TransSteel 3500-5000.pdf - Digitalweld

TransSteel 3500-5000.pdf - Digitalweld

TransSteel 3500-5000.pdf - Digitalweld

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

System and handling<strong>TransSteel</strong> stands for extremely easy handling – for in steel welding,easy-to-use tools with intelligent functions are what is needed.Optimally matching system components ensure 100 % systemperformance.Comfort Wire means autonomous feeder-inching. Allthe welder need do is hold out the wire to the machineand it will be inched into the wirefeeder unaided. Thetime-consuming business of opening up the wirefeederand the feed rollers is no longer necessary. This resultsin faultless feeder-inching.Small, lightweight, all-in-one motor plate: The hosepackis anchored directly to the motor plate, ensuring bothstable wirefeed and thus a stable welding process.Longer service-lives for the inner liner, contact tip andfeed rollers are a welcome side-effect of this.Improved handling of the feed rollers: These are colourcodedby diameter, making them quick and easy torecognise. The rollers are changed simply by openingthe feedroller device.

Comfort WireAutonomous feeder-inching, withno need to open the wirefeeder –saves timeIndividual adjustment-guidesInterchangeable adjustmentguidetemplates for differentmaterial thicknesses make manualoperation much easierFronius System Connector- central connection-point forall media- hosepack can be lockedsimply and safely, with notools, to ensure definedcurrent transferFill-level windowMakes it easy to keep an eye onthe coolant level

EasyJobFor storing the power, arc-forcedynamic and correction valueswith one push of the buttonWirefeeder viewing panelFor seeing at a glance howmuch wire is leftEasy, operator-friendly user interface for quickoperation with no need for time-consumingintroductory training. The sturdy protectivecover is available as an optional extra.Tool-holderIndividually extendable, so that thetools you need are always on boardFastSnapTwist and pull: that’s all it takesto safely change and lock the gasnozzleFunctional industrial designThe System Connector is the “spinal cord” ofthe <strong>TransSteel</strong>. All media are routed through thiscentral connection-point. A fastening lever locksthe hosepack in place quickly, accurately andwithout needing any tools.- protected control panel- easy to read off, even from a lyingposition- rugged and attractively styledThe ergonomically shaped torch restscomfortably in the welder’s hand. The ball-andsocketjoint provides effective strain relief, andthe soft-touch grip pads on the handle-shellprevent the torch slipping out of the user’s hand.The Up/Down option lets the welder regulate theamperage right from the welding workplace.

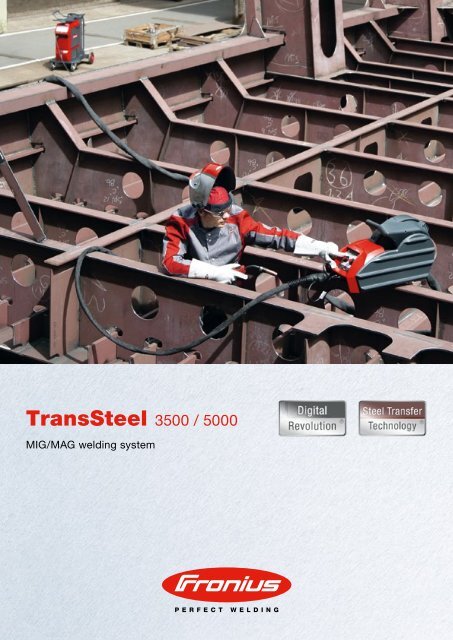

Perfection in detail<strong>TransSteel</strong> YardThe Yard edition is a custom-tailored welding systemdesigned for use in building ships and oil rigs. Thewelding programs on the <strong>TransSteel</strong> Yard are designedfor applications where flux-cored and solid wires arepreferred, and have been optimised with this in mind.A selection of suitable characteristics, as used inthis sector, is stored in the welding system. The YardEdition machines have a gas-flow regulator in thewirefeeder, for providing the central gas supply that isusual in the industry, and a welding-current outlet forusing a rod electrode directly. The Yard Edition satisfiesthe greater need for mobility in shipyards by having aspecial trolley with integrated crane-hoisting lugs. Aspecially developed crane attachment point directlyon the wirefeeder provides yet more scope for jobsitemobility.The wirefeeder has a low-friction, wear-resistantmoulded base, which makes it easy to drag the unitacross the weldment. The wirefeeder comes as standardwith a side-mounted, temperature-resistant andimpact-proof metal slide, enabling the unit to be usedboth in the upright and on its side.<strong>TransSteel</strong> Yard – the perfect welding system forshipbuilding and offshore platforms.

