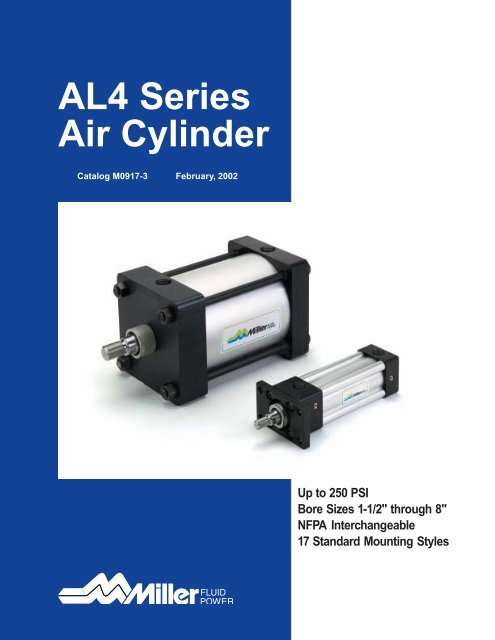

Miller AL4 Series

Miller AL4 Series

Miller AL4 Series

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PistonAluminum piston with nylon wear band increases cylinderlife, eliminates metal-to-metal contact. Optional magnet*piston for use with reed or solid state switches. Anaerobicadhesive is used to permanently lock and seal the pistonto the rod.*Magnet option must be specified when placing order orpiston will be equipped with wear band and seals only.PortsN.P.T.F. ports are standard.Check Seal Cushion*Cushion Needle Valves make preciseadjustment quick and easy. Captivecushion design allows for safe cushionadjusting while cylinder is underpressure. Brass material to resistcorrosion.Rounded lip piston seals glide onlubricant film to maximize life.Piston-Rod — Hard chrome-plated andpolished piston rod of 100,000 psi yield,high tensile strength steel, case hardenedto 50-54 Rc for reliable performance andlong rod seal life, less friction.<strong>Miller</strong> Fluid Power provides the ultimate in design flexibilityby offering two styles of impact dampening bumpers forthe <strong>AL4</strong> cylinder line in bore sizes ranging from 1-1/2" - 4".Conventional bumpers can be provided on one or bothsides of the piston with a 1/4" stroke loss per bumper. Thisstyle of bumper is ideal for applications subjected to highspeeds where cycle time may discourage the use ofcushions.Impact dampening bumper seals can be combined withcushions to provide the ideal solution for applications thatexperience high speed cycling and heavier loads. Thebumper seal option combines the features of a low friction,round lip seal and impact resistant bumpers to providesmooth end of stroke deceleration. With system pressuresabove 80 PSI, the bumper seal option offers minimalstroke loss.For additional information regarding the bumper sealoption, refer to “Bumper Seal Options” page. Forinstructions on how to order these options, refer to“How To Order” page.BUMPER OPTIONBUMPER SEAL OPTION1/41/4LOSS OFSTROKELOSS OFSTROKE3

