ENG - Copertina - pag 01

ENG - Copertina - pag 01

ENG - Copertina - pag 01

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BAMBOO JOURNALibra online newsletteryear 6issue 10february 2<strong>01</strong>3italian bamboo rodmakers association

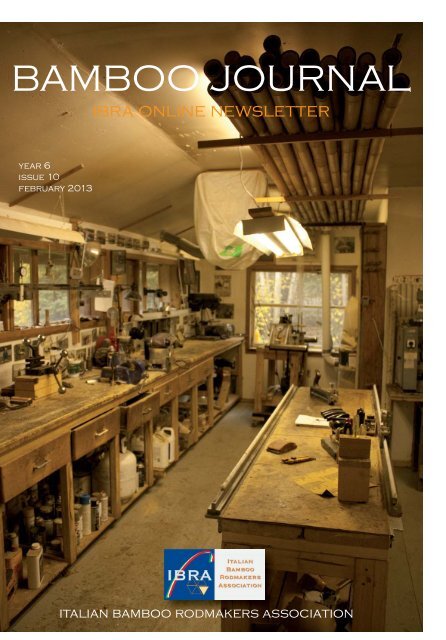

<strong>pag</strong>e 02Bamboo JournalIn this issue:<strong>pag</strong>e 3 Editorialby Marco Giardina<strong>pag</strong>e 4 Happinessby Giovanni Nese<strong>pag</strong>e 7 5th European Gathering - Report -by Alix Antoni<strong>pag</strong>e 16 A beginner at the Carcassonne Gatheringby Olivier Brosset<strong>pag</strong>e 20 Splicing blockby Patrick Maleig<strong>pag</strong>e 26 Stress in bamboo rods ...by Gabriele Gori<strong>pag</strong>e 35 Respectby Alberto Poratelli<strong>pag</strong>e 39 The Heat Treating "Mystery"by Massimo Paccotti e Marco di Lorenzo<strong>pag</strong>e 44 The“second” irstby Enrico FrancioniBamboo Journal n. 10 - February 2<strong>01</strong>3EditorSteering Committee:Photos by:Graphic art work andcreative director :Transation:Front cover:Photo on <strong>pag</strong>e 2:Marco O. GiardinaMarco O. Giardina, Gabriele Gori, Alberto PoratelliGiovanni Nese, Alix Antoni, Olivier Brosset, Patrick Maleig,Alberto Poratelli, Massimo Paccotti, Enrico Francioni, Andrea Satto,Alberto PoratelliMoreno e Doria Borriero (info@damlin.com)The shop of rodmaker Bob Clay - Kispiox BCGabriele Gori President of IBRA welcomes the mayor of the CarcassonneItalian Bamboo Rodmakers Association

