</strong> environment change,consider the SDE family of tools<strong>and</strong> dies.For more information, seeCatalog 1773379.24For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>626 <strong>and</strong> Micro Pneumatic Tool SystemSDE Compatible KitComplete tool withh<strong>and</strong>-held power unitP/N 1213855-10.3 - 6.0 mm 2(22-10 AWG)Tool <strong>and</strong> Adapter Holders*Large ToolHolderSmall ToolHolderAdapter HolderLength(with Head Assembly)100 mm [3.88] 70 mm [2.75] 70 mm [2.75]Weight(with Head Assembly)0.76 kg [1.68 lb]0.44 kg[0.96 lb]0.44 kg [0.96 lb]P/N 356302-1 356303-1 356304-1*Measurements are averages.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe25

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>626 <strong>and</strong> Micro Pneumatic Tool SystemConfigurations <strong>and</strong> Ordering InformationThe basic 626 <strong>and</strong> Micro Pneumatic Tool Systems require a power unit, a tool holder, a head assembly, <strong>and</strong>a die set, when applicable. Tool holder assemblies (i.e., tool holder <strong>and</strong> cam) accept the crimping heads,adapters, <strong>and</strong> die sets listed in section 1.2Power Unit Tool Holders Crimping Heads Adapters626 SeriesLarge Tool HoldersPart No. 189767-1Part No. 356302-1 (w/ratchet)H<strong>and</strong> Actuated Power UnitPart No. 189721-1PRO-CRIMPER III ToolDie Set AdapterPart No. 679304-1Foot Actuated Power UnitPart No. 189722-1(-2 required for C Head Adapter)Small Tool HoldersPart No. 189766-1Part No. 356303-1(w/ratchet)2614 SeriesAdapter HoldersPart No. 189928-1Part No. 356304-1(w/ratchet)CERTI-Crimp II,SAHT AdapterPart No.1583527-1 Power Units with a -1suffix can be convertedto -2 by orderingBooster Addition Kit,Part No. 189720-1. 3.05 m [10 ft] Air SupplyHose (Part No. 38111)included with eachpower unit.Double ActionH<strong>and</strong> ToolH<strong>and</strong>le AssemblyDAHT Adapter(Including cam)Part No. 1213563-1(See pages 5 & 6.)Heavy HeadH<strong>and</strong> Tool AdapterPart No. 525432-126For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>626 <strong>and</strong> Micro Pneumatic Tool SystemConfigurations <strong>and</strong> Ordering InformationPower UnitTool HoldersAdaptersAdapter HoldersPart No. 356304-1 (w/ratchet)H<strong>and</strong> Actuated Power UnitPart No. 1490567-1CERTI-CRIMP II,SAHT AdapterPart No. 1583527-1Small Tool HoldersPart No. 1673611-1 (w/ratchet)2614 SeriesCrimp HeadFor more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe27

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.6 Hydraulic <strong>Equipment</strong>Fast Facts• St<strong>and</strong>ard 68,950 kPa [10,000 psi]rated hydraulic pumps <strong>and</strong>heads• Interchangeable AMP-designU-dies for crimp force up to14 t [125 kN]• U-die stroke options of 1 in[25 mm] <strong>and</strong> 1.5 in [38 mm]• Termination range varies byproduct type• Integrated head/die for crimping7-34 mm 2 [#8-2 AWG]SOLISTRAND terminals• Heads compatible withshank-dies available for largerwires requiring crimp forcegreater than 14 t [125 kN]• Portable power, using a h<strong>and</strong>heldtool with rechargeablebattery, or a Portable BatteryHydraulic Unit for st<strong>and</strong>ardcrimping system• Electric & manual hydraulicpumps for crimping at fixedlocations• Produced under a QualityManagement System certifiedto ISO 9001. A copy of thecertificate is available uponrequest.Tyco Electronics continues thequality tradition of AMP crimpingtools with a new line of industryst<strong>and</strong>ard68,950 kPa [10,000 psi]hydraulic compression crimp heads,pumps, <strong>and</strong> interchangeable U-dies.A new battery-powered pump <strong>and</strong>tool options provide unprecedentedportability for any crimpingapplication.The U-dies, made with the AMPdesign precision <strong>and</strong> performanceyou have come to expect, are wellsuited for applications requiring acrimp force of up to 14 t [125 kN].For wire sizes requiring more than14 t [125 kN], Tyco Electronicsoffers five heavy-duty AMP crimphead configurations that are compatiblewith shank dies.There are four light-duty crimphead options, including three in theU-die format. U-dies are availablein two types, with 25 mm [1 in] <strong>and</strong>38 mm stroke [1.5 in], respectively.The two 12 t [101 kN] head optionshave 25 mm [1 in] stroke.The 14 t [125 kN] head is for largerproducts that call for a 38 mm [1.5in] stroke. Also available is an integratedhead/die for crimping #8 to#2 SOLISTRAND