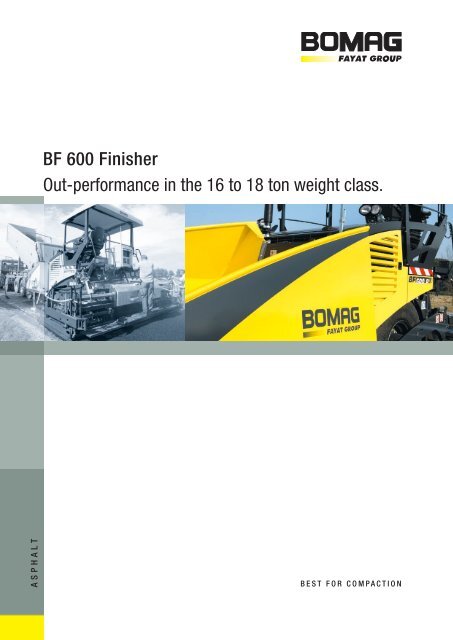

BF 600 Finisher Out-performance in the 16 to 18 ton weight class.

BF 600 Finisher Out-performance in the 16 to 18 ton weight class.

BF 600 Finisher Out-performance in the 16 to 18 ton weight class.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A S P H A L T<strong>BF</strong> <strong>600</strong> <strong>F<strong>in</strong>isher</strong><strong>Out</strong>-<strong>performance</strong> <strong>in</strong> <strong>the</strong> <strong>16</strong> <strong>to</strong> <strong>18</strong> <strong>to</strong>n <strong>weight</strong> <strong>class</strong>.

BOMAG <strong>BF</strong> <strong>600</strong> – <strong>the</strong> new <strong>performance</strong> <strong>class</strong>.BOMAG products embody <strong>the</strong> essence of quality, <strong>performance</strong> andefficiency. These fundamentals are <strong>the</strong> keys <strong>to</strong> BOMAG‘s worldwideleadership <strong>in</strong> compaction technology, and <strong>the</strong> company‘s ongo<strong>in</strong>g developmen<strong>to</strong>f new products and application technologies. These samequalities are present <strong>in</strong> <strong>the</strong> new BOMAG <strong>BF</strong> <strong>600</strong> <strong>F<strong>in</strong>isher</strong>.n Maximum built-<strong>in</strong> width: 7.55 mn Maximum plac<strong>in</strong>g capacity: <strong>600</strong> t/hn Eng<strong>in</strong>e output: 120 kWn Maximum plac<strong>in</strong>g thickness: 300 mmn Transport width: 2.55 mn Operat<strong>in</strong>g <strong>weight</strong>: <strong>16</strong>-<strong>18</strong> t2

B F 6 0 0 F i n i s h e rThe design premise was: <strong>to</strong> outperform on site us<strong>in</strong>g <strong>the</strong> absolute m<strong>in</strong>imum of technicalcomplexity.n HS screed – for up <strong>to</strong> 93 percent precompactionn L.C.S. screen release – for high placement qualityn SIDEVIEW – for a perfect overviewn ECOMODE – for big fuel sav<strong>in</strong>gsn Operat<strong>in</strong>g concept – for easy mach<strong>in</strong>e operationn Scraper belts – <strong>in</strong>dividually controllable and reversiblen Auger drives – <strong>in</strong>dividually controllable and reversiblen B<strong>in</strong> flaps – <strong>in</strong>dividually controllableW<strong>in</strong>ner of <strong>the</strong> prestigious design prize, <strong>the</strong> ”red dot award: product design“.Awarded for outstand<strong>in</strong>g design, <strong>in</strong>ventiveness and quality.3

T e c h n o l o g yOptimum material output.With its high 12.4 t capacity, <strong>the</strong> hopper has <strong>the</strong>reserves <strong>to</strong> handle jobs that need extra-large pav<strong>in</strong>gcapacity.n Top-quality, wear resistant plates <strong>in</strong>creaseservice life and lower costs.n Reversible scraper belts are <strong>in</strong>dividually controllable.n Sturdy, dis<strong>to</strong>rtion resistant b<strong>in</strong> flaps featurem<strong>in</strong>imum curvature and are <strong>in</strong>dividually controllable.n Self-adjust<strong>in</strong>g push rollers for hook up <strong>to</strong> trucksand a controlled push<strong>in</strong>g force.6