<strong>pag</strong>e 03Bamboo JournalEditorialCome now! 2<strong>01</strong>3 is inally here.We’re a little creased, battered and bruised butwe made it.That awful 2<strong>01</strong>2 is behind us forever: manydoubted we would make it but we did and this isour starting block.IBRA has had dificult moments which werereally the members’ dificulties but let us neverforget that IBRA is its members and it livesthanks to themWe had to forfeit the Rodmaking Course that hadbecome a fundamental highlight of our association.A series of lessons, seminars, meetings andparticipation in National exhibition events werecancelled. The economic crisis forced many torenounce.This economic crisis has discouraged most of us.But now 2<strong>01</strong>2 is behind us, it is the pastNow is the time to roll up our sleeves and look ahead with tenacity and hope.It is like the aftermath of an earthquake – alas I have a long experience of them! – irst the fear, thenthe bewilderment and in the end the dejection but if one does not react and start over lookingforwards, the hope to overcome it wanes and everything becomes impossible.If there are ruins it is the moment to rebuild, re-establish with a different view of things.On May 24, 25 and 26 there is the Italian Gathering..It will be the time to meet, to see old friends and make new ones. Let us make this a gathering ofenthusiasm, new energy and the conirmation of the great skills that the Italian Rodmaking has shownover the years.It is also the chance to confront each other and evaluate what the Association will be in the future. Afundamental moment of the association will be the 2<strong>01</strong>4 Elections, they are round the corner and Ithink it is the time to ask ourselves, all together, what kind of IBRA we want in the near future.But I dare to go beyond that, what type of rodmaking we want in the coming years! The directions, thefunctions, the logic Italian rodmaking must seek in the future!I will leave you to the reading of the Bamboo Journal and I dutifully thank, without rhetoric or lattery,the writers that made the issue of the Bamboo Journal number ten possible.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 04Bamboo JournalHappinessdi Giovanni Giò NeseI saw a happy man. A rare event, considering it was Monday!Josè came to visit me about a month ago. He came to collect his bamboo rod. By now I am more conidentwith bamboo and I am aware of what I am selling but it is still a very stressful situation. Everytime I compare it to my daughter’s wedding. You have accumulated stress for twenty years, hoping shewill leave the house and then when you see her leave you feel you have not completed her education,maybe it is not good enough for her future husband, perhaps in a few years she will come back homewith a couple of kids, that maybe you are not the good father you thought you were...Now, if you substitute the word “daughter” with “bamboo rod”, I feel the same way.Perhaps I’m not the great rodmaker I thought I was. I always start off with high hopes and big promisesof rigour and then along the way I realize there is something I could have done better, something thatis not as perfect as I had imagined and I accumulate stress.At the end the varnish dresses up the rod like the dress does the bride but I know that underneaththere is that tiny defect; he will not notice, only I know, but it is stressful. I examine it with a critical eyebut I am fed up with it in my garage, stretched out, hung up, tied… I must give it away quickly or I willbreak it up in pieces.The person that will pick it up is kept constantly updated on the work progress, he followed theconstruction phases and he is as tense as a violin, he will never spot the defect, he doesn’t see it. Itmust be the same special lining we use for the eyes of people who fall in love.Exhausted I give it away. But it is still stress.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 05Bamboo JournalI have read that artists react the same way with their work. Picasso was not like that. He was good.Better than anyone. Even if he did not invented a style, he made it his own and used it in a better waythan the inventor. He was the best. And he knew it too.I consider myself a modest artist, a very modest artist, one of those that once a work is done, they putit down with the idea of touching it up because it is not perfect. I know of many very famous examples:Leonardo carried the Mona Lisa with him half way across Europe, it was never inished, a work inprogress.But eventually money, the will to buy another piece of equipment to do a certain job better, imposesone to exchange: rod and stress on one side of a scale, money and happiness in exchange on the other.Nonetheless, after almost twenty years I sell a couple of rods a year. Only two have returned, thosewithout nodes. It was not my fault… the glue failed. I managed to ind a tube of glue that did not work.Luckily I only made two rods with it. None of the defects I am aware of and I know are hidden in theother rods have ever been noticed. Imperfect but long-lasting marriages!Jose’ comes with a few friends. I had met them ishing and we had chatted. The meeting was organisedin time and there was the opportunity to try the rods, better than at the show. That time they not onlytried the usual wooden rods but also my irst “Cut and Sew” graphite rod. They didn’t cast badly but Icould tell they were not taught and they were lacking in application, the casting is not their irst thought,one of the three is enthusiastic about the C&S. When at dark we stop casting, he is still holding itdismounted in his arms, as if cuddling it, a sweet image, unusual even for me who builds them. He givesit back unwillingly as if separating himself from it. It would not have been the irst rod I gave away on agenerous impulse but it is my irst graphite prototype and I have a name as a bamboo rodmaker toprotect. I take it back.We inish our chat in a pizzeria with a new convinced bamboo enthusiast, an indifferent user oftelescopic rods and an unhappy man.The next day Jose' phones me.Stress!Everything is alright! The rod is fantastic, etc. but.... Axxxxxx is in love with the S&C graphite rod. I tellJose’ again that I cannot give it to him but there is another blank the same as that one where I got mineand I offer to explain how Axxxxxx can build it, it is not dificult...Josè refers and eventually after a few more phone calls I tell him I will build it for him. Axxxxxx is soshy he doesn’t even phone me, I didn’t think I was so intimidating.The following Friday I phone Jose' to tell him the rod is ready.Monday when I put the plastic tube with the rod in Axxxxxx’s hand he says “I haven’t slept for twonights waiting for this moment”He mounts the rod, he tries it and his face lights up.Stress on one side of the scale, on the other there is only happiness,like a bride on her wedding day.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 06Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 07Bamboo JournalReportdi Alix AntoniAfter Italy (twice), Switzerland andGermany, in 2<strong>01</strong>2 France organised the 5thEuropean Rodmakers Gathering.Among the best Italian, Swiss, Belgian, Danishrodmakers met on 10th and 11th of Novemberin the south of France at the feet of the medievalcity of Carcassonne. Andy Royer, the importer ofbamboo culms and who is well known byrodmakers all over the world came from theUSA to participate to our meeting together withhis partner Alice who speaks French perfectly.For the event, the Mayor of Carcassonne let ususe the best hall in town - a very spacious andwell organised hall. We laid out our tables forthe exhibition of the rods and we even managedto create a spaces for the meals and for castingwithout having to leave the hall.Après l’Italie (deux fois) la Suisse etl’Allemagne, la France a organisé en 2<strong>01</strong>2 les5ème Rencontres Européennes des constructeursde cannes en bambou refendu.C’est dans le sud de la France, au pied de la citémédiévale de CARCASSONNE que se sont réunisles 10 et 11 novembre les meilleurs constructeursitaliens, suisses, belges, danois, hollandais,allemands et français. Andy ROYER, l’importateurde bambou bien connu des facteurs du mondeentier, a fait le déplacement spécialement desEtats Unis pour participer à notre meeting,accom<strong>pag</strong>né de sa iancée Alice qui parle parfaitementle français.Pour cette occasion, le maire de CARCASSONNEavait mis à notre disposition la plus belle salle dela ville, très spacieuse et magniiquement aménagée.Dans le même lieu nous avons pu disposerles tables pour l’exposition des cannes, une airepour les repas et des espaces de casting qui ontpermis d’essayer les cannes sans sortir de la salle.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 08Bamboo JournalThe programme :On Saturday morning the participants occupiedtheir spaces and laid out their wares and it ishere that the contacts with the other exhibitorstook place.On Saturday afternoon. Pierre Perrot and PaulAgostini held a rodmaking laboratory forbeginners. Straight after that, Christian Burgerfrom Germany explained his method forconstructing ferrules in carbon ibre and epoxy.Jean SANTOS brought his whole engravingworkshop and with extreme patience he let theparticipants try their hands with their istengravings while he dispensed advice andinformation.At 6 pm the IBRA president Gabriele Gori,introduced his association to the spectatorshelped by Moreno Borriero who translated intoFrench.While the participants were exchanging rodmakingexperiences, the ladies were accompaniedon a visit of the medieval city of Carcassonne.The Gala dinner took place at 8 pm with atraditional regional dish: la cassoulet.On Sunday morning Gabriele Gori held a briefseminar on the resistance of materials andexplained the method used to calculate anddesign tapers. Jean Louis Taravella (Gino) hadthe dificult job of translating Gabriele’s talk.After that Alberto PORATELLI presented hisoriginal concepts regarding bamboo ferrules.The winning rafle tickets were drawn straightafter lunch and there were 40 magniicentprices offered by the participants.Le déroulement du programme :Le samedi matin les participants ont investi leslieux, ont installé leurs matériels et établi lescontacts avec les autres exposants.Samedi après midi, après le repas, Pierre PERROTet Paul AGOSTINI ont animé un atelier deconstruction à l’intention des débutants. Puis,l’allemand Christian BURGER a expliqué sonprocédé de fabrication des viroles en ibres decarbone enduites de résine époxy.Jean SANTOS avait transporté son atelier degravure et, avec beaucoup de patience, a mis sesoutils et ses conseils à la disposition des volontairesqui ont désiré faire leurs premiers pas dans ledomaine de la gravure.A 18H00 Gabriele GORI, le président italien del’IBRA nous a présenté son association, assisté deMoreno BORRIERO pour la traduction enfrançais.Au milieu de l’après midi, pendant que les participantséchangeaient leurs expériences deconstruction, leurs épouses étaient invitées àvisiter la cité médiévale de CARCASSONNE.A 20H, le repas de gala réunissait tous les participantsautour du plat traditionnel régional : uncassoulet.Le dimanche matin, Gabriele GORRI a fait un brefexposé sur la résistance des matériaux aind’expliquer les éléments de calculs qui sontretenus pour la conception des proils de cannes.Le français Jean Louis TARAVELLA (Gino) a eu ladificile tâche de traduire les propos de Gabriele.Puis à son tour, Alberto PORATELLI a présentéson concept original de viroles en bambou.Après le repas de midi, nous avons procédé autraditionnel tirage de la tombola. 40 magniiqueslots, offerts par de nombreux participants,composaient cette tombola.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 09Bamboo JournalAt 4 pm the participants said their sad goodbyes.During the two days, some participants wehappy to ind old friends and the new participantsdiscovered the spirit of conviviality thatanimated these gatherings. Everyone wassurprised by the fact that there were no languagebarriers and so there was hindrance to theexchanges.The organisers – the Club Mouche Audois, wererewarded for their 12 months of hard work bythe great spirit of friendship that characterisedthe meeting.We will certainly be back !!A 16H 00, les participants se sont séparés àregret.Pendant ces 2 journées certains, habitués de cesmeetings, étaient heureux de se retrouver. Lesnouveaux découvraient l’esprit de partage et laconvivialité qui animent les regroupementseuropéens. Tous étaient surpris de s’apercevoirque la diversité des langues n’était pas un obstacleaux échanges.Pour le Club Mouche Audois, organisateur dumeeting, l’esprit qui a régné pendant ces 2journées est une récompense au travail fournipendant 12 mois pour la préparation de cesrencontres.Nous recommencerons certainement !The prizes for the rafle.le lots de la tombolaItalian Bamboo Rodmakers Association

<strong>pag</strong>e 10Bamboo JournalA much coveted prize:a reel engraved by Jean SantosUn lot très convoité :moulinet gravé par Jean SANTOSThe dining areaL’espace réservé aux repasItalian Bamboo Rodmakers Association

<strong>pag</strong>e 11Bamboo JournalGabriele GORI during his seminaryassisted by Gino for the translation.Gabriele GORI pendant son exposé,assisté de Gino pour la traduction.Pierre PERROT and Paul AGOSTINIduring their demonstrationPierre PERROT et Paul AGOSTINIpendant leur démonstrationItalian Bamboo Rodmakers Association

<strong>pag</strong>e 12Bamboo JournalThe rods on exhibitionL’exposition des cannesL’atelier de gravure de Jean SANTOSJean Santosand his engraving laboratoryItalian Bamboo Rodmakers Association