terminals. Theheavy-duty heads are available infive different configurations.Note: These heads are notcompatible with 8,200 psi[56,540 kPa] tooling.The basic 68,950 kPa [10,000 psi]hydraulic tool system requires apump, hose (multiple lengths areavailable with all configurations),crimp head, <strong>and</strong> crimp die.There is a Tyco Electronics hydraulicpump to meet the dem<strong>and</strong>s of anycrimping application. For maximumportability, the h<strong>and</strong>-heldcrimping tool with rechargeablebattery is an effective solution.U-Die Line up, including #8–#2SOLISTRAND tool head, for 68,950kPa [10,000 psi] systems providingup to 14 t [125 kN] of crimp forceShank-Die Line up, for wiring sizesrequiring more than 14 t [125 kN] ofcrimp forceHeavy-Duty Crimp Head (U-Die).Or, to power a st<strong>and</strong>ard crimpingsystem at any location, order thePortable Battery Hydraulic Unit.For fixed crimping locations, youcan choose between a 110 V or220 V Electric Hydraulic Pump(with optional remote h<strong>and</strong> control),or manual foot <strong>and</strong> h<strong>and</strong>hydraulic pumps.28For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Selecting a Hydraulic System?Have you remembered a... Pump H<strong>and</strong> or Foot control Hose Crimp Head Crimp DieHydraulic <strong>Tooling</strong> Selection Guide - 70,000 kPa / 10,000 psiPumps, <strong>and</strong> Hose OptionsThe Heavy-duty Pump is designed for continuous use.ORWITHLight Duty Electric Hydraulic PumpP/N 523199-1 (220 V) 1, 2Heavy Duty Electric Hydraulic PumpP/N 1804700-2 (220 V) 1, 2Hydraulic Hoses 3P/N 1583662-1 - 1.8 m / 6 ftP/N 1583662-2 - 3.0m / 10 ftP/N 1583662-3 - 6.1 m / 20 ftHeavy-Duty Crimp Heads (Shank Dies) ( > 25,000 cycles)8 - 4/0 A22 t output force 16 lbsP/N 1752877-1IS 408-89564/0 AWG-1000 MCM26 t output force 29 lbsP/N 1752786-1IS 408-89588 - 4/0 AWG33 t output force 28 lbsP/N 1752787-1IS 408-891412-10 AWG - 350 MCM18 t output force 13 lbsP/N 1752868-1IS 408-8959Medium-Duty Crimp Heads & H<strong>and</strong> Tools (U-Dies)Shank DiesU-DiesAMPLI-BOND 8 AWG-4/0 AWGAMPOWER 6 AWG-1500 MCMAMPOWER QuickDisconnect1/0 AWG-600 MCMInsulation Piercing10 AWG (Cu)-3/0 AWG)COPALUMSealed COPALUM 10 AWG-3/0 AWGBar COPALUM 10 AWG (Cu)-400 MCMSOLISTRAND 8 AWG-600 MCMSTRATO-THERM 8 AWG-2/0 AWGTERMINYL 1/0 AWG thru 4/0 AWGAMPLI-BONDAMPOWERSOLISTRANDTERMINYL8 AWG - 2 AWG6 AWG - 4/0 AWG8 AWG - 4/0 AWG8 AWG - 1/0 AWG12 t output force1.5” stroke; 50,000 cycleCompression HeadU-Die CompatibleP/N 1901821-1IS 408-1011212 t output force1” stroke TitaniumCompression HeadU-Die CompatibleP/N 1490747-1IS 408-8715SOLISTRAND (Integrated Crimp Dies)#8-#2 AWG SOLISTRAND Compression Head(No crimp dies required)P/N 1673672-1 / IS 408-891014 t output force1.5” strokeHeavy-DutyCompression HeadU-Die CompatibleP/N 1976230-1IS 408-1014514 t output force1.5” strokeCompression ToolU-Die CompatibleP/N 1976230-1IS 408-87171” stroke H<strong>and</strong>Compression ToolU-Die CompatibleP/N 1490748-1IS 408-8716#8-#2 AWG SOLISTRAND Compression Tool(No crimp dies required)P/N 59975-1 / IS 408-67581 Foot Pump 523199-2 ORH<strong>and</strong> Pump 1583661-1 can be substituted asmanual options for Electro-Hydraulic Pumps2 Includes male screw-to-connect, 3 /8" NPT quickcouplers3 Includes female screw-to-connect, 3 /8" NPTquick couplersFor more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe29

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Dies, H<strong>and</strong> Tools <strong>and</strong> Hydraulic HeadsConfiguration OptionsThe Tyco Electronics hydraulic crimping tool line offers a wide array of die, h<strong>and</strong> tool, <strong>and</strong> hydraulic headconfigurations.Use the following tables to determine the configuration that best matches your requirements.The tables are color-coded to help you identify the new 68,950 kPa [10,000 psi] rated configurations thatcorrespond to previous 56,540 kPa [8,200 psi] tooling.TERMINYL Terminals <strong>and</strong> SplicesHydraulic Crimp <strong>Tooling</strong> 10,000 psi Operating PressureDYNA-CRIMP Tool System 8,200 psiOperating PressureH<strong>and</strong> Tools(U-Die)Hydraulic Heads(U-Die)Hydraulic Heads(Shank-Die)H<strong>and</strong> ToolHydraulic Heads(Shank Die)Wire Sizein AWG [mm 2 ]1490748-1 1490749-11901820-11490747-11901821-11976230-11752877-1 1752787-1 59974-1 § 69051 § 69066 58422-18 [7-8.5] 1490597-1 1490597-1 1490597-1 1490597-1 47820 § 47820 §6 [13-15] 1490598-1 1490598-1 1490598-1 1490598-1 47821 § 