BUFFING COMPOUND

BUFFING COMPOUND

BUFFING COMPOUND

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

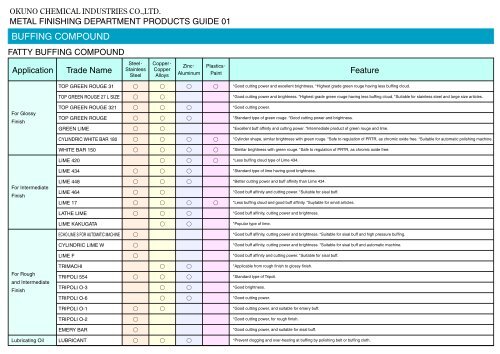

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 01<strong>BUFFING</strong> <strong>COMPOUND</strong>FATTY <strong>BUFFING</strong> <strong>COMPOUND</strong>ApplicationTrade NameSteelStainlessSteelCopperCopperAlloysZincAluminumPlasticsPaintFeatureTOP GREEN ROUGE 31*Good cutting power and excellent brightness. *Highest grade green rouge having less buffing cloud.TOP GREEN ROUGE 27 L SIZE*Good cutting power and brightness. *Highest grade green rouge having less buffing cloud. *Suitable for stainless steel and large size articles.For GlossyFinishTOP GREEN ROUGE 321TOP GREEN ROUGEGREEN LIME*Good cutting power.*Standard type of green rouge. *Good cutting power and brightness.*Excellent buff affinity and cutting power. *Intermediate product of green rouge and lime.CYLINDRIC WHITE BAR 180*Cylinder shape, similar brightness with green rouge. *Safe to regulation of PRTR, as chromic oxide free. *Suitable for automatic polishing machine.WHITE BAR 150*Similar brightness with green rouge. *Safe to regulation of PRTR, as chromic oxide free.LIME 420*Less buffing cloud type of Lime 434.LIME 434*Standard type of lime having good brightness.For IntermediateFinishLIME 448LIME 464LIME 17*Better cutting power and buff affinity than Lime 434.*Good buff affinity and cutting power. *Suitable for sisal buff.*Less buffing cloud and good buff affinity. *Suytable for small articles.LATHE LIME*Good buff affinity, cutting power and brightness.LIME KAKUGATA*Popular type of lime.ECHO LIME S FOR AUTOMATIC MACHINE*Good buff affinity, cutting power and brightness. *Suitable for sisal buff and high pressure buffing.CYLINDRIC LIME W*Good buff affinity, cutting power and brightness. *Suitable for sisal buff and automatic machine.LIME F*Good buff affinity and cutting power. *Suitable for sisal buff.For Roughand IntermediateFinishTRIMACHITRIPOLI 554TRIPOLI O-3TRIPOLI O-6*Applicable from rough finish to glossy finish.*Standard type of Tripoli.*Good brightness.*Good cutting power.TRIPOLI O-1*Good cutting power, and suitable for emery buff.TRIPOLI O-2*Good cutting power, for rough finish.EMERY BAR*Good cutting power, and suitable for sisal buff.Lubricating OilLUBRICANT*Prevent clogging and over-heating at buffing by polishing belt or buffing cloth.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 02LIQUID <strong>BUFFING</strong> <strong>COMPOUND</strong> AND <strong>COMPOUND</strong> FOR BARREL POLISHINGLIQUID <strong>BUFFING</strong> <strong>COMPOUND</strong> (O/W EMULSION TYPE)ApplicationFor Glossy FinishFor Intermediateand Glossy FinishFor Rough FinishLubricating OilFor Mirror FinishGR-330GL-251L-240L-246L-120L-439L-119L-430S-107L-540T-17Trade Name Stainless CopperZincAluminumFeature Viscosity (dPaEs)L-630CUTTING OIL<strong>COMPOUND</strong> MSteelSteelCopperAlloys*Green rouge type having good cutting power and excellent brightness.*Green lime type having cutting power and brightness correspond to those of GR-330.*Lime type having brightness similar to green rouge. *Safe to regulation of PRTR, owing to chromic oxide free and fine powder alumina type.*Lime type having brightness similar to L-240. *Safe to regulation of PRTR.*Lime type, standard product having good brightness.*Lime type, low viscosity type of L-120. *Easy in handling.*Lime type, high viscosity type.*Lime type, low viscosity type having good cutting power.*Lime type having good cutting power.*Lime type having good cutting power.*Tripoli type having good cutting power.*Excellent cutting power.*prevent clogging and over-heating at butting by polishing belt or buffing cloth.*Give mirror finish without scratch. *In wet type butting, Compound M is supplied continuously by circulation.LIQUID <strong>BUFFING</strong> <strong>COMPOUND</strong> (SOLVENT TYPE)ApplicationFor IntermediateFinishTrade NameWHITE PASTE 2PASTE C-14SteelStainlessSteelCopperCopperAlloysZincAluminumFeature*Solid form and applied after abjusting viscosity by kerosene or machine oil. *Lime type having excellent cutting power.*Tripoli type paste form<strong>COMPOUND</strong> FOR BARREL POLISHINGApplicationFor IntermediateFinishFor Glossy FinishTrade NameTOP BARCOM K-112TOP BARCOM K-224TOP BARCOM K-141TOP BARCOM K-245SteelStainlessSteelCopperCopperAlloysZincAluminum Feature*Weak alkaline type powder form having good cleaning power.*For exclusively stainless steel, weak alkaline type liquid form. *Applicable in one process from de-scaling to glossy finish.*Applicable in one process from rough finish to glossy finish. *Weak alkaline type powder form.*Neutral type liquid form having excellent brightness.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 03PRE - TREATMENT AGENTALKALINE SOAK CLEANER (FOR DIPPING)ApplicationTrade Name Composition FeatureFor Ultrasonic Wave CleaningOMPA CLEAN JK30 ~ 50 g/l*Cleaning by fuly non-brushing is possible by applying of uitrasonic wave, and long bath life and economical. *Can be applied at middle ~ high temperature bath. *Cleaning and buffing residue removal in short time is possible.ACE CLEAN30 ~ 50 g/l*Phosphate-free type, reasonable price and popular type.H ACE CLEAN30 ~ 50 g/l*Strong alkaline and phosphate-free type for exclusively steel base. *Excellent cleaning effects.For High BathACE CLEAN 80150 g/l*Excellent cleaning effects to various kinds of oils. *Strong alkaline type, and for exclusively steel base.TemperatureACE CLEAN 530020 ~ 50 g/l*Excellent dissolution and emulsifying effects to various kinds of oils. *Strong alkaline and popular type cleaner.ACE CLEAN 150040 ~ 60 g/l*Cleaner for copper and copper alloys, and applicable to phosphorus copper or steels with strong and stable cleaning power. *Applicable to electrolytic cleaning at anodic and cathodic.KASSEI ORTHO50 g/l*Excellent wetting, permeation and emulsifying effects by dispersion effects of silicata and function of surfactant.NT CLEAN 3040 g/l*Less water quality contamination as use of biodegradable surfactant. *Can be applied for long period by oil separation removal effects.ACE CLEAN C50 g/l*Air agitation is applicable, and phosphate-free and ABS-free type. *Has oil separation effects.For Middle BathACE CLEAN A-11030 ~ 50 g/l*Suitable for cleaning of many kinds of oils, and ABS-free type. *Air agitation can be applied.TemperatureACE CLEAN A-22030 ~ 50 g/l*Air agitation applicable silicate-free and ABS-free type. *Has oil separation effects.ACE CLEAN 66030 ~ 50 g/l*Phosphate-free type and applicable to steels and non-ferrous metals.ACE CLEAN 85020 ~ 70 g/l*Excellent cleaning power to any kind of oils such as mineral, animal and vegetable oils and others. *Excellent removing effects of oils, inactive film, carbon and others sticked to mainly copper or copper alloys surface.For Low BathACE CLEAN 3030 ~ 100 g/l*Can be applied at low bath temperature with air agitation. *Phosphate-free and ABS-free type.TemperatureACE CLEAN 7040 ~ 60 g/l*Strong cleaning power at even low bath temperature, and can be applied to uiltrasonic wave cleaniing at 10 ~ 20 g/l.Additive for Alkaline CleanerACE CLEAN AD2 ~ 15 ml/l*Improve cleaning power and bath life extremely by adding to alkaline cleaning bath.For SprayingACE CLEAN S 10 ~ 30 g/l*Cleaner for spray application having excellent cleaning power at even low bath temperature of 20 ~ 40CACID CLEANER (FOR DIPPING)Application Trade Name Composition FeatureAcid cleanerTOP DESCALE SK50 ml/l, HCI: 50 ~ 300 ml/l*Remove oils and rust on steel surface at one treatment.Corrosion InhibitorTOP DESCALE B1 ml/l*Suppress base etching of steel without delaying of de-scaling time. *Applicable to both sulfuric acid bath and hydrochloric acid bath.<strong>BUFFING</strong> RESIDE REMOVERApplicationTrade Name Composition FeatureWeak Alkaline Buffing Residue RemoverKOMA CLEAN BN30 ~ 50 ml/l*Remove buffing residue on steel, coppeer and copper alloys surface. *Weak alkaline type, and applicable as pre-cleaning.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 04PRE-TREATMENT AGENTACTIVATOR AND NEUTRALIZERApplication Trade Name Composition FeatureActivatorTOP SANTOP SAN NF50 ~ 200 g/l30 ~ 150 g/l*Solid acid containing fluoride. *Activate metal surface and prevent blister and peeling-off.*Fluoride-free solid acid. *Activate metal surface and prevent blister and peeling-off.Cyanide-Free NeutralizerNC BASE50 g/lCYANIDE- FREE ELECTROLYTIC CLEANER*Alkaline neutralizer. *Easy in waste water treatment.Application Trade Name Composition FeatureCyanide-Free Chelate-FreeNCC 10100 g/l*Excellent cleaning power and less contamination to water. *For steel base, and no iron deposition.Electrolytic CleanerNC-120030 ~ 150 g/l*Good de-smutting effects and buffing residue removal effects. *Easy waste water treatment, and can be applied for long period.NC RUSTOL POWDER50 g/l, NaOH : 50 g/l*Powder form cleaner having good cleaning and de-rusting power and reasonable price.Cyanide-FreeElectrolytic CleanerNC RUSTOL LIQUIDTOP CLEANER EOTOP CLEANER E100 ~ 120 ml/l40 ~ 50 ml/l, NaOH : 40 ~ 50 g/l30 ~ 70 ml/l, NaOH : 40 ~ 60 g/l*Electrolytic cleaner having excellent cleaning, de-rusting effects. *Single solution type, so easy in bath maintenance.*Liquid form electrolytic cleaner which removes smut, buffing residue and rust, and prevents iron deposition. *Applicable to both steels and non-ferrous metals.*Excellent de-scaling, de-smutting and de-rusting effects.