Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

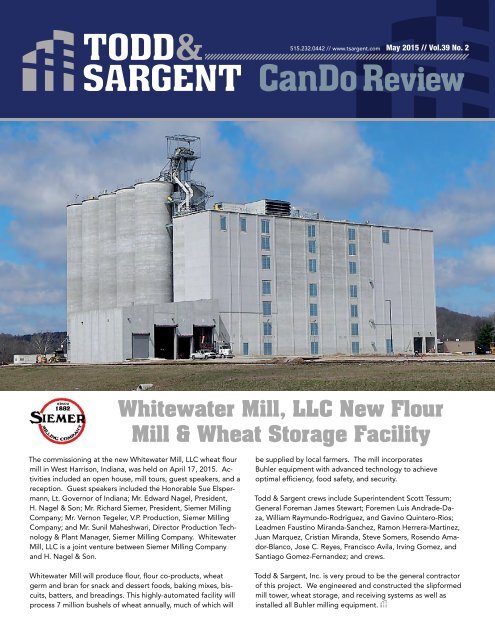

515.232.0442 // www.tsargent.com May <strong>2015</strong> // Vol.39 No. 2CanDo ReviewWhitewater Mill, LLC New FlourMill & Wheat Storage FacilityThe commissioning at the new Whitewater Mill, LLC wheat flourmill in West Harrison, Indiana, was held on April 17, <strong>2015</strong>. Activitiesincluded an open house, mill tours, guest speakers, and areception. Guest speakers included the Honorable Sue Elspermann,Lt. Governor of Indiana; Mr. Edward Nagel, President,H. Nagel & Son; Mr. Richard Siemer, President, Siemer MillingCompany; Mr. Vernon Tegeler, V.P. Production, Siemer MillingCompany; and Mr. Sunil Maheshwari, Director Production Technology& Plant Manager, Siemer Milling Company. WhitewaterMill, LLC is a joint venture between Siemer Milling Companyand H. Nagel & Son.Whitewater Mill will produce flour, flour co-products, wheatgerm and bran for snack and dessert foods, baking mixes, biscuits,batters, and breadings. This highly-automated facility willprocess 7 million bushels of wheat annually, much of which willbe supplied by local farmers. The mill incorporatesBuhler equipment with advanced technology to achieveoptimal efficiency, food safety, and security.Todd & Sargent crews include Superintendent Scott Tessum;General Foreman James Stewart; Foremen Luis Andrade-Daza,William Raymundo-Rodriguez, and Gavino Quintero-Rios;Leadmen Faustino Miranda-Sanchez, Ramon Herrera-Martinez,Juan Marquez, Cristian Miranda, Steve Somers, Rosendo Amador-Blanco,Jose C. Reyes, Francisco Avila, Irving Gomez, andSantiago Gomez-Fernandez; and crews.Todd & Sargent, Inc. is very proud to be the general contractorof this project. We engineered and constructed the slipformedmill tower, wheat storage, and receiving systems as well asinstalled all Buhler milling equipment.

NOTES FROMLEEI would like to take this opportunity tocongratulate and extend best wishesto Gerald Luedtke, Darrel Bobzien, andEd Jones on their recent retirementfrom Todd & Sargent. Gerald Luedtke,Design Development, retired in Januaryafter 28 years of service. Darrel Bobzien,Field Superintendent, retired inMarch after 44 years. Ed Jones retiredin April after 33 years. Thank you allfor the many years of service and hardwork. All of us at Todd & Sargent wishyou the very best on your retirement.<strong>2015</strong> Superintendents’Meeting Held in AmesTodd & Sargent held its <strong>2015</strong> Superintendents’ Meeting on March 12 and 13 at thehome office in Ames, Iowa. All superintendents were in attendance. The two-dayseminar consisted of presentations and group discussions that included input fromall the different departments of the company. Robby Shell was selected as the 2014Superintendent of the Year. He received a trophy and cash. Also during this timeEpifanio Gudino was promoted to Superintendent.Todd & Sargent Superintendents (left to right): Scott Tessum, Dennis Taggart, RussShady, Mike Taggart, James Beck, Randy Durby, Epifanio Gudino, Randy Hullinger, RobbyShell, and Ralph Shank.Gerald LuedtkeTodd & SargentPresident BillBokhovencongratulatesRobby Shell onbeing the 2014Superintendent ofthe Year. Robby wasthe Todd & SargentSuperintendent atthe Superior East,LLC project in Aurora,Nebraska, and iscurrently at HeartlandCoop in Fairfield,Iowa.Darrel BobzienTodd & SargentProject Manager PatTaggart congratulatesEpifanio Gudinoon his promotionto Superintendent.Epifanio was theGeneral Foremanat the Cobbfeedmill in Albany,Kentucky, prior to hispromotion.Ed Jones2 // tsargent.com