47821 §4 [21] 1490599-1 1490599-1 1490599-1 1490599-1 47822 § 47822 §4HD 69463 69463 69463 694632 [34-35] 1490406-1 1490406-1 47823 § 47823 §1/0 [50-60] 1490700-1 1490700-1 47824 47824 47824 478242/0 [67-70] 47825 47825 47825 478253/0 [80-95] 47915 47915 47915 479154/0 [100-125] 47918 47918 47918 47918AMPLI-BOND <strong>and</strong> PLASTI-GRIP Terminals <strong>and</strong> SplicesHydraulic Crimp <strong>Tooling</strong> 10,000 psi Operating PressureDYNA-CRIMP Tool System 8,200 psi Operating PressureH<strong>and</strong> Tool(U-Die)Hydraulic Head(U-Die)Hydraulic Heads(Shank Die)H<strong>and</strong> ToolHydraulic Heads(Shank Die)Wire Sizein AWG [mm 2 ]1490749-11901821-11976230-11752877-1 1752787-1 59974-1 § 69051 § 69066 58422-18 [7-8.5] 1490534-1 1490534-1 48858-1 48858-1 48752-1 § 48752-1 § 48858-1 48858-16 [13-15] 1490535-1 1490535-1 48859-1 48859-1 48753-1 § 48753-1 § 48859-1 48859-14 [21] 1490536-1 1490536-1 48860-1 48860-1 48754-1 § 48754-1 § 48860-1 48860-12 [34-35] 1490410-1 1490410-1 48861-1 48861-1 48755-1 § 48755-1 § 48861-1 48861-11/0 [50-60] 48756-1 48756-1 48756-1 48756-12/0 [67-70] 48757-1 48757-1 48757-1 48757-13/0 [80-95] 48758-1 48758-1 48758-1 48758-14/0 [100-125] 48759-1 48759-1 48759-1 48759-1§These products will bediscontinued30For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Dies, H<strong>and</strong> Tools <strong>and</strong> Hydraulic HeadsConfiguration OptionsAMPLI-BOND <strong>and</strong> PLASTI-GRIP Large Expansion TerminalsWire Sizein AWG [mm 2 ]Hydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureHydraulic Heads(Shank Die)DYNA-CRIMP Tool System8,200 psi Operating PressureHydraulic Heads(Shank Die)1752877-1 1752787-1 69066 58422-18 [7-8.5] 47236-1 47236-1 47236-1 47236-16 [13-15] 47237-1 47237-1 47237-1 47237-14 [21] 47238-1 47238-1 47238-1 47238-12 [34-35] 47239-1 47239-1 47239-1 47239-11/0 [50-60] 47378-1 47378-1 47378-1 47378-1Stationary DieMoving DieSelf-Contained Die Use Adapter 69760 Use Adapter 69834§These products will bediscontinuedSOLISTRAND TerminalsHydraulic Crimp <strong>Tooling</strong> 10,000 psi Operating PressureDYNA-CRIMP Tool System 8,200 psi Operating PressureH<strong>and</strong> Tool(DiesIncluded)H<strong>and</strong>Tools(U-Die)HydraulicHeads(U-Die)Hydraulic Heads(Shank Die)H<strong>and</strong>ToolHydraulicHeadsHydraulic Heads(Shank Die)Wire Sizein AWG[mm 2 ]59975-1 1490748-11490749-11901820-11901821-11490747-11976230-1673672-1 1752868-1 1752788-1 1752786-1 59973-1 §69065 §69067 §69097 § 69069 § 69099 58445-1 690828 [7-8.5] 1490413-11490414-11490413-1 1490414-1 6921648126 §48355 §48126 §48355 §46146 §46145 § 692166 [13-15] 1490413-2 1490413-2 1490414-2 1490414-2 6921748128 §48127 §48128 §48127 §46134 §46133 § 692174 [21] 1490413-3 1490413-3 1490414-2 1490414-2 6921848129 §48127 §48129 §48127 §46135 §46133 § 692182 [34-35] 1490413-4 1490413-4 1490414-2 1490414-2 4543348130 §48127 §48130 §48127 §46136 §46133 § 454331/0 [50-60]1490413-5 1490413-5 1490414-3 1490414-3 4543648132 §48131 §48132 §48131 §46138 §46137 §454362/0 [67-70]1490413-6 1490413-6 1490414-3 1490414-3 4543948133 §48131 §48133 §48131 §454393/0 [80-95]1490413-7 1490413-7 1490414-3 1490414-3 4544248134 §48131 §48134 §48131 §454424/0 [100-125]1490413-8 1490413-8 1490414-3 1490414-3 45445300430 §48131 §300430 §48131 §45445250-300 MCM[127-152]48816 69911 48816 69911300-350 MCM[152-177]400 MCM[203]500-600 MCM[253-304]48817 69912 48817 6991248818 69913 48818 6991348819 69914 48819 69914For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe31

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Dies, H<strong>and</strong> Tools <strong>and</strong> Hydraulic HeadsConfiguration OptionsHeavy Duty SOLISTRAND TerminalsHydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureDYNA-CRIMP Tool System8,200 psi Operating PressureWire Sizein AWG [mm 2 ]H<strong>and</strong> Tools(U-Die)Hydraulic Heads(U-Die)H<strong>and</strong> ToolsHydraulic Heads(Shank Die)1490748-1 1490749-11901820-1, 1901821-11490747-1, 1976230-1 59973-1 § 69065 § 69067 §8 [7-8.5]1490413-9 1490413-2 1490413-9 1490414-2 48128-1 §48127-1 §48128-1 §48127-1 §6 [13-15]1-1490413-0 1490414-2 1-1490413-0 1490414-2 48129-1 §48127-1 §48129-1 §48127-1 §4 [21]1-1490413-1 1490414-2 1-1490413-1 1490414-2 48130-1 §48127-1 §48130-1 §48127-1 §2 [34-35]1-1490413-2 1490414-3 1-1490413-2 1490414-3 48132-1 §48131-1 §48132-1 §48131-1 §1/0 [50-60]1-1490413-3 1490414-3 1-1490413-3 1490414-3 48133-1 §48131-1 §48133-1 §48131-1 §SOLISTRAND Flag TerminalsHydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureDYNA-CRIMP Tool System8,200 psi Operating PressureWire Sizein AWG [mm 2 ]H<strong>and</strong> Tools(U-Die)Hydraulic Heads(U-Die)H<strong>and</strong> Tool(Shank Die)Hydraulic Heads(Shank Die)1490749-1 1901821-1, 1976230-1 1752868-1 69067 § 690998 [7-8.5]1752680-8 1752681-2 1752680-8 1752681-2 48506-1 48505-1 48506 §48505 §48506-1 48505-1 6 [13-15]1752680-7 1752681-3 1752680-7 1752681-3 48508-1 48507-1 48508 §48507 §48508-1 48507-1 4 [21]1752680-6 1752681-3 1752680-6 1752681-3 48509-1 48507-1 48509 §48507 §48509-1 48507-1 2 [34-35]1752680-5 1752681-3 1752680-5 1752681-3 48510-1 48507-1 48510 §48507 §48510-1 48507-1 1/0 [50-60]1752680-4 1752681-1 1752680-4 1752681-1 48652-1 48511-1 48652 §48511 §48652-1 48511-1 2/0 [67-70]1752680-3 1752681-1 1752680-3 1752681-1 48805-1 48511-1 48805 §48511 §48805-1 48511-1 3/0 [80-95]1752680-2 1752681-1 1752680-2 1752681-1 48806-1 48511-1 48806 §48511 §48806-1 48511-1 4/0 [100-125]1752680-1 1752681-1 1752680-1 1752681-1 48807-1 48511-1 48807 §48511 §48807-1 48511-1 Stationary DieMoving DieSelf-Contained Die Use Adapter 69760 Use Adapter 69834§These products will bediscontinued32For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Dies, H<strong>and</strong> Tools <strong>and</strong> Hydraulic HeadsConfiguration OptionsAMPOWER Quick Disconnect TerminalsWire Sizein AWG [mm 2 ]Hydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureHydraulic Heads(Shank Die)DYNA-CRIMP Tool System8,200 psi Operating PressureHydraulic Heads(Shank Die)1752868-1 1752786-1 690991/0 [50-60] 68361-1 / 68200-1 68361-1 / 68200-12/0 [67-70] 68253-1 / 68201-1 68253-1 / 68201-13/0 [80-95] 59867-1 59867-1 4/0 [100-125] 68304-1 68304-1 250 MCM [127] 68203-1 68203-1350 MCM [177] 68204-1 68204-1400 MCM [203] 68332-1 68332-1 500 MCM [253] 68206-1 68206-1 600 MCM [304] 46757-3 46757-3With locatorDual CrimpInsulation Piercing Crimp COPALUM Terminals <strong>and</strong> SplicesWire Size in AWG [mm 2 ]Hydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureDYNA-CRIMP Tool System8,200 psi Operating PressureH<strong>and</strong> Tool(U-Die)Hydraulic Head(U-Die)Hydraulic Heads(Shank Die)Hydraulic Heads(Shank Die)Al Cu 1490749-11901821-11976230-11752868-1 1752786-1 69099 690828 [7-8.5] 10 (5-6] 1490714-1 1490714-1 68084 680846 [13-15] 8 [7-8.5] 1490715-1 1490715-1 68085 680854 [21] 6 [13-15] 1490716-1 1490716-1 68086 680862 [34-35] 4 [21] 1490717-1 1490717-1 68130 681301/0 [50-60] 2 [34-35] 1490718-1 1490718-1 68131 681312/0 [67-70] 1/0 [50-60] 68132 681323/0 [80-95] 2/0 [67-70] 68133 681334/0 [100-125] 3/0 [80-95] 318106-1 68129 318106-1 68129For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe33

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Dies, H<strong>and</strong> Tools <strong>and</strong> Hydraulic HeadsConfiguration OptionsAMPOWER Terminals <strong>and</strong> SplicesHydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureDYNA-CRIMP Tool System8,200 psi Operating PressureWire Sizein AWG[mm 2 ]H<strong>and</strong> Tools (U-Die)Hydraulic Heads(U-Die)Hydraulic Heads(Shank Die)H<strong>and</strong>ToolHydraulic Heads(Shank Die)1490748-1 1490749-1 1901820-11490747-11901821-11976230-11752868-1 1752788-1 1752786-1 59973-1 §69065 §69067 §68073-2 69099 58445-1 690826[13-15]4[21]2[34-35]1/0[50-60]2/0[67-70]3/0[80-95]4/0[100-125]250 MCM[127]300 MCM[152]350 MCM[177]400 MCM[203]500 MCM[253]600 MCM[304]1583092-1 1583092-1 1583092-1 1583092-1 69133-1 69133-11583093-1 1583093-1 1583093-1 1583093-1 69134-2 69134-21583094-1 1583094-1 1583094-1 1583094-1 46765-3 46321-3 § 46321-3 § 46765-31583095-1 1583095-1 1583095-1 1583095-1 46766-2 46322-2 § 46322-2 § 46766-21583096-1 1583096-1 1583096-1 1583096-1 46767-2 46323-2 § 46323-2 § 46767-21583097-1 46749-2 46324-2 § 46324-2 § 46749-21583098-1 46750-2 46325-2 § 46325-2 § 46750-246751-2 46326-2 46751-2 46326-246752-2 46752-246753-2 69653 46753-2 6965346754-2 46754-246755-2 46755-246756-2 46756-2600 HD 59870-1 59870-1700 MCM[355]800 MCM[405]900 MCM[456]1000 MCM[507]1250 MCM[634]1500 MCM[761]46757-2 46757-246758-2 46758-246759-2 46759-246760-2 46760-268114-168282-11976230-1 only34For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Dies, H<strong>and</strong> Tools <strong>and</strong> Hydraulic HeadsConfiguration OptionsSealed Crimp COPALUM Terminals <strong>and</strong> SplicesWire Size in AWG [mm 2 ]H<strong>and</strong> Tool(U-Die)Hydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureHydraulic Head(U-Die)Hydraulic