Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

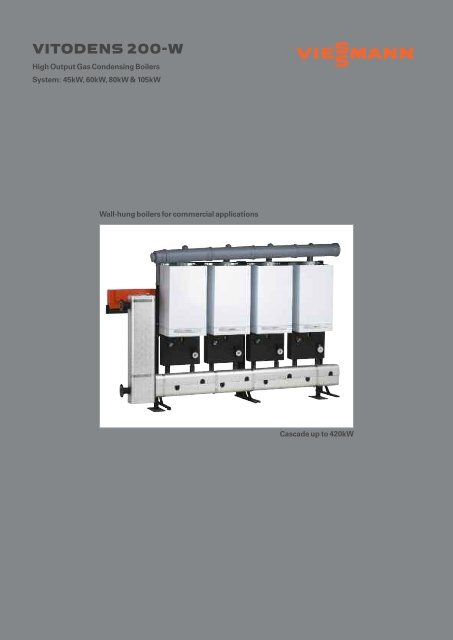

VITODENS <strong>200</strong>-WHigh Output Gas Condensing BoilersSystem: 45kW, 60kW, 80kW & 105kWWall-hung boilers for commercial applicationsCascade up to 420kW

VITODENS <strong>200</strong>-WHigh output gas fired system boilers forcommercial applications.45kW, 60kW, 80kW, 105kW. Cascade up to 420kWThe<strong>Vitodens</strong> <strong>200</strong>-W high specification boiler is one of themost efficient and quietest condensing boilers in this sector.It is now available for commercial applications of up to420kW – good news if access is difficult, floor space islimited, if you prefer the reassurance of having more than oneboiler running as a back-up - or if you want all the features ofthis great wall-hung gas condensing boiler2, 3 or 4 boilers can be cascaded in various configurations,giving a maximum output of 420kW. Simply tell us yourrequired output and we can supply all the components youneed for the best cascade combination for your project – seepage 5.KEY FEATURES:Gross efficiency up to 98%NOx credit rating 4 (

VITODENS <strong>200</strong>-WFeaturing<strong>Viessmann</strong>’s unique energymanagement systemIntelligent Lambda Pro gas management system foroptimum efficiency and performanceThe Lambda Pro is designed to work efficiently irrespectiveof gas quality – a factor which will become increasinglyimportant as international gas supplies become less reliable.The Lambda Pro combustion controller works alongside theburner to constantly monitor the air to gas ratio. Instead ofthe gas/air mix remaining fixed from commissioning, the mixis self adjusting as required, to maintain optimum boilerefficiency in relation to the gas quantity – in a similar way tothe fuel management system in a car engine.The control also replaces the traditional gas valve control andchanging to LPG takes just a few seconds – with no changingof any parts.Modulating MatriX pre-mix burnerDeveloped by<strong>Viessmann</strong>, the stainless steel MatriX pre-mixburner burns with thousands of tiny flames instead of onelarge one, to distribute heat cleanly and efficiently to the heatexchanger.With a modulation range of 1:4 the heat demand is optimisedand maximum efficiency levels are achieved.The extremelylow NOx and CO emissions meet or exceed all national cleanair regulations and guidelines.The stainless steel MatriX mesh ensures long term reliability.Inox Radial heat exchangerAs with all<strong>Viessmann</strong> wall-hung boilers, the<strong>Vitodens</strong> <strong>200</strong>-Wfeatures<strong>Viessmann</strong>’s unique stainless steel heat exchanger,designed for long term reliability, high performance and selfcleaning.The design of the heat exchanger ensures high heat transferthrough laminar hot gas flow across defined gaps. Highcorrosion resistance is maintained by the use of high gradestainless steel 1.4571 and thick walls.This component is soreliable that it comes with a 10YEARWARRANTY againstcorrosion.Advanced controlsThe<strong>Vitodens</strong> <strong>200</strong>-W is loaded with features and functions tomake installation, maintenance and servicing easy.Theseinclude in-built software for remote data communication andmonitoring, additional heating circuits, a solar/heat pumpinterface, safety monitor sensors and automaticcommissioning functions.Weather compensation controlsThe<strong>Vitodens</strong> <strong>200</strong>-W is available with optional weathercompensation controls (theVitotronic <strong>200</strong>). Constant, smalladjustments in the boiler flow temperature, in response tochanges in the outside temperature, enable the boiler to runcost effectively and efficiently at lower temperatures,condensing for longer.This results in additional fuel savingsof up to 15%.3