<strong>pag</strong>e 13Bamboo JournalThe casting areaL’espace pour le castingDuring the Gala dinner,the Italian ladies were entertainedby the two best French participants.Pendant le repas de galales belles italiennes étaient assistéespar nos plus beaux représentants français.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 14Bamboo JournalThe group of participantsLe groupe des participantsThe Italian delegationLa délégation italienneItalian Bamboo Rodmakers Association

<strong>pag</strong>e 15Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 16Bamboo JournalA beginner at theCarcassonneGatheringBY Olivier BrossetUn novice auxRencontres deCarcassonnedi Olivier BrossetCarcassonne!The 5th European Bamboo Rodmakers Gathering.I have dreamed about it for months.Feverishly. With the doubt I may not be able togo. But after many uncertainties here I am.How nice!Carcassonne !Les 5es rencontres européennes des constructeursde cannes en bambou refendu ! Des moisque j’en rêve. Fébrilement. Sans être sûr depouvoir venir. Après bien des incertitudes, ça yest, j’y suis quand même. Bon sang que c’estbon !I can meet those crazy people I encounteralmost daily on the "Gillum Forum". I can seeand touch their work. I can listen to experts’advice. I can take photos, ilm if possible. Observe,observe, observe.The 10th of November I take advantage of everystep that brings me nearer to the Salle du Dome.Not too quick, I must savour every minute. Thenight before I had found the address. It can’t betoo far.Entering, I already imagine putting the faces tothe names and the pseudonyms. It is true, wehide behind avatars, we invent strange names…only to realise this does not facilitate the identi-ication of the participants. What a pity, I shouldhave thought of it beforehand!Je vais pouvoir rencontrer ces doux dingues queje croise quasi quotidiennement sur le forum deGillum. Voir et toucher leurs réalisations.Ecouter les conseils de ceux qui savent, de ceuxqui ont déjà fait. Prendre des photos, ilmer sipossible. Observer, observer, observer.Ce 10 novembre 2<strong>01</strong>2, je proite de chaque pasqui me rapproche de la salle du Dôme. Pas tropvite, faire durer l’instant. La veille au soir, j’airepéré l’endroit. Ça doit être grand là-dedans.En entrant, j’imagine déjà mettre des visagessur des noms, sur des pseudos. C’est vrai ça, onse cache derrière des avatars, on s’invente desnoms bizarres… pour inalement se rendrecompte que ça ne va pas faciliter l’identiicationdes participants. Tant pis, fallait y penser avant !Italian Bamboo Rodmakers Association

<strong>pag</strong>e 17Bamboo JournalWith my irst 18 strips under my arm, I feelcomfortable and completely “awkward” at thesame time. Even more when I see the hugetables laid out in front of me with beautiful rodson them. I was expecting this but it goes beyondmy expectations.- «Good morning. Olivier "Fox-589"on theforum. »- «Welcome. Come, your space is over there! »I have a dedicated space? An exhibitor’s badge?The members of the Club Mouche Audoise haveorganized this grandly!- «Thanks a lot. »I put my modest parcel down and I take time tohave coffee. Along the grandstand in front of methey are trying some rods, extending lines. I likeall this. At the end, on the left, there is a nice –very nice – exhibition that catches my eye. Verygood! The prices for tomorrow’s lottery! It isbetter than a Christmas window.Quick, I must buy some tickets, one neverknows. At the same time I feel a little ashamed. Icould have offered something too. Obviously nota rod but a book, a bamboo strip, anything else.Next time I will not fail.Ok, let’s meet some contacts now. It is notdificult, everyone is here for the same reason.- «Hello! Nice rods ». They look familiar. I sawthem on the Gillum site obviously. At least one ofthem. Actually it is even better. A lot of work ofSilverly31. And here we see the master’s touchin the construction.I only have a little theoretical knowledge of allthis. And I am lacking in many things – I know –despite all the hours watching videos in manylanguages I don’t know very well.- «No, it is not dificult. Not even the bambooferule, you’ll see. »- «All those that have built at least one rod, saythe same thing. But it looks complicated to me ...mostly because I don’t have all the tools yet. »Mes 18 premières baguettes sous le bras, je mesens en même temps à ma place et complètement« à côté de la plaque ». Surtout quand jevois les immenses tables disposées devant moiet les cannes splendides posées dessus. Je m’yattendais, mais ça dépasse quand même mesespérances.– « Bonjour. Olivier “Fox-589” sur le forum. »– « Bienvenue. Venez, votre place est là ! »J’ai une place attitrée ? Un badge d’exposant ? Ilsont fait les choses en grand, les membres duClub mouche audois !– « Merci beaucoup. »Je pose discrètement mon modeste fagot etprend le temps d’un café. Tout autour, ça discutegentiment. Le long des gradins en face, on testedes cannes, on étend de la soie. J’aime ça. Aufond à gauche, un bel - un très bel - étalage attiremon regard. Bien sûr ! Les lots offerts par latombola de demain ! C’est mieux qu’une vitrinede Noël. Vite, acheter quelques tickets commeprévu, on ne sait jamais. En même temps, j’ai unpeu honte. J’aurais pu offrir quelque chose moiaussi. Pas une canne évidement, mais un livre,un tronc de bambou, quelque chose quoi. Laprochaine fois, faudra pas louper le coche.Bon, maintenant établir le contact. Pas dificile,tout le monde est là pour ça.– « Salut ! Jolies cannes. » Il me semble que je lesai déjà vues. Sur le site de Gillum évidement.Au moins l’une d’entre elles. En vrai, c’estencore mieux. Un sacré boulot de Silverly31.C’est là que je vois la maîtrise, tant dans laconstruction que quand il s’agit d’en parler.Moi, je n’ai qu’une connaissance théorique detout ça. Et il me manque énormément de choses– le ressenti – malgré les heures de vidéovisionnées dans tout un tas de langues que je nemaîtrise pas.– « Non, ce n’est pas dificile. Même les virolesbambou, tu verras. »– « Tous ceux qui ont au moins une canne à leuractif disent la même chose. Moi, ça me semblecompliqué… surtout que je n’ai pas encore tousles outils. »Italian Bamboo Rodmakers Association