<strong>TransSteel</strong> Robotics – a total systemThe <strong>TransSteel</strong> Robotics welding system comprisesthe power source with single to universal robotinterfaces, an interconnecting hosepack, thewirefeeder, the new magnetic crash-box and the torchbody. The components are optimised for all types ofrobot, and also specifically for hollow-shaft robots.The wirefeeder is equipped with an innovative motorplate and the Fronius System Connector. This makesit considerably smaller and compacter, resulting ina much decreased obstacle contour. A retractablewirefeeder holder facilitates handling when changingthe inner liner. Particularly with hollow-shaft robots,this leaves ample space for quick and easy inner-linerchanges.The new magnetic crash-box ensures high systemavailability and operational and workplace safety.Another newcomer to <strong>TransSteel</strong> Robotics is themagnetic crash-box. With its shorter design, anddecreased obstacle contours in the 6th robot axis, itprovides higher safety against outages, and greateroperating and workplace safety. The magnetic ringscan be flexibly interchanged, allowing various differenttrigger forces to be obtained.The interface can be attached in 2 different ways:either directly to the power source, or externally e.g. tothe wall of the robot cell. This means that changing overto a different power source it is no longer a problem.A new and very handy function is Easy-Job, which letsusers save up to five different parameter records withjust one push of a button. <strong>TransSteel</strong> Robotics comeswith a dust filter as standard. This gives the inside ofthe power source the best possible protection againstcoarse soiling.<strong>TransSteel</strong> Robotics system configuration.Interface attached directly to the power source or to thewall of the robot cell.

ECONOMYSAFETYwww.reklamebuero.atLong life comes built-in- Rugged appliance concept for greater durability ofall components- Dust filter protects the inner workings of the powersource from soiling- Water filter cleans the coolant, prolonging theservice life of the whole system- The use of high-strength plastic for the housingmakes the wirefeeder break-proof and gives itcomplete, all-round insulation- Thermostat-controlled fan runs only when needed,which lessens dirt accumulation inside the unitDesigned for robust deployment- Slanted connector plate protects the connectionpointson the power source from damage- The hosepack connections are concealed by the“sleigh” on one side of the wirefeeder- Shielded filler neck on the cooling unit, to protectagainst mechanical damage- Temperature sensor protects the welding systemagainst overheating- Earth leakage monitoring prevents welding currentfrom flowing via the earthing (grounding) lead anddestroying the PE conductor systemTECHNICAL DATA- International test certificates for worldwidedeployment (S Mark, CE Mark, CSA, CCC)TSt <strong>3500</strong> TSt 5000Mains voltage +/- 10 % 380 V / 400 V / 460 V 380 V / 400 V / 460 VWelding current range 10 - 350 A 10 - 500 AWelding current at:10 min/40°C (104°F) 40 % Duty cycle 350 A 500 – 350 A10 min/40°C (104°F) 100 % Duty cycle 250 A 360 – 350 AOpen-circuit voltage 60 V 65 VWorking voltage 15.5 V 14.5 VDegree of protection IP 23 IP 23Dimensions L x W x H mm 747 x 300 x 497 mm 747 x 300 x 497 mmWeight 26.5 kg 30.15 kgText and illustrations technically correct at time of going to print. We reserve the right to make modifications.This document may not be copied or otherwise reproduced, whether in part or in its entirety, without the express prior written consent of Fronius International GmbH.FRONIUS USA LLC10421 Citation Drive, Suite 1100Brighton, Michigan 48116, USATel: +1 810 220 4414Fax: +1 810 220 4424E-Mail: sales.usa@fronius.comFRONIUS INTERNATIONAL GMBHBuxbaumstrasse 2, P.O.Box 264A 4602 Wels, AustriaTel: +43 7242 241-0, Fax: +43 7242 241-3940E-Mail: sales@fronius.comwww.fronius.comFRONIUS CANADA LTD2875 Argentia Road, Units 4,5 & 6Mississauga, ON L5N 8G6, CanadaTel: +1 905-288-2100Fax: +1 905-288-2101E-Mail: sales.canada@fronius.com40,0006,3051,EN v02 2010 aw06