B F 6 0 0 F i n i s h e rEven material flow.Each of <strong>the</strong> two <strong>in</strong>dividually controllable andreversible scraper belts has a mechanical sensoras standard which controls <strong>the</strong> scraper beltdepend<strong>in</strong>g on <strong>the</strong> chosen material volume. Thisprovides high pav<strong>in</strong>g capacity and a controlledmaterial flow. Naturally <strong>the</strong> <strong>BF</strong> <strong>600</strong> f<strong>in</strong>isher canbe equipped with ultrasound sensors as well, byrequest.The scraper belts run on wear resistant plateswhich makes <strong>the</strong>m highly durable. The augershave cast auger w<strong>in</strong>gs which can be <strong>in</strong>dividuallyreplaced when needed. This not only makesservic<strong>in</strong>g easier but generates considerable costbenefits <strong>to</strong>o. Cus<strong>to</strong>mers have <strong>the</strong> option of specify<strong>in</strong>ga hydraulic adjuster <strong>in</strong> addition <strong>to</strong> <strong>the</strong> standardmechanical auger height adjuster.Supplied as standard are two ultrasound sensorson <strong>the</strong> auger and two channel plates <strong>in</strong> <strong>the</strong> augertunnel. This ensures even material distribution andprevents unwanted build-up of material <strong>in</strong> front of<strong>the</strong> board. Exceptionally uniform pav<strong>in</strong>g is achievedwith <strong>the</strong> stressed smooth steel sk<strong>in</strong>s measur<strong>in</strong>g up<strong>to</strong> 400 millimetres <strong>in</strong> length.The screed itself is operated easily and <strong>in</strong>tuitivelyei<strong>the</strong>r from a ma<strong>in</strong> or side-mounted opera<strong>to</strong>r station.The side-mounted opera<strong>to</strong>r station can also be setby a potentiometer on <strong>the</strong> respective auger sensor.7

T e c h n o l o g yThe screed provides excellent precompaction.The screed is at <strong>the</strong> heart of every f<strong>in</strong>isher and iswhere BOMAG‘s know-how with high compactionand uniform pav<strong>in</strong>g pays off. The outstand<strong>in</strong>g<strong>performance</strong> of <strong>the</strong> <strong>BF</strong> <strong>600</strong> is based on BOMAG‘sexperience <strong>in</strong> compaction technology.standard ground screed and a maximum layerthickness of 300 mm. The BOMAG <strong>BF</strong> <strong>600</strong> deliverssuperior <strong>performance</strong> without <strong>the</strong> disadvantagesof high technical complexity. BOMAG screeds aresimple <strong>in</strong> design and heavy-duty <strong>in</strong> construction.In practice this means: The <strong>BF</strong> <strong>600</strong> producespre-compaction of up <strong>to</strong> 93 percent – with aTrue for each one of <strong>the</strong> four screed types available<strong>in</strong> this series.8

S t r a ß eB nF f e6 r0t i0 g eF r i nB iF s h6 e0 r0Four screed versions for all requirements.HCE screed board HCG screed board HSE 500 HSG 500Heat<strong>in</strong>g technology Electric Gas Electric GasBasic widths 2,50 - 4,75 m 2,55 - 5,00 mMaximum quality us<strong>in</strong>g variable screed widths*Each screed has both a fully au<strong>to</strong>mated temperature moni<strong>to</strong>r and side-extensions powered by hydraulics.The work<strong>in</strong>g width of each screed can also be extended us<strong>in</strong>g o<strong>the</strong>r attachment modules <strong>to</strong> a maximum width of up <strong>to</strong> 7.55 metres on <strong>the</strong>track-drive version or 6.85 metres on <strong>the</strong> wheel-drive version.HC screed board(HCE / HCG)2,500HS screed board(HSG 500 / HSE 500)2,5502,5002,500Basic width+ hydraulic extensions2,5502,5501,125 1,1254,7501,2255,0001,225350 3503,200 - 5,450+ fixed extensions2503,050 - 5,500250700 7003,900 - 6,1507504,050 - 6,500750350 700 700 3504,<strong>600</strong> - 6,850250 7504,550 - 7,000750 250700 700 700 7005,300 - 7,550*All measurements are <strong>in</strong> are millimetres. <strong>in</strong> millimetres.The heat<strong>in</strong>g genera<strong>to</strong>r with a cont<strong>in</strong>uous output of25 kW cuts <strong>the</strong> heat-up time of <strong>the</strong> heat<strong>in</strong>g rods <strong>to</strong>just 20 <strong>to</strong> 30 m<strong>in</strong>utes.400 millimetre long stressed smooth steel sk<strong>in</strong>sproduces superior uniformity <strong>in</strong> <strong>the</strong> asphalt layer.9 9

