Specalog for 525B Skidder - Kelly Tractor

Specalog for 525B Skidder - Kelly Tractor

Specalog for 525B Skidder - Kelly Tractor

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

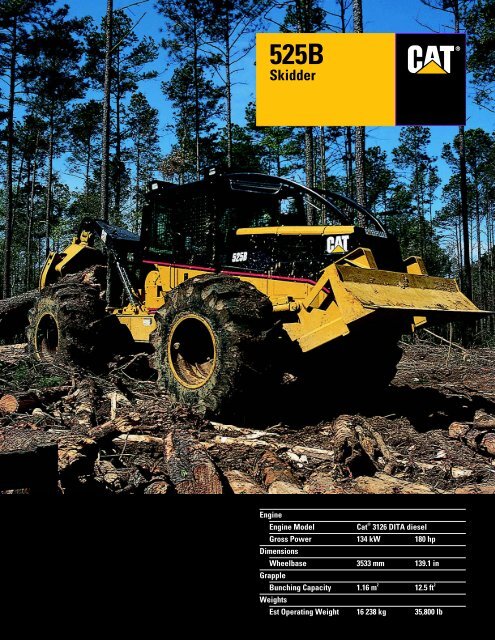

<strong>525B</strong><strong>Skidder</strong>®EngineEngine ModelCat ® 3126 DITA dieselGross Power 134 kW 180 hpDimensionsWheelbase 3533 mm 139.1 inGrappleBunching Capacity 1.16 m 2 12.5 ft 2WeightsEst Operating Weight 16 238 kg 35,800 lb

<strong>525B</strong> <strong>Skidder</strong>The <strong>525B</strong> <strong>Skidder</strong> is built to exceed all expectations <strong>for</strong> skidding per<strong>for</strong>mance, reliability and com<strong>for</strong>t,while maximizing productivity.Per<strong>for</strong>mance - Power TrainThe field-proven Cat 3126 DITA dieselengine, heavy-duty torque converterwith lock-up, five speed transmissionand re-engineered differential locksystem provide higher horsepower tothe ground to maximize per<strong>for</strong>manceand productivity, and minimize fuelconsumption. pg. 4Per<strong>for</strong>mance - HydraulicsThe state-of-the-art closed-center,variable displacement, pressurecompensating hydraulic systemprovides power <strong>for</strong> braking, steering,blade and grapple functions. pg. 5Durability - UndercarriageThe exclusive front axle design,expanded tire options, and largerfootprint provide outstanding skiddingper<strong>for</strong>mance and a com<strong>for</strong>table ride <strong>for</strong>the operator. pg. 6ServiceabilityRegular maintenance is simple witheasy access to daily service points.Access to less frequent service points isalso simplified. Major components aremodular and most can be removedwithout disturbing or removing others.On-board diagnostic systems helpprevent problems, and electronicanalysis shortens analysis and repairtime <strong>for</strong> higher productivity. pg. 10Customer SupportYour Cat dealer offers a wide range ofservices that help you operate longerwith lower costs. pg. 11Engineered <strong>for</strong> demanding work.This skidder is a state-of-the-artmachine that represents theCaterpillar ® commitment to thelogging industry.Reliable, durable operation.Rugged construction and easymaintenance provide long hours ofservice with the low operating costsyou expect from Cat machines.2

Durability - StructuresThe <strong>525B</strong> mainframe, hitch and deckingblade are designed and built to surpassthe expectations of the logging industry.pg. 7Application FlexibilityThe <strong>525B</strong> Wheel <strong>Skidder</strong> providesunsurpassed per<strong>for</strong>mance andapplication flexibility due to superior<strong>for</strong>e-aft stability, torque converter withlock-up power train, ground clearanceand an extended wheelbase. pg. 8Operator Com<strong>for</strong>tThe <strong>525B</strong> operator environment uses anergonomic design that creates acom<strong>for</strong>table work area with easy-to-usemachine controls to reduce fatigue andincrease efficiency and productivity.pg. 93