Heads(Shank Die)DYNA-CRIMP Tool System8,200 psi Operating PressureHydraulic Heads(Shank Die)Al Cu 1490749-1 1901821-1 1976230-1 1752877-1 1752787-1 69066 58422-18 [7-8.5] 10 (5-6] 1490555-1 1490555-1 68006 68006 68006 680066 [13-15] 8 [7-8.5] 1490556-1 1490556-1 68007 68007 68007 680074 [21] 6 [13-15] 1490557-1 1490557-1 68008 68008 68008 680082 [34-35] 4 [21] 68009 68009 68009 680091/0 [50-60] 2 [34-35] 68010-1 68010-1 68010-1 68010-12/0 [67-70] 1/0 [50-60] 314964-1 68011-1 314964-1 68011-13/0 [80-95] 2/0 [67-70] 59877-1 59877-14/0 [100-125] 3/0 [80-95] 314948-1 314948-1Bar Crimp COPALUM Terminals <strong>and</strong> SplicesWire Size in AWG [mm 2 ]H<strong>and</strong> Tool(U-Die)Hydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureHydraulic Head(U-Die)Hydraulic Heads(Shank Die)DYNA-CRIMP Tool System8,200 psi Operating PressureHydraulic Heads(Shank Die)Al Cu 1490749-11901821-11976230-11752868-1 1752786-1 69099 690828 [7-8.5] 10 [5-6] 1490572-1 1490572-1 68043 680436 [13-15] 8 [7-8.5] 1490573-1 1490573-1 68044 680444 [21] 6 [13-15] 1490574-1 1490574-1 68045 680452 [34-35] 4 [21] 1490575-1 1490575-1 68046 680461/0 [50-60] 2 [34-35] 68047 680472/0 [67-70] 1/0 [50-60] 68048 680483/0 [80-95] 2/0 [67-70] 68049 680494/0 [100-125] 3/0 [80-95] 68050 68050250 MCM [127] 4/0 [100-125] 68034 68034300 MCM [152] 250 MCM [127] 68035 68035400 MCM [203] 300 MCM [152] 68036 68036500 MCM [253] 400 MCM [203] 68037 68037For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe35

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Dies, H<strong>and</strong> Tools <strong>and</strong> Hydraulic HeadsConfiguration OptionsSTRATO-THERM Terminals <strong>and</strong> SplicesWire Size inAWGWire Size inmm 2Hydraulic Crimp <strong>Tooling</strong>10,000 psi Operating PressureHydraulic Head(Shank Die)DYNA-CRIMP Tool System8,200 psi Operating PressureHydraulic Head(Shank Die)1752868-1 690998 7-8.5 69211-1 69211-16 13-15 69212-1 69212-14 21 69213-1 69213-12 34-35 69214-1 69214-11/0 50-60 69215-1 69215-12/0 67-70 69254-1 69254-136For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Hydraulic <strong>Equipment</strong> Options <strong>and</strong> more detailed Informationfor 70,000 kPa / 10,000 psiElectric Hydraulic Pumps, heavy dutyP/N 1804700-2 (220 V)suitable for continuous use Two speed cycle reduces cycle time for improved productivity Footswitch <strong>and</strong> 1.8 meter hose included Pump shuts down after pressure-switch setting is reached Easy to read integrated oil level sight glass Totally enclosed fan-cooled motor - ideal for use in any environment Quiet operation 70-79 dB(A) Swivel wheels provide easy manoeuvrabilityPortable Electric Hydraulic Pump, light dutyP/N 523199-1 (220 V) Lightweight <strong>and</strong> compact design 10 kg Large Carry-h<strong>and</strong>le for easy portability Two speed cycle reduces cycle time for improved productivity 24 V DC remote motor control, 3m length for operator safety Starts under full load High strength moulded shroud Supplied with male quick coupler (no hose supplied)Pressure Gauge options:P/N 523200-1 Pressure GaugeP/N 523200-2 Digital Pressure GaugeP/N 523200-3 1/4" Adapter (required when using either Gauge)Hydraulic Foot Pump, manualP/N 523199-2 Pump action operation Clicker valve pressure regulation Supplied with male quick-couplingHydraulic H<strong>and</strong> Pump, manualP/N 1583661-1This pump action unit allows hyraulic heads via optionallength hydraulic hoses a degree of positional flexibilty.Battery-Hydraulic Tool Kit 12 t 'U' DieP/N 1213875-2Kit Includes: Complete Kit with Crimp ToolEU Power Plug Battery Charger 220 V Suitable for all 'U' Dies (PN 1213873-2)with the exception of Rechargeable Battery'U' Die Assy (14 t) (PN 1213872-1) Rotating Head 320° Carry Case with strap Excellent powerto weight ratio circa 10,000 Cycles3-WayMultidirectional ValveP/N 1901782-1 (Manual)P/N 1901783-1 (Electric)For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe37

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.7 Insertion <strong>and</strong> Extraction ToolsInsert discrete terminals into connector housings orremove them, without causing damage to either theterminal, housing or yourself.To reference the relevant tool(s) to your Terminal P/Nplease visitwww.tooling.tycoelectronics.com/europe/H<strong>and</strong>tools.asp38For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.8 H<strong>and</strong> Tool Control GaugesTo reference the relevant gauge(s) to your H<strong>and</strong> Tool Gauges are available for most closed barrel crimp toolsplease visitfor regular wear checks.www.tooling.tycoelectronics.com/europe/H<strong>and</strong>tools.asp However, factory recalibration is recommended every6 months or 5,000 cycles. See section 1.9For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe39