VITODENS <strong>200</strong>-WTechnical SpecificationGeneral Specifications and Performance Data<strong>Vitodens</strong> <strong>200</strong>-WWB2BAppliance 17 - 45kW 17 - 60kW 19 - 80kW 19 - 105kWModeUnitDimensions/ConnectionsBoiler dimensions - H xW x D mm 850 x 480 x 360 850 x 480 x 530CH flow & return G 1 1 / 2 Ø 42mmCylinder flow and return G 1 1 / 2Condensate20 - 24mmGas R 1"Rated Central Heating OutputAtTf/Tr 50/30°C (condensing) kW 17.0 - 45.0 17.0 - 60.0 30.0 - 80.0 30.0 - 105.0AtTf/Tr 80/60°C (non-condensing) kW 15.4 - 40.7 15.4 - 54.4 27.0 - 72.6 27.0 - 95.6Rated Central Heating Input (net) kW 16.1 - 42.2 16.1 - 56.2 28.1 - 75.0 28.1 - 98.5Rated Central Heating Input (gross) kW 17.9 - 46.8 17.9 - 62.4 31.2 - 83.2 31.2 - 109.3Max. gas rate NG m 3 /h 4.47 5.95 7.94 10.42Max. gas rate LPG m 3 /h 3.3 4.39 n/a n/aEfficiency @ full load (80/60°C) % 86.8 86.8 86.8 86.8Efficiency @ part load (50/30°C) % 96.7 96.7 96.8 96.8Seasonal Efficiency accordance to Part L2 % 97.5NOx (at 0% air) mg/kWh < 39CO mg/kWh < 50CH performanceMinimum CH system pressure - cold bar 1Maximum CH system pressure - hot bar 4CH flow temperature range °C 30 - 75 (80*)General specificationTotal water capacity ltr 7 7 12.8 12.8Lift weight kg 65 65 83 83Total weight (incl. packaging) kg 68 68 86 86Electricity supply230v, 50HzInternal fuse A 6Maximum power consumption W 30 50 105 150Water protection ratingIP x 4DAvailable flue pressure Pa 100Inner flue duct diameter mm 80 100Outer flue duct diameter mm 125 150Product ID CE-0085 BR 0432* Optional coding plug required to increase flow temperature to 80°C4

VITODENS <strong>200</strong>-W45kW & 60kW DimensionsBoiler Dimensions80kW & 105kW Dimensions5