Per<strong>for</strong>mance - Power TrainThe <strong>525B</strong> <strong>Skidder</strong> combines the Cat 3126 DITA engine and torque converter/direct drive <strong>for</strong>relentless pulling power.3126 DITA Engine. The Cat 3126delivers reliable power with lowemissions, excellent fuel economy, andtraditional Caterpillar durability.Engine Design. Precise engineering andfour-stroke cycle provide power,reliability, serviceability and fueleconomy.Direct-Injection Fuel System. Individualunit fuel injectors deliver efficient,accurate fuel metering, reducedemissions, reliable power, high torquerise and responsive per<strong>for</strong>mance.Turbocharger. Enhances per<strong>for</strong>manceand engine efficiency, especially at highaltitudes, by increasing air supply to thecylinders <strong>for</strong> excellent combustion.Aftercooler. Jacket water aftercoolerreduces smoke and emissions byproviding cooler, more efficientcombustion. This also extends the lifeof the piston rings and bore.Fuel Pre-filter. Two high-efficiency fuelfilters in series with a water separatorelement ensure excellent fuelcleanliness <strong>for</strong> extended injector andfuel system life.Torque Converter. The large, heavydutytorque converter with a lockupclutch is matched to the Cat 3126engine <strong>for</strong> excellent rimpull andimproved skidding per<strong>for</strong>mance.High Breakout Loads. The <strong>525B</strong> torqueconverter is also well suited <strong>for</strong> the highbreakout loads required in grappleskidding.Travel Speeds. Direct drive capabilityallows high travel speeds and minimalpower train component wear.Reduced Wheel Slip. Direct drivecapability reduces wheel slip, whichminimizes tire wear, component stressand fuel consumption.Lock-Up Clutch. The integral lock-upclutch allows operation in converterdrive or direct drive <strong>for</strong> high efficiencyhauling, faster travel speeds, andreduced shock loads to the drive train.• Auto Lock-up locks the converterclutch whenever the torque converter isin direct drive, maximizing travel speedand rimpull <strong>for</strong> fast, fuel-efficienthauling.Five-Speed Transmission. TheCaterpillar powershift countershafttransmission easily matches enginepower to the load size and groundconditions. Gear 1 provides industryleading rimpull capability <strong>for</strong> heavyload applications, gears 2, 3 and 4 are<strong>for</strong> lighter loads and higher speedoperations, while gear 5 providesexcellent empty return speeds.Differential Locks. Hydraulicallyengaged differential locks in both axlessignificantly expand the operating rangeof the <strong>525B</strong>. They reduce tire slipduring turns, improve flotation, andreduce tire wear. In addition, theyenhance maneuverability by improvingtraction and allowing a tighter turningradius.4

Per<strong>for</strong>mance - HydraulicsState-of-the-art hydraulic system contributes to system efficiency and operational ease andproductivity.Load Sensing Hydraulics. A loadsensing variable displacement pumpand pressure compensating systemcontinually monitor hydraulic powerrequirements, and provide hydraulicpower based on demand.Less Hydraulic Pump Demand. Thehydraulic pump doesn't runcontinuously under load, but operatesonly when needed. This lowershorsepower consumption, maximizespower to the ground as well as loadingand grapple <strong>for</strong>ces. It also increasesfuel efficiency, extends hydrauliccomponent life, and reduces systemheat.Auto-Grab Feature. Auto-Grabconstantly monitors tong pressure andadjusts as needed to securely holdgrapple loads. Like the load sensinghydraulic system, Auto-Grab placesdemand on engine horsepower onlywhen the system senses a shift in theload that requires a change in tongpressure. It is easily activated ondemand by a switch located on theright-hand control lever. <strong>Tractor</strong>operation is easier, constant tongpressure is maintained, and operatingcosts are reduced through greater fuelefficiency and less time spent regrippingslipped loads.Winch. The <strong>525B</strong> uses a high capacitywinch with four-function control. Thisself-contained unit has a separate oilpump using winch sump oil <strong>for</strong> control,and to cool and lubricate the winch.Cat Hoses. Caterpillar hose technologyallows high pressures <strong>for</strong> maximumpower and reduced downtime, andintelligent routing minimizes exposureto damage.Steering. Fully hydraulic control.Meets the following standards: SAEJ1511 OCT90, ISO 5010-1992.5