PROJECT >WHITEWATER MILL,LLC// LOCATION >WEST HARRISON, INThe new Whitewater Mill officesat front left, 1 million bushelwheat storage at back right, and 10,000CWT soft wheat flour mill at back left.The truck probe and packaging warehouseat front right of picture.The second floor of flour millwhich houses the Buhler rollermills.There are a total of 23 rollermills,incorporating both single high anddouble high units.The fifth floor ofthe flour mill thathouses the Buhlersifters. There arefour Buhler ModelMPAK-1026 siftersand one BuhlerModel MPAK-426sifter.T&SANNIVERSARIESMAY // JUNEJULY // AUGUST50 Years44 Darrel Bobzien43 Russ Long42 Russ Shady40 Years40 Randy Durby39 Paul Noelck, Mike Baumhover32 Pat Taggart30 Years30 Rick Knoll, Jim Marshek29 Dale Mittlieder, Robby Shell,Everett Shaw27 Vickie Ayers, Bill Bokhoven26 Scott Tessum21 Dean Petersen, Stephanie Taylor20 Years20 Epifanio Gudino, Mike Evans19 Scott Schoba17 Doris Wheelock13 Josh Schneider12 Craig Sondgeroth11 David Ramirez10 Years10 Kyle Greenwood, Ryan Rock, KevinBaumhover, James Stewart9 Mark Schemmel6 Anibal Fuentes-Cartagena5 Years5 Wayne Henderson, EduardoAlamillo, V. John Deppe, Juan Ruiz-Cano, Elvin Barrera3 Alicia Cifuentes-Perez, Jose OGarcia, Rolando Soriano, DavidGravlin, Jose Arias, Fidel Perez-Escobar, Leonardo Gamez, BainAcosta-Martinez, Manuel Figueroa,Rodolfo Rodriquez-Castillo2 Jessica Taggart, Justin Cooper1 Luis Hernandez, Jesus Reyes-Gonzalez, Cruz Hernandez-Puentes, Noe Romero, BrodyCarlberg, Rick Grunig, OmarFranco, Bill Eichinger, Ariel Rios-Ruiz, Martin Gudino-Maqueda,Merlin Lopez-Nunez, MarcosMontes-PenaCanDo Review // 3

CONGRATULATIONSTO THE FOLLOWINGBIRTHSCongratulations to Jim Marshek(T&S Engineering) and wife Sue onthe birth of their grandson, ZayneSchmidt, born on March 18, <strong>2015</strong>, toDan & Joelle Schmidt of Ames, Iowa.Zayne joins his big brother, Daniel.HIRES & PROMOTIONSOffice // Salvador Marroquin, SafetyDirector; Kelly Taggart, Part-TimePurchasing Expediter; David Gravlin,Transferred from Engineering toDesign Development GroupSuperintendent // Epifanio GudinoGeneral Foreman // Levi JoanetteLeadman // Terry “TJ” Palmer// PROJECT >HEARTLAND CO-OP// LOCATION >FAIRFIELD, IAAMES OFFICEENJOYS A NOONLUNCH FROM THE“SUPERDOG CART”The Ames office enjoyed a grilledlunch from the “Superdog Cart”on March 19 while watchingIowa State play basketball inthe NCAA tournament. Lunchconsisted of a hotdog, gyrosandwich, chips, and beverage.Pictured above are Mike Leners,Craig Sondgeroth, JasonGengler, Kevin Baumhover, andother employees in line for theirlunch.Crews are installing top-fill and reclaim spouting and are ontrack for the new Heartland Co-op shuttle train loading facility inFairfield, Iowa, to open this summer. The slipformed structure consists of four siloswith 890,000 bushels of storage, a screenings bin, a 4,000 bushel rail loadout surgebin, two “off-spec” grain interstice bins, and an 85,000 bushel wet grain bin. Totalstorage is approximately 1,030,000 bushels.This facility includes three 30,000 BPH bucket elevators routing grain from the twotruck receiving pits and a third auxiliary truck/rail unload pit to the top fill system.Facility also incorporates dust aspiration equipment, scalping, screening, and an80,000 BPH rail loadout system. Considerations have also been made for HeartlandCo-op’s 7,000 BPHdryer system andsteel bin storageannex.Todd & Sargentcrews includeSuperintendentRobby Shell;General ForemanDiego Avitia;Foremen SamRamos, Sr., DanaBlack, and BernabeRodriquez-Hernandez; andLeadmen Luis Rojas-Tellez, Rick Grunig,and JoaquinDominguez-Monroy.4 // tsargent.com