VITODENS <strong>200</strong>-WCascade PackagesThe<strong>Vitodens</strong> <strong>200</strong>-W can be cascaded with 2, 3 or 4 units,offering outputs up to 420kW.<strong>Viessmann</strong>’s comprehensivecascade packages are designed for easy installation on allapplications.Components of cascade unit packs<strong>Vitodens</strong> <strong>200</strong>-W45kW, 60kW, 80kW or 105kW(one output type only)SeparateAccessoriesFlue gas cascade &boiler coding card(higher speed fan)Cascade controllerWall mounted or selfsupporting mountingframe (for freestandinginstallation)Cascade units comprising:distributor /headerlow loss headerinsulationHeating circuit connectionset up with stepped pumpsInsulated copper pipes<strong>Vitodens</strong> <strong>200</strong> Cascade PackagesEach package comprises the boiler,Vitotronic controller, pump, connection sets and low loss header with cascade pipework.Overall Dims. in mm Overall Dims. in mmRequired output Combination 45kW 60kW 80kW 105kW (H xW x D) Inc. Frame Quad Block (H xW x D)90 2 x 45kW X X 1876 x 1610 x 675120 2 x 60kW X X 1876 x 1610 x 675135 3 x 45kW X X X 1905 x 2270 x 675160 2 x 80kW X X 1876 x 1700 x 675180 4 x 45kW - - - - 1876 x 1585 x 8433 x 60kW X X X 1905 x 2270 x 675210 2 x 105kW X X 1876 x 1700 x 675240 4 x 60kW - - - - 1876 x 1585 x 8433 x 80kW X X X 1905 x 2395 x 675315 4 x 80kW X X X X 1876 x 1765 x 12803 x 105kW - - -420 4 x 105kW X X X X 1934 x 2960 x 675 1876 x 1765 x 1280X Number of boilers per cascade- - - - Not part of standard deliveryCascade installation can be wall mounted or free standing on a purpose built framework. Flue items should be ordered asseparate accessories, as required.6

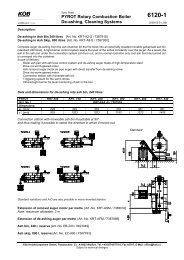

VITODENS <strong>200</strong>-WPre-installation, multi boiler systemHydraulic cascade for wall mountingand installation on self-supportingframes. Flow and return collectors withlow loss header for multi-boilersystems of 2 to 4<strong>Vitodens</strong> boilers inseries or 4 boilers arranged as a block.Heating circuit connections either onthe right or left.Boiler Number 2x45kW 2x80kW 3x45kW 3x80kW 4x105kW (2x2) 45kW * 1 (2x2) 80kW * 12x60kW 2x105kW 3x60kW 3x105kW (2x2) 60kW * 1 (2x2) 105kW * 1Heating Circuit R 2” – – – – – –Connection PN6/DN – 65 65 100 100 65 100Boiler Connection G 1 1 /4” 2” 1 1 /4” 2” 2” 1 1 /4” 2”Max. flow rate m 3 /h 6.9 12.1 10.3 18.1 24.1 13.8 24.1Dimensions a mm 970 1320 1320 1340 1340 1302 1340b mm 845 1250 1250 1260 1260 1250 1260c mm 295 250 250 260 260 250 260d mm 100 150 150 150 150 150 150e mm 160 <strong>200</strong> <strong>200</strong> 280 280 <strong>200</strong> 280f mm 230 210 210 190 190 210 190g mm 1560 1640 2220 2335 2900 1585 1765h mm 120 160 160 <strong>200</strong> <strong>200</strong> 160 <strong>200</strong>k mm 350 370 370 390 390 370 390l mm 80 80 80 120 120 80 120*1 Cascade supplied as a block in a back to back boiler arrangement7

VITODENS <strong>200</strong>-WMaximum Flue LengthsSingle boiler installationsOutput Flue Balanced Flue Max. flue length in mDiameter Diametermm mm Duct Roof Ext.Wall Routing over Duct balancedopen flue outlet terminal ext. wall flue45kW 80 25Open flued60kW 80 1580kW 100 20105kW 100 2045kW 80/125 10 10 12 20Concentric60kW 80/125 6 6 12 1580kW 100/150 15 15 20 20105kW 100/150 15 15 20 20Cascaded installationsFlue gas cascade type – each kit comprising:Flue gas non-return device, flue pipe, terminalwith condensate drain & boiler coding card.45 - 60kW 80 - 105kWDiameter Max.flue length Diameter Max. flue lengthFlue gas 125 12m 150 20mcascade twinFlue gas cascade triple 125 12m 150 20mFlue gas cascade triple 150 20m <strong>200</strong> 25mFlue gas cascade quad – – <strong>200</strong> 20m(only for 105kW)Flue gas cascade quad block 150 15m <strong>200</strong> 20m8