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersMounting StylesMounting Styles That Fit Your Installation Requirement<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong> air cylinders operate at internal pressures up to 250 PSI, and incorporate proven <strong>Miller</strong> designcharacteristics to provide safe, reliable power for many heavy-duty industrial applications. Available in 17 standardmounting configurations to provide centerline, foot or pivot installations as explained below.Centerline MountingThe preferred cylinder installationmethod, centerline mounting placesthe mounting bolts in simple shearor simple tension so that the mountingmechanism is protected fromcompound forces. Centerlinemounting is a rigid mounting styleand this requires accurate cylinderalignment to prevent damage to thecylinder working parts.<strong>Miller</strong> <strong>AL4</strong> mounting configurationsthat provide centerline supportinclude: tie rod mounts (51, 52, 53),and flange mounts with rectangularflanges affixed to the head or capend of the cylinder (61 and 62).Foot MountingFoot mounting allows the cylinder tobe mounted and secured along itsside, on both the head and cap end.When considering this style ofmount, it should be noted that themounting surface plane is not trulycentered with the line of force plane.Therefore, the mounting bolts maybe subjected to a significant amountof shear stress. Foot mounts arerigid in nature. Accurate cylinderalignment must be practiced whenselecting this type of mount.<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong> mounting configurationsthat provide foot mountingsare: side end angle (71), side lug(72), and side tap (74). Side tapmounting incorporates flush, tappedmounting holes on the head and capof the cylinder providing an alternativeto side lugs and foot brackets.Pivot MountingPivot mounting is used when thecylinder must pivot during pistonmotion. Clevis and trunnion mountsare the two methods used to allowthis motion.The clevis end design locates thepivot point at the cap end of thecylinder (84, 86, 96). Trunnionmounting allows pivoting of thecylinder via the head or cap (81, 82),or intermediate location (89). Bothclevis and trunnion mount configurationsallow the cylinder to pivot inone plane only.Centerline mounting is preferablesince it prevents compound forcesfrom acting on the mounting bolts(flange model shown).Foot mounting secures the cylinderon its side, but can subject themounting bolts to compound stress(cylinder side lugs shown).Pivot mounting allows the cylinder topivot during piston motion (clevismethod shown).4

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersStandard Specifications & Mounting StylesStandard Specifications• N.F.P.A. Interchangeable• Bore sizes – 1-1/2", 2", 2-1/2", 3-1/4" and 4"• Rod Diameters – 5/8", 1", and 1-3/8"• Rod Ends – three standard, specials to order.• Cushions – optional at either end or both endsof stroke• Strokes – available in any practical stroke length.• 250 P.S.I. Air Service/Optional 250 P.S.I.,Hydraulic Service (non-cushioned only).Available Mounting StylesTie Rods Extended Both Ends Tie Rods Extended Cap End Tie Rods Extended Head End Head Rectangular FlangeModel 511 1 /2 -4"Model 521 1 /2 -4"• Standard Fluid – Filtered Air• Standard Temperature – -10°F to +165°F• Fluorocarbon Seals for high temperature service –-10°F to +250°F (optional)• Single rod end or double rod end• Mounting styles – 17 standard• Optional noise damping bumpers• Non-LubeModel 531 1 /2 -4"Model 61*1 1 /2 -4"(NFPA MX1)(NFPA MX2)(NFPA MX3)(NFPA MF1)Cap Rectangular Flange No Mount Side End Angle Side LugModel 62*1 1 /2 -4"Model 501 1 /2 -4"Model 71*1 1 /2 -4"Model 721 1 /2 -4"(NFPA MF2)(NFPA MX0)(NFPA MS1)(NFPA MS2)Side Tap Head Trunnion Cap Trunnion Intermediate TrunnionModel 741 1 /2 -4"Model 811 1 /2 -4"Model 821 1 /2 -4"Model 89 ▲1 1 /2 -4"(NFPA MS4)(NFPA MT1)(NFPA MT2)(NFPA MT4)Cap Fixed Clevis Cap Detachable Clevis Cap Detachable EyeModel 84*1 1 /2 -4"Model 86*1 1 /2 -4"Model 96*1 1 /2 -4"Side End LugModel 771 1 /2 -4"(NFPA MP1)(NFPA MP2)(NFPA MP4)(NFPA MS7)Sleeve NutModel 551 1 /2 -4"Rod End #1Double Rod EndModel D<strong>AL4</strong> Shown1 1 /2 -4"▲Tie Rod Design(NFPA MX5)(NFPA MDX0)Rod End #2*Indicates Bolt onMounting Design1 1 /2 -4" Bores5

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersNo Mount BasicModel 50(NFPA MX0)YNo Mount (Basic)Head Rectangular Flange MountCap Rectangular Flange Mount1-1/2" to 4" Bore SizesZJ + STROKEP + STROKEWFLF + STROKEEE1E SQ.42MMAA3R SQ.K1 G JHead Rectangular FlangeModel 61(NFPA MF1)ZJ + STROKEYP + STROKEWLB + STROKEUFEE1R142EMM3ETFFB4 HOLESFG JK1Cap Rectangular FlangeModel 62(NFPA MF2)ZF + STROKEYP + STROKEWFLB + STROKEEEUF1MMR1 24E3K1G JZJ + STROKEFETFFB4 HOLES6