PROJECT >PARRISH &HEIMBECKER// LOCATION >GLADSTONE,MANITOBAEMPLOYEESPOTLIGHTMike WillmanConstruction continues at the new Parrish & Heimbecker inland grainterminal near Gladstone, Manitoba. The scope of work includes a343,000 bushel (9,325 tonne) grain elevator capable of receiving,cleaning, and shipping wheat, canola, soybeans, barley, and oats. Theslipformed workhouse incorporates 20 bins, including eight (8) 21’diameter by 120’ tall silos and twelve (12) interstice bins, all with 9 on 12 lean-mixsandfill/slickcoat hoppers. Truck receiving is rated at 20,000 BPH, and rail loadoutis rated for 40,000 BPH. It also includes a reclaim system that facilitates cleaningwhile shipping to rail. The elevator is designed to accommodate grain routing to flatstorage and a future dryer system. Crews have finished all foundations and belowgradeconcrete and will slip the workhouse. Receiving building erection and facilityequipment installation will be initiated immediately following the slip.Todd & Sargent would like tocongratulate and thank MikeWillman, Design Development,for 20 years of service and hishard work. Mike started with Todd& Sargent on January 9, 1995.Mike and his wife LuAnn live inAmes, Iowa. Mike’s interests andhobbies include road cycling,camping, hiking, mountain biking,cross country skiing, and gardenprojects. He is also an avid fan ofSouth Dakota State University andIowa State University athletics.Todd & Sargent crews include Superintendent Russ Shady, General Foremen LeviJoanette and Thomas Alexander II, and Leadmen Travis Musselman and Terry “TJ”Palmer.// PROJECT >RAHR MALTING// LOCATION >SHAKOPEE, MNTodd & Sargenthas been selectedto construct a newslipformed concretemalt house for RahrMalting Company, to belocated at Rahr’s facilityin Shakopee, Minnesota.This structure will beRahr’s sixth malt houselocated at this site. Thisfacility will provide forsteeping, germination,and kilning of barleymalt. Overall, thestructure is 212’ longand 82’ wide. The germ tower is 167’ tall and the kiln tower is 74’ tall. Constructionbegan in April with completion planned in 2016. Randy Hullinger is the Superintendenton this project.Ryan RockTodd & Sargent would like to congratulateRyan Rock, Sr. ProjectManager, for 10 years of service.Ryan started with Todd & Sargenton June 27, 2005. Ryan lives withhis wife Andrea and two daughters,Ava and Reese, in Ankeny,Iowa. In Ryan’s spare time he enjoysspending time with his familyand friends, home improvementprojects, and rebuilding classiccars. Thank you, Ryan, for all yourhard work and 10 years of service.CanDo Review // 5

PROJECT >SANDERSON FARMS// LOCATION >OAKWOOD, TXMetalliCyTodd & Sargent is happy toannounce that the front entranceto the Ames office has becomethe home to MetalliCy, one of thethirty Cy statues previously locatedaround Ames.CyclONE City was founded by theLeadership Ames Class XXVII (aprogram of the Ames Chamber ofCommerce) as a “tour” of life-sizedCy statues throughout the Amescommunity to raise funds for localcharities and create an Iowa StateUniversity scholarship for a StoryCounty resident. The statues weresponsored by local businessesand organizations and decoratedby artists with local connections.Construction continues at the new Sanderson Farms poultry feedmill inOakwood, Texas. Sanderson Farms has been making feed from the firstpellet line since mid-March. Crews are currently finishing the soybeanmeal storage silos reclaim system, starting up the second 400 HP Boiler,the second 85 TPH pelleting system, and paving around the site.This new mill will feature high speed rail and truck receiving systems, mill ingredient storage andbatching tower with 600,000 bushels of whole grain storage, 8,400 tons of soybean meal storage,220 TPH batching system, two 85 TPH pelleting systems, and support systems.Superintendents Dennis Taggart, Randy Durby, and Ralph Shank; General Foremen Dale Mittlieder,Jorge Ugalde-Uribe, and Lyle Sondgeroth; Foremen Eric Gay, Eliseo Gudino-Maqueda, JesusMendiola, Jesus Garcia, Eduardo Alamillo, Efrain Perez-Escobar, and Patricio Dominguez-Rosas;Leadmen Juan Manuel Lopez-Perez, Fidel Gudino,David Ramirez, Reynaldo T Velasquez, Rafael Alicea-DePablo, Marco Lopez, and Edgar Ugalde-Ugalde;and crews are working on this facility.Five of the 30 statues were upfor auction on December 4, 2014,and brought in a grand total of$23,450! The total fundraisingamount came to $66,000! $11,000went to each of the three charities(Mainstream Living, EmergencyResidence Project, and Youth &Shelter Services), and $33,000 wentto create an endowment at IowaState University.6 // tsargent.comThe new Sanderson mill features twoCPM 9042-12 pellet mills with 600 HPmotors. Mills are rated at 80-85 TPH.Each pellet mill is fed from dual 30LT16conditioners.In the new CPM HDHC7D54 horizontalpellet cooler, pellets are spread ontothe top cooling bed through an oscillatingfeeder.