VITODENS <strong>200</strong>-WBoiler ControlsCascade controls (Vitotronic 300-K)TheVitotronic 300-K weather compensated cascadecontroller can regulate up to four<strong>Vitodens</strong> <strong>200</strong>-W boilers as asingle heating centre. By communicating with the individualboiler controls, theVitotronic 300-K ensures that the boileroutput is automatically matched to the heat demand. As aresult, subject to the demand, either one boiler modulates orall four boilers operate concurrently.FUNCTIONS:Weather compensated regulation of system/boiler watertemperature of a multi boiler system with up to 4<strong>Vitodens</strong> <strong>200</strong>-W withVitotronic100, type HC1(modulating temperature) and the flow temperature ofthe heating circuits with mixerControl of theVitotronic 100, type HC1 of the boilers inaccordance with a boiler sequence strategy (can be freelyselected)Electronic maximum temperature limiterDemand-dependent heating circuit pump shut downAdjustment of a variable heating limitAnti-seizing pump protectionCentral fault messageIntegral diagnostic systemAdaptive cylinder thermostat with priority control(heating circuit pump OFF, mixer closed)Screed drying, for underfloor heating systemsBoiler controlsRoom temperature-dependent and remote control units Vitotronic 100 Vitotronic <strong>200</strong>(constant(Weathertemperature) compensation)Vitotrol <strong>200</strong> remote controller – 7450 017to adjust one heating circuit for• Day temperature and heating program• with party and economy keys• with room temperature sensor for room temperature hook-up (only for heating circuit with mixer)ifVitotrol <strong>200</strong> is used for room temperature hook-up, locate the devicein a main living space (lead room)Vitotrol 300 remote controller – 7248 907to adjust one heating circuit for• Day and night temperature, DHW temperature, heatingand holiday program plus party and economy keys• Switching times for one heating circuit, DHW cylinder and DHW circulation pump• with illuminated display and plain text support• with room temperature sensor for room temperature hook-up (only for heating circuit with mixer)ifVitotrol 300 is used for room temperature hook-up, locate the devicein a main living space (lead room)Room temperature sensor (as additionalVitotrol) – 7408 012if theVitotrol <strong>200</strong> or 300 cannot be located in a suitable positionto capture the room temperature9

VITODENS <strong>200</strong>-WBoilerAccessories & ControlsBoiler accessories (contd.)Heating circuit and DHW cylinder (only for single boiler 45 and 60kW)Part NumberConnection set for heating circuit without circulation pump - comprising: 7245 738• Tee with ball valve• Fill & drain valve• Safety valve• Straight-through gas valve with integral thermally activated safety shut off valveSpare pump plug set (3 pieces) for the use of third party pumps has to be ordered separately 7415 057Connection set for heating circuit with circulation pump - comprising:• Tee with ball valve• Check valve• Fill & drain valve• Built-in non return valve• Thermal insulation• Straight-through gas valve with integral thermally activated safety shut off valve• Safety valveand• Circulation pump (3-stage),Wilo typeVIRS-25/7 BUS 3 7247 341or• Circulation pump (variable speed),Wilo typeVIRS-25/7 BUS 7247 374Connection set for DHW cylinder - comprising: Z006 183• Ball valve• Check valve• Built-in non return valve• Cylinder primary pump,Wilo, typeVIRS-25/6-3• Cylinder temperature sensor (3.75m long)For integration into thermal insulation of connection set for heating circuit with circulation pumpBall valve (G 1 1 /4”)Required if the heating circuit pump or the cylinder primary pump is to be installed without draining the heating system 7247 373Heating circuit and DHW cylinder (only for single boiler 80 and 105kW)Part NumberConnection set for heating circuit with circulation pump and low loss header - comprising: Z006 144• Tee with ball valve• Check valve• Fill & drain valve• Safety valve• Straight-through gas valve with integral thermally activated safety shut off valve• Ball valve (2 pce)• Circulation pump (3-stage),Wilo typeVIRS-25/10-3 BUS• Low loss header• Thermal insulation (connection set and low loss header)• Immersion temperature sensor for the low loss headerBrackets for low loss header(order separately)• for floor mounting 7346 787• for wall mounting 7346 788Connection set for DHW cylinder - comprising: 7348 934• Cylinder flow and return• Fittings G 1 1 /4”• Cylinder temperature sensor10