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSFRONT FLANGEThread Style 2(NFPA Style SM)Small MaleAKKCLAFLAWWFVFNA MM BFThread Style 5(NFPA Style IM)Intermediate MaleNAD WRENCH FLATSFRONT FLANGEIMACLAFLAWWFVFFMM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleNAFRONT FLANGEKKCLAWFAWVFNo Mount (Basic)Head Rectangular Flange MountCap Rectangular Flange Mount1-1/2" to 4" Bore SizesFMM B“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsBore AA EEE(NPTF)F FB G J K1 R R1 TF UFADD STROKELB LF P1 1 / 2 2.02 2 3/ 83/ 85/ 16 1 7 / 16 15/ 161/ 8 1.43 1.43 2 3 / 4 3 3 / 8 4 3 5 / 8 2 5 / 162 2.6 2 1 /2 3/8 3/8 3/8 1 7 /16 15/16 5/32 1.84 1.84 3 3 /8 4 1 /8 4 3 5 /8 2 5 /162 1 / 2 3.1 3 3/ 8 3/ 8 3/ 8 111/ 16 15/ 16 5/ 32 2.19 2.19 33/ 8 45/ 8 41/ 8 33/ 4 23/ 83 1 / 4 3.9 3 3 / 41/ 25/ 87/ 16 1 11 / 16 1 3 / 163/ 16 2.76 2.76 4 11 / 16 5 1 / 2 4 7 / 8 4 1 / 4 2 5 / 84 4.7 4 1 /2 1/2 5/8 7/16 1 11 /16 1 3 /16 3/16 3.32 3.32 5 7 /16 6 1 /4 4 7 /8 4 1 /4 2 5 /8Table 2—Rod DimensionsRod5/ 8 1/ 2-201 1 / 21* 7/8-145/ 8 1/ 2-2021 7/ 8-145/ 8 1/ 2-202 1 /21 7/ 8-141 7/ 8-143 1 / 41 3 /8 1 1 /4-121 7/ 8-1441 3 /8 1 1 / 4-12*Cushion not available head end.ThreadStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LA NA VF W WF Y7/ 16-203/ 4-167/ 16-203/ 4-167/16-203/ 4-163/ 4-161-143/ 4-161-143/ 4 1.1241 1 / 8 1.4993/ 4 1.1241 1 / 8 1.4993/4 1.1241 1 / 8 1.4991 1 / 8 1.4991 5 / 8 1.9991 1 / 8 1.4991 5 / 8 1.9993/ 81/ 23/ 81/ 23/81/ 21/ 25/ 81/ 25/ 81/ 27/ 81/ 27/ 81/27/ 87/ 81 1 / 87/ 81 1 / 81 3 / 82 1 / 81 3 / 82 1 / 81 3 /82 1 / 81 7 / 82 5 / 81 7 / 82 5 / 89/ 1615/ 169/ 1615/ 169/1615/ 1615/ 161 5 / 1615/ 161 5 / 165/ 87/ 85/ 87/ 85/87/ 87/ 817/ 815/ 815/ 815/813/ 413/ 41ZF1 1 7 / 8 51 5 / 8 2 11 / 16 6 1 / 21 3 / 8 2 1 / 4 5 3 / 81 1 7 / 8 51 3 / 8 2 1 / 4 5 3 / 81 1 15 /16 5 1 /81 3 / 8 2 5 / 16 5 1 / 21 3 / 8 2 7 / 16 6 1 / 41 5 / 8 2 11 / 16 6 1 / 21 3 / 8 2 7 / 16 6 1 / 4Table 3–Envelopeand MountingDimensionsADD STROKEZJ4 5 / 854 5 / 854 3 /45 1 / 85 5 / 85 7 / 85 5 / 85 7 / 87