Durability - UndercarriageState-of-the-art engineering of rugged undercarriage components and systems <strong>for</strong> the <strong>525B</strong>wheel skidder sets the industry standard <strong>for</strong> reliability and durability.Cradled Front Axle. Exclusive toCaterpillar wheel skidders, the cradledfront axle with a high pivot center actsas a working counterweight, anddelivers enhanced per<strong>for</strong>mance andoperator com<strong>for</strong>t. It provides excellent<strong>for</strong>e-aft stability <strong>for</strong> large grapples andthe dual-function arch. Heavy-dutytrunnion bearings assure durable,reliable operation. The 15 degreeoscillation absorbs minor shock loads,isolating the cab from axle movement<strong>for</strong> a smoother ride.Final Drives. Heavy-duty inboard finaldrives are protected from the harshlogging environment, and use splash oillubrication and cooling. Thisconfiguration makes wheel and tireremoval and installation easier.Brake Components. Brake componentsare housed inside the axles, protectingthem from dirt, dust and wet groundconditions. Inboard brakes allow <strong>for</strong>splash lubrication and cooling, arevirtually maintenance free, and providereliable brake per<strong>for</strong>mance in the mostdemanding logging applications.Oil Sump. Full axle-length oil sumpdelivers excellent lubrication and heatrejection <strong>for</strong> long component life. Allcomponents housed in the axle aresplash lubricated, and outboard bearingsare maintenance free.• Large oil capacity provides excellentheat rejection, ensuring properlubrication.Differential Locks. Differential locksprovide added traction in poor groundconditions. On-the-go engagement /disengagement allows operator tomaintain production without stopping.Wheel Options. The <strong>525B</strong> offers achoice of configurations allowing singleor dual wheels. Dual or flotation tires(using 30.5 x 32 inner and 24.5 outer)increase flotation in wet, sloppyunderfoot conditions, and improvestability on grades with large loads.6

Durability - StructuresThe <strong>525B</strong> mainframe, hitch and decking blade are designed and built to surpass theexpectations of the logging industry.Box-Section Construction. The <strong>525B</strong>frames use resilient box sectionconstruction that sets the industrystandard <strong>for</strong> reliability and durability.Front Frame. The front frame isdesigned with higher clearance toaccommodate the front axle cradlemounts, and lower blade pivotmounting position.Rear Frame. Tough rear frame providesthe plat<strong>for</strong>m to support the grapple archor cable arch configurations.Ground Clearance. Maximized groundclearance improves maneuverability andavoids damage. Full belly guardsprotect all undercarriage components.Decking Blade. Fabricated, box-sectionsteel arms mount directly to themainframe <strong>for</strong> superior strength.Hitch. The bottom hitch is doubletapered<strong>for</strong> improved weightdistribution, which reduces flexingstress and maintains tight joints.Hitch Pins. The wide hitch pin spreadreduces horizontal loads on hinge pins,and increases room <strong>for</strong> hydraulic hoserouting.Arches. The <strong>525B</strong> single- and dualfunctionarches, and the cable arch aredesigned and tested to exceed durabilityrequirements.Grapples. Durable, high capacitysorting or bunching grapples arematched to machine size andhorsepower <strong>for</strong> optimum per<strong>for</strong>mance.Sorting Grapples. Sorting grapples arebest <strong>for</strong> quickly selecting a few stemsfrom a pile of logs.Bunching Grapples. The strongbunching grapples offer large capacity<strong>for</strong> improved production in harvestingsmaller trees and large loads.Grapple Snubbers. Grapple snubber lifehas been improved, reducing grappleswing, hydraulic hose stresses andincreasing component life.Winch. The <strong>525B</strong> winch attachmentdelivers the power and durability ideal<strong>for</strong> log truck towing, self-retrieval andlog skidding.ROPS / FOPS. Roll-Over Protection andFalling Object Protection guards offerprotection to the operator and themachine.7

Application FlexibilityThe <strong>525B</strong> Wheel <strong>Skidder</strong> can easily handle the variety of tasks <strong>for</strong> today's loggers.Balance. Long front and rear framesand a low center of mass createexcellent skidder balance. Thepowerful mechanically driven, heavydutywinch provides outstandinggrapple or cable skidder per<strong>for</strong>mance.Torque Converter. The heavy duty lockuptorque converter offers two driveoptions: direct drive, the only option inmany skidders, delivers excellentskidding power and speed; and torqueconverter drive, which provides torquemultiplication and speed control, whichreduces the need <strong>for</strong> frequenttransmission gear changes.Wheelbase. The <strong>525B</strong> skidder has awider, longer wheelbase to handlesingle- and dual-function arches andlarge capacity bunching grapples.Tire Options. Expanded tire optionsallow the <strong>525B</strong> to maintain outstandingskidding per<strong>for</strong>mance in a wide rangeof ground conditions.Dual-Capable. The <strong>525B</strong> is capable ofusing dual wheels with the installationof an optional dual axle. Duals increaseflotation in poor underfoot conditions,and improve stability, especially whenhauling large loads on a grade.Arches and Blade. The <strong>525B</strong> isavailable with a single- or dual-functionarch, or the cable arch, and a deckingblade to match the machine to theapplication.Single Function Arch. Has less weightand fixed reach, making it ideal <strong>for</strong> fastskidding operations.Dual-Function Arch. Offers variablereach and large grapple capacities, wellsuited <strong>for</strong> large bundles of small stems.Cable Arch. Allows outstanding lineskidding per<strong>for</strong>mance with a twoposition adjustable height fairlead tomatch site conditions.Decking Blade. Efficiently clearslandings and roads, and maintainsstockpiles.8