VITODENS <strong>200</strong>-WBoilerAccessories & ControlsAccessories (contd)Heating circuit – Modular-DiviconPump versionsModular-Divicon Heating Distributor with manually regulated differential pressure regulatedHeating circuit pump with check valve, fully wired2 ball valves with thermometer Wilo Wilo Grundfos Grundfos Wilo Grundfos GrundfosThermal insulation (4-3) (6-3) (UPS-40) (UPS60) (E/1-5) (Alpha+ 40) (Alpha+ 60)with mixer-3R 3 /4” Z000 716 Z000 717 Z000 712 Z000 713 Z000 719 Z000 714 Z000 715with mixer-3R 1” Z000 732 Z000 733 Z000 728 Z000 729 Z000 735 Z000 730 Z000 731Bypass valvefor Modular-Divicon 9557 011without mixerR 3 /4” Z000 724 Z000 725 Z000 720 Z000 721 Z000 727 Z000 722 Z000 723without mixerR 1” Z000 740 Z000 741 Z000 736 Z000 737 Z000 743 Z000 738 Z000 739Modular-DiviconWall Mounting (individual)1 per Modular-Divicon 7174 886NOTE: Actuator for mixer to be ordered separately - see price guideHeating circuit - Modular DiviconPart NumberManifold for 2 Modular Divicon – wall mounted 7147 860with thermal insulation (black)(wall mounting to be ordered separately) (also order 7147 887)Manifold for 3 Modular Divicon – wall mounted 7147 861with thermal insulation (black)(wall mounting to be ordered separately) (also order 7147 887)Low loss headerVolume flow up to 4.5m 3 /h 7148 100connection to the manifoldswith thermal insulation (black)with integral sensor well 50mm longfor<strong>Vitodens</strong> <strong>200</strong>-W with 45 and 60kW (also order 7179 448)Immersion temperature sensor 7179 448for measuring the temperature in the low loss headerfor<strong>Vitodens</strong> <strong>200</strong>-W with 45 and 60kW (for multi boilersystems withVitotronic 300-K and<strong>Vitodens</strong> <strong>200</strong>-Wwith 80 and 105kW in the heating circuit set connection set standard delivery)DHW heating (only for single boiler)Part NumberCylinder temperature sensor 7179 114for measuring the DHW temperature (3.75m long), with part no. Z006 183 and 7348 934 in standard deliverySensor well (for cylinder temperature sensor) 7819 693Part of the standard delivery for<strong>Viessmann</strong> DHW cylinders11

A leading manufacturer of heating equipment since 1917, <strong>Viessmann</strong>is at the forefront of heating and renewable energy technology.<strong>Viessmann</strong> has 12 production plants, subsidiaries in 34 countries anda turnover of €1.4 billion, yet remains a family owned company, with aflexible, responsive corporate structure and a strong commitment tothe future.With an international reputation for quality products and installations,<strong>Viessmann</strong> is a name to be trusted for reliability, performance andcustomer support.To find out more about<strong>Viessmann</strong> and to download brochures andtechnical documents please visit www.viessmann.co.ukHortonwood 30TelfordShropshireTF1 7YPUnited Kingdom+44 (0) 1952 675000 – Switchboard+44 (0) 1952 675040 – Fax+44 (0) 1952 675010 – Domestic sales+44 (0) 1952 675090 – Commercial Sales+44 (0) 1952 675060 – Customer Service - Commissioning/Breakdowns+44 (0) 1952 675070 – InstallerTechnical Advicewww.viessmann.co.uk02/09/1