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>1.9 Service <strong>and</strong> CalibrationMost premium tools <strong>and</strong> some commercial tools canbe economically serviced <strong>and</strong> repaired. Our toolingService Centres hold spares for all commonly usedtools along with the specialist equipment <strong>and</strong> skillsrequired to re-calibrate after repair.Tyco Electronics recommends that for h<strong>and</strong> tools acalibration check is carried out every 6 months orevery 5,000 crimp cycles, whichever the sooner.We calibrate <strong>and</strong> provide certificates for the followingTyco Electronics / AMP equipment: Premium tools complete Interchangeable dies (independent of the optionalequipment they are used in) Any equipment that has measurable parameters.We will be pleased to quote for any of the aboveoptions or to service all other types of equipment.Only Tyco Electronics authorised Service Centreslisted below have the necessary access to engineeringdrawings <strong>and</strong> specialised equipment required for ourrepair <strong>and</strong> calibration processes.Tyco Electronics uses crimp height as the primarymeasure of crimp quality integrity, <strong>and</strong> does notrecognize pull-off values alone as a measure.If you would like more information on this subject,why not get in touch with your Country Contact whowill be happy to arrange a visit to present explanatoryinformationwww.tooling.tycoelectronics.com/europe/Contact.aspApproved Service CentreTyco Electronics AMP GmbHReparatur ServiceAmpèrestr. 7-1163225 LangenGermanyTel +49 (0)6103 709 1534Fax +49 (0)6103 709 3076email gherzog@tycoelectronics.com40For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>2 Wire Processing <strong>Equipment</strong>2.1 Stripping MachinesAVG 0160 Cable Strip <strong>and</strong> Twist MachineThe AVG 0160 is a stripping <strong>and</strong> twisting machine for wires withinsulation such as PVC, TEFLON, Silicon, Fiberglass, Rubber etc.The machine can cover a wire size range from 0.03 mm 2 up to 6 mm 2with an adjustable stripping length from 0.5 mm up to 29 mm.The machine utilizes rotary stripping blades for a smooth, 360°cutting of the insulation.P/N 1481003-1JacketStrip 8400 Jacket Stripping MachineThe JacketStrip 8400 enables automatic jacket stripping of round cablesup to 26 mm in diameter <strong>and</strong> a stripping length of 200 mm. After thecable jacket has been cut, the piece of insulation is removed using a strongelectric motor (full/partial or window strip can be selected).Pneumatically operated clamping jaws guarantee optimal cable retentionduring the stripping process. All functions of the machine are electronicallymonitored <strong>and</strong> diagnosed by means of a LCD display.P/N 1-528453-7UniStrip 2015/2100 Stripping MachinesThe pneumatically operated stripping machine UniStrip 2015 primarilyprocesses str<strong>and</strong>ed wires <strong>and</strong> single wires. Due to the minimal distancebetween the acryl safety cover <strong>and</strong> the stripping blades, this machinecan perform stripping on extreme short cables.The UniStrip 2100 is an electrically driven stripping machine.Ease of operation, fast cycle times, a powerful yet silent motor drive aswell as a vast cable processing range are the main features of this machine.UniStrip 2015 P/N 1-528453-0UniStrip 2100 P/N 528453-8UniStrip 2500 Stripping MachineThis pneumatically driven stripping machine comes st<strong>and</strong>ard withV-blades, with no blade changeover necessary. Through the use ofspecial blades, the range of applications can be exp<strong>and</strong>ed to include flatribbon cable, double-str<strong>and</strong>ed wire, thin multistr<strong>and</strong>ed wire or dem<strong>and</strong>ingisolations. The adjustable way-back prevents the conductor frombeing damaged during the stripping process.P/N 528453-7CoaxStrip 5300 - Programmable Coaxial Cable Stripping MachineThe Coax Strip 5300 is a semi-automatic, programmable multi-stepstripping machine for coaxial, triaxial, multi-conductor cable <strong>and</strong> singleconductor wire.This benchtop unit can easily process coaxial <strong>and</strong> triaxial cables up to7 mm (0.276”) outer diameter <strong>and</strong> strips lengths up to 30 mm (1.18”).PN 1-528453-5TEFLON is a trademark of E.I. duPont deNemours <strong>and</strong> Co.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe41