PROJECT >STAR OF THE WESTMILLING// LOCATION >WILLARD, OHT&SJOBSITESECRETARIESWhitewater Mill, LLC // WestHarrison, INAmy MillerHeartland Coop // Fairfield, IAMaria OrtegaSanderson Farms // Oakwood, TXJenny StevensStar of the West Milling // Willard,OHKadi HardyParrish & Heimbecker // Gladstone,Manitoba, CanadaSusan CummerTodd & Sargent crews are busy at the new Star of the West MillingCompany flour mill in Willard, Ohio. Underground concrete work issubstantially complete. The 32’ diameter by 137’ tall 4-pack of wheatstorage silos were slipped the week of March 23 with the mill buildingto be slipped in June.Todd & Sargent crews include Superintendent Mike Taggart; General Foremen RickSchnelker and Ricardo Roque, Jr.; Foremen Eric Butler, Matt Prater, Ismael Acosta-Martinez, V John Deepe, and Jesse Granado, Jr; and Leadmen Anibal Fuentes-Cartagena, Edgar Avitia-Molina, Rolando Soriano, Jose Arias, and Noe Cornejo-Morales.T&S InsideGolf TournamentOn February 6, <strong>2015</strong>, the Todd &Sargent office held their annual “InsideGolf Tournament” during the noonhour. After lunch, which was grilledby employees Pete Clausen and JeffMoyer, the golfers began their gamethroughout the office on the insidecourse set up by Ed Jones.PeteClausen &Jeff MoyerMike Leners, MikeAnderson, DrewBresnahan & JoshSchneiderTom Poggensee,Charles Taylor &Justin CooperMike Evans,Janelle Thomas,SalvadorMarroquin &David GravlinCanDo Review // 7

PROJECT >STAR OF THE WEST MILLING// LOCATION >WILLARD, OHStar of the West Milling Company, withheadquarters in Frankenmuth, Michigan, isbuilding a new flour mill capable of producing1 million pounds of flour per day in Willard,Ohio. All of the facility’s milling capacity is tobe dedicated to milling soft red winter wheat.Star of the West was founded in 1870. The companyowns and operates five flour mills, ten grain elevators, andtwo fertilizer plants. Daily milling capacity is 2.55 millionpounds per day.Todd & Sargent crews mobilized onto the Willard siteOctober 2014. The truck and rail receiving system belowgrade concrete work is nearly complete. The wheat silos4-pack, 32’ in diameter by 137’ tall, were slipformed inMarch <strong>2015</strong>. The capacity of these slipformed wheatsilos are 337,000 bushels. The flour mill main slab wascompleted on April 8, <strong>2015</strong>. Crews are building forms forthe flour mill slipforming process which is scheduled forJune. The mill tower is 34’ wide by 230’ long by 115’-6”tall and incorporates six floors which house the Buhlermilling equipment.Upcoming TradeshowsMay 4 - 8, <strong>2015</strong>IAOM - International Associationof Operative MillersRenaissance Palm SpringsConvention CenterPALM SPRINGS, CA BOOTH #910Our Mission Todd & Sargent, Inc. is in business to servethe engineering and construction needs of our clientsto help ensure their continued growth and success.The “CanDo” Review is a publication of Todd & Sargent. Editor: Vickie Ayers2905 SE 5th Street // Ames, Iowa 50010 // Phone: 515.232.0442 // www.tsargent.com