*Can be applied to both steels and non-ferrous metals, and incase of non-ferrous metals,to be used by cathodic electrolysis at concentration of 30 ~ 60 ml/l with 10 ~ 40 g/l of sodium hydroxide.TOP CLEANER SAN 20 200 ml/l*Phosphate-free, chelate-free acidic electrolytic cleaner for steels. *Excellent rust, scale and smut removal effects.Acid Type Electrolytic CleanerTOP CLEANER SAN 200 15 ~ 25 ml/l, H2SO4 : 100 ~ 180 g/l*Excellent cleaning and rust and scale removal effects, for steel. *Low foaming type and good corrosion inhibiting effects.CYANIDE TYPE ELECTROLYTIC CLEANERGAS PREVENTING AGENTApplication Trade Name Composition FeatureCyanide TypeSUPER CLEAN50 g/l, NaCN : 75 g/l*Powder form cleaner having good cleaning and de-rusting effects. *To be used with sodium cyanide.Electrolytic CleanerEDTA-P30 g/l, NaCN : 50 g/l, NaOH : 100 g/l*Good cleaning and de-rusting effects. *To be used with sodium cyanide and sodium hydroxide.Gas Preventing AgentGAS PREVENTING AGENT0.3 ~ 1.0 ml/l*Suppress mist scattering at electrolysis by small addition.COPPER PLATING BRIGHTENERCOPPER PLATING BRIGHTENERApplication Trade Name Composition FeatureTOP LUCINA 870MU : 5 ml/l, A : 0.5 ml/l*Excellent leveling with wide brightness range.Acid Copper Plating BathELECOPPER 25TOP LUCINA 2000MU : 5 ml/l, A : 0.5 ml/lMU : 5 ml/l, A : 0.5 ml/l*Excellent brightness and leveling, and fast brightening effects. *Excellent appearance at even high bath temperature for 40C.*Excellent brightness, leveling and film properties. *Wide control range.EPACK HMU : 5 ml/l, R : 0.2 ml/l*Excellent ductility and long activated carbon treatment interval. *Additive for acid copper electro-forming.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 05NICKEL PLATING BRIGHTENER AND ADDITIVESEMI-BRIGHT NICKEL PLATING BRIGHTENERApplication Trade Name Composition FeatureCoumarin-Free TypeACNA SXACNA SLMU : 2 ml/lMU : 2 ml/l*Bath maintenance is easy and activated carbon treatment interval can be extended, as less formation of decomposed by-products. *Suitable for application to plating on plastics.*High leveling and excellent physical properties. *Less formation of waste materials at electrolysis, and continuous filtration with activated carbon pre-coating is possible.Coumarin-Free Formalin-Free TypeACNA HSBACNA NCFMU : 4 ml/l, R : 1ml/lMU : 2 ml/l*Excellent leveling, good ductility, low stress and easy bath control.*Excellent in work and sanitation environment, and less oder. *Less accumulation of decomposed by-products.Pit Preventing AgentACNA H3 ml/l*Excellent pit preventing effects, and less electrolytic consumption.BRIGHT NICKEL PLATING BRIGHTENERApplication Trade Name Composition FeatureHigh Leveling BrightenerSUPER NEOLIGHT1 : 3 ml/l, 2 : 0.2 ml/l*Excellent leveling, brightness and fast brightening effects. *Give blackish brightness in short time.Brightener forACNA B-35B-10 : 10 ml/l, B-35 : 1 ml/lNickel Carrier : 3 ml/l*Give deep blackish high leveling brightness.*Gain uniform and leveling deposition in wide range of current density.Blackish Tone DepositsACNA B1 : 20 ml/l, 2 : 1 ml/l*Give deep blackish high leveling brightness. *Wide brightness range and easy in bath maintenace.SUPER ZENA1 : 10 ml/l, 3 : 5 ml/l*Excellent leveling, and wide brightening range. *Improve workability.Brightener of Wide Control RangeTOP LEONA NL1 : 15 ml/l, 2 : 0.75 ml/lNickel Carrier : 3 ml/l*Gain uniform and bright deposits in wide current density area.*Butyne-diol-free additive having excellent activity and pit preventing effects.TOP LUNA1 : 20 ml/l, 2 : 2 ml/l*Excellent leveling and brighteness. *Insensitive to impurities.TOP SELENA BRBR : 0.5~1 ml/l, MU : 10 ml/l*Wide acceptable addition amount and temperature ranges, and excellent brightness and covering power and high resistance to fluctuation of bath condition and composition.Barrel Plating BrightenerTOP LEONA BRNLCKLINER 12BR : 0.15 ml/l, MU : 20 ml/l1 : 10 ml/l, 2 : 1 ml/l*Excellent brightness and leveling at low current density area. *Less consumption and gain uniform brightness in sohrt time.*Excellent covering power and uniform leveling and brightness. *Suitable for post-processing after plating.NICKLINER 77-MU : 10 ml/l, 7 : 1 ml/l*Excellent covering power, and leveling and brightness, and whitish color tone deposits. *Suitable for underlying nickel plating of gold plating.Brightener for UnderlyingPlating of Precious MetalsACNA B-40B-10 : 10 ml/l, B-40 : 1 ml/lNickel Carrier : 3 ml/l*Whitish color tone deposits, and wide workable range.*Suitable for underlying plating of precious metals and on plastics.Single Solution Type BrightenerMONOLIGHTTOP SELENA1 ml/lMU : 10 ml/l*Give high leveling blackish brightness, and easy bath maintenance. *To be applied as initial addition and correction of Acna B-1.*Less accumulation of decomposed by-products, excellent covering power, and wide temperature and addition amount ranges. *Butyne-diol-free type brightener.Brightener for Brass and ZincDie-CastingACNA A-115 ml/l*Primary brightener having excellent acceptable limit to zinc.*To be applied with adequate secondary brightener.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 06ADDITIVE FOR NICKEL PLATINGAUXILIARY ADDITIVE AND IMPURITIES REMOVING AGENT FOR NICKEL PLATINGApplication Trade Name Composition FeatureLeveling ImproverTOP LEVELER1 ml/l*Excellent leveling and give mirror finish nickel plating film. *Effective to applying of plating in short time.NICKEL ADAPTOR1 ~ 3 ml/l*Improve covering power and suppress influence of impurities (zinc group) of bright nickel plating.Auxiliary AdditiveMU-21 ~ 5 ml/l*Excellent auxiliary effects of primary brightener of bright nickel. *Effective to improve poor brightness and poor properties of the deposits at high current density area.NICKEL CARRIER1 ~ 5 ml/l*Give excellent brightness and leveling by using with normal brightener (espacially, butyne-diol-free type) in bright nickel plating.Zinc Impurities InhibitorZINC IMPURITIES INHIBITOR0.5 ~ 1 ml/l*Suppress temporally troubles caused by dragging-in of zinc impurities in bright nickel plating solution.Pit Preveting Agent forSUPER ZENA 43 ml/l*Suppress pitting at high load factor bath, weak agitation position and at replenishment of brighteners.Bright Nickel PlatingPIT PREVENTING AGENT1 ~ 3 ml/l*Reduce surface tension and prevent pitting in bright nickel plating.Metal Impurities RemoverTOP SCUT CL0.5 ~ 4 ml/l*Remove metal impurities (especially copper) in bright nickel plating solution.Additive for High Corrosion ResistanceTOP NSA-38 ml/l, Acna H : 3 ml/l*Give excellent corrosion resistance by applying striking between semi-bright and bright nickel platings.Special Treatment AgentTOP SURFCON BR50 ~ 150 ml/l*Color tarnish preventing agent for nickel plating. *Prevent red rust and color tarnish after barre nickel plating.Activated CarbonACTIVATED CARBON1~5 g/l*Excellent adsorption effects. *Dry type and wet type are available.ADDITIVE FOR SPECIAL NICKEL PLATINGApplication Trade Name Composition FeatureSpecial AdditiveTOP SELENA 73XTOP SELENA 95X73X : 5 ml/l, MU-2 : 5 ml/lMU : 15 ml/l*Give uniform plating in wide current density area. *Excellent ductility and suitable for post-processing.*Additive giving only brightening effects by suppressing leveling. *Wide addition amount and workable ranges.High Speed Nickel Plating BrightenerTURBO LIGHT1 : 10 ml/l, 2 : 0.5 ml/l*Brightener for hoop nickel plating, and can be applied as additive to improve brightness at high current density.SMPC-1 : 10 ml/l, SMPC-2 : 0.2 ml/lAdditive for Seal Nickel PlatingSMPC SERIESSMPC-3 : 4 ml/l, SMPC-4 : 0.5 g/l*By adding to nickel plating solution, co-deposit powder with nickel and make micro-porous chromium plating, and improve corrosion reistance remarkably.SMPC-AD : 2 ml/l,TREATMENT CHEMICALS FOR CHROMIUM PLATINGADDITIVEPRE-AND POST-TREATMENT CHEMICALS FOR CHROMIUM PLATINGApplication Trade Name Composition FeatureAdditive for Chromium PlatingLC-12025 ~ 75 ml/l*Additive to improve covering power of chromium plating. *Can be applied at low concentration and low bath temperature.Mist Preventing AgentTOP SHUT0.5 ~ 1 g/l*Prevent scattering of chromium mist, and improve work efficiency and work environment.Black Color Chromium PlatingSUPER MACRON450 g/l, Adjusting Agent : 10 ml/l*Give uniform black color chromium plating film with high heat-resistance and high corrosion resistance in wide ranges of bath temperature and current density.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 07CHEMICALS FOR PLATING ON PLASTICSCHEMICALS FOR TOP METALATE PROCESSApplication Trade Name Composition FeatureAir-Pocket Preventing AgentTOP PLACON10 ml/l, H2SO4 : 200 g/l*Eliminate poor adhesion by air accumulation. *To be used with sulfuric acid.Coating for PlatingMAGICOAT PTUConcentration as supplied*Special thermoplastic paint applied by spray coating at plating on non-conductive materials having poor adhesion.NeutralizerADDITIVE FOR TMP NEUTRALIZER10 ml/l, HCl : 10 ml/l*Reduce chromic acid sticked on resin surface at chemical etching, prevent bad influences of chromic acid at the following step,improve adsorption effects of catalyzer and eliminate skipping.B-200 NEUTRALIZER200 ml/l*Strengthen adsorption of catalyst at plating on other resins except ABS Resin (such as PP, Noryl), and make deposition of electroless plating smooth.Surface ConditionerCONDIRISER SPCONDIRISER FR CONC150 ml/l50 ml/l*Condition resin surface after etching and make deposition good. *For super engineering plastics.*Improve adsorption of catalyst to other engineering plastics except ABS Resin, fibers or others.SensitizerSENSITIZER100 ml/l*Adsorb reducing agent on wettable resin surface after etching.ActivatorACTIVATOR50 ml/l*Deposit catalyzing metal on non-conductive material surface.A-30 CATALYST140 ml/l, HCl : 140 ml/l*Strong acidic solution containing catalyzing metal. *Excellent stable and no formation of star-dusts. *Can be applied for long period by replenishment method.CatalyzerA-40 CATALYSTCATALYST C50 ml/l, HCl : 180 ml/l60 ml/l, HCl : 150 ml/l*No formation of star-dusts and excellent resistance to chromic acid.