E q u i p m e n tSimple operation.n L.C.S. for au<strong>to</strong>matic control of <strong>the</strong> screed and<strong>to</strong> boost start-up traction. Under control of <strong>the</strong>pav<strong>in</strong>g crew, <strong>the</strong> screed can be au<strong>to</strong>maticallyreleased or locked dur<strong>in</strong>g work breaks andprecisely adjusted <strong>to</strong> different material thicknesses.The screed heat<strong>in</strong>g system can also beadjusted and moni<strong>to</strong>red.Central screed opera<strong>to</strong>r stationn Tamper and vibration frequency can be setfrom <strong>the</strong> driver‘s station. The auger sensor canalso be activated from <strong>the</strong> side operat<strong>in</strong>gpositions with a potentiometer.n The HSE electric screed has <strong>16</strong> heat<strong>in</strong>g rods aswell as two optional heated side plates. Theoperation of each heat<strong>in</strong>g rod is constantly moni<strong>to</strong>redby LED displays. Advantage: Functions canbe <strong>in</strong>dividually moni<strong>to</strong>red.Side-mounted screed opera<strong>to</strong>r stationn All-round light<strong>in</strong>gThe <strong>BF</strong> <strong>600</strong> f<strong>in</strong>isher has a powerful all-roundlight<strong>in</strong>g system as standard – only available fromBOMAG. Four lights on <strong>the</strong> roof and four b<strong>in</strong> andscreed lights for perfect all-round visibility evenat night.LED display moni<strong>to</strong>rs <strong>the</strong> heat<strong>in</strong>g rodsStandard all-round light<strong>in</strong>g10

B F 6 0 0 F i n i s h e rn SIDEVIEWSeat and opera<strong>to</strong>r station for a maxi-adaptableunit. The entire opera<strong>to</strong>r station can be extendedlaterally <strong>to</strong> an overhang of 60 cm.Advantage: <strong>the</strong> driver ma<strong>in</strong>ta<strong>in</strong>s perfect visibility<strong>to</strong> <strong>the</strong> b<strong>in</strong>, travel drive and screed and alwaysrema<strong>in</strong>s protected aga<strong>in</strong>st wea<strong>the</strong>r by <strong>the</strong> highquality roof feature.Unobstructed view on<strong>to</strong> <strong>the</strong> guide rodn Operat<strong>in</strong>g consoleNo unnecessary switches, no endless <strong>in</strong>formationscreens with complicated navigation menus,no awkward or service-<strong>in</strong>tensive control panels.Instead BOMAG offers robust technology wellproven on <strong>to</strong>ugh site work. Here’s a goodexample: <strong>in</strong>terchangeable <strong>to</strong>ggle switchesdesigned <strong>to</strong> cut replacement costs and save time.Operat<strong>in</strong>g console with <strong>in</strong>dividual switchesn Grad<strong>in</strong>g systemIn addition <strong>to</strong> <strong>the</strong> operat<strong>in</strong>g console on <strong>the</strong> driver‘sstation, <strong>the</strong> pav<strong>in</strong>g height and transverse <strong>in</strong>cl<strong>in</strong>ationcan also be regulated by a grad<strong>in</strong>g systemoperated by <strong>the</strong> pav<strong>in</strong>g crew. The <strong>in</strong>terface forgrad<strong>in</strong>g is an add-on system and supports <strong>the</strong>BOMAG unit but also allows <strong>the</strong> use of o<strong>the</strong>r typesof system – available as an option with electromechanicalsensors, ultrasound or also lasersensors.The grad<strong>in</strong>g system11