Operator Com<strong>for</strong>tThe <strong>525B</strong> cab is designed <strong>for</strong> com<strong>for</strong>t and ease of operation, to maximize efficiency andproductivity.Com<strong>for</strong>table Work Station. The <strong>525B</strong>work station incorporates years of cabdesign innovations to maximizeoperator com<strong>for</strong>t and productivity.Air Suspension Seat. Standard airsuspension seat swivels 30 degrees tothe right <strong>for</strong> maximum com<strong>for</strong>t.Sealed Cab. Sealed and pressurized <strong>for</strong>efficient heating and cooling, and <strong>for</strong>keeping out dust, fumes and insects.Air-Conditioning. Standard withenclosed cab attachment.Windows. Large polycarbonatewindows protect the operator and allowan excellent side and rear view. Slidingglass windows protected by metalscreens in both doors provide fresh airand communication outside themachine.Mounting. The modular ROPS/FOPScab is resiliently mounted to the skidderframe to reduce vibration. The lowestentrance step has been lowered <strong>for</strong>easier cab access, and designed <strong>for</strong>greater durability.Sound Insulation. Ample soundinsulation reduces sound levels andboosts operator com<strong>for</strong>t.Machine Controls. The com<strong>for</strong>table<strong>525B</strong> operator environment usesergonomically designed and placedmachine controls to reduce fatigue andincrease productivity.Steering Control. Tilts and telescopes,and incorporates controls <strong>for</strong>transmission direction and rangeselection <strong>for</strong> maximum convenienceand productivity.Transmission Controls. Transmissioncontrols <strong>for</strong> <strong>for</strong>ward, reverse and gearrange are located on the steering wheel<strong>for</strong> easy fingertip control.Single-lever Grapple Control. A singlefour-function lever controls all grappleand tong functions <strong>for</strong> simplifiedoperation and reduced operator ef<strong>for</strong>t.Decking Blade Control. Excellentmodulation and precise control <strong>for</strong>various decking and clearing functions.Auto-Grab Switch. System monitors andadjusts tong pressure as needed tomaintain a secure grip on grapple loads.Lock-up Torque Converter Drive.Selection switch and engagementindicator light helps match transmissionspeed range to skidding requirements.Differential Lock Switch.Ergonomically located rocker switchallows quick engagement of differentiallocks when needed.Analog Gauges. Four gauges indicateengine coolant temperature, hydraulicoil temperature, transmission oiltemperature and fuel level.Caterpillar Monitoring System.Monitors key fluid levels andtemperatures, gear speed and direction,and vital electrical systems. A threelevelwarning system alerts the operatorof potential problems.Additional. Pre-wired <strong>for</strong> anentertainment radio: two speakers,antenna and standard built-in 24-to-12-volt converter. The machine is fittedwith on-off key switch engineoperation.9