*As high concentration type, less dragging-out at replenishment. *Excellent bath stability and improve covering power.CATALYSY HI-CONC30 ml/l, HCl : 150 ml/l*Extremely high concentration type having good bath balance, as less dragging-out amount at replenishment.AcceleratorACCELERATOR XACCELERATOR KN0.5 g/l, H2SO4 : 100 ml/l5 ml/l, H2SO4 : 100 ml/l*Prevent skipping and improve covering power at electroless plating, and extend bath life by using with sulfuric acid.*Long bath life and less formation of rough deposition.Copper Substitution AgentANC ACTI10 ml/l, MU : 2 ml/l, H2SO4 : 30 ml/l*After treatment, electrolytic acid copper plating can be applied directly. *Less formation of burning-out at racking points.Alkaline Electroless Copper PlatingSolutionELECTROLESS COPPER NEW 100ELECTROLESS COPPER 500A : 100 ml/l, B : 100 ml/lC : 25 ml/lA : 125 ml/l, B : 125 ml/l*Fine particle and less formation of pitting and rough deposition in deposited copper.*Can be applied for long period by replenishment method.*Excellent bath stability. *Can be applied for long period by replenishment method.Formalin-Free ElectrolessCopper Plating SolutionCOPPER LPMU : 250 ml/l, B : 150 ml/l*As weak alkaline type, give almost no aging or etching base materials, and less formalin odor.*Less scratching to deposition film and good bath stability. *Can be applied for long period by replenishment method.TMP ELECTROLESS NICKELA : 160 ml/l, B : 160 ml/l*Economical as it is not necessary to throw away solution at replenishment owing to powder form.Alkaline ElectrolessNickel Plating SolutionPOWDER FORM NEW ELECTROLESSNICKEL RTTMP ELECTROLESS NICKEL CONCFor ReplenishmentFor Replenishment*High concentration type of TMP Electroless Nickel, which is used at exclusively replenishment.*As less dragging-out at replenishment, good in waste water treatment and running costs.ELECTROLESS NICKEL HR-TA : 150 ml/l, B : 150 ml/l*Excellent bath stability and low internal stress of the deposits.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 08CHEMICALS FOR PLATING ON PLASTICSCHEMICALS FOR TOP METALATE PROCESSApplication Trade Name Composition FeatureSURF 2000Concentration as supplied*Pre-etching agent for Poly Ether Imide (Ultem 2000 Series).SURF PPE-1129 CONC250 ml/l*Pre-etching agent for Noryl Resin.Pre-Treatment Agent forLM ETCHANT200 ml/l, HCl : 200 ml/l*Etchant for PPE/PA polymer alloy. *Excellent appearance and adhesion after plating.Plating on Engineering PlasticsSURF PC-724Concentration as supplied*Pre-treatment agent for plating on Poly Carbonate. *Give same degrees of adhesion and appearance with ABS Resin.SURF MULTIConcentration as supplied*Pre-etching agent for plating on Multion Resin. *Give same degrees of adhesion and appearance with ABS Resin.*Plating line for ABS Resin can be applied without modification. *Excellent heat-resistance and impact resistance.CHEMICALS FOR CRP PROCESSApplication Trade Name Composition FeatureCleanerCRP CLEANER50 g/l*Silicate-free alkaline cleaner. *Remove oils, finger prints and dirts on resin surface.CatalyzerCRP CATALYST65 ml/l, HCl : 300 ml/l*Excellent bath stability and good in resistance to chromic acid.Conductivity InducerCRP SELECTORA : 200 ml/l, B : 200 ml/l*Can be applied for long period continuously by replenishment. *Easy waste water treatment, as not containing of formalin and strong chelating agents.CHEMICALS FOR PLATING ON NYLON RESINApplication Trade Name Composition FeatureEtchantTN ETCHANTTR ETCHANT200 ml/l, HCl : 200 ml/l200 ml/l, HCl : 200 ml/l*Give good adhesion by applying with hydrochloric acid. (for Toyobo Nylon Resin)*Give good adhesion by applying with hydrochloric acid. (for Toray Nylon Resin)CatalyzerTN CATALYST170 ~ 200 g/l, HCl : 50 ml/lCatalyst C : 15 ml/l*Additive to prevent aging of nylon resin surface and maintain stability of catalyst.AcceleratorTR POST-ACCELERATOR10 g/l, NaOH : 10 g/l*Enhance sensitivity of catalyst particles inactivated, and improve deposition effects of electroless plating. (For Toray Nylon Resin)TOM PROCESS TREATMENT CHEMICALS (FOR TORAY PBT RESIN)Application Trade Name Composition FeatureEtchant PBT ETCHANT TR200 ml/l, NaOH : 200 g/l *Give roughness to PBT Resin surface, prevent aging of matrix, and give high adhesion.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 09ZINC PLATING BRIGHTENER AND MIST PREVENTING AGENTBRIGHTENER FOR ALKALINE CYANIDE-FREE BATHApplication Trade Name Composition FeatureNC ZINC 6060B : 2.5 ml/l, 60R : 0.3 ml/lPUR : 2 ml/l*Deposition film has good physical properties, no formation of blister at heat-treatment, and excellent adhesion, brightness and leveling.For Barrel PlatingNC ZINC K-6600MU : 4 ml/l, R : 1 ml/l*Good in brightness at low current density area, and good in chromating effects after baking.NC ZINC K-180K-180 MU : 6 ml/l, CM : 4 ml/lHL : 0.1 ml/l*Nice in plating appearance and good in chromating finish. *As chelating agent free, removal of heavy metals at waste water treatment is easy.*Applicable at high current, and excellent post-processing effects.NC ZINC S-30A : 2 ml/l, B : 8 ml/l*Good productivity, as applicable at full strangth cyanide bath and high current.NC ZINC S-40A : 0.5 ml/l, B : 5 ml/l*At even full strength cyanide bath, can gain excellent brightness and covering power and good physical properties at low current density area.For Rack PlatingNC ZINC S-100S-100 MU : 6 ml/l, CM : 4 ml/lHL : 0.5 ml/l*Nice in plating appearance and good in chromating finish. *As chelating agent free, removal of heavy metals at waste water treatment is easy.*Applicable at high current, and excellent post-processing effects.NC ZINC 90A : 1 ml/l, B : 3 ml/l*Wide brightness range and excellent brightness and leveling. *Easy bath maintenance and excellent film physical properties. *Can be applied to both rack plating and barrel plating.BRIGHTENER FOR CYANIDE BATHApplication Trade Name Composition FeatureFor Barrel PlatingZINC LIGHT K-2500ZINC LIGHT K-75002 ml/l2 ml/l*Excellent brightness at low current density area and good dissolution. *For low and half strength cyanide baths.*Excellent brightness and leveling, wide workable bath temperature range, and excellent brightening effects at current density area. *Applicable from low to full strength cyanide baths.For Rack PlatingDUO ZINC 100ZINC LIGHT S-34002 ~ 5 ml/l3 ml/l*Wide brightness range and workable range, and excellent brightness and covering power. *For half and full strength cyanide bath, and applicable to barrel bath.*Excellent brightness, fast brighening effects and wide brigheness range. *Applicable to low, half and full strength cyanide baths.MIST PREVENTING AGENT FOR ALKALINE ZINC PLATINGApplication Trade Name Composition FeatureNC ZINC MIST0.2 ~ 1 ml/lMist Preventing AgentZINC MIST0.5 ~ 2 ml/lBRIGHTENER FOR ACID TYPE CYANIDE-FREE BATH*For alkaline cyanide-free bath. *Prevent mist scattering completely by small addition.*For cyanide bath, and prevent mist scattering completely by small addition.Application Trade Name Composition FeatureZINC NH1 : 30 ml/l, 2 : 1.5 ml/l*For barrel bath and solvent-free ammonium chloride bath. *Excellent brightness and leveling, and soft in plating film.Acid BathZINC A-100, A-200ZINC ACKA-100 : 30 ml/l, A-200 : 1 ml/l1 : 30 ml/l, 2 : 2 ml/l*For both rack and barrel plating baths, and for common use bath of ammonium chloride and potassium chloride. *Low running costs and economical.*For barrel plating bath and for ammonia-free potassium bath. *Excellent brightness and leveling.ZINC A1 : 30 ml/l, 2 : 1 ml/l*For both rack and barrel plating baths, and for common use bath of ammonium chloride and potassium chloride. *Induce properties of each bath maximally.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 10POST-TREATMENT AGENT FOR ZINC PLATINGCHROMATING AGENTApplication Trade Name Composition FeatureLOWMAT 7515 ml/l, HNO3 : 15 ml/l*Extremely easy treatment, and has excellent chemical polishing effects in short time.Low ConcentrationLOWMAT BP-10315 g/l, HNO3 : 15 ml/l*Powder form low chromic acid concentration type. *Applicable to both manual treatment and fully automatic line.Blue Color Chromating AgentLOWMAT NF-210 ml/l*Fluoride-free, and give excellent corrosion resistance film.LOWMAT NF-910 ml/l*Fluoride-free, excellent corrosion resistance and easy bath control.LOWMAT 21010 ml/l*Give reddish film having excellent corrosion resistance. *can be applied short time and suitable for manual treatment.LOWMAT 22010 ml/l*Give deep reddish beautiful chromating film having excellent corrosion resistance.Low ConcentrationLOWMAT 31710 ml/l*Give reddish film having good adhesion. *Wide workable range and easy treatment.Rainbow Color Chromating AgentLOWMAT 32610 ml/l*Give reddish film having good adhesion and baking resistance. *Applicable to both manual treatment and automatic line.LOWMAT 32910 ml/l*Give reddish film having good adhesion. *Applicable to both manual treatment and automatic line.NICOZINC CR-230 ml/l*Rainbow color chromating agent for zinc-nickel alloy plating. *Give chromating film having bright color tone.TOP HAC BLACK 8181 : 60 ml/l, 202 : 10 ml/l*Give uniform black color chromating film having good corrosion resistance. *Applicable to barrel poeration.TOP HAC BLACK 8282 : 60 ml/l, 202 : 10 ml/l*Give uniform black color chromating film having good corrosion resistance.Black Color Chromating AgentTOP HAC BLACK 201202201 : 200 ml/l, 202 : 10 ml/l*Give uniform and beautiful black color chromating film.TOP HAC BLACK 601603601 : 100 ml/l, 202 : 10 ml/l*Give uniform black color chromating film. *Low concentration chromic acid type.TOP HAC BLACK K-800 SERIESK-801 : 100 ml/l, K-802 : 10 ml/l*Low concentration type black color chromating agent and give excellent brightness and color tone. *Low in waste water treatment cost, as long renewal interval.TOP HAC CG-2525 ml/l*Deep green color chromating agent having excellent corrosion resistance, weather resistance and abrasion resistance.Green Color Chromating AgentTOP HAC CG-30-JTOP HAC CG-3530 ml/l50 ml/l*Give deep green color film having good brightness and excellent corrosion resistance. *Applicable to both rack plating and barrel plating.