E q u i p m e n tPerfect comfort.Thanks <strong>to</strong> its generous size, <strong>the</strong> f<strong>in</strong>isher‘s opera<strong>to</strong>rplatform provides perfect visibility <strong>to</strong> <strong>the</strong> site, <strong>the</strong>b<strong>in</strong>, <strong>in</strong>dica<strong>to</strong>rs, drive wheels and <strong>the</strong> screed. S<strong>in</strong>ce<strong>the</strong> platform only mounts one seat <strong>the</strong>re is ampleroom for s<strong>to</strong>rage. The driver also has <strong>the</strong> entireauger tunnel <strong>in</strong> sight from <strong>the</strong> operat<strong>in</strong>g position,which means material flow can be permanentlymoni<strong>to</strong>red.Comfort requires <strong>in</strong>dividual adjustment, which iswhy <strong>the</strong> BOMAG <strong>BF</strong> <strong>600</strong> deluxe seat has a numberof ways <strong>to</strong> achieve <strong>the</strong> ultimate <strong>in</strong> seat<strong>in</strong>g comfortfor every driver. The BOMAG deluxe seat canbe turned, shifted or adjusted <strong>in</strong> height <strong>to</strong> suit allopera<strong>to</strong>rs.The BOMAG f<strong>in</strong>isher is <strong>the</strong> only unit on <strong>the</strong> market<strong>to</strong> be able <strong>to</strong> elim<strong>in</strong>ate a second seat as <strong>the</strong> entiredriver‘s station (SIDEVIEW) and seat<strong>in</strong>g unit(compris<strong>in</strong>g operat<strong>in</strong>g console and deluxe seat)can be moved sideways. Option: seat heat<strong>in</strong>g foradded comfort.The operat<strong>in</strong>g console is designed <strong>to</strong> <strong>the</strong>highest ergonomic standard for ease of operationand <strong>in</strong>st<strong>in</strong>ctive handl<strong>in</strong>g. Practicality: <strong>the</strong> hoodprovides vandal protection. It is fitted with ah<strong>in</strong>ged lid that does not require <strong>to</strong> be s<strong>to</strong>wed dur<strong>in</strong>goperation.12

B F 6 0 0 F i n i s h e rEasy ma<strong>in</strong>tenance and servic<strong>in</strong>g are <strong>to</strong>p of <strong>the</strong> lis<strong>to</strong>n <strong>the</strong> <strong>BF</strong> <strong>600</strong> specification sheet. BOMAG designers<strong>to</strong>ok this <strong>in</strong><strong>to</strong> account <strong>in</strong> <strong>the</strong> early stages of development<strong>to</strong> allow quick and easy access <strong>to</strong> all areas of<strong>the</strong> mach<strong>in</strong>e.A central key provides access <strong>to</strong> all operat<strong>in</strong>g areasof <strong>the</strong> mach<strong>in</strong>e.The eng<strong>in</strong>e compartment is accessible from foursides. The same applies <strong>to</strong> <strong>the</strong> central hydraulicsystem with its generously-sized open<strong>in</strong>gs.Servic<strong>in</strong>g beg<strong>in</strong>s immediately with no need forprelim<strong>in</strong>ary work.Compact transportation: The roof can be hydraulicallylowered and also offers protection <strong>to</strong> <strong>the</strong>driver‘s station aga<strong>in</strong>st wea<strong>the</strong>r and vandalism onsite and dur<strong>in</strong>g transport.13

C u s t o m e r b e n e f i t sBOMAG <strong>BF</strong> <strong>600</strong>: The No 1 choice.The BOMAG <strong>BF</strong> <strong>600</strong> f<strong>in</strong>isher has already made itsmark on every type of site: <strong>in</strong> <strong>in</strong>ner-city areas <strong>in</strong>tight conditions and work on multi-lane mo<strong>to</strong>rways.The paver comb<strong>in</strong>es both precise pav<strong>in</strong>g withunbeatable driver comfort and economy.Precise pav<strong>in</strong>g:n high capacity of up <strong>to</strong> <strong>600</strong> t/hn 40 cm long stressed smooth steel sk<strong>in</strong>s foroutstand<strong>in</strong>g evennessn precompaction of up <strong>to</strong> 93 percentn outstand<strong>in</strong>g traction and screed adjustmentthanks <strong>to</strong> L.C.S.A new way <strong>to</strong> cut costs:n reduced fuel consumption with ECOMODEn efficient screed heat<strong>in</strong>g for fast start-upn exchangeable components save time and cut <strong>the</strong>cost of servic<strong>in</strong>gn rapid supply of spare parts through <strong>the</strong> extensiveBOMAG dealer and service networkReal comfort:n easy and <strong>in</strong>tuitive operat<strong>in</strong>g conceptn SIDEVIEW for unobstructed all-round visibilityfrom <strong>the</strong> driver‘s stationn multiple seat sett<strong>in</strong>gs for stress-free operationn easy access <strong>to</strong> all service areasCus<strong>to</strong>mers throughout <strong>the</strong> world trust <strong>the</strong>BOMAG name.The company has been part of <strong>the</strong> FAYAT Groups<strong>in</strong>ce 2005. BOMAG has six branches <strong>in</strong>Germany as well as eleven <strong>in</strong>dependentsubsidiary companies across <strong>the</strong> globe. Morethan 500 dealers <strong>in</strong> over 120 countriesguarantee world distribution of BOMAG productsand service.14