ServiceabilityThe most serviceable machines from the most committed dealers.Built-in Servicing Ease. Caterpillar usesintelligent engineering to make regularmaintenance procedures quick andsimple. Easy access to daily servicepoints increases the likelihood thatmaintenance will be done, extendingmachine service life and loweringoverall operating costs. In addition, lessservice time means more working timeand greater productivity.Ground Level Access. Most filters andlube points are accessible from theground. Remote lubrication pointsmake daily attention to hard-to-reachjoints easy.Centrifugal Pre-Cleaner. Centrifugalpre-cleaner removes large debris be<strong>for</strong>eit reaches the internal air cleaner toprovide significant engine protection.S•O•S SM and Coolant Sampling Valves.Provide a fast, convenient means ofobtaining uncontaminated fluidsamples, which improves analysisreliability.Radial Seal Air Filters. Hand accessmakes them easy to change, reducingair filter maintenance times.Bolt-on Guards. Offer protection tocritical components, but are easilyremovable <strong>for</strong> fast service access.Removable floor plates and side plateallow access to components under thecab.Turbocharger Location. The relocatedturbocharger provides easy access to theair cleaner and allows the cabcompartment to be sealed from dust anddebris.Spin-on Oil Filters. Spin-on filters <strong>for</strong>fuel and oil systems reduce changingtime, and help assure clean, tight seals.Pressure Taps. Conveniently located <strong>for</strong>easy access to hydraulic systempressure measurements.Ecology Drains. Located on the axle andtransmission to make regularmaintenance easier, and protect theenvironment from accidental oil spills.Electrical System. 24-volt electricalsystem delivers increased electricalpower <strong>for</strong> engine cranking, lights, andengine diagnostics. Wiring circuits arecolor coded, numbered and protected bycircuit breakers.On-Board Diagnostic Systems. TheCaterpillar Monitoring Systemcontinuously checks all critical machinefunctions and components, and helpslocate faults quickly <strong>for</strong> faster repair.10

Customer SupportCat dealer services help you operate longer with lower costs.Product Support. You will find nearlyall parts at our dealer parts counter. Catdealers use a world-wide computernetwork to find in-stock parts tominimize machine down time. Savemoney with genuine Cat Reman parts.You receive the same warranty andreliability as new products at costsavings of 40 to 70 percent.Machine Selection. Make detailedcomparisons of the machines underconsideration be<strong>for</strong>e purchase. Catdealers can estimate component life,preventive maintenance cost, and thetrue cost of lost production.Purchase. Look past initial price.Consider the financing options availableas well as day-to-day operating costs.Look at dealer services that can beincluded in the cost of the machine toyield lower equipment owning andoperating costs over the long run.Customer Support Agreements. Catdealers offer a variety of productsupport agreements, and work withcustomers to develop a plan that bestmeets specific needs. These plans cancover the entire machine, includingattachments, to help protect thecustomer's investment.Operation. Improving operatingtechniques can boost your profits. YourCat dealer has training videotapes,literature and other ideas to help youincrease productivity.Maintenance Services. Choose fromyour dealer's range of maintenanceservices when you purchase yourmachine. Repair option programsguarantee the cost of repairs up front.Diagnostic programs such as S•O•S SMand Coolant Sampling and Technicalanalysis help you avoid unscheduledrepairs.Replacement. Repair, rebuild orreplace? Your Cat dealer can help youevaluate the cost involved so you canmake the right choice.11

EngineEngine ModelCat 3126 DITA dieselGross Power 134 kW 180 hpTorque Rise 50%Max Torque @ Rated Speed 779.1 @ 1400 NmNumber of Cylinders 6Net Flywheel Power 119 kW 160 hpNet Power - ISO 9249 119 kW 160 hpNet Power - SAE J1349 119 kW 160 hpNet Power - EEC 80/1269 119 kW 160 hpGoverned Speed at Rated Power 2,200 RPMDisplacement 7.24 L 441.78 in 3Bore 110 mm 4.33 inStroke 127 mm 5 inDerating Altitude 3250 m 10,663 ftAir Cleanerdry centrifugal precleanerAlternator75 AmpFan Speed1,909 RPMFan TypeblowerElectrical System24 VBattery - Quantity 2Battery - Volts12 VBattery - Capacity950 CCAStarting Systemdirect electric• Net power advertised is the power available at the flywheelwhen the engine is equipped with fan, air cleaner, mufflerand alternator. No derating required up to 3250 m (10,663 ft)altitude.• Based on standard air conditions of 25°C (77°F) and 99 kPa(29.32" Hg) dry barometer. Used 35° API gravity fuel havingan LHV of 42,780 kJ/kg (18,390 BTU/lb) when used at 30°C(86°F) [ref. a fuel density of 838.9 g/L (7.001lb/gal)].• The Caterpillar 3126DITA meets the current European andNorth American emission regulations (ISO 8178).Power TrainTravel Speed - Fwd. 1st 6.36 kph 3.95 mphTravel Speed - Fwd. 2nd 8.94 kph 5.55 mphTravel Speed - Fwd. 3rd 10.87 kph 6.75 mphTravel Speed - Fwd. 4th 15.28 kph 9.49 mphTravel Speed - Forward 5th 27.53 kph 17.1 mphTravel Speed - Rev. 1st 6.18 kph 3.84 mphTravel Speed - Rev. 2nd 10.46 kph 6.5 mphTravel Speed - Rev. 3rd 18.6 kph 11.55 mphMax Drawbar Pull 172 kN 38,730 lbTorque Converter - Model 3308 Lock-upTorque Converter - Typesngl stg, rotating housingTransmissionCountershaft 5fwd/3revSteeringhydraulic controlBrakes - Service Typehydraulic, wet discBrakes - Parking TypedrumTransmission Cooler Location Lower tank radiatorTransmission Cooler Type PlateHydraulic SystemCircuit Typeclosed cntr, load sensingPump Typeaxial pistonPump Output @ 2200 RPM 190 L/min 50 gal/minReservoir Tank Capacity 62.5 L 16.5 GalRelief Valve Setting 21 000 kPa 3,045 PSISteering Valvedirect link, non-followSteering Cylinder - Bore 76.2 mm 2.97 inSteering Cylinder - Stroke 436.4 mm 17.02 inSteering Cylinder - RodDiameter 44.45 mm 1.73 inSteering Relief ValveSettings 21 000 kPa 3,045 PSIDozer Valvedirect linkage controlDozer Cylinder - Bore 101.6 mm 3.95 inDozer Cylinder - Stroke 470 mm 18.33 inDozer Cylinder - Rod Diameter 57.1 mm 2.23 inGrapple Valve3or4 stack, pilot controlGrapple System Relief ValveSettings 21 000 kPa 3,045 psi12 <strong>525B</strong> <strong>Skidder</strong> specifications