<strong>pag</strong>e 18«Stop complaining Olivier, you are in the bestplace to learn, so get a move on! I told myself. Youhave already met many people you know aremasters of rodmaking. Go on, ask. »In fact, Alberto Poratelli is there, in front of me.To say that I admire his work is a euphemism. Aweek does not go by without a visit to his site,his twitter account to see his latest work. Iintroduce myself and I show him my strips. Thedefects I found. He throws out two strips andgathers the others. Six for the tip, six for thebutt. He takes one of his 7'#4 rods and puts itnext to my strips. «You must cut here. And here»With one hand movement after the other healigns the strips, marking the reference points.«I will send you the drawings by email. An easytaper to build for a beginner. No problems. »I was hoping to collect some advice. I washoping that someone would tell me what to doand what not to do… and there, in ive minutes,Alberto put me at ease. Pleasantly, simply. Myeyes were sparkling with admiration. He? Ithink he was amused by the fact he had a fanlike me.A little later I went to see the demonstration ofPaul Agostini and Pierre Perrot, of ChristianBurger, of Patrick Maleig, Jean Santos and MihaiStanciu. And then there were the discussionswith Alix, Alain, Gino, Laurent, Gillum, MrHooligan, Sabryt, Moreno, Gabriele, Josselin,Gary ... and many others whom I thank for theirkindness and availability.There was nothing but meetings like these fortwo days. Simple, without prejudice. With onlyone idea in mind: sharing knowledge andexperience. Thanks to all, without exceptions.Truly.Bamboo Journal« Arrête ton laïus Olivier, t’es justement aumeilleur endroit pour apprendre, alors bouge-toi! me dis-je. T’as déjà reconnu un tas de gens donttu sais qu’ils sont des maîtres en matière deconstruction. Vas-y, demande. »Justement, Alberto Poratelli est là, pile devantmoi. Dire que j’admire réellement son travail estun euphémisme. Il ne se passe pas une semainesans que j’aille faire un tour sur son site, que jeconsulte les tweets sur ses derniers travaux. Jeme présente et lui montre mes brins. Lesdéfauts que j’ai identiiés. Il écarte en effet deuxbaquettes, en regroupe d’autres. Six pour lescion, six pour le talon. Vous connaissez tout ça.Il prend une de ses propres cannes 7’ #4, laplace à côté. « Il faudra couper là. Et là. » D’ungeste sûr il ajuste les brins, trace les repères. « Jet’envoie les plans par e-mail. Un modèle facile àréaliser pour un débutant. Pas de problème. »Moi qui espérais glaner quelques conseils. Quiespérais qu’il y aurait quelqu’un pour me direquoi faire ou ne pas faire… Et là, en cinq minutes,Alberto en personne m’a mis à l’aise. Aimablement,simplement. Moi, admiratif, j’ai lesyeux en billes de loto. Lui ? Je crois que ça l’aamusé d’avoir un fan comme moi.Un peu plus tard, j’irai voir les démonstrationsde Paul Agostini et Pierre Perrot, de ChristianBurger, de Patrick Maleig, Jean Santos et MihaïStanciu. Et puis il y aura les discussions avecAlix, Alain, Gino, Laurent, Gillum, MrHooligan,Sabryt, Moreno, Gabriele, Josselin, Gary… et tantd’autres que je remercie pour leur gentillesse etleur disponibilité.Pendant deux jours, ce ne seront que desrencontres comme ça. Simples, sans a priori.Avec une seule idée en tête : partager sesconnaissances et expériences. Merci à tous sansexception. Vraiment.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 19Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 20Bamboo JournalPatrick is a French rodmaker fromMoumour in south east PyreneanFrance.At the Carcassonne gathering Ihad the chance to admire thesplicing block and he enthusiasticallyaccepted that we publish thedrawings of this tool.Like many rodmakers he is a manof few words and of great talent;he is not deterred by dificultiesand has in fact adopted MarkTwain’s motto:“They did not know it was impossible,so they did it”.Moreno BorrieroSplicing Blockby Patrick MaleigDepuis que j'ai adopté la méthode nodless,je n'ai cessé de chercher à améliorer l'outil quisert à la taille du splice.J'ai commencé avec un bloc splice en nylon ( P.E)qui m'a permis de faire ma 1ère canne.ça marche très bien mais il faut le maintenirfermement plaqué sur la table avec la maingauche.Pour une canne de 8', il faut compter 96 splices,et là, ça devient fastidieux.Avec le bloc en métal sur l'étau, on gagne enconfort et en temps, la baguette est bien maintenueet le coup de rabot est bien plus précis eteficace.After having adopted the “nodeless”constructive method, I have not stopped to lookfor the best tool to cut the strip.I started with a nylon block splice with which Ibuilt my irst rod.This worked very well but I needed to keep itstill on the table with my left hand.To build an 8’rod you need 96 splices and itbecomes annoying.With the metal block in the vice, you gain incomfort and time, the strip is well ixed and thepassage of the plane is more precise and moreeficient.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 21La petite gorge qui se trouve sur le dessus sert àéviter de toucher le bloc avec la lame du rabot.La largeur de la rainure où l'on engage labaguette est fonction de la longueur de la canneque l'on veut réaliser.J'avais mis 8mm sur un 1er bloc, et quand j'aivoulu réaliser une canne à saumon, j'ai dû enfaire un second avec une gorge de 10mm.La profondeur de celle-ci ne doit pas dépasser4mm pour pouvoir serrer les brins de faibleépaisseur.Sur les plans,je n'ai pas côté ni les ressorts, ni lesguides, ni les supports, chacun fera en fonction dece qu'il va trouver comme fourniture.Par mesure d'économie, j'ai réalisé mon outil enassemblant 2 barres d'acier étiré de 25x12 et16x12, mais on peut le réaliser dans la masse enfraisage.PS: j'ai oublié de côter la longueur de l'ensemble:il fait 45cm de long.Bamboo JournalThe small groove on the surface helps to avoidtouching the metal with the blade of the plane.The width of the slot where we insert the stripdepends on the length of the rod to build.I made it 8 mm on the irst block and when Ihad to build a rod for salmon I had to makeanother one with a 10mm slot.The depth of these slots must never be morethan 4 mm to grip the thinner strips.On the drawings I did not indicate the springs orthe guides; everyone will put them according towhat one will ind more easily from one’ssuppliers.For the purpose of saving, I built my tool byconnecting two steel bars of 25x12 and 16x12,but it can be built by milling a whole block.I forgot to indicate the entire length: it is 45 cmlong.My mail address is:patrick.maleig@club-internet.frItalian Bamboo Rodmakers Association

<strong>pag</strong>e 22Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 23Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 24Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 25Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 26Bamboo JournalGabriele GoriStress in bamboo rods,basic concepts,and the Garrison model§ § §The purpose of this work is an attempt toprovide the basic elements of the stress inbamboo rods which are needed to interpret thediagrams one inds associated to the varioustapers.The basic concepts we will illustrate are alsovalid to understand and to use the mostcommon rod design software in the Internationalcommunity of rodmakers, i.e. RodDnaDesignLarry Tusoni and Hexrod, with awareness of thefacts.In fact, although these programmes vary inoffering the possibility to intervene in thedesign of the taper with different approaches,each with its good and bad points, they have onefundamental aspect in common.Both are based on the Everett Garrison’s calculationpattern.I presume you have all read the book “A masterguide to build a bamboo ly rod” written byHoagy CarmichaelIf not, it is time to read it: no rodmaker worthyof this name can go without knowing the workof the “master”Italian Bamboo Rodmakers Association

<strong>pag</strong>e 27Bamboo JournalThis does not mean that one must accept his“philosophy” on rodmaking completely orfollow his methods slavishly in every phase ofconstruction: it means, again, that a rodmakerworthy of this name must compare his workwith that of the Master.IMHO naturally.What is certain is that Garrison’s entire work isguided by reasoned aesthetical technical andfunctional choices, which are acceptable or notbut they give the big picture of his work that wecould deine as Garrison’s rodmaking philoso-phy-His approach to rod design is also particular: forthe irst time the design of the rod is tackledwith scientiic methods, i.e. with the analysis ofa calculation model that although it is schematicand simpliied, it represents the rod considerablywell in some aspects.In the last part of the book there are the detailedcalculations that Garrison did manually witha slide rule and the patience of Job.Today we have calculators that do that in aninstant: as I mentioned previously, both Hexrodand RodDna Design are based on the Garrisonmodel.It stands to reason that to reach this goal onemust understand how the Garrison modelworks.I will not do the numerical calculations and Iwill only use mathematical formulae if forced toand anyway they will be as simple as possible.Instead I will try to illustrate the method followedby Garrison in a qualitative way: I hope totransmit those basically simple, indispensableconcepts to use the RodDna Design programmewith more awareness.Unfortunately some basic concepts need to beclariied otherwise we cannot understand theterms used in Garrison’s model (or any other).First of all we must explain stress because asyou know the Garrison method is based on thestress graph.The stress or “internal tensional state” is thestrain that is created in the material of which abody is made when it is stimulated by an externalaction.For example let’s look at the case of a pillar (inthe drawing it has the shape of a hexagon)stimulated by a vertical axial load N.Italian Bamboo Rodmakers Association