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersTie Rods Extended Head End MountTie Rods Extended Cap End MountTie Rods Extended Both Ends MountSleeve Nut Mount1-1/2" to 4" Bore SizesTie Rods Extended Head End MountModel 53(NFPA MX3)DDWFYZJ + STROKEP + STROKELF + STROKEEE1E SQ. 42MMAA3R SQ.KBBG JK1Tie Rods Extended Cap End MountModel 52(NFPA MX2)WFYZJ + STROKEP + STROKELF + STROKEEEDD1E SQ. 42MMAA3R SQ.KK1G J BBTie Rods Extended Both Ends MountModel 51(NFPA MX1)DDWFYZJ + STROKEP + STROKELF + STROKEEEDD1E SQ. 42MMAA3R SQ.KKBBG JBBSleeve Nut MountModel 55(NFPA MX5)YZJ + STROKEP + STROKEWFLF + STROKEDDEE1ESQ.42MMAA3R SQ.BGGJBG8

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCTie Rods Extended Head End MountTie Rods Extended Cap End MountTie Rods Extended Both Ends MountSleeve Nut Mount1-1/2" to 4" Bore SizesWFVFNA MM BA“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsBore AA BB BG DD E11/ 2 2.022 2.62 1 / 2 3.13 1 / 4 3.94 4.71 .45 1/ 4-28 121 1 /81 1 / 81 3 / 81 3 /8.48 5/16-24.48 5/ 16-24.50 3/ 8-24.50 3/8-242 1 /233 3 / 44 1 /2EE(NPTF)G J K K1 R3/ 8 1 7 /1615/ 16 1/ 4 1/ 8 1.431/ 2 1 11 / 16 1 3 / 16 3/ 8 3/ 16 3.323/ 8 1 7 / 1615/ 16 5/ 16 5/ 32 1.843/ 8 1 7 / 1615/ 16 5/ 16 5/ 32 2.191/ 2 1 11 /16 1 3 / 16 3/ 8 3/ 16 2.76ADD STROKELF3 5 / 83 5 / 83 3 / 44 1 / 44 1 / 4P2 5 /162 5 / 162 3 / 82 5 / 82 5 / 8Table 2—Rod DimensionsTable 3–Envelope andMounting DimensionsRod ThreadADDStyle Style +.000STROKEBore Dia 5 2 &4 -.002Size MM IM KK A B C D LAF NA VF W WF Y ZJ11/ 222 1 / 23 1 / 445/ 8 1/ 2-20 7 / 16-20 3/ 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 4 5 / 81* 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 1 1 3 / 8 2 1 / 4 55/ 8 1/ 2-20 7 / 16-20 3/ 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 4 5 / 81 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 1 1 3 / 8 2 1 / 4 55/ 8 1/ 2-20 7 / 16-20 3/ 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 15 / 16 4 3 / 41 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 1 1 3 / 8 2 5 / 16 5 1 / 81 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 5 5 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 5 7 / 81 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 5 5 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 5 7 / 8*Cushion not available head end.9

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersSide End Angle MountSide End Lug MountSide Lug MountSide Tap Mount1-1/2" to 4" Bore SizesSide End Angle MountModel 71*(NFPA MS1)EWFK1YZA + STROKEXA + STROKEP + STROKELF + STROKEEEAB6 HOLES4E31MMS.1252.125*Maximum recommendedpressure of 150 PSIAHAO AL FAEG JSA + STROKEAL 1 AOZE + STROKESide End Lug MountXE + STROKEModel 77YP + STROKE(NFPA MS7) LF + STROKE1WFK1EEE SQ.42MMETGHEB4 HOLESET3RETG JEO EM ELEOSE + STROKESide Lug MountModel 72(NFPA MS2)EYWFZJ + STROKEP + STROKELF + STROKEEEK11SB4 HOLESE42MMSTLH3SWSWTSSWSWG JUSSWSWXSSS + STROKESide Tap Mount*Model 74(NFPA MS4)WFYZJ + STROKEP + STROKELF + STROKEK1EE1E SQ.42MMTH3*Not available in 1-1/2" bore, 1" rod.TNNT THREAD, ND DEEP4 TAPPED MTG. HOLESG JXT SN + STROKE10