*Light green color chromating agent having excellent corrosion resistance, weather resistance and abrasion resistance.TOP HAC CG-4040 ml/l*Deep green color chromating agent having excellent corrosion resistance, weather resistance and abrasion resistance, and can be treated in short time.Post-Treatment AgentLOWMAT ACLOWMAT AC-1110 ml/l2 ml/l*Improve corrosion resistance remarkably as post-treatment.*Post-treatment agent for black color chromating. *Improve appearance and corrosion resistance of final finish.Water Repelling AgentLOWMAT AC-202 ml/l*Post-treatment agent for black and green color chromatings. *Good water repelling effects and shorten drying time.DYE-STUFF FOR ZINC PLATINGApplication Trade Name Composition FeatureDye for Zinc Plating FilmTOP ZINC COLOR PROCESS*Dyeing process applied after bright chromating, green color chromating or others on zinc plating film.*Rich variety of color tone from light pink to black.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 11TREATMENT CHEMICALS FOR ALUMINUM AND ALUMINUM ALLOYSCLEANER AND <strong>BUFFING</strong> RESIDUE REMOVERApplication Trade Name Composition FeatureWeak Alkaline Type CleanerTOP ALCLEAN 101TOP ALCLEAN 16130 g/l30 g/l*Excellent cleaning power and almost no etching and loss of brightness of base materials. *Can be applied at higher bath temperature as high cloudy point.*Air agitation is applicable as low foaming type. *Excellent cleaning power and almost no etching and loss brightness of base materials.Acid Cleaner for Sulfuric Acid BathTOP ALCLEAN SO-410 ~ 40 ml/l, H2SO4 : 25 ~ 75 ml/l*Applicable at low bath temperature by using with sulfuric acid. *Long bath life and economical as waste solution of anodizing bath can be used.Phosphoric Acid Type Acid CleanerTOP ALCLEAN SP-150 ~ 100 ml/l, H2SO4 : 0 ~ 20 ml/l*Low foaming type and excellent cleaning power. *Air agitation and shower cleaning are applicable by using with sulfuric acid.Buffing Residue RemoverKOMA CLEAN CP : 15 ~ 25 g/l, L : 15 ~ 25 ml/l*Remove buffing residue of Tripoli or Lime by only dipping. *Acid type and for exclusively alminum base.SATIN MAT FINISHING AND ALAKALINE ETCHING AGENTApplication Trade Name Composition FeatureEtchimg AgentALSATIN B10 ~ 150 g/l, NaOH : 50 ~ 150 g/l*Strong dissolution accelerating effects and improve etching effects. *Suitable for etching and give uniform and strong satin finish.Additive for Satin FinishALSATIN L10 ~ 100 m/l, NaOH : 50 ~ 150 g/l*Excellent etching effects and good clinker suppressing effects. *Give fine silver white color satin finish.Additive for EtchingALSATIN SK2 ~ 5 m/l, NaOH : 50 ~ 100 g/l*Excellent suppressing effects of clinker formation.Soft Etching AgentTOP ALSOFT 10850 g/l*Soft etching agent having cleaning effects and less dissolution. *Suitable for etching of aluminum before plating.ACID TYPE ETCHING AGENTApplication Trade Name Composition FeaturePearl Tone Finishing AgentALSATIN M-05ALSATIN OL-8230 g/l150 ~ 250 g/l*Good bath stability and suitable for pure aluminum cosmetic bottle cap. *Give pearl tone finish having less roll marks.*Long bath life and suitable for optical instrument parts. *Give fine semi-bright white color finish.Mat Surface White ColorALSATIN M-02100 g/l*Suitable for precision optical instrument parts as less dimension decreaing to any materials, and give fine and mat white color finish.Finishing AgentALSATIN OL-25100 g/l*Give slightly rough mat white color finish. *Applicable to aluminum alloys and suitable for optical instrument parts.Micro-Etching Agent forZincateALSATIN PRE600 ml/lHNO3 : 400 ml/l*By micro-etching effects, improve adhesion and appearance extremely of all materials,and suitable for etching as pre-treatment of electroless nickel plating on aluminum.ADDITIVE FOR CHEMICAL POLISHINGMIST PREVENTING AGENT AND OTHERSApplication Trade Name Composition FeatureAdditive for chemical PolishingALGLOSS S-20010 g/l, HNO3 : 60 ml/l, H3PO4 : 900 ml/l*Give excellent bright polished surface and reduce nitrite gas formation. *Economical as powder form addition type.Mist Preventing Agent for Anodizing BathALMIST W0.01 ~ 1 ml/l*Low foaming type excellent mist preventing agent making uniform layer of small bubbles on solution level. *Most suitable for micro explosion air agitation system.De-Smutting AgentTOP DESMUT N-20TOP DESMUT S-10100 ml/l25 ml/l, H2SO4 : 75 ml/l*Remove smut at etching or chemical polishing of even copper or zinc type effectively, and less content of nitric acid.*Strong de-smutting effects by adding to nitric acid free sulfuric acid de-smutting bath.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 12TREATMENT CHEMICALS FOR ALUMINUM AND ALUMINUM ALLOYSZINCATE TREATMENT AGENTCHEMICAL TREATMENT AGENT AND OTHERSApplication Trade Name Composition FeatureCorrosion Inhibitor at Stock TankTOP IBITOR AL-20020 ml/l*No corrosion and decrease in brightness at prolonged dipping. *No containing of harmful materials.Chemical Conversion AgentTOP ALCOLOR 220A : 20 ml/l, B : 6 ~ 10 ml/l*Rainbow color chromating agent for aluminum and aluminum alloys having excellent corrosion resistance and uniformity.SUBSTAR ZN-1250 ml/l*Cyanide-free type zincate treatment agent for aluminum having excellent adhesion and leveling effects.SUBSTAR ZN-2500 ml/l*Cyanide-free type zincate treatment agent for aluminum having excellent adhesion and leveling effects. *Give fine zinc / nickel / copper ternary alloy film.SUBSTAR ZN-3Concentration as supplied*Direct plating is applicable to all kinds of aluminum alloys. *No peeling-off by bending or cutting. *Excellent adhesion and no blister by thermal cycle test.SUBSTAR ZN-8400 ml/l*Cyanide-free type and give excellent appearance and adhesion as underlying layer of electroless nickel plating.Zincate Treatment AgentSUBSTAR ZN-10SUBSTAR ZN-111300 ml/l500 ml/l*Less taking-out amount replenishment, as concentrated type. *Cyanide-free type and excellent adhesion.*Suitable for zincate treatment for aluminum alloys containing copper, magnesium, zinc or others. *Cyanide-free type and very thin in substitution film.SUBSTAR ZN-222500 ml/l*Cyanide-free type applicable to any kind of aluminum alloys. *Fine ternary alloy film of having excellent adhesion.SUBSTAR ZN-291500ml/l*Cyanide-free zincate solution of ternary alloy film having excellent adhesion as underlying film of electrolytic plating.SUBSTAR AZAZ : 100 ml/l, AZ Adjusting Agent : 100 ml/l*Cyanide-free acid type zincate treatment solution. *Suitable for treatment of vacume deposited film and less dissolution of aluminum.SPECIAL SUBSTAR ZN-3500 ml/l*Cyanide type and suitable for any kind of aluminum alloys. *Excellent adhesion and safe to accumulation of impurities.COLORING AGENTDYE AND RESIST INK FOR ANODIZING FILMApplication Trade Name Composition FeatureWater Soluble DyeTAC DYES*High quality dipping type dyes for aluminum anodizing film. *Excellent weather resistance and dyeing affinity, and long bath life.*Baside basic color tones. matched color tones are also available.Water Soluble Inorganic DyeTOP SHUTETSUAN15 ~ 30 g/l*Ammonium ferric oxalate applicable as inorganic gold color dye. *Excellent heat-resistance and weather resistance.TAC KABIKORON0.3 ~ 0.5 g/l*Mold inhibitor for dyeing bath of aluminum. *No bad influences to dyeing bath and inhibit for long period.Treatment Agent for DyeingTAC SORMAL 121TAC CONTROLLER PH-550 g/l10 ~ 20 ml/l*Prevent poor dyeing by coming-out of acids from mold cavities or screw holes, and improve dyeing affinity of TAC Dyes.*Improve pH stability and dyeing affinity of dyeing bath. *Suppress corrosion at dyeing step.TAC ANTIFOAM0.001 ~ 0.01 ml/l*De-foaming agent of aluminum dyeing bath having no bad effects.Secondary ElectrolyticColoring AgentTOP ALCOLORD ED300 ml/lNiSO4 : 50 g/l , H3BO4 : 40 g/l*Additive for nickel type secondary electrolytic coloring. *Good covering power and good black color tone*Suitable for treatment of small size articles.Screen Printing InkOKUNO COLORW Type (water soluble type) Ink : Can be removed by water. E Type (oil soluble type) Ink : Can resist to etching and re-anodizing.Thermal Curing Type InkTOP RESIST 1000*Resist ink for etching having excellent acid-and alkaline-resistance. *Easy in ink removal.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 13TREATMENT CHEMICALS FOR ALUMINUM AND ALUMINUM ALLOYSSEALING AGENT FOR ANODIZINGApplication Trade Name Composition FeatureTOP SEAL DX-2007 g/l*Prevent de-coloring of dye, white powdery bloom, rainbow surface. *Give enough sealing effects in short time.Sealing Agent forNickel Acetate Type BathTOP SEAL DX-300TOP SEAL DX-500TOP SEAL H-2987 g/l7 g/l40 ml/l*Sealing agent for architectural materials for applying of filter. *Excellent sealing effects, long bath life and easy filtration.*Suitable for sealing of cosmetic cap, as giving smooth surface. *Long bath life and easy filtration.