<strong>pag</strong>ina 28The material from which the pillar is madereacts to oppose the external force and to keepthe static equilibrium: the internal stimulationof the pillar will be such to balance the axialload N and thus, if we consider that the wholesection will react uniformly, it will be equal toN/A where A is the area of the section. Thisinternal stimulation that has the dimensions ofa pressure, i.e. a force divided by a surface iscalled stress.Bamboo JournalIf the stress is greater than the resistance of thematerial, the pillar collapses.The stress can be of traction or of compressionaccording to the action of the external force.Being pressure, it is measured in kg/square cm,oz/square inch, in pound/square inch, Pascal,Bar etc.Let us now look at the lexing which is whatinterests us directly because, obviously, it is themain action of a rod.If you take a beam, in our case a rod, and youlex it like in the igure, the upper ibres will betense while the lower ones will be compressed:in other words tensions and compressions willdevelop inside the material to form a “torque”able to balance the external lexing.In a symmetrical section like those we areinterested in, they vary linearly (it is a simpliication)from the maximum value on the edge tothe zero value on the neutral axis of the lexure,in this case it coincides with the barycentre axis.Another way of looking at it is that the upperibres that are tense lengthen, the lower onesthat are compressed shorten and those on theneutral axis remain unchanged.The value of the stress, in this case equal on thecompressed side and the tense side, is given bySt=Sc= M*y/J, where y is the distance from theneutral axis and J is the inertia moment of thesection which we will mention shortly.As mentioned previously, the value of the stressincreases from zero on the neutral axis to theedges where it reaches its maximum value.Italian Bamboo Rodmakers Association

<strong>pag</strong>ina 29If the beam height is H,Sc=St= M*H / 2*J,because on the edges y= H/2It is easily seen that the value of the stressdecreases with the moment of inertia of thesection, that is to the denominator.The moment of inertia of a geometrical igure isa largeness that deines its resistance (inertia)to rotate around an axis.Bamboo JournalIt considers the shape of the section, i.e. how themass of the section is distributed related to thebarycentre: it is everyone’s experience that astrip with a rectangular section is a lot morerigid if one tries to lex it on a plane as opposedto a perpendicular one.The area is the same (weight) but the rigidityis very different.In fact one can imagine the moment of inertia asthe sum of ininitesimal areas that constitutethe section multiplied by the square of thedistance from the axis.Once and for all if a beam has a transversalsection that as a moment of inertia double thatof another, the latter will lex double the former,subject to the same lexing actionEach geometrical igure has its formula tocalculate the moment of inertia, like it has itsformula to calculate the area.With equal surfaces, each geometrical igure;square, pentagon, octagon, empty square has adifferent moment of inertia because the mass,although it is the same, is distributed differently.Italian Bamboo Rodmakers Association

<strong>pag</strong>ina 30Bamboo JournalFor our purposes sufice it to know that if wetake a series of strips, each with a differentshape, triangular, hexagonal or other, all of thesame length and of the same material and wesubject them to the same load after havingblocked one end in a vice, all the strips willdeform in the same way, if they have the samemoment of inertia.As many of you know after having attended theGerman Gathering in Waischenfeld in October2007 or the 1st European Gathering in Sansepolcroin 2008, the study in the various sectionsof a rod and the relative chart of the “Comparisonof Sections” are in fact based on thisconcept: the various typical sections of ourbamboo rods, different one from the other, full,hollowed, luted and so on, if they have the samemoment of inertia, with other factors equal(length, taper, material) they will have the samerigidity in the lexure and thus they will deformin the same way.THE GARRISON MODELThe Garrison model is rather simple: it illustratesa rod like a shelf blocked at the handle andfree at the point.This rod is then subjected to a system of loadsthat are:- A concentrated load on the tip top which is theweight of the line and the tip top- One or more concentrated loads which are theferrules- A distributed load which is the varnish-A distributed load which is the weight of thebamboo itself.-A series of concentrated loads which are theguides and stripping guideAll these loads induce an action in every sectionof the rod called torque that stimulates the rodwith bending actions and it is done with thesingle load multiplied by the “arm” i.e. thedistance between the point of application of theforce and the section in which we have decidedto calculate the torque.There are also axial stimulations (negligible)and cutting stimulations which are not negligiblebut are not considered in Garrison’s chart.Once the torque has been found for everysection of the rod, Garrison stated that his rodsmust be stimulated in each point equally, i.e. thestress of the material will be constant for theentire length of the rod.He deines the maximum safety stress as170.000-180.000 oz/si (approximately800kg/cm2) and an average of approximately150.000 oz/si (about 660 kg/cm2) and with theinverse formula he calculates the diameter ofeach section.Italian Bamboo Rodmakers Association

<strong>pag</strong>ina 31Bamboo JournalSo Garrison’s rods are designed this way, to haveconstant stress on the whole rod, of coursewhen they are loaded according to the Garrisonload chart.The author deines them as “progressive” and itis the only correct way to associate the term“progressive” to the action of a rod.Is the chart correct?For one let us lay down that no calculationmodel is absolutely correct:there are models come more or less close toreality.Garrison’s one is frankly rather rough.Garrison was a civil engineer and as such wascomfortable with calculations relative to structuralconstructive elements.In this type of technical sector, the real deformationsof the structure are very small and allowone to not consider certain effects with negligibleerrorsGarrison’s hypothesis is that the rod, subject tostatic loads will not deform or better, willdeform very little: it is clear that this hypothesisis quite far from reality.The rod deforms a lot and the stimulation statechanges considerably.The rod subject to the load deforms and consequentiallythe point of the application of forcechangesThis results in the moment calculated with theGarrison chart being greater than the real one.There are more reined calculations to resolve astructure, for example the Eulero-Bernoulli onesthat take into account the great deformations.Hereunder is the Garrison stress diagram(upper line) and the one calculated taking intoaccount the real deformation of the rod (lowerline), for three typical rods with tip action,parabolic action and progressive action.Italian Bamboo Rodmakers Association

<strong>pag</strong>ina 32Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 33Bamboo JournalThe current version of RodDna Design providesthe stress curve calculated with the Garrisonmethod and the one calculated taking intoaccount the deformations of the rod, whileHexrod only uses the Garrison.It is immediately obvious, as previously explainedand as must be expected, that the stress islower than the stress calculated with the Garrisonmethod (because the lexure moment islower) .However, on the other hand one notices thatthey are very similar in terms of lexing.Thus we can say that the stress curves calculatedwith the more correct method (great deformations)round off, per se, the ones calculatedwith the Garrison method and all in all theyunderline less the characteristic of the taper.Let us consider that the curves calculated withthe Eulero-Bernulli method also refer to theGarrison static chart and they too are quite farfrom reality:during the casting the rod is stimulated bydynamic forces, and not by static ones, thatinvolve the inertial aspects and the resistance ofthe air.In conclusion, in my opinion, the calculationmethod used by Garrison cannot establish theexact distribution of the stress in the variouspoints of the rod.It can, instead, provide the stress curves thatrepresent well the action of the rod and thatallow the experienced rodmaker to understand(and predict) the real behaviour of the rod.For this reason I believe that a non rigorousmethod like the Garrison one was accepted bythe rodmaker community and it continues, eventoday, to be used: because with a quite simplechart, it provides results which are usable in thedesign of a rod.Gabriele GoriItalian Bamboo Rodmakers Association