B F 6 0 0 F i n i s h e rOptions:Special solutions for every job: BOMAG offers a wide range of optional equipment and extensions for<strong>the</strong> <strong>BF</strong> <strong>600</strong> f<strong>in</strong>isher.n a grad<strong>in</strong>g system for vertical and horizontal sens<strong>in</strong>g(optional ultrasound or mechanical sensors)n heated side plates for <strong>the</strong> HCE 500/HSE 500 electric screedn <strong>to</strong>w skis <strong>in</strong> lengths of 6.00 and 9.00 metres for mechanicalsensorsn large skis <strong>in</strong> lengths of up <strong>to</strong> 9.00 metres and up <strong>to</strong>12.00 metres for ultrasound sensorsn laser skis with a sensor length of up <strong>to</strong> 12.00 metresn hydraulically adjustable roof profile (standard <strong>in</strong> connectionwith <strong>the</strong> HS screed)n screed extensions for built-<strong>in</strong> widths of up <strong>to</strong> 7.55 metres –heated ei<strong>the</strong>r electrically or by gasn reduction pads for built-<strong>in</strong> widths of up <strong>to</strong> 1.90 metresn auger drivers with hydraulic height adjustment, availableon requestn straight seam heat<strong>in</strong>gn 4x6 and 6x6 drive for <strong>the</strong> <strong>BF</strong> <strong>600</strong> P wheel-drive f<strong>in</strong>isherLarge skisGrad<strong>in</strong>g system15

www.bomag.comHead Office / Hauptsitz:BOMAGHellerwald56154 BoppardGERMANYTel. +49 6742 100-0Fax +49 6742 3090<strong>in</strong>fo@bomag.comBOMAG Masch<strong>in</strong>enhandelsgesellschaftm.b.H.Porschestraße 91230 WienAUSTRIATel. +43 1 69040-0Fax +43 1 69040-20austria@bomag.comBOMAG (CANADA), INC.3455 Semenyk CourtMississaugaOntario L5C 4P9CANADATel. +1 905 361 9961Fax +1 905 361 9962canada@bomag.comBOMAG (CHINA)Compaction Mach<strong>in</strong>ery Co. Ltd.2808 West Huancheng RoadShanghai ComprehensiveIndustrial Zone (Fengxian)Shanghai 201401CHINATel. +86 21 33655566Fax +86 21 33655508ch<strong>in</strong>a@bomag.comBOMAG France S.A.S.2, avenue du Général de Gaulle91170 Viry-ChâtillonFRANCETel. +33 1 69578<strong>600</strong>Fax +33 1 69962660france@bomag.comBOMAG (GREAT BRITAIN), LTD.Sheldon WayLarkfield, AylesfordKent ME20 6SEGREAT BRITAINTel. +44 <strong>16</strong>22 7<strong>16</strong>611Fax +44 <strong>16</strong>22 7<strong>18</strong>385gb@bomag.comBOMAG Italia Srl.Z.I. Via Mella, 625015 Desenzano del Garda (BS)ITALIATel. +39 030 9127263Fax +39 030 9127278italy@bomag.comBOMAG Japan Co. Ltd.12-7, Daidoh-Cho 2-ChomeAkashi-CityHyogo-Pref 673-0029JAPANTel. +81 78 924 <strong>16</strong>31Fax +81 78 924 <strong>16</strong>33japan@bomag.comBOMAG Polska Sp. z o.o.Ul. Szyszkowa 5202-285 WarszawaPOLANDTel. +48 22 482 0400Fax +48 22 482 04 01poland@bomag.comRepresentative officeof BOMAG GmbHLen<strong>in</strong>gradsky prospect, h.72, b. 4Office 2307125315 MoscowRUSSIATel. +7 (495) 287 92 90Fax +7 (495) 287 92 91russia@bomag.comBOMAG GmbH300 Beach RoadThe Concourse, #38-03S<strong>in</strong>gapore 199555SINGAPORETel. +65 6 294 1277Fax +65 6 294 1377s<strong>in</strong>gapore@bomag.comBOMAG Americas, Inc.2000 Kentville RoadKewaneeIll<strong>in</strong>ois 61443U.S.A.Tel. +1 309 8533571Fax +1 309 8520350usa@bomag.comPart of <strong>the</strong> FAYAT GROUP09/08 PRE 107 405