*No forming of white powdery bloom, and easy usage as liquid form.TOP SEAL H-37940 ml/l*Sealing agent for architectural materials for applying of filter. *Prevent stain in spots at drying, excellent sealing effects, long bath life.Additive for Preventing White Powdery BloomTOP SEAL E-1252 ~ 5 ml/l*Prevent white powdery bloom by adding to nickel acetate type bath. *Extend bath life by recovering of sealing solution.Additive for Sealing at Room TemperareTOP SEAL L-1003 ~ 5 g/l*Excellent sealing effects and suitable for sealing of architectural materials and hard anodizing film.Additive for Boiling Water SealingTOP SEAL E-1103 ml/l*Prevent completely white powdery bloom and rainbow (irregular) color at boiling water sealing. *Suitable for auxiliary sealing of Top Seal L-100.Post-Treatment Agent for White Powdery Bloom PreventingTOP SEAL CLEAN100 ml/l*Remove white powdery bloom at sealing without aging of anodizing film and no changing of color tone and brightness.TOP ADD PROCESS TREATMENT CHEMICALS (DYEING FOR ALUMINUM DIE-CASTING)Application Trade Name Composition FeatureSoak CleanerTOP ADD-100100 ml/l, H2SO4 : 70 ml/l*Excellent cleaning power and remove cutting oil and lubricant quickly.ActivatorTOP ADD-20010 g/l, H3PO4 : 900 ml/l, HNO3 : 100 ml/l*Acivate and improve dyeing affinity of high silicate type alloys surface.Activating and De-Smutting AgentTOP ADD-320TOP ADD-350Concentration as supplied10 ~ 50 g/l*Activate uniformly and remove smut on aluminum die-casting base.*Recover de-smutting effects of Top ADD-320.Corrosion InhibitorTOP ADD-40030 ml/l*Prevent corrosion of active surface in the rinsing water after Top ADD-320 treatment.Black DyeTOP ADD-50010 g/l*Excellent dyeing effects as black dye for high silicate type alloys (ADC-12).Sealing AgentTOP ADD-6007 g/l*Give excellent sealing effects in short time.Post-Treatment AgentTOP ADD-700Concentration as supplied*Improve color properties and corrosion resistance and give brightness. *Paraffin type.for Rust PreventingTOP ADD-85030 ml/l*Give lubricating effects and water repelling effects. *Silicon type and water soluble dispersion type.LUBRICATING AGENT FOR HARD ANODIZING FILMApplication Trade Name Composition FeatureTOP LUBREND50 ml/l*PTFE water soluble dispersion solution for un-sealed articles. *Improve the initial stage sliding effects by adsorbing PTFE fine particles to hard anodizing film.Lubricating AgentTOP CATILUS50 ml/l*PTFE water soluble dispersion solution for sealed articles. *Improve the initial stage sliding effects and lubricating effects by adsorbing PTFE fine particlesto sealed film by nickel acetate type bath.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 14RUST PREVENTING AGENT AND STRIPPING AGENTRUST PREVENTING AGENTApplication Trade Name Composition FeatureWater Soluble Rust Preventing AgentTOP RUST PREVETING AGENT 55120 ~ 30 ml/l*Remove water from copper plating surface quickly and prevent color tarnish.Anti-Color Tarnish Agent for SilverECB 1000100 ml/l*Color tarnish preventing agent for silver to various gases. *Form protective film on silver surface by cathodic electrolysis.Electrolytic Chromating AgentELECTROLYTIC CHROMATING AGENT ECB1 : 100 ml/l, 2 : 10 ml/l*Cathodic electrolytic chromating agent which improves corrosion resistance and color tarnish prevention of chromium plating and various alloy platings.Water SolubleTOP GUARD YDDilution into 3 ~ 4times*Water soluble clear lacquer which is co-polymer of special acrylic monomers and has self-bridging effects. *Give clear film having good adhesion on metals and chemical conversion films.Clear LacquerTOP GUARD SANDilution into 2 ~ 5times*Suitable for clear lacquer as post-treatment of black color chromating. *No film reoeling at drying, and will not hurt to appearance. *Weak acidc water soluble clear lacquer having special acrylic resin as main component.Water Repelling AgentTOP RINSE1 ~ 2 ml/l*Remove water drops on plating surface, make thin film and prevent color tarnish.STRIPPING AGENTApplication Trade Name Composition FeatureFor Cu . Ni Plating / DippingTOP RIP F-60100 g/l, NaCN : 90 ~ 120 g/l*For steel base. *Excellent stripping power and economical as low price.TOP RIP C-15050 ml/l, F-60 : 150 g/lH2SO4 : 100 ml/l*For copper and brass bases. *Easy handling as liquid form and less hazardousness.*To be applied with Top Rip F-60.For Nickel Plating / DippingTOP RIP NSAFE RIP 21 : 200 ml/l, 2 : 200 ml/l300 ml/l, F-60 : 100 g/l*For steel, copper and brass bases. *Easy handling as liquid form and less hazardousness.*For steel, copper and brass bases and to be applied with Top Rip F-60. *Excellent stripping power and easy handling.D SAFE RIP 900A : 40 g/l, B : 200 ml/l*For steel base and strong stripping power and fast in stripping speed and less attacking of base materials.For Acid Type ElectrolessNickel Plating / DippingTOP RIP AZTOP RIP PF-1TOP RIP AX1 : 40 g/l, 2 : 500 ml/lNaOH : 30 g/l180 ml/l, F-85 : 90 g/l500 ml/l, F-85 : 50 g/lNaOH : 50 g/l*Cyanide-free type stripping agent for acid type electroless nickel plating film on copper and copper alloys bases.*Cyanide-free type for steel base*To be applied with Top Rip F-85, and can strip at low temperature.*Cyanide-free type stripping agent for acid type electroless nickel plating film on exclusively steel base.*Excellent stripping power and stripping speed and less attacking of base materials. *To be applied with Top Rip F-85.For CuNiCr Plating / ElectrolysisTOP RIP ERA : 100 ml/l, B : 100 ml/l*Stripping agent for plating film on stainless steel jigs. *Excellent stripping power and less attacking of base materials. *Applicable for long period by replenishment method.For NiCr Plating / ElectrolysisTOP RIP EP1 : 100 ml/l, 2 : 100 ml/l*Stripping agent for copper, nickel and chromium plating films on stainless steel jigs. *Less attacking of base materials.For CuCu Alloy Plating / DippingTOP RIP FC1 : 15 g/l, 2 : 30 g/lNH4OH : 60 ml/l*Cyanide-free type for steel base.*Fast in stripping speed.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 15VARIOUS TREATMENT CHEMICALSTREATMENT CHEMICALS FOR STAINLESS STEEL AND CHEMICAL POLISHING AGENTApplication Trade Name Composition FeatureAdditive for Electro-Polishingfor Stainless SteelASLES EP-2ASLES EP-1350 ml/lH2SO4 : 300 ml/l, H3PO4 : 600 ml/l250 ml/l, H3PO4 : 750 ml/l*Chromium-free type for stainless steel base.*Improve brightness and leveling of arstenite type materials. *Reduce mist scattering at electrolysis.*For martensitic stainless steel base.Chemical Polishing Agent for Zinc Die-CastingTOP SAN ZConcentration as supplied*Chemical polishing agent for zinc die-casting.Chemical Polishing Agent for SteelTOP SAN L140 ml/l, H2O2 : 140 ml/l*For high carbon steel base, and suitable for scale removal, surface activation and de-burring.Chemical Polishing Agent for Copper, Copper AlloysTOP GLUP CU 8M : 500 ml/l*Chemical polishing agent for copper and copper alloys. *As nitric acid free, no NOx gas formation and less odor.ADDITIVE FOR ALLOY PLATINGApplication Trade Name Composition FeatureGold Color PlatingSY GOLD60 ~ 200 g/l*Can make gold color plating film of color tone from brass color to reddish gold color, and easy bath maintenace.Tin-Nickel Alloy PlatingNISTALLOY PROCESSTN-1 : 20 g/l, TN-2 : 3 ml/l*Pyrophsphate bath having high current efficiency and excellent throwing power, and easy in waste water treatment.*Give bright Plating of similar color tone with stainless steel.Nickel-Phosphorus Alloy PlatingNICKELIN AA-1 : 200 ml/lNiSO4 : 160 g/l*Excellent chemical resistance, abrasion resistance, corrosion resistance and non magnetism.*Easy in bath maintenance and waste water treatment.Tin-Lead Alloy Plating /Semi-Bright BathTOP TEENA No.10Sn(BF4)2 : 100 g/lPb(BF4) 2 : 40 g/lHBF4 : 300 g/lNo.10 : 40 ml/l*Additive for semi-bright tin-lead plating from fluoroborate bath.*Give fine and uniform plating.*Suitable as metal resist for printed wiring board.Sn Conc : 200 ml/lTin-Lead Alloy Plating /Bright BathTOP TEENA NFPb Conc : 30 ml/lSalt : 200 g/lNo.1 : 20 ml/lNo.2 : 4 ml/l*Fluoride-free and wide brightness range.*Give excellent brightness at even low current density area.*As weak acidic type, less corrosion to base materials and easy waste water treatment.HCHO : 6 ml/l

METAL FINISHING DEPARTMENT PRODUCTS GUIDE 16TREATMENT CHEMICALS FOR MAGNESIUM AND MAGNESIUM ALLOYSTREATMENT CHEMICALS FOR TOP MAGLOCK PROCESS (PLATING ON MAGNESIUM AND MAGNESIUM ALLOYS)Application Trade Name Composition FeatureEtching AgentActivatorZincate Treatment AgentCleanerActivatorChemical Conversion AgentTOP MAGLOCK E-10TOP MAGLOCK A-20TOP MAGLOCK Z-40TOP MAGSTAR CLEANERTOP MAGSTAR ACIDTOP MAGSTARTOP MAGSTAR ETOP MAGSTAR CR100 ml/lCrO3 : 180 g/l500 ml/lH3PO4 : 100 ml/lConcentration as supplied15 g/l50 ml/lA : 10 g/lB : 300 ml/lA : 10 g/lE : 200 ml/lA : 200 ml/l*Remove oxide film or old chemical conversion film on base surface, and less formation of dimention decreasing.*Remove thin chromating film or oxide film ehich formed at etching step, and make zinc uniform.*Dissolve thin oxide film or hydroxide film on magnesium surface and deposit uniform zinc film. *Weak alkaline substitution so at around pH 11.TREATMENT CHEMICALS FOR TOP MAGSTAR PROCESS (CHEMICAL CONVERSION OF MAGNESIUM ALLOYS)Application Trade Name Composition Feature*Weak alkaline cleaner. *Remove stains on base surface by mild etching effects.*Excellent removeal effects of oxides or impurities on substrate. *Chromic acid free type, and give uniform surface condition.*Form chemical conversion film having excellent corrosion resistance.*Chromic acid free type.*Form chemical conversion film having low resistance value.*Chromic acid free type.*Form chemical conversion film having excellent corrosion resistance and low resistance value. *Chromic acid free type.WASTE WATER TREATMENT CHEMCALS AND WATER QUALITY ANALYZERApplication Trade Name FeatureMetal preciptation RemoverChromic Acid Type Waste SolutionTreatment AgentPolymer Type FlocculantMetal Flocculant and PrecipitantDe-Foaming AgentWaste Solution Treatment Agent for DyeTOP CATCH M-150TOP CATCH CR-200TOP CATCH F-400TOP CATCH F-450TOP CATCH Z-500TOP CATCH D-900*Remove almost all heavy metals as precipitation. *can remove metals having complex with except cyanide.*Can treat chromic acid in waste solution at 1 step from reduction to neutralization. *Easy treatment and no formation of harmful gas at treatment.*Quickly flocculate and settle hydroxide of metal and chelate precipitations. *Dissolve in water quickly.*Disperse almost all heavy metals at presence with iron, and make neutralization, flocculation and sedimentation possuble, and give clean treated water without SS and oil contents.*Excellent de-foaming effects to any kind of foam by small addition amount.*Can treat any kind of concentrated waste solution of dye easily in very short time. *Low costs in waste solution treatment.Simple Water Quality AnalyzerYOSHITEST*Analyze concentrations of materials in waste water quickly and easily in high accuracy, so suitable to speed-up and simplifying of analysis.(Phenol, Chromium, Copper, Iron, Sulfur, Nickel, Znic, Mercury, Lead, Cadmium, Cyanogen, Arsenic, Fluorine, Manganese)