GrappleBunching Capacity 1.16 m 2 12.5 ft 2Sorting Capacity 0.836 m 2 9 ft 2Bunching - Full Open Height 1874.5 mm 73.8 inBunching - Fully ClosedHeight 1532 mm 60.32 inBunching - Minimum StemDiameter 134.6 mm 5.3 inBunching - Reach @ Full Open 711.2 mm 28 inBunching - Tip to Tip Height 2263 mm 89.1 inBunching - Tong Opening 3048 mm 120 inSorting - Full Open Height 1562.1 mm 61.5 inSorting - Fully Closed Height 1829 mm 72 inSorting - Minimum StemDiameter 76.2 mm 3 inSorting - Tip to Tip Height 2197.1 mm 86.5 inSorting - Tong Opening 2540 mm 100 inArchArch Typessingle/dual/cableDual Function - Reach Max 2801.6 mm 110.3 inDual Function - Lift MaxReach 1150.6 mm 45.3 inDual Function - Lift Highest,Farthest 1828.9 mm 72 inDual Function - Lift Highest,Retracted 2694.9 mm 106.1 inDual Function - Lift Lowest,Farthest 2725.4 mm 107.3 inDual Function - Lift Lowest,Retracted 1125.2 mm 44.3 inDual Function - ReachHighest, Farthest 2654.3 mm 104.5 inDual Function - ReachHighest, Retracted 1242.1 mm 48.9 inDual Function - Reach Lowest,Farthest 2725.4 mm 107.3 inDual Function - Reach Lowest,Retracted 1491 mm 58.7 inSingle Function - Reach Max 2517 mm 99.1 inSingle Function - LiftHighest 2169 mm 85.4 inSingle Function - ReachMinimum 1666 mm 65.6 inSingle Function - Lift Lowest 343 mm 13.5 inWinchLine Pull - Std Drum 175 kN 39,300 lbLine Speed 103.6 m/min 340 ft/minDrum Capacity 19.0mm (3/4in) 45 m 148 ftDrum Capacity 22.2mm (7/8in) 32 m 106 ftDrum capacity 25.4mm (1in) 25 m 82 ftDrum Diameter 254 mm 10 inDrum Width 171.5 mm 6.69 inService RefillFuel Tank 315 L 83.2 GalCooling System 50 L 13.2 GalDifferential & Final Drives -Front 52 L 13.73 GalDifferential & Final Drives -Rear 52 L 13.73 GalEngine Oil 27 L 7.13 GalTransmission & TorqueConverter 54 L 14.26 GalMechanical Winch 24.5 L 6.47 GalHydraulic System - Tank 62.5 L 16.5 GalHydraulic System - Total 123 L 32.47 GalDimensionsWheelbase 3533 mm 139.1 inLength 6195.4 mm 241.62 inWidth 3385 mm 133.3 inHeight 3233.5 mm 126.11 inGround Clearance 581.7 mm 22.9 in<strong>525B</strong> <strong>Skidder</strong> specifications13