<strong>pag</strong>e 34Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 35Bamboo JournalRespectby Alberto PoratelliI believe that bamboo rods can be considered“timeless” human achievements like paintingsand sculptures.Timeless because they never age and becausethe logic behind them and the building techniquesspeak to us about an era – a way of life anda special way of considering ly ishing. Bamboorods inevitably transmits to those who holdthem a sensation of respect and deference andthis, I believe is aptly demonstrated by theepisode I’m about to narrate and that happenedto me.Most ishermen have had some form of a moreor less serious misadventure. Trees and branches.My last misadventure goes back toSeptember 2<strong>01</strong>1: I was ishing Steelhead in BCwith a group of friends and one day whiledrifting down the Kispiox River, the person whowas supposed to know the river well took awrong turn and we found ourselves in somerapids which led to a great barrier of tree trunksand branches.Four hundred meters of tumultuous descent,trying to control the impressive force of thewater with our paddles, only to land up againstthe barrier of branchesMy waders got full of water and this made me asheavy as an anvil and I was forced to a superhumaneffort to free myself and to drag my legs,which were as heavy as rocks and that werepulling me underwater, onto the barrier oftrunks made slippery by the moss growing onthem.I lay on my back exhausted and I looked to myright where I could see my rod, my 12’ bamboorod which was caught up in some branchesabout 10 metres away from me.Lying on the branches, I looked at it…it was onthe opposite side of where I was and where Iwould have had to crawl to get out of the ragingtorrent under me.Attempting to save it would have meant riskingto land up in the water again and I did not havethe strength to ight the current again. I tookone last look at it and I crawled along thebarrier in the opposite direction towards thebank.A few hours after having reached the bank, Ifound my ishing friends who were also exhaustedafter having fallen into the river. They toohad lost their rods but likewise were happy tohave made it.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 36Bamboo JournalThat evening we spoke about what had happened in front of acup of hot coffee and a bottle of whisky. We were all sad forhaving lost three two handed rods that we would have neverseen again.Mine was not on the bottom of the river like the other two buthad became part of the barrier of branches and trunks and whoknows where it was going to land up after the irst springloods that would have washed everything away.It was a beautiful blonde rod with green wrappings and reel seat. It was strong and powerful.Now it was going to inish its existence in the forests of ir trees in BC. After all it is a beautifulplace.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 37Bamboo JournalTime passed and in my log book where I carefullywrite all the particulars about the rods Imake – I wrote - “Lost in BC” and forgot aboutit.I continued making rods for a while until oneday, after 15 months I receive a mail.It was Bob Milward – a Canadian rod makerwho wrote« Dear Alberto, An angler has found a doublehanded rod near Smithers, British Columbia … Isit yours or did you sell it to someone? … The buttis O.K. except one amber line guide and a fewsnakes need to be replaced. The middle sectionhas a serious bend which will require heatstraightening. The tip section has a severe bendand some bamboo is missing completely from themiddle. The whole tip section must be replaced.”… “What do you want me to do?—Mail it back toyou, or repair it for the inder?»It is she!She has spent 4 seasons in the woods and now aisherman has found it and taken it to a rodmakerfor repairs. But irst he asks if he can keep itor if he should send it back to me. That is therespect I was talking about earlier – the respectthat every isherman has for a bamboo rod.This isherman is 9000 Kilometres away.He could just keep the rod and nobody wouldask where he had got the rod, but he has respectfor it and asks whether he should send it back tome.«Dear ... I will be happy if you repair the rod andif it becomes your rod …» was my answer.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 38Bamboo JournalItalian Bamboo Rodmakers Association

<strong>pag</strong>e 39Bamboo JournalThe Heat Treating "Mystery"by Massimo Paccotti and Marco di LorenzoIn our magical bamboo world, we are sometimesfaced with constructive phases that seembanal and quick but to which we must payutmost attention and precision. One of these issurely the heat treatment, a chemical/physicalphase to modify the structure of a part of theorganic components of bamboo; the componentsof the lignin, in this process, pass from asingle bond to a double bond by polymerizationand thus making the bamboo stronger, moreelastic and more reactive.These bamboo characteristics are very importantin terms of ishing results and according tous they are directly proportional to the way weexecute the right heat treatment. For want of abetter explanation, if we glued a non heattreated blank, the result would be a "soft" rod,without back bone, lacking the essential requisitesof a good tool. Instead, with the right heattreatment, the sugars contained in the goodibres "caramelize" and once the strips cooldown they harden to the point of transformingthe soft rough wood into an elastic, functionalrod. To obtain this an initial drying phase isimportant (especially if, like us, you work in anambient with high humidity) and a second heattreating phase, both executed at the righttemperatures, otherwise the work would be invain (later we will see the best way to performthem).Unfortunately nowadays the culms we receiveare not always perfectly seasoned, with somehumidity in them; in other words our bamboo istoo damp to construct excellent ishing rods sowe will have to not only store it in an open andventilated environment (certainly not in a cellaror a tin shed),obviously protected from the rain but also heattreat it it to the best of our ability once we havechosen the culm and smoothed the strips.Now we come to our experience in the matter:we realised that some rods, once they are glued,did not have an instantaneous return or better,subjecting the tip to bending , it tended toremain strangely curved, bending it the otherway would restore its original linearity.At this point there were many doubts regardingthe causes of this and by asking the opinion ofsomeone more experienced than us, we resortedto blaming this defect on the glue that wasnot gripping the strips correctly, maybe due tothe temperature of the drying times or thehumidity in the strips (we use epoxy glue).Re-gluing produced the same result; the rod didnot have a good return as if it were lacking"back bone". At this point we began to do sometrials in the oven, our problem could have beenthe heat treatment which was not executedproperly and after having spent a day sacriicinga few strips, things inally started tochange.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 40Bamboo JournalWe insert the smoothed and tied strips in thesmaller chamber of the cold oven, we turn onthe gun that feeds the large chamber and webring the internal temperature to 110/120degrees; we remind you that it must be uniformfor the entire length of the oven (this is guaranteedby the presence of two thermometersplaced at the two ends of the oven). Once wehave reached the temperature, the strips arekept to dry for about an hour (this does notaffect the molecular composition of the bambooor the colour of the rod), being careful not to letthe temperature drop below 100 degreesOur procedureWe start with a ventilated oven about 2m longcomposed of a double chamber fed by a hot airgun. Some rodmakers use ovens powered by aresistance with excellent results, the mostimportant thing is to have perfect control of theinternal temperature.In the past, we too used this type of oven butwe could not - due to our construction errors -uniform heat and the risk of burning the stripswas ever present.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 41Bamboo Journal(this allows us to let the excess water in thebamboo evaporate). At this point we decide ifwe want a light coloured rod a slightly ambercoloured; for the irst option we remove thestrips from the oven and we raise the temperatureto 190/195 degrees (careful not to go overthis temperature) and we put the strips backinto the oven for eight minutes,this time for the heat treatment. The otheroption entails leaving the strips in the ovenwhile we raise the temperature with our thermalgun which will - with its hot air low -colour the rod.This time too, once we have reached 190/195degrees, after eight minutes, we will havetreated the strips. Now, when they have beenremoved from the oven, it would be detrimentalto untie them and immediately start planingthem; if we saw the inside of the strip immediatelyafter the heat treatment, we would noticethat the ibres (the dark, good side of thebamboo) are compact, almost "caramelized"and our strip that is still warm, is soft andsupple (think of the straightening process).Italian Bamboo Rodmakers Association