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR ELECTRONICS AND ENGINEERING PARTS" 01CHEMICALS FOR ELECTROLESS PLATINGApplication Trade Name Bath Composition FeatureTOP NICORON PALPAL - M : 100 ml/lPAL - 1 : 60 ml/l*Excellent brightness, leveling, chemical resistance and anti-color-tarnishing effects.*Good in bath stability.TOP NICORON KITKIT - S : 200 ml/l*Excellent bath stability and brightness maintain effects.*Suitable for application for long period continuously.TOP NICORON ZZ - S : 200 ml/l*Less decrease in deposition speed at continuous usage for long period.*Excellent brightness and bath stability.TOP NICORON BLBL - M : 100 ml/lBL - 1 : 60 ml/l*Excellent brightness and bath stability.*Suitable for application to aluminum.TOP NICORON RDRD - M : 200 ml/lRD - A : 70 ml/l*Phosphorus Content : 12~13%*Can be applied for long period by replenishment method.*Non-magnetic type deposits.*Excellent corrosion resistance and chemical resistance.TOP NICORON Y-45Y - 45 - S : 200 ml/l*Less decrease in deposition speed and brightness at continuous prolonged usage.*Extremely less formation of pitting.Electroless Nickel-PhosphorusAlloy Plating Solution(Continuous Replenishment Type)TOP NICORON SA-98TOP NICORON TOMTOP NICORON NACSA - 98 - M : 100 ml/lSA - 98 - 1 : 60 ml/lTOM - S : 200 ml/lNAC - A : 80 ml/lNAC - B : 200 ml/l*Excellent chemical resistance and corrosion resistance.*Good covering power and less color tarnishing.*Less decrease in deposition speed and brightness at continuous prolonged usage.*Excellent bath stability.*Excellent leveling and chemical resistance.*Non-magnetic type deposits.*Less change in properties at aging.TOP NICORON ONON - S : 200 ml/l*Wide workable range.*Suitable to application for large articles, thick film.TOP NICORON ALTALT - M : 100 ml/lALT - 1 : 60 ml/l*Excellent chemical resistance and corrosion resistance.*Excellent deposition effects to aluminum substrate.TOP NICORON LPHLPH - S : 250 ml/l*Low phosphorus type (1~2%) continuous usage type.*High in hardness of the deposits as plate (Hv 700).TOP NICORON PBWPBW - S : 250 ml/l*Ni-P-B-W alloy plating solution.*Give high hardness, and excellent in abrasion resistance.TOP NICORON LLSLLS - M : 150 ml/lLLS - 1 : 60 ml/l*Exellent bath stability, can be applied for long period (8 turn overs).*Excellent brightness and leveling.TOP NICORON BL 80BL 80 - M : 150 ml/lBL 80 - 1 : 60 ml/l*Can be applied at a low temperature (80). Less decrease in brightness.*Applicable for TOLL SEPTA.TOP NICORON VSVS : 200 ml/l*High utility efficiency of nickel content in the solution.*Applicable for general usage.Electroless Nickel-PhosphorusAlloy Plating Solution(Batch Type)TOP NICORON P-13TOP NICORON YMTOP NICORON CU-50P - 13 : 250 ml/lYM - A : 100 ml/lYM - B : 200 ml/lCU - 50A : 50 ml/lCU - 50B : 950 ml/l*High in phosphourus content at 13 %.*Excellent chemical resistance and magnetic properties.*Suitable for application as non-magnetic film or resistor film.*Phosphorus Content : 2~4%*Excellent electro-conductivity.*Electroless nickel- copper-phosphorus alloy plating solution for metal film resistor.*Copper Content : 50% (T.C.R. : 180~220ppm/)TOP NICORON FY-2900 ml/lFerrous Sulfate : 12.5 g/l*Electroless nickel- iron-phosphorus alloy plating solution for metal film resistor.*Iron Content : 10% (T.C.R. : 50~70ppm/)Electroless Copper Plating SolutionOPC COPPER TT - 1 : 60 ml/lT - 2 : 12 ml/lT - 3 : 100 ml/l*High speed thick film type electroless copper plating solution for dielectric ceramics.*Excellent high frequency wave properties.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR ELECTRONICS AND ENGINEERING PARTS" 02CHEMICALS FOR ELECTROLESS PLATINGApplication Trade Name Bath Composition FeatureElectroless Nickel-Boron AlloyPlating SolutionTOP CHEM ALLOY B-1TOP CHEM ALLOY 66Concentration as supplied66 - M : 60 ml/l66 - 1 : 60 ml/l66 - 2 : 60 ml/l*Excellent deposition effects.*High in hardness of the deposits as plate.*Suitable for plating ceramic or others.*Boron Content : 0.2~0.6%.*Excellent deposition effects.*High in hardness of the deposits as plate.*Suitable for plating to ceramic or others.*Boron Content : 0.2~0.6%.*Continuous replenishment type.Electroless Tin Plating SolutionSUBSTAR SN-5SN - 5 A : 60 ml/lSN - 5 B : 500 ml/lSN - 5 C : 120 g/l*Fluoride-free type electroless tin plating solution.*Excellent deposition effects.*Can be applied for long period by replenishment.Electroless RhodiumPlating SolutionELECTROLESS RHODIUMRH-1RH - 1 A : 500 ml/lRH - 1 B : 150 ml/lRH - 1 C : 100 ml/l*Excellent hardness, abrasion resistance and chemical resistance.*Uniform deposition to complicated shape articles and inside of pipe.Electroless RutheniumPlating SolutionELECTROLESS RUTHENIUMRURU - 1 : 500 ml/lRU - 2 : 50 ml/lRU - 3 : 50 ml/l*Excellent hardness, abrasion resistance and chemical resistance.*Less change in contact resistance even under the circumstance of corrosive gas.Electroless PalladiumPlating SolutionMUDEN NOBLE PDPD - 1 : 50 ml/lPD - 2 : 50 ml/lPD - 3 : 100 ml/l*Excellent corrosion resistance and solderability.*As cyanide-free, easy in waste water treatment.*Good in bath stability, and fine deposition film.*Can be applied for long period.PALLA TOPA : 100 ml/lB : 100 ml/l*Neutral auto-catalytic type, give over 99.9% purity film.*Excellent corrosion resistance, solderability at high temperature and hydrogen permeability.OPC MUDEN GOLD100 ml/l*Substitution type electroless gold plating solution.*Excellent adhesion to under-lying electroless nickel plating film, and wide applicable range.OPC MUDEN GOLD 2525 - M : 200 ml/l25 - 1 : 200 ml/l25 - 2 : 150 ml/l*Can control film thickness, as auto-catalytic type.*Excellent bonding effects and fine deposition.Electroless Gold Plating SolutionMUDEN NOBLE AUAU - 1 : 500 ml/lAU - 2 : 200 ml/lAU - 3 : 100 ml/lSodium Aurous Sulfite (as Au) : 2 g/l*Additive for neutral cyanide-free substitution type electroless gold plating.*As neutral bath, less influence to resist film.SELF GOLD OTKOTK - 1 : 200 ml/lOTK - 2 : 200 ml/lSodium Aurous Sulfite (as Au) : 2 g/l*Additive for neutral reduction type thick film type electroless gold plating.*Good bath stability and less influence to resist film.FLASH GOLD NB100 ml/l*Substitution type.*Excellent adhesion to under-lying electroless Ni-B plating film electroless Ni-P plating film and electrolytic Ni plating film.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR ELECTRONICS AND ENGINEERING PARTS" 03TREATMENT CHEMICALS FOR TOP MAGNESIUN AND MAGNESIUM ALLOYSTOP MAGROCK PROCESSApplication Trade Name Bath Composition FeatureEtchingActivatorZincate TreatmentCleanerActivatorTOP MAGROCK E-10TOP MAGROCK A-20TOP MAGROCK Z-40TOP MAGSTARCLEANERTOP MAGSTARACIDTOP MAGSTAR100 ml/lChromic Anhydride : 180 g/l500 ml/l89% Phosphric Acid : 100 ml/lConcentration as supplied15 g/l500 ml/lA : 10 g/lB : 300 ml/l*Acid type oxide film remover for surface.*Improve adhesion, and make surface uniform.*Less formation of change in dimension.*Remove chromate and oxide films formed at etching, and give uniform brightness.*Enable to deposit uniform zinc film at next step.*Dissolve thin films at surface such as oxide film or hydroxide film of magnesium, and form smooth and uniform zinc film.*Improve adhesion.TREATMENT CHEMICALS FOR TOP MAGSTAR PROCESS (CHEMICAL CONVERSION OF MAGNESIUN ALLOYS)Application Trade Name Bath Composition Feature*Weak alkaline Cleaner. *Remove stains on base surface by mild etching effects.*Exellent removal effects of oxides or impurites on substrate. *Chromic acid free type, and give uniform surface condition.*Form chemical conversion film having excellent corrosion resistance.*Chromic acid free type.ChemicalConversionAgentTOP MAGSTAR EA : 10 g/lE : 200 ml/l*Form chemical conversion film having low electric resistance value.*Chromic acid free type.TOP MAGSTAR CRCR - A : 200 ml/l*Form chemical conversion film having excellent corrosion resistance and low electric resistance value.*Chromic acid free type.COMPOSITE PLATING CHEMICALSCOMPOSITE PLATING CHEMICALSApplication Trade Name Bath Composition FeatureElectrolytic Composite PlatingTOP BNBN : 200 ml/lAcna B - 1 : 5 ml/lAcna H : 5 ml/l*Composite plating which disperse particles having high wear resistance to metal matrix uniformly.*Excellent wear resistance and wettability.TOP NICOSITE BNM : 100 ml/l1 : 50 ml/lBN - A : 60 ml/l*Boron nitride type electroless composite nickel plating.*Excellent sliding effects under low loading.TOP NICOSITE SCSC - M : 100 ml/lSC - 1 : 60 ml/lSC - L : 20 ml/l*Silicon carbide type electroless composite nickel plating.*Excellent wear resistance, mould releasing effects and lubrication effects.*Easy in replenishment, as liquid form dispersion agent.Electroless Composite PlatingTOP NICOSITE TFTF - S : 250 ml/lTF - A : 10 ml/lFL - M : 250 ml/l*Excellent wear resistance and sliding effects at low loading, and non-sticking film.