ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

ROTAX MOJO MAX Challenge Technical ... - Rotaxmax.ch

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

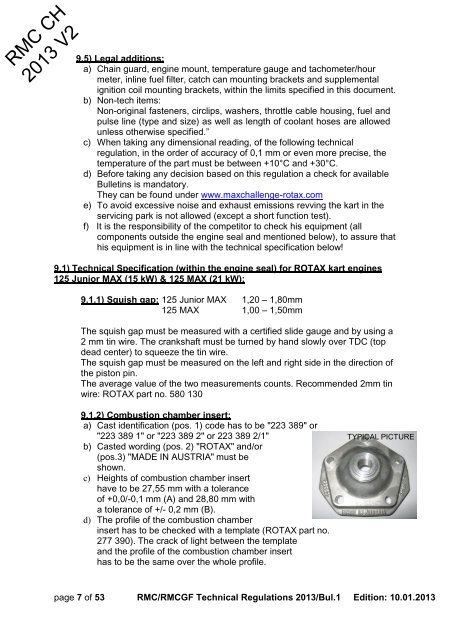

9.5) Legal additions:a) Chain guard, engine mount, temperature gauge and ta<strong>ch</strong>ometer/hourmeter, inline fuel filter, cat<strong>ch</strong> can mounting brackets and supplementalignition coil mounting brackets, within the limits specified in this document.b) Non-te<strong>ch</strong> items:Non-original fasteners, circlips, washers, throttle cable housing, fuel andpulse line (type and size) as well as length of coolant hoses are allowedunless otherwise specified.”c) When taking any dimensional reading, of the following te<strong>ch</strong>nicalregulation, in the order of accuracy of 0,1 mm or even more precise, thetemperature of the part must be between +10°C and +30°C.d) Before taking any decision based on this regulation a <strong>ch</strong>eck for availableBulletins is mandatory.They can be found under www.max<strong>ch</strong>allenge-rotax.come) To avoid excessive noise and exhaust emissions revving the kart in theservicing park is not allowed (except a short function test).f) It is the responsibility of the competitor to <strong>ch</strong>eck his equipment (allcomponents outside the engine seal and mentioned below), to assure thathis equipment is in line with the te<strong>ch</strong>nical specification below!9.1) <strong>Te<strong>ch</strong>nical</strong> Specification (within the engine seal) for <strong>ROTAX</strong> kart engines125 Junior <strong>MAX</strong> (15 kW) & 125 <strong>MAX</strong> (21 kW):9.1.1) Squish gap: 125 Junior <strong>MAX</strong> 1,20 – 1,80mm125 <strong>MAX</strong> 1,00 – 1,50mmThe squish gap must be measured with a certified slide gauge and by using a2 mm tin wire. The crankshaft must be turned by hand slowly over TDC (topdead center) to squeeze the tin wire.The squish gap must be measured on the left and right side in the direction ofthe piston pin.The average value of the two measurements counts. Recommended 2mm tinwire: <strong>ROTAX</strong> part no. 580 1309.1.2) Combustion <strong>ch</strong>amber insert:a) Cast identification (pos. 1) code has to be "223 389" or"223 389 1" or "223 389 2" or 223 389 2/1"b) Casted wording (pos. 2) "<strong>ROTAX</strong>" and/or(pos.3) "MADE IN AUSTRIA" must beshown.c) Heights of combustion <strong>ch</strong>amber inserthave to be 27,55 mm with a toleranceof +0,0/-0,1 mm (A) and 28,80 mm witha tolerance of +/- 0,2 mm (B).d) The profile of the combustion <strong>ch</strong>amberinsert has to be <strong>ch</strong>ecked with a template (<strong>ROTAX</strong> part no.277 390). The crack of light between the templateand the profile of the combustion <strong>ch</strong>amber inserthas to be the same over the whole profile.TYPICAL PICTUREpage 7 of 53 RMC/RMCGF <strong>Te<strong>ch</strong>nical</strong> Regulations 2013/Bul.1 Edition: 10.01.2013