<strong>pag</strong>e 42Bamboo JournalThe best thing to do, in our opinion, is to keep them tied on a lat surface at least one day; this will givethe strips enough time to cool down and to harden without deformations after the thermal shockduring the tempering in the oven.Now you can test it: take a heat treated strip and a strip form the same culm that has not been subjectedto this procedure and apply the same lexure to both and you will see that something has deinitelychanged (you will also have dificulty in straightening some small imperfection in the strips).In conclusion, we do not want to afirm that our method is the only one or the best one, in fact the moreexperienced rodmakers will maybe contradict us but it certainly has given us excellent results.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 43Bamboo JournalAndrtoWRkerAndrea Satto is the creatorof wood reel published inthe previous <strong>pag</strong>es.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 44Bamboo JournalTHE “SECOND” FIRSTby Enrico FrancioniThe day after I was handed my rodmakercertiicate (at Podere Violino in Gricignano,Sansepolcro AR - Italy, on 30 November2<strong>01</strong>1), [photo_<strong>01</strong>: My rodmaker certiicate] Ifelt invested in the role and charged with acertain responsibility that went beyond alight commitment (for that matter taken withawareness and conscience), to prove … but –note well – to prove to myself irst of all, thatI too was really able to organise all thematerial and to start thinking about buildingmy irst real bamboo rod: obviously “second”irst.One of the things I thought I would be able tokeep in mind, as if in an only image or in a solesequence of actions, was the entire work planthat punctuates almost “religiously” what goesinto the building of a bamboo rod: I assure youthat – at least in my case initially – there isnothing more dificult to control all at once,everything looks so complex and the wholecourse is so articulated …!The sacriice for the construction of the Number0 rod, the Heddon, would soon be rewarded bythe beautiful sensations given by the fascinationof casting with the new material, bamboo, thatreplaced graphite and by some noteworthycatches that also gratiied the ly isherman aswell as the novice rodmaker!To be truthful, I still had to complete the varnishingon my Heddon ("Folsum" 7' #4 2 pc), builtat the IBRA 2<strong>01</strong>1 course.Once I had bought the Cecchi products(Spinnaker and thinners) I redid the varnishingand the sanding (grain 600) of the wrappings, Isigned it with a nib and black China ink andinally the meticulous brush varnishing –perhaps the most simple method (in the spontaneoussense) but at the same time the mostdificult to obtain an excellent result … (I amcomparing it to the immersion varnishing thatensures better results right from the irst trials).Italian Bamboo Rodmakers Association

<strong>pag</strong>e 45It was mid-December and my hands wereitching to start a new one all by myself …My debut would have to wait two more months:this was the time it took to organise a satisfactory,suitable space and to buy the necessarymaterial, practically everything!With my inseparable notebook and thanks tothe constant help of competent and patientpeople like Poratelli, Giardina, Giuliani, Gori andFiorani (literally looded by my emails and Ilisted them in the order of the amount of messagesI sent them), I was learning about thevarious models of planes, blade sharpeners,stones for smoothing, comparators with pointsand bases, Japanese saws, the various Europeanand overseas producers and distributors …, andthen comparing prices for the right quality-pricebalance in buying the material, which sometimesis just Utopia …Not to mention the constant contacts with myrodmaker friend Simone Paci, whom I thank forhis incessant availability.I admire his precision and his generosity inexchanging/ comparing advice and solutions; heis also my purchasing partner.Bamboo JournalLuckily I found a corner in the garage under myhouse and that is where I stacked the irstthings I got to start the work on my own: awell-lit work bench with a vice, some tools Iconsidered indispensable in the irst stage ofconstruction and then obviously drawers withdifferent types of gloves, iles, sandpaper andvarious other toolsWhile waiting for the arrival of the material tostart (wooden planing form, plane – a Dictum:an absolute novelty - blade sharpener, stoneand steel planing form) I was carefully goingthrough the notes of the course and I wasstarting to measure the cuts of my irst bamboostalk: on one side the butt and on the other thetip while trying to resolve the question of the“nodes”: three on the butt and two on the tip(that is how it is normally), to have the bestpossible division.After a round of consultations I chose my taper(keeping the 7’ length as we were advised at theend of the IBRA course) – it was a Lyle Dickerson7<strong>01</strong>2,Italian Bamboo Rodmakers Association