WeightsEst Operating Weight 16 238 kg 35,800 lbArch - Dual Function 1119 kg 2,466 lbArch - Cable Skidding 769 kg 1,696 lbDecking Blade 796 kg 1,755 lbDozer, Extended Width 1015 kg 2,238 lbEnclosed Cab 63 kg 138 lbEnclosed ROPS + AC 1205 kg 2,657 lbFrame - Cable Fenders 1320 kg 2,911 lbFrame - No Fenders 1018 kg 2,245 lbGrapple - Bunching 1.04 m 2 /11.2 ft 2 814 kg 1,795 lbGrapple - Bunching 1.16 m 2 /12.5 ft 2 1045 kg 2,302 lbGrapple - Sorting .84 m 2 /9.0 ft 2 807 kg 1,780 lbInstrument Panel Guard 1 kg 2 lbLights - 4 Standard 67 kg 148 lbLights - 8 Optional 163 kg 359 lbOpen ROPS 1073 kg 2,366 lbOperating Weight - Cable 769 kg 1,695 lbStarting Aid, Ether 5 kg 11 lbTires - 24.5 x 32, 16 PR 322 kg 710 lbTires - 30.5L x 32, 16 PR 2353 kg 5,188 lbTires - 35.5L x 32, 16 PR 2960 kg 6,512 lbWinch 785 kg 1,731 lbStandardsCab• Enclosed cab with or without screens and open canopy withscreens meet operator protective structure criteria <strong>for</strong><strong>for</strong>estry equipment SAE J1084 APR80• When properly installed and maintained, the enclosed caboffered by Caterpillar when tested with doors and windowsclosed according to ANSI/SAE J1166 MAY90, meets OSHAand MSHA requirements <strong>for</strong> operator sound exposure limitsin effect at the time of manufacture.ROPS• ROPS (Rollover Protective Structure) offered by Caterpillar<strong>for</strong> the machine meets ROPS criteria SAE J1040 APR88 andISO 3471-1994. FOPS (Falling Object Protective Structure)meets FOPS criteria SAE J231 JAN81 and ISO 3449-1984.Brakes• Brakes meet the following standards: OSHA, SAE J1473OCT90, ISO 3450-1985• Operating weight includes enclosed cab, 30.5 tires, blade,dual-function arch, 1.16 m 2 /12.5 ft 2 bunching grapple,standard lights, full fuel tank.14 <strong>525B</strong> <strong>Skidder</strong> specifications

<strong>525B</strong> GrapplesBDACSorting GrappleDimension Sorting Bunching BunchingA Grapple capacity 0.83 m 2 (9.0 ft 2 ) 1.04 m 2 (11.2 ft 2 ) 1.16 m 2 (12.5 ft 2 )B Tip to tip height 2197.1 mm (86.5 in) 2225 mm (87.6 in) 2263 mm (89.1 in)C Tong opening 2540 mm (100 in) 2794 mm (110 in) 3048 mm (120 in)D Full open height 1562 mm (61.5 in) 1979 mm (77.9 in) 1874.5 mm (73.8 in)E Minimum stem diameter 76.2 mm (3 in) 134.6 mm (5.3 in) 134.6 mm (5.3 in)F Fully closed height 1829 mm (72 in) 1516 mm (59.7 in) 1532 mm (60.3 in)G Reach @ full tong opening — 792.5 mm (31.2 in) 711.2 mm (28.0 in)BDACGBunching GrappleFE<strong>525B</strong> <strong>Skidder</strong> specifications15

➤➤➤➤➤➤➤➤➤➤➤➤➤➤Arch Configurations➤➤BB2➤D1➤➤➤➤➤➤➤➤➤➤BB1➤DDSingle Function➤➤EAC➤➤Dual Function➤➤E➤A2A1A➤➤C1C➤➤➤➤➤Dimension Single Function Dual FunctionA Reach maximum 2517 mm (99.1 in) 2801.6 mm (110.3 in)A1 Reach, highest farthest — 2654.3 mm (104.5 in)A2 Reach, lowest farthest — 2725.4 mm (107.3 in)B Lift maximum 2169 mm (85.4 in) 2694.9 mm (106.1 in)B1 Lift, highest farthest — 1828.9 mm (72.0 in)B2 Lift at maximum reach — 1125.2 mm (44.3 in)C Reach minimum 1666 mm (65.6 in) 1150.6 mm (45.3 in)C1 Reach, nearest lowest — 1491 mm (58.7 in)D Lift minimum 343 mm (13.5 in) 2725.4 mm (107.3 in)D1 Lift, lowest nearest — 1125.2 mm (44.3 in)E Loaded tire radius 724 mm (28.4 in) 724 mm (28.4 in)16 <strong>525B</strong> <strong>Skidder</strong> specifications

