Zünd UVjet 250-Combi

Zünd UVjet 250-Combi

Zünd UVjet 250-Combi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Zünd</strong> <strong>UVjet</strong> <strong>250</strong>-<strong>Combi</strong>True flatbed and roll to roll capability4 or 6 colour and whitespot colour option for white ink or varnishindoor and outdoor applicationsfor uncoated, rigid and flexible media up to100 mm thick, <strong>250</strong>0 mm wide, any lengthboards, sheets or rolled material

<strong>Zünd</strong> – your strong partner forflatbed printing and cuttingFor more than 20 years Swiss flatbed cutters have set high standardsas accurate, versatile and reliable processing systems.<strong>Zünd</strong> has gained its reputation as the pacemaker in developingnew flatbed technology. Pioneer and market leader in one, <strong>Zünd</strong>offers the widest range of multi-functional, high precision flatbedplotters and cutters.Well over 10,000 flatbed systems ˝made in Switzerland˝ are inoperation throughout the world, in the graphic, textile, packaging,leather and other industries.The introduction of digital printing utilizing UV curable ink allowsscreen printers, photo labs, digital printers, sign shops etc. toproduce a wide range of products. Such companies arebecoming solution providers of POS, exhibition- and event graphics,architectural-, interior- and commercial signage. Even printson carpets, ceiling tiles and wall panels are possible as well as artreproductions, packaging proto types /low runs etc.The <strong>UVjet</strong> <strong>250</strong>-<strong>Combi</strong> is designed to meet the requirements ofthe future graphic market. Highest print-quality and unmatchedversatility for the widest range of materials.Not only designer creativity is challenged with this new range ofmaterials. Such materials can often be heat sensitive, moistureabsorbent or charged with static electricity resulting in reducedprint-speed and poor print-quality. The <strong>UVjet</strong> <strong>250</strong> includesfeatures to facilitate such difficult material characteristics as wellas standard mesh, fabrics, vinyl, banner, sheets and boards.Designed for industrial use, the <strong>UVjet</strong> <strong>250</strong>-<strong>Combi</strong> guaranteescontinuous production and minimum downtime.Standard 4 colour printing (CMYK) with 400 dpi addressableresolution. Optional 6 colour printing (CMYKLcLm) with 600+ dpiapparent resolution for smoother gradients, better skin tonesetc. With the addition of white ink and selective varnish the newopportunities are almost unlimited.From a roll to roll printer to agenuine flatbed with a vacuumtable …… in just a few minutes!

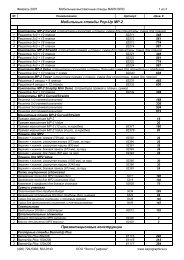

Print-table with optional vacuum material fixation<strong>Combi</strong>ne the advantages of a ˝genuine˝ flatbed printer withthe versatility of a ˝hybrid roll to roll and flatbed printer˝.Perfect material fixation/ flatness is essential for high printqualityand is guaranteed with the <strong>Zünd</strong> vacuum system. Inaddition it offers easy and precise material registration, mostefficient handling for sheets and pre-cut boards and the abilityto simultaneously print multiple smaller formats.The spot colour optionThe <strong>UVjet</strong> <strong>250</strong>-<strong>Combi</strong> can be configured or easily upgradedwith a 5th resp. 7th colour module to be used for either whiteink or varnish.Boards up to 100mm thicknessWhite ink can be printed either before (under), after (over) or withother colours to achieve all possible optical effects. The whitedensity is controllable through software settings.Varnish can be printed either as ˝fill˝ (with other colours) to giveunprinted areas the same gloss level as the printed areas or as˝selective/spot varnish˝ (after other colours) for creative opticaleffects.Roll to roll up to <strong>250</strong>0mm widthTechnical dataPrint widthup to <strong>250</strong>0mmPrint lengthunlimitedMaterial thickness up to 100mmAdressable resolution 400dpiPrint speed 14–40m 2 /hInk consumptionapprox. 80m 2 / litre (CMYKLcLm)Specifications are subject to change without prior notice.ALL ADVANTAGES AT A GLANCEVERSATILETrue flatbed and roll to roll capabilities in one machineVirtually any materials up to 100mm thickVacuum table for material fixationTextile/mesh printing featureSIMPLE AND EFFICIENT IN OPERATIONControl panel at the front and the back for easy medialoading/unloadingSimple and fast change over for roll, board and sheetapplicationsTandem modus for non-stop productionSimultaneous printing of multiple small formatsSkip white space feature˝on the fly˝ adjustment of print-head distance, vacuumwidth, left stop …˝on the fly˝ print-head maintenanceEasily accessible in daily use and for serviceStartup in a few minutesACCURATEHighest material registration and transport accuracyTrue size panel printingMODULARAvailable as 4 or 6 colour modelSpot colour option for white ink or varnishAntistatic optionPrint-table with vacuum fixationRELIABLE AND SERVICE FRIENDLYSwiss quality engineeringLow maintenance requirementNozzle compensation feature allows continued printing evenwith nozzle or print-head errorsEasy print-head replacement and adjustmentInstalled and operational in less then half a day

<strong>Zünd</strong> – one step aheadWe are always striving for new ideas and innovativesolutions.<strong>Zünd</strong> stands for efficient processing systems for most versatileapplications with highest customer benefits. The rapid evolutionof production needs requires <strong>Zünd</strong> to constantly extenddevelopments.Digital workflow with integration of our cutting systems intocomplex operations is the challenge of the future.<strong>Zünd</strong>’s universal flatbed printers, camera controlled cuttingheads and automatic feeding systems are already offeringtomorrow’s solution today!From printing to cuttingThe trend towards just-in-time production and the ever-growingneed for customization makes manual cutting and traditionaldie-cutting inefficient, if not obsolete. The solution is digitalproduction including digital finishing, commonly referred to as<strong>Zünd</strong> PRINT+CUT.<strong>Zünd</strong> cutting systems offer automated cutting and trimming ofvirtually any printed graphics. Typical benefits include increasedproductivity and reduced waste at lower cost.Worldwide, accessible, reliableThe level of first class cutters and printers also extends to theaftersales service. Worldwide sales and service centres withspare parts for all <strong>Zünd</strong> and Wild plotters, regular trainingcourses for service technicians and system suppliers as wellas hotline support give customers complete assurance in theirpurchasing decision.Well over 1000 digital and screen printers worldwide rely onthis proven concept in their daily production of displays, POS,banners, posters, labels, decals etc.Whatever the material, whatever the shape <strong>Zünd</strong> has the perfectsolution for cutting printed graphics.<strong>UVjet</strong> <strong>250</strong>-<strong>Combi</strong> 09/06 3000 en rvaWe care about our products, about people and the environment.The use of environment friendly and solvent-free ink is for us asnatural as our idyllic company surroundings.distributed by:Please refer to separate brochures for further details on our cutting systems.<strong>Zünd</strong> Systemtechnik AGIndustriestrasse 8CH-9450 AltstättenTel. +41 71 757 81 00Fax +41 71 757 81 11E-Mail: info@zund.comZund America, Inc.5068 W. Ashland WayFranklin, WI 53132Tel. +1 414 433 0700Fax +1 414 433 0800Email: infous@zund.com<strong>Zünd</strong> Asia Ltd.Rm 911, 28 Hoi Chak StreetQuarry Bay, Hong KongTel. +852 2561 1812Fax +852 2564 4417E-Mail: info@zundasia.comwww.zund.com