*Excellent releasing effects, lubrication effects, water repellent and oil repellent effects.TOP NICOSITE FLFL - 1 : 55 ml/lFL - A : 3 ml/l*As co-deposition ratio of PTEF is low at 5-10%, hardness is lower than Top Nicosite TF.*Deposition film is non-sticking, and has excellent releasing effects and sliding effects.TOP NICOSITE AFAF - M : 100 ml/lAF - 1 : 60 ml/lAF - A : 0.4 ~ 1.5 ml/lAF - AD : 6 ml/l*The lowest PTFE composite.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR ELECTRONICS AND ENGINEERING PARTS" 04VARIOUS TREATMENT CHEMICALSELECTROLYTIC PLATING CHEMICALSApplication Trade Name Bath Composition FeatureNickel PlatingTOP SELENA 73XTOP SELENA 95X73X : 5 ml/lMU - 2 : 5 ml/l95X - MU : 15 ml/l*Uniform deposition at wide current density area, and excellent ductility.*Suitable for application of after processing.*Give brightness by suppressing of leveling.*Wide addition amount range and workable range.Tin PlatingTOP FLOONAMU : 20 ml/lR : 8 ml/l*Additive for sulfuric acid type tin plating.*Excellent leveling, throwing power and solderability.Nickel-Tin Alloy PlatingNISTALLOYTN - 1 : 20 g/lTN - 2 : 3 ml/l*Pyro-phosphate bath having high current efficiency and excellent thowing power.*Give stainless steel tone brightness.*Easy waste water treatment.Nickel-Phosphorus Alloy PlatingNICKELINA - 1 : 200 ml/l orB - 1 : 200 ml/l*Excellent magnetic properties, chemical resistance, wear resistance and corrosion resistance.*Easy bath maintenance and waste water treatment.Tin-Lead Alloy PlatingTOP TEENA MSMS Sn : 120 ml/lMS Pb : 20 ml/lMS : 100 ml/lBright Bath:Brightener No.1:20ml/l,Brightener No.2:30ml/l,*Organic sulfonate bath. *As fluoride ion free, waste water treatment is easy.Semi Bright Bath:No.10:30ml/l*Good uniformity and solderability.Tin-Copper Alloy PlatingTOP FLEAD SC(Bright Barrel Bath)SC - M : 2 ml/lSC - R : 3 ml/lSC - S : 1 g/lSC - 1 : 40 ml/lSC - 2 : 2 ml/l*As sulfuric acid bath, low costs and waste water treatment is easy.(Applicable in hoop and rack bath.)*Tin - copper alloy plating for lead-free solder.*Can get bright film containing 1-3% of coppe .Palladium PlatingPRECIA PDPRECIA PDSConcentration as suppliedConcentration as supplied*Excellent brightness and covering power.*Excellent solder wettability and bonding effects, in special.Palladium-Nickel Alloy PlatingPRECIA PN-HSHigh Speed Bath(Hoop)PRECIA PN-HSStandard Bath(Rack, Barrel)PN-HS Base : 80 g/lPD Salt : 50 g/lPN-HS Conc : 150 ml/lPN-HSR : 50 ml/lPN-HS Base : 80 g/lPD Salt : 25 g/lPN-HS Conc : 75 ml/lPN-HSR : 100 ml/l*Excellent brightness.*Give deposition with stable alloy ratio.*Applicable in high speed plating.*Excellent brightness.*Give deposition with stable alloy ratio.*Applicable in barrel plating.STRIPPING AGENTSFor Electroless Nickel Plating FilmTOP RIP AZTOP RIP PF-1AZ - 1 : 40 g/lAZ - 2 : 500 ml/lSodium Hydroxide : 30 g/lF - 85 : 90 g/lPF - 1 : 180 ml/l*Cyanide-free stripping agent for electroless nickel plating film on copper or copper alloys.*Cyanide-free stripping agent for electroless nickel plating film on exclusive steel base.*Less self-consumption of oxidizing agent and erosion of base.For Tin Plating FilmTOP RIP WSWS - 2 : 400 ml/l62% Nitric Acid : 300 ml/l*Nitric acid type stripping agent for tin plating film on copper base.*Applicable continuously by spray method.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR ELECTRONICS AND ENGINEERING PARTS" 05TREATMENT CHEMICALS FOR LEAD-FRAMEHOOP MATERIALTREATMENT CHEMICALS FOR STEEL42 ALLOYSApplication Trade Name Bath Composition FeatureSoak CleanerTLF-130040 g/l*Low COD phosphate type cleaner for lead-frame or hoop materials of steel42 alloys.Rust Removing AgentTLF-52003000 ml/l*Effective to removal for rust and scale of steels.*Suitable for pre-treatment of TLF-4000.Chemical Polishing AgentTLF-4000400 ml/l35%-Hydrogen Peroxide : 300 ml/lTREATMENT CHEMICALS FOR LEAD-FRAMEHOOP MATERIALNeutral Rust RemoverUltra High Speed NickelBrightener for Hoop PlatingTLF-5500TURBOLIGHT200 ml/l1 : 7~13 ml/l2 : 0.2~0.8 ml/lTREATMENT CHEMICALS FOR COPPERCOPPER ALLOYSSoak CleanerElectrolytic CleanerTLF-1800TLF-1900TLF-390040 g/l40 g/l60 g/l*Give uniform chemical polishing to steel and 42 alloys.*Neutral rust removal agent for steels, copper, brass and others. *Less erosion of base at rust removal*Additive for ultra high speed continuous nickel plating on brass, steels and others.*Excellent brightness and leveling, and less formation of burning.(Current Density : 90 A/dm 2 , 50 - 75)*Strong cleaning power and less de-coloring of base material.*Cleaner for copper type lead-frame, hoop material.*Cleaner for copper type lead-frame and hoop material, having good de-foaming effects.*Applicable to normal copper type materials.*As low alkalinity, has wide applicable range of electrolysis time.Oxide Film RemoverTLF-6100TLF-8300100 ml/l500 ml/l*Phosphate type and good cleaning power.*Remove oxide film of copper type materials uniformly.*Oxide film remover for copper type materials.*Effective to remove resist residues.Chemical Polishing AgentTLF-4900TLF-ETCHBRUST300 ml/l35% Hydrogen Peroxide : 300 ml/l300 ml/l*Suitable for mirror finish polishing for copper type materials.*Spray type etching agent for copper type materials.TREATMENT CHEMICALS FOR ELECTRO-MAGNETIC SHIELDTREATMENT CHEMICALS FOR TOP SHIELD PROCESSElectroless Copper PlatingTSP-810ELECTROLESS COPPER1 : 30 ml/l2 : 15 ml/l3 : 1 ml/l4 : 200 ml/l*Excellent bath stability, and deposition film is fine and has good ductility.*Deposition speed is 4 m/h at standard bath.*Long bath life and continuous replenishment type electroless copper plating solution.Multiple Electrolytic Nickel PlatingTSP-48 NICKELA : 100 ml/lC : 200 ml/l*Weak acidic plating solution. *As applying of small current at the intial stage, deposition film has good corrosionresistance and less formation of stain spots by corrosion.(Current Density : 0.2 A/dm 2 )Paste for Partial PlatingTSP PASTE NITSP Paste NI : 650 ml/lTSP Thinner NI : 350 ml/l*Electro-conductive nickel paste.*Small particle diameter, and good appearance after plating.*Thinner has 2 types, for summer and for winter.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR PRINTED WIRING BOARD" 01Application Trade Name Bath Composition FeatureOPC - 370 CONDICLEAN M100 ml/l*Excellent cleaning and conditioning effects.*Improve adsorption of catalyst.*Especially good adsorption of catalyst to glass cloth.Cleaner / ConditionerOPC - 380 CONDICLEAN M50 ml/l*Excellent cleaning and conditioning effects.*Improve adsorption of catalyst.*Alkaline type cleaner / conditioner.OPC - 390 CONDICLEAN M100 ml/l*Excellent cleaning and conditioning effects.*Improve adsorption of catalyst.*Suitable for application to plating on flexible boards.OPC CONDICLEAN GG - 1 : 50 ml/lG - 2 : 35 ml/l*2 solutions type alkaline cleaner / conditioner.*Especially, improve adsorption of catalyst.ConditionerOPC-350 CONDITIONER30 ml/l*Improve adsorption of catalyst to P. W. Boards.*Improve covering power of plating to hole wall.OPC-400 SOFT ETCH150 ml/lMU : 10 ml/l35% Hydrogen Peroxide : 100 ml/l*Improve adhesion between laminated copper film and electroless copper plating film.*Sulfuric Acid / Hydrogen Peroxide base soft etching agent.Soft Etching AgentOPC-450 SOFT ETCH50 ml/l98% Sulfuric Acid : 70 ml/l35% Hydrogen Peroxide : 100 ml/l*Sulfuric Acid / Hydrogen Peroxide base soft etching agent.*Suppress decomposition of Hydrogen Peroxide.*Give uniform etching surface.OPC-480 SOFT ETCH150 g/l98% Sulfuric Acid : 10 ml/l*Powder form soft etching agent.*Compared with Sulfuric Acid / Hydrogen Peroxide type, can give finer etching surface.*Suitable for application as pre-treatment of leveller.*Less local erosion of blind holes.OPC-SAL180 g/l35% Hydrochloric Acid : 30 ml/l*Effective pre-dipping agent for low-HCl type catalyst.Pre-Dipping AgentOPC-SAL M260 g/l*Effective pre-dipping agent for HCl-free type catalyst.*Suitable for application to multi-layer boards.OPC PRE-DIP 4910 ml/l98% Sulfuric Acid : 1.5 ml/l*Pre-dipping agent for alkaline type catalyst.OPC-80 CATALYST50 ml/lSAL M : 260 g/l*Excellent bath stability and catalyzing effects.*Can be applied with HCl-free bath.*Make through-hole plating smooth.CatalyzerOPC-80 CATALYST MOPC-90 CATALYST45 ml/lSAL M : 260 g/l30 ml/lSAL M : 260 g/l*Excellent bath stability and applicable for long period.*Suitable for application to multi-layer boards.*Excellent bath stability.*As low stannous type, can extend bath life of accelerator.OPC-50 INDUCERA : 50 ml/lC : 50 ml/l*Alkaline type catalyzer, and excellent wetting effects.*Suitable for application to small hole boards or multi-layer boards.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR PRINTED WIRING BOARD" 02Application Trade Name Bath Composition FeatureOPC-500 ACCELERATORMXMX-1 : 100 ml/l*Fluoride-free acid type accelerator.*Activate catalyst and make adhesion strong.*Make deposition of electroless plating uniform.AcceleratorOPC-505 ACCELERATORA : 100 ml/lB : 10 ml/l*Fluoride-free acid accelerator.*Activate catalyst and make adhesion strong.*High acceptable limit of tin and long bath life.OPC-555 ACCELERATOR MM : 100 ml/l*Fluoride type acid accelerator.*Activate catalyst strongly and make adhesion strong.Accelerator for Alkaline CatalystOPC-150 CRYSTERMU : 150 ml/l*Reduce palladium strongly and improve deposition effects of plating.OPC-700 ELECTROLESSCOPPER MM-A : 100 ml/lM-B : 100 ml/lM-C : 2 ml/l*Excellent bath stability and covering power.*Excellent color tone of the deposits.*Formalin-Rochells Salt type.OPC-750 ELECTROLESSCOPPER MM-A : 100 ml/lM-B : 100 ml/lM-C : 2 ml/l*Excellent bath stability.*Can be applied for long period continuously.*Formalin-EDTA type.Electroless Copper PlatingSolutionOPC COPPER H(High Speed Type)H-1 : 60 ml/lH-2 : 8 ml/lH-3 : 250 ml/l37% Formalin : 6 ml/l*High speed thick film type electroless copper plating solution for Semi-Additive Method.