DimensionsAll dimensions are approximate.GrappleJAIBGHCKDLEDimension<strong>525B</strong>A Ground level to center line of top roller (grapple)*dual function3419 mm (134.6 in)single function2893 mm (113.9 in)A1 Ground level to center line of top roller (cable)*2694 mm (106.1 in)B Ground level to axle center line* 724 mm (28.5 in)C Rear axle center line to pin 1798 mm (70.8 in)D Wheel base 3533 mm (139.1 in)E Length without dozer or arch 6195 mm (243.9 in)F Overall length (grapple)dual function6487 mm (255.4 in)single function6911 mm (272.1 in)F1 Overall length (cable)6495 mm (273.4 in)G Ground clearance* 463 mm (18.2 in)H Decking blade lift height* 1226 mm (48.3 in)I Height to top of cab* 3233 mm (127.3 in)J Decking blade width 2678 mm (105.4 in)K Tread width 2260 mm (88.0 in)L Overall width 3385 mm (133.3 in)*With 30.5 x 32 tiresFCableJA1IBGHCDEKLF1<strong>525B</strong> <strong>Skidder</strong> specifications17

Standard EquipmentStandard and optional equipment may vary. Consult your Caterpillar dealer <strong>for</strong> specifics.Electrical- 24-volt system- 75 Amp alternator- 2) 12-volt maintenance free, high CCA batteries- alarm, back-up- warning horn- sealed electrical connectors- color coded and numbered wiresGuards- engine enclosures- ground access <strong>for</strong> daily service- engine fan guard- hinged radiator grill- integral underguards- front brush sweepsOperator Environment- air suspension seat30 degree swivel3 position lockingretractable seat belt- two pedal operation- rearview mirrors- tilt and telescoping steering wheel- cup holder- computer diagnostics and monitoringwith three level in<strong>for</strong>mation system- controls and gauge packageelectronic transmission control on steering wheellocking differential selector and indicator lightlock-up torque converter selector and indicator lightPower Train- Cat 3126 turbocharged and aftercooled engine- electric pre-heat <strong>for</strong> cold starting- multi-stage, dry centrifugal precleaner- two-stage radial seal filter air cleaner- radiator- blower radiator fan- coolant- 50% extended life antifreeze50% anti-boil protection- lock-up torque converter- five speed <strong>for</strong>ward countershaft transmission- brakes: service, secondary, parking- four-wheel enclosed wet disc hydraulic service brakes- inboard planetary final drives- front and rear differential locks, with isolated control system- high capacity fuel tank- lubed <strong>for</strong> life driveline slipjoint and universal joints- variable flow-modulated 1⁄4 turn steering- mufflerHydraulics- closed center-load sensing system- variable displacement piston pump- full flow return line filterOther Standard Equipment- ecology drains on axles and engine- vandalism protection- cap locks - fuel tank, hydraulic tank, oil dipstick, oil filler18 <strong>525B</strong> <strong>Skidder</strong> specifications

Optional EquipmentStandard and optional equipment may vary. Consult your Caterpillar dealer <strong>for</strong> specifics.Alternator - 100 AmpArch- dual function- single function- cable skiddingCold weather starting aid packageDecking blade- narrow- wide with bolt on edgeEnclosed cab window screensFrame- no fenders- grapple fenders- cable fendersWinch arrangementGrapple -- 11.2 ft 2 /1.04 m 2 bunching- 12.5 ft 2 /1.16 m 2 bunching- 9.0 ft 2 /.83 m 2 sortingLights- four standard- eight optional (twelve total)Axle <strong>for</strong> wide tiresOperator environment- open ROPS- enclosed ROPS + ACTires- 24.5 x 32, 16 PR- 30.5L x 32, 16 PR- 35.5L x 32, 16 PR<strong>525B</strong> <strong>Skidder</strong> specifications19

<strong>525B</strong> <strong>Skidder</strong>www.CAT.com© 2000 CaterpillarPrinted in U.S.A.AEHQ5391 (8-00)(Replaces AEHQ5056)Materials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.See your Caterpillar dealer <strong>for</strong> available options.R