ITT's Place in the Cycle of Water - Water Solutions

ITT's Place in the Cycle of Water - Water Solutions

ITT's Place in the Cycle of Water - Water Solutions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

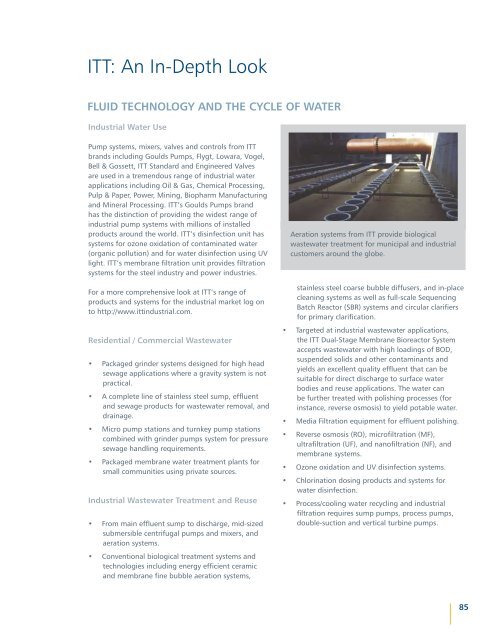

ITT: An In-Depth LookFluid technology and <strong>the</strong> cycle <strong>of</strong> waterIndustrial <strong>Water</strong> UsePump systems, mixers, valves and controls from ITTbrands <strong>in</strong>clud<strong>in</strong>g Goulds Pumps, Flygt, Lowara, Vogel,Bell & Gossett, ITT Standard and Eng<strong>in</strong>eered Valvesare used <strong>in</strong> a tremendous range <strong>of</strong> <strong>in</strong>dustrial waterapplications <strong>in</strong>clud<strong>in</strong>g Oil & Gas, Chemical Process<strong>in</strong>g,Pulp & Paper, Power, M<strong>in</strong><strong>in</strong>g, Biopharm Manufactur<strong>in</strong>gand M<strong>in</strong>eral Process<strong>in</strong>g. ITT’s Goulds Pumps brandhas <strong>the</strong> dist<strong>in</strong>ction <strong>of</strong> provid<strong>in</strong>g <strong>the</strong> widest range <strong>of</strong><strong>in</strong>dustrial pump systems with millions <strong>of</strong> <strong>in</strong>stalledproducts around <strong>the</strong> world. ITT’s dis<strong>in</strong>fection unit hassystems for ozone oxidation <strong>of</strong> contam<strong>in</strong>ated water(organic pollution) and for water dis<strong>in</strong>fection us<strong>in</strong>g UVlight. ITT’s membrane filtration unit provides filtrationsystems for <strong>the</strong> steel <strong>in</strong>dustry and power <strong>in</strong>dustries.For a more comprehensive look at ITT’s range <strong>of</strong>products and systems for <strong>the</strong> <strong>in</strong>dustrial market log onto http://www.itt<strong>in</strong>dustrial.com.Residential / Commercial Wastewater• Packaged gr<strong>in</strong>der systems designed for high headsewage applications where a gravity system is notpractical.• A complete l<strong>in</strong>e <strong>of</strong> sta<strong>in</strong>less steel sump, effluentand sewage products for wastewater removal, anddra<strong>in</strong>age.• Micro pump stations and turnkey pump stationscomb<strong>in</strong>ed with gr<strong>in</strong>der pumps system for pressuresewage handl<strong>in</strong>g requirements.• Packaged membrane water treatment plants forsmall communities us<strong>in</strong>g private sources.Industrial Wastewater Treatment and Reuse• From ma<strong>in</strong> effluent sump to discharge, mid-sizedsubmersible centrifugal pumps and mixers, andaeration systems.• Conventional biological treatment systems andtechnologies <strong>in</strong>clud<strong>in</strong>g energy efficient ceramicand membrane f<strong>in</strong>e bubble aeration systems,Aeration systems from ITT provide biologicalwastewater treatment for municipal and <strong>in</strong>dustrialcustomers around <strong>the</strong> globe.sta<strong>in</strong>less steel coarse bubble diffusers, and <strong>in</strong>-placeclean<strong>in</strong>g systems as well as full-scale Sequenc<strong>in</strong>gBatch Reactor (SBR) systems and circular clarifiersfor primary clarification.• Targeted at <strong>in</strong>dustrial wastewater applications,<strong>the</strong> ITT Dual-Stage Membrane Bioreactor Systemaccepts wastewater with high load<strong>in</strong>gs <strong>of</strong> BOD,suspended solids and o<strong>the</strong>r contam<strong>in</strong>ants andyields an excellent quality effluent that can besuitable for direct discharge to surface waterbodies and reuse applications. The water canbe fur<strong>the</strong>r treated with polish<strong>in</strong>g processes (for<strong>in</strong>stance, reverse osmosis) to yield potable water.• Media Filtration equipment for effluent polish<strong>in</strong>g.• Reverse osmosis (RO), micr<strong>of</strong>iltration (MF),ultrafiltration (UF), and nan<strong>of</strong>iltration (NF), andmembrane systems.• Ozone oxidation and UV dis<strong>in</strong>fection systems.• Chlor<strong>in</strong>ation dos<strong>in</strong>g products and systems forwater dis<strong>in</strong>fection.• Process/cool<strong>in</strong>g water recycl<strong>in</strong>g and <strong>in</strong>dustrialfiltration requires sump pumps, process pumps,double-suction and vertical turb<strong>in</strong>e pumps.85