*Formalin type.*Can be applied as primary panel copper plating.OPC COPPER TT-1 : 60 ml/lT-2 : 12 ml/lT-3 : 100 ml/l*High speed thick film type electroless copper plating solution for ceramic.*Excellent film properties, especially excellent high frequency wave properties.OPC COPPER JJ-1 : 80 ml/lJ-2 : 55 ml/lElectroless Copper R-H : 25 ml/l*Excellent adhesion and deposition effects to holes.*Excellent bath stability.*Can be applied for long period by replenishment.TOP LUCINA 81-HL2.5 ml/lMU : 10 ml/lCurrent Density : 3 A/dm 2*Excellent throwing power and film properties.*Suitable for application to high aspect ratio boards.TOP LUCINA H-300SW2.5 ml/lCurrent Density : 7 A/dm 2*Can be applied at high current density to 10 A/dm 2 .*Additive for high speed type acid copper plating.TOP LUCINA H-3802.5 ml/lCurrent Density : 5 A/dm 2*Additive for middle ~ high speed through-hole acid copper plating bath by jet flow system.*Shorten plating time and improve productivity.Acid Copper PlatingBrightenerTOP LUCINA HAR1 : 5 ml/l2 : 1 ml/lMU : 10 ml/lCurrent Density : 2 A/dm 2*Excellent throwing power and brightness at low current density area.*Suitable for application to small hole boards or high aspect ratio boards.TOP LUCINA LSA : 2.5 ml/lB : 1 ml/lMU : 5 ml/lCurrent Density : 2.5 A/dm 2*Low internal stress in the deposits.*Suitable for application to plating on flexible boards.TOP LUCINA SFSF-M : 5 ml/lCurrent Density : 3 A/dm 2*Excellent throwing power and low stress in deposits.*Suitable for application to flexible boards or others which is afraid to form deformation ordimention change by residual internal stress in the deposits.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR PRINTED WIRING BOARD" 03Application Trade Name Bath Composition FeatureNeutral CleanerOPC CLEAN 65500 ml/l*Remove copper oxide film, resist residue and dirts.OPC-180 CLEANER200 ml/l*Suitable for cleaning and surface conditioning between electroless copper and acid copper platings.Alkaline CleanerOPC-250 CLEANER M50 g/l*Remove oil and finger prints at copper surface and inside hole, and give wettability.*Weak alkaline type cleaner.Acid CleanerOPC-120 CLEANEROPC ACID CLEAN 115100 ml/l200 ml/l*Excellent removal effects of finger prints and light degree oil or rust on copper surface.*Suitable for cleaning and surface conditioning between electroless copper and acid copper platings.OPC CLEAN 9180 ml/l*Excellent removal of finger prints, light degree oil or rust and others on copper surface with etching effects.Etching Type Acid CleanerOPC CLEAN 95100 ml/l*Remove oxid film, dirts and others on copper surface with etching effects.*Suitable to apply before electroless nickel plating also.OPC ETCH CLEANNo.1 : 100 ml/lNo.2 : 1 ml/l*Spray type acid cleaner.*Suitable for cleaning of copper surface of flexible boards.Electrolytic CleanerPRECLEAM M50 g/lAnodic Current Density : 1 A/dm 2*Alkaline type electrolytic cleaner.*Excellent removal of finger prints and oxide film.*Suitable for cleaning and surface conditioning after electroless copper plating.OPC PERSORRY50 ml/lSodium Hydroxide : 35 g/l*Additive for alkaline soluble resist stripping solution.*Suppress erosion of tin or solder plating films.OPC PERSORRY 1025 ml/lSodium Hydroxide : 35 g/l*Additive for alkaline soluble resist stripping solution.*Suppress erosion of tin or solder plating films.*Suppress de-coloring of copper pattern.Special Treatment AgentOPC DEFENSOR8 ml/l*Anti-tarnishing agent for copper plating films.*Can be removed by acids easily.BUBBRAT R-30.1 ~ 2 ml/l*Nonionic surfactant base de-foaming agent.*Excellent durability and de-foaming effects at stripping and developing of dry film by small quantity addition.BUBBRAT R-60.1 ~ 2 ml/l*Low foaming type nonionic non-silicate type surfactant base alkaline resisting de-foaming agent.*Excellent de-foaming effects to resist stripping solution.Solder CleanerOPC BOARD CLEANConcentration as supplied*Halogen-free type surface conditioner for solder plating.*Excellent removal effects of dirts inside through-holes.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR PRINTED WIRING BOARD" 04Application Trade Name Bath Composition FeatureElectroless Palladium Plating SolutionOPC MUDEN NOBLE PDPALLA TOPPD-1 : 50 ml/lPD-2 : 50 ml/lPD-3 : 100 ml/lA : 100 ml/lB : 100 ml/l*Auto-catalytic type electroless palladium plating solution.*Thick film over 10 m is possible, and low stress film.*Suitable for application to P. W. B. or electronics parts.*Neutral auto-catalytic type, give over 99.9% purity film.*Excellent corrosion resistance and solderability.OPC MUDEN GOLD100 ml/l*Substitution type electroless gold plating solution.*Excellent adhesion to under-lying electroless nickel plating, and wide usable range.OPC MUDEN GOLD AD50 ml/lPotassium Aurous Cyanide : 3 g/l*Additive for substitution type electroless gold pating solution.Electroless Gold Plating SolutionOPC MUDEN GOLD 2525-M : 200 ml/l25-1 : 200 ml/l25-2 : 150 ml/l*High speed thick film auto-catalytic cyanide type electroless gold plating solution.*Excellent adhesion and high purity of gold film.*Can be applied for long period by replenishment.*At fresh bath, contain metallic gold for 4g/l.MUDEN NOBLE AUAU-1 : 500 ml/lAU-2 : 200 ml/lAU-3 : 100 ml/lSodium Aurous Sulfite (as Au) : 2 g/l*Additive for neutral cyanide-free substitution type electroless gold plating solution.SELF GOLD OTKOTK-1 : 200 ml/lOTK-2 : 200 ml/lSodium Aurous Sulfite (as Au) : 2 g/l*Additive for neutral reduction type electroless gold plating solution.*Good bath stability and less influence to resist film.Electroless Tin Plating SolutionSUBSTAR SN-5SN-5A : 60 ml/lSN-5B : 500 ml/lSN-5P : 120 g/l*Dipping and substitution type fluoride-free electroless tin plating solution.*Give uniform and fine film.Pure Palladium Plating SolutionPRECIA PDPRECIA PDSConcentration as suppliedPDS-MU :Concentration as supplied*Excellent brightness and covering power.*Suitable for application as decorative plating.*Excellent solder wettability and bonding effects.*Suitable for application to electronics parts.Solder Plating SolutionTOP TEENA MS(Bright Bath)TOP TEENA MS(Semi-Bright Bath)MS Sn Conc : 120 ml/lMS Pb Conc : 20 ml/lMS Acid : 100 ml/lMS Brightenr No.1 : 20 ml/lMS Brightenr No.2 : 30 ml/lMS Sn Conc : 120 ml/lMS Pb Conc : 20 ml/lMS Acid : 100 ml/lNo.10 : 30 ml/l*As fluoride-free, waste water treatment is easy.*Excellent brightness at even low current density area.*Wide brightness range.*Organic sulfonate bath.*Fluoride-free organic sulfonate bath.*Excellent covering power at low current density area.*Extremely stable in solder ratio in the deposits.*As equipments, stainless steel materials can be used.*Waste water treatment is easy.

METAL FINISHING DEPARTMENT PRODUCTS GUIDE "CHEMICALS FOR PRINTED WIRING BOARD" 05Application Trade Name Bath Composition FeaturePalladium / Nickel Alloy PlatingSolutionPRECIA PN-HSHigh Speed Bath(Hoop)PRECIA PN-HSStandard Bath(Barrel, Rack)PN-HS Base : 80 g/lPD Salt : 50 g/lPN-HS Conc : 150 ml/lPN-HS R : 50 ml/lPN-HS Base : 80 g/lPD Salt : 25 g/lPN-HS Conc : 75 ml/lPN-HS R : 100 ml/l*Excellent brightness and stable alloy ratio in the deposits.*High speed plating is possible.*Suitable for application to electronics parts and decoration.*Excellent brightness and stable alloy ratio in the deposits.*Barrel plating can be applied.*Suitable for application to electronics parts and decoration.TOP RIP LT-2300 ml/l62% Nitric Acid : 300 ml/l*Fluoride-free, Hydrogen Peroxide-free dipping type stripping agent for solder and tin films.*No erosion of copper and copper alloys substrate.TOP RIP LT-2(S)300 ml/l98% Sulfric Acid : 100 ml/l62% Nitric Acid : 100 ml/l*Fluoride-free, Hydrogen Peroxide-free spray type stripper for tin film on copper substrate.*Easily remove tin migration layer.Tin / Nickel / Solder Stripping AgentTOP RIP BTConcentration as supplied35% Hydrogen Peroxide : 40 ml/l*Dipping type stripping agent for nickel plating resist film on copper substrate.TOP RIP WSWS-2 : 400 ml/l62% Nitric Acid : 300 ml/l*Fluoride-free, Hydrogen Peroxide-free spray type stripper for tin plating resist film on copper substrate.OPC RIP SOLDER TConcentration as supplied*Solder and tin stripping agent for terminal plating.*No attack to copper substrate.OPC-B101 PRE ETCH500 ml/l*Condition Epoxy Resin surface and make etching easy.*As swelling power is slightly week, suitable for resins which are etched easily.OPC-B102 PRE ETCH500 ml/l*Condition Epoxy Resin surface and make etching easy.*As swelling power is strong, suitable for resins which are etched hardly.OPC-B103 PRE ETCH300 ml/lSodium Hydroxide : 13 g/l*Condition Epoxy Resin surface and make etching easy.*As swelling power is moderate, suitable for resins which are etched hardly.OPC-B201 EPO ETCH60 ml/lPotassium Permanganate : 45 g/l*Electroless nickel plating solution for ICP process.*Less generation of skipping and bridge phenomenon.Chemicals for Build-UpBoards Treatment(OPC-B Series)OPC-B303 NEUTRALIZEROPC-B41 CONDICLEAN200 ml/l100 ml/l*Electroless nickel plating solution for ICP process.*Excellent chemical resistance and corrosion resistance.*Electroless nickel plating solution for ICP process.*Especially, excellent chemical resistance and corrosion resistance.OPC-B61 CATALYST30 ml/lSAL M : 260 g/l*Excellent to adhesion effects.*Can get the stable deposition with the wide range of material.*Applicable for build-up board.OPC-B71 ACCELERATOR200 ml/l*Non-fluoride acidic liquid.*Catalyst metal is activated, and close adhesion is made strong.BUILD COPPER1 : 30 ml/l2 : 15 ml/lMU : 200 ml/l*Excellent bath stability.and deposition to blind via-hole is excellent.*It is especially suitable for build-up circuit board.