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>2.2 Cutting <strong>and</strong> Stripping MachinesThe Kappa family strippers are ideal for cutting individual <strong>and</strong> special wires to length <strong>and</strong> stripping them.They can strip in sections, allowing them to strip even extremely long length in perfect quality. The machinescover an extraordinarily broad range of cross sections.Kappa 310, 320, 321, 330 <strong>and</strong> 350 strippers support a variety of processing options such as wire markingwith hot-stamp or ink jet markers.Hot stamp marking can even be done on the Kappa 310 stripper, the entry-level model.New KAPPA Generation: Dynamic, flexible cutting<strong>and</strong> stripping unit New intelligent sensors New electronic <strong>and</strong> software Optional TOPWIN softwareKAPPA 350 MachineKAPPA 330 MachineKAPPA, KAPPAWIN <strong>and</strong> TOPWIN are trademarks of KOMAX AG.42For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>2.3 4/8 Indent Stripper Crimper with Touch Sensor SystemFast Facts• Modular open design• Fast <strong>and</strong> simple tool kit changes• Fast changeover times• Variety of tool kits• Touch sensor system• Wire sizes from 0.14 - 2.5 mm• Insulation diameter0.35 - 2.5 mm• Jacket strip length 30 mm• Strip length 2.0 - 10 mm• Electric power supply:115 V / 230 V• Compressed air: 500-700 kPa• Cycle time: 2.5 seconds• Weight: Approx. 60 kg• Dimensions machine [mm]W x H x D = 530 x 620 x 800The machine is suitable for stripping<strong>and</strong> crimping loose piececontacts to accepted MIL specificationswith 4/8 indent crimpform.The machine feeds, sorts <strong>and</strong>separates the contacts prior tothe stripping an crimping process.A variety of contact specific toolkits is available or can be createdto suit almost all screw machinedcontacts.The machine is easy to operate<strong>and</strong> can be changed from onecontact to another quickly <strong>and</strong>easily.The touch sensor is a safety systemdesigned to monitor when thestripping blades contact the conductorduring insulation stripping.If the blades make contact withthe conductor then the machinewill not crimp the contact.The system allows for partial or fullmonitoring or can be turned offcompletely.The touch sensor system is particularlyuseful when stripping wireswhere a non-contact situationis required.Application specific equipment:Please address your request toyour local Tyco Electronics representative.The relevant GATD contact can befound on the website below.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe43

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>2.4 AM03 Universal Stripper CrimperFast Facts• Stripping range 0.14-2.50 mm 2[AWG 26-14]• Special version up to 4 mm 2• Programmable adjustment forstripping <strong>and</strong> crimping depth• Data memory 50 programs• Rapid <strong>and</strong> reliable crimpingprocess• Insertion wire length:min. 32 mm• Drive: Electro-pneumatic• Electrical connection:230 V, 50 Hz, 120 VA• Pneumatic connection:550 kPa (5.5 bar)• Dimensions [mm]WxDxH = 500x500x460• Weight: 40 kgThe AM03 Universal StripperCrimper processes loose pieceturned male <strong>and</strong> female pin contacts.As st<strong>and</strong>ard the machine uses the4/8 ident crimp corresponding toMIL 22520/1-01.The adjustment of the stripping<strong>and</strong> crimping depth is motorised.Different values for up to 50 programscan be memorised.Adjustment <strong>and</strong> programmingcan be made though the keyboard.The LCD display shows all importantdata, functions <strong>and</strong> errors.The machine can also be convertedfor different contacts by usingspecific tool kits.All tools are quick <strong>and</strong> easilyexchangeable.Machine Components Basic machine Oscillating conveyor Tool unit equipped with4/8 ident crimping dies Motorised adjustment unit forstripping <strong>and</strong> crimping Stripping unit with V-knifes Contact specific toolingfeeding tube Singling unit Contact holder Contact stopper Wire centraliserA crimp quality monitoring systemis available as an option.AM03 Basic Machinewithout KitsPN 0528375-844For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>2.5 Crimp Quality Control <strong>Equipment</strong>Micrograph LaboratoryFeatures Quick process flow of 5 to 10 minutes No cross section potting Evaluation according to DIN <strong>and</strong> different electrical <strong>and</strong> physical parameters PC specific software for micrograph evaluationThe micrograph laboratory is designed for Tyco Electronics crimp terminalsystems but is not restricted to them.With a modified sample holder, cross sections of competitors products arealso possible.The flexibility of the CSL allows cross sections of a variety of crimp terminals.Better than conventional processes the new cutting method makes potting<strong>and</strong> long drying times a thing of the past. So processing time can bereduced dramatically.For special requirements an optional impregnation module is available. With itthe cutting area can be lightly fixed.If you need more detailed information please contact your local representative.The relevant contact can be found on the website below.Our GATD team will be very pleased to assist you.PN X-528000-XFor more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe45

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>Portable Micrograph Laboratoryfor Crimp Terminal SystemsFeatures Compact, easy to operate Optional electrolyte Etching module Easy fixation station for sampleholder Secure mechanism for Optic duringtransportation 1.3 Mpixels USB 2.0 Camera withSL Vision II Evaluation <strong>and</strong>Documentation moduleThe flexibility of the CSL allowscross sections of a variety of crimpterminals.Nowadays quick <strong>and</strong> significantprocess monitoring gains increasingimportance as a competitive factor.The CSL brings you a decisiveadvantage in order to evaluate thequality of your crimp connectionssimply <strong>and</strong> safely, fast <strong>and</strong> economicallypriced.The Micrograph Laboratory isdesigned for Tyco Electronics crimpterminal systems but is notrestricted to them.With a modified sample holder,cross sections of competitors productsare also possible.Due to the mobility you can use theCSL everywhere. Thereby you areable to decide on the release forproduction, e.g. after a tool change,in best time <strong>and</strong> on site. You willloose less of your value scoopingproduction time.PN 1-528000-246For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe

<strong>Aerospace</strong> <strong>Tooling</strong> <strong>and</strong> <strong>Equipment</strong>3 Test <strong>Equipment</strong>3.1 High Voltage Test <strong>Equipment</strong>Tyco Electronics offers a comprehensive range of automatic testequipment for wiring harnesses <strong>and</strong> associated systems.Overall maintenance procedures require a 100% electrical inspectionby means of high voltage testing.The automatic test equipment provides up to 500,000 test points in2-wire or 4-wire Kelvin measurement.Capability ranges from a simple harness to the most complex highdensity back planes can be analyzed in an unrivaled accuracy, quality<strong>and</strong> reliability.19” Rack Based SystemSt<strong>and</strong>ard test systems are built into19” cabinets with test point numbersvarying from 32 to over 500,000.Test voltages can range from 10 V DCto 25 kV DC.AC voltages are optional upon request.19” racks can also be built asmoveable units.Portable SystemEspecially for harsh environments, Tyco Electronicsoffers portable systems in ruggedized, waterproofcases.Systems come completely with PC <strong>and</strong> ticket printer.The test voltage of 500 V DC can be supplementedwith 250 V AC.Remote ControlPOCKETMEGWhen it comes to planning a testenvironment, hooking-up a largeunit under test or when troubleshootingon larger applicationsneeds to be performed, theoperator will benefit frombeing able to move around theapplication while at the same timehaving full control over the test software.Using WiFi communication <strong>and</strong> data transfer protocol,POCKETMEG wireless PDA offers full remote control<strong>and</strong> operator interaction with the automatic test system.The operator can move around the unit under test, withPOCKETMEG wireless PDA in h<strong>and</strong>, while receiving testprogress information, test results <strong>and</strong> pictorial guides <strong>and</strong>instructions. Productivity <strong>and</strong> test speed can be drasticallyimproved.MK <strong>and</strong> POCKETMEG are trademarks of MK Test Systems, Ltd.For more detailed information please visit our websitewww.tooling.tycoelectronics.com/europe47