<strong>pag</strong>e 46and so after many measurements with a measuringtape (rigorously in inches) and various felttip pens in hand, I decided to cut the culm withmy brand new Japanese saw, to split it with akitchen knife and then with the nail ixed in thevice, I divided the strips in their classical sets(1+1, 3+3, 6+6, 12+12).As a further reminder I had made a small(recycled) cardboard case where I had copiedthe splitting procedure on a section of a bamboostrip.Bamboo JournalAnd secondly I was carrying some errors in thesplitting which hadn’t been done quite right …Before iling the nodes in my strips, I decided tosquare them a little better in the 90° guide ofthe wooden planing form with my brand newDictum, to get a section as rectangular aspossible or slightly isosceles-trapezoidal:this operation would greatly facilitate the nextphase of the irst roughingNonetheless I immediately made some mistakes:I extracted material for only three rods …(sigh!), three butts and three tips; probably adefect in the inclination of the strip on the nail:maybe the operation was done in too muchhurry, well, I don’t understand …I will not bore you with the description of thenext passages in the construction but I will saythat in all the phases I trod very carefully, like“walking on eggshells”; I could feel everyonestaring: the rodmaking world, my friends andfamily who in the construction period looked atme with an expression I would describe assupportive but with a hint of scepticism regardingthe results I had announced.After the staggering I moved on to the treatmentof the nodes and the straightening of the strips,very busy phases: irstly because there are atleast two or three different methods tied to theorder in which to do these two operations ….The choice (autonomous this time) was theright one and the perfume of bamboo heatingwith the air pistol made me feel more like arodmaker!I must confess that another phase I thoroughlyenjoyed was the roughing (i.e. the planing of thelevels) of the 12 strips; the plane with a new,sharp blade was moving smoothly and conidently,the shavings accumulating and the work,although tiresome, was particularly enjoyable.Only after a few days did I notice that the newblade I had used in the Dictum was sharpenedat 25°.I tied the two sets of strips manually andwithout the use of the Garrison Binder and aftera couple of days I was ready for the heat treatmentin Simone’s oven, the temperature wasright and after two passages out came fumingtip and butt. I was ready for the next phases.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 47Bamboo JournalRespectful of the experts’ advice and with thebest intentions I spent a whole afternoonsharpening my blade to the 35° inclination…. Iwas not aware of the blade’s 25° inclination yetand that I could have sharpened only a part ofthe blade…. but I was not satisied: I wanted tosee a mirror inish on all the cutting edge of theblade….. imagine how much extra work! Tofollow bevel and micro bevel and the cuttingtest; the result seemed satisfactory and the nextday I proceeded to the planing of the strips inthe steel planing form.Unfortunately I didn’t have my own personaldepth guage, so once again I relied on Simone’sgenerosity who kindly lent it to me.With the taper measurements under my nose, Iset my planing form for the butt; the planingform that I had previously cleaned, greased andpolished for the occasion.I must admit that working with the plane is notan effort for me – perhaps this made me alreadyfeel like a rodmaker? – and this time too Ienjoyed this activity of movement and precisioncombined.I put together the six butt strips and six tipstrips and I was ready for the irst test of themeasurements from the taper with my digitaldisplay Vernier calliperAfter cleaning the enamel, I would proceed toplaning as precisely as possible but I needed asharp blade in place; considering I had had thegood sense to buy the Dictum with a secondblade, I decided to use this second blade exclusivelyfor the precision planing (obviously theirst blade would be dedicate to the roughing,this is my current “economical” alternative tobuying two planes).Now was the moment to sharpen it properlyand I have to tell you how it went!The few thousandths of inches in excess werecorrected by the resetting of the planing formand I achieved the measurements that, evenaccording to the experts, satisied my conscience;the error was contained between an oscillationof ± 0.0<strong>01</strong> inches!: I was satisied and couldnow think about the glue.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 48Bamboo JournalAnyway, after a few minutes the two sides wereglued, tied, “rolled”, hung and subjected to thevertical rolling with a bottle of water, tomato,tuna cans, books and anything else …Perhaps time is the critical element to faceduring the gluing operation.Obviously this problem is tied to the dryingtimes, but also, as in the case of the two componentglue Cecchi (C-Systems 10 CFS), to theamount of thickener and thus to the desiredthicknessWhile waiting for the glue to dry, I meticulouslywent over (for myself) the complex phases ofcutting the rough pieces for the mounting of theferule (see notes from the Building Course2<strong>01</strong>1).During the 2<strong>01</strong>1 Course Massimo GiulianiIn this operation I received help from noneother than my wife: her support has beenfundamental; even though it was clear to methat in future I would have to think about adifferent strategy to enable me to do everythingon my own.I thought of the “wise” construction of a GarrisonBinder…when we reached this phase had warned usagainst “cutting”: a thousand measurements,one cut only; in fact, for safety reasons he hadmore than once encouraged us to mark thecutting point with tape on the tip and on thebutt … "there is plenty of time to cut ", herepeated.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 49Bamboo JournalSo after untying and cleaning the blanks, accordingto the constructive requisites, here was themoment – measurements at hand – to mark thecuts.To be truthful and to avoid misunderstanding,the two blanks had been on the work bench fortwo days before the deinite cut; then came thework on the ferrule before the gluing with thetwo components glue.just to have an idea of the dimensions, theshapes and the number of discs to use … Idecided on 27 discs, perhaps too many for a 7',although at this point – according to everyone –the quantity is rather subjective and is substantiallybased on the grip as well as the position ofthe reel (up or down locking).Once I had chosen the appropriate glue, waterresistant, Vinavil D3,After a few hours the ferrules (appropriatelymachined) were in place and the cork discs ofthe latest Purchasing GroupI made a hole with an 8mm die in the discs andthen inserted them in a threaded iron bar forthe compression, ready the next day to bemounted on the drill for the shaping withsandpaper.The “pear” shape of the handle came quitenaturally but it also gives the handle moresolidity, it was pleasant and it reminded me ofmany rods from the 50s or some Paul Younghandleswere waiting for the construction of the handle;the construction work of the handle is really funbut irst, to have a satisfactory stock, I drew on asheet the outline of the handles of ly ishingrods I had in the house;Italian Bamboo Rodmakers Association

<strong>pag</strong>e 50Simone and I had decided to work in such a wayas to create our own models of reel seats: littleblocks of burl (Thuja and Amboyna are still thefavourites), small lathe, drill bit for the mortise,guiding tool to construct the mortise, iller andimmersion in inal varnish.Bamboo JournalI placed the guides on the rod and with an eyeon my dwindling spools of silk, I thought of thetying models I had played around with in myhead and I chose this one, even if it seems a littletoo elaborate as a irst original tying.After a few days my reel seat was ready tomount;I must admit that this element requires a lot ofwork: after choosing the type of reel seat (uplocking or down locking, with or withoutmortise), one chooses the type of wood, theshape, the length, the diameter… and then thetype of hardware to mount. Thus, this elementcan complicate the construction process considerably.Honestly, I was a little disappointed in the resultafter the varnishing; in my opinion the varnish Iuse in this application acts alone, in the sensethat it darkens all tones very much; seeing thetip and butt with the tying varnished alreadygave me a minimum of satisfaction and a littlepleasure.Well, once I found the thorns (in the tip and thebutt) I was ready to glue, with the Saratoga twocomponents glue, the handle and the reel seat.Everything was carefully gripped – but not tootightly – in a homemade pressFor the very delicate last phase of the work, i.e.the immersion varnishing of the rod, I had onceagain teamed up with Simone and together wehad calculated the mixture to use of varnish andthinners, the tube to use and the cabinet whereto store the varnished pieces.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 51Bamboo JournalWe studied the movements,where to work,the timing, the materialsand the substances touse for the preliminaryclearing of the varnish,the number of immersionson each side, theprecautions and remediesto adopt to reducethe dust in the environment…Finally after twenty long days, the time necessaryfor the polymerization of the varnish, I wasbeholding my irst rod, i.e. “the second irst”,complete, built on the Dickerson 7<strong>01</strong>2 7' #4 2pctaperFrom this irst, solitary (or almost) experience, Ihave perhaps begun to really understand themeaning of the expression “rodmaking is not anexact science”, a statement made by the greatestItalian constructors; the best part of this activityis indeed the fact that each rodmaker can puthis own personal skills into the work: in eachphase of construction, in every small detail ortrick to use, even if, in my opinion, it is importantthat this methodology and creative freedombe within the limits of the classical constructionphases.Man, what a satisfaction to be able to go ishingwith one’s own irst creature!Walking along the river I felt somewhat important;with each cast I was aware that I washolding between my ingers the idea that wasnow – not without sacriices – physical, it wastransformed into matter; it was of the samematerial that for several months every day I hadseen and handled with my hands; this for mewas a great gift that alone still sufices today tomake me feel fulilled on the river, also as a man.Italian Bamboo Rodmakers Association

<strong>pag</strong>e 52Bamboo JournalThe 6th European Rodmakers Gathering2<strong>01</strong>3, SwitzerlandFrom 4th to 6th of October 2<strong>01</strong>3»gespliesste.ch« will organizethe 6th European Rodmakers Gatheringin Charmey (Freiburg), Switzerland.In 2<strong>01</strong>3 the Meeting will be held in the small village of Charmey,in the french speaking part of Switzerland.The program is not yet ixed,but as in the past meetings we will have talks on different subject.Taper-design, ferruling technics, inishing are just some examples.Next to the seeches we will present different practical workshops.If you have some special interests, don't hesitate to write a mail toinfo@gespliesste.chwww.gespliesste.chItalian Bamboo Rodmakers Association

<strong>pag</strong>e 53Bamboo JournalSANSEPOLCRO - ITALYMAY 24-25-262<strong>01</strong>39°ITALIANBAMBOO RODMAKERS GATHERINGwww.rodmakers.itwww.rodmakers.euItalian Bamboo Rodmakers Association

<strong>pag</strong>e 54Bamboo JournalSkeena River - B.C.Newsletterof the Italian Bamboo Rodmakers Associationc/o Podere ViolinoLocalità GricignanoSansepolcro (AR) - Italywww.rodmakers.itibra@rodmakers.it§Bamboo Journalwww.rodmakers.eueditor@rodmakers.itItalian Bamboo Rodmakers Association