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BASide End Angle MountSide End Lug MountSide Lug MountSide Tap Mount1-1/2" to 4" Bore Sizes“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor CC orKK, A and W orWF. If otherwisespecial, furnishdimensionedsketch.Table 1—Envelope and Mounting DimensionsADD STROKEBore AB AE AH AL AL1 AO E EE EB EL EM EO ET F G GH J K1 LH NT S ST SW TH TN TS US(NPTF) ±.003±.003 ±.003LF P SA SE SN SS11/ 2 7/ 16 1 3 / 8 1 3 / 16 1 1 3/ 8 2 3/ 8 9/ 32 3/ 4 1 1 / 8 1/ 4 9/ 16 3/ 8 1 7 / 16 .993 15 / 16 1/ 8 .993 1 / 4-20 1 1 / 4 1/ 2 3/ 8 .993 5/ 8 2 3 / 4 3 1 / 2 3 5 / 8 2 5 / 16 6 5 1 / 2 2 1 / 4 2 7 / 82 7/ 16 1 3 / 8 1 7 / 16 1 1 3/ 8 2 1 / 2 3/ 811/ 3215/ 16 1 5 / 16 5/ 1611/ 16 3/ 8 1 7 / 16 1.243 15 / 16 5/ 32 1.243 5 / 16-18 1 3 / 4 1/ 2 3/ 8 1.243 7 / 8 3 1 / 4 4 3 5 / 8 2 5 / 16 6 5 7 / 8 2 1 / 4 2 7 / 82 1 / 2 7/ 16 1 3 / 8 1 5 / 8 1 1 3/ 8 3 3/ 8 11/ 32 1 1 / 16 1 7 / 16 5/ 16 13/ 16 3/ 8 1 7 / 16 1.493 15 / 16 5/ 32 1.493 3 / 8-16 2 1 / 4 1/ 2 3/ 8 1.493 1 1 / 4 3 3 / 4 4 1 / 2 3 3 / 4 2 3 / 8 6 1 / 8 6 1 / 4 2 3 / 8 33 1 / 4 9/ 16 1 7 / 8 1 15 / 16 1 1 / 4 1 1 / 4 1/ 2 3 3 / 4 1/ 2 13/ 32 7/ 8 11/ 2 3/ 8 1 5/ 8 1 11 / 16 1.868 1 3 / 16 3/ 16 1.868 1 / 2-13 2 3 / 4 3/ 4 1/ 2 1.868 1 1 / 2 4 3 / 4 5 3 / 4 4 1 / 4 2 5 / 8 7 3 / 8 6 5 / 8 2 5 / 8 3 1 / 44 9/16 – 2 1 /4 1 7 /8 1 1 /4 1/2 4 1 /2 1/2 13/32 1 1 5 /8 3/8 1 3 /16 – 1 11 /16 2.243 1 3 /16 3 /16 2.243 1 /2-13 3 1 /2 3 /4 1/2 2.243 2 1 /16 5 1 /2 6 1 /2 4 1 /4 2 5 /8 7 3 /8 6 7 /8 2 5 /8 3 1 /4Table 2—Rod DimensionsTable 3–Envelope andMounting DimensionsRodThreadADD STROKEStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LAF NA VF W WF Y ND XS XT XA XE ZA ZE ZJ1 1 /222 1 / 23 1 /445/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 3/ 8 1 3 / 8 1 15 / 16 5 5 / 8 5 3 / 8 6 5 5 / 8 4 5 / 81* 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 1 1 3 / 8 2 1 / 4 – 1 3 / 4 – 6 – 6 3 / 8 – 55/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 7/ 16 1 3 / 8 1 15 / 16 5 5 / 8 5 9 / 16 6 5 7 / 8 4 5 / 81 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 1 1 3 / 8 2 1 / 4 7/ 16 1 3 / 4 2 5 / 16 6 5 15 / 16 6 3 / 8 6 1 / 4 55/8 1/2-20 7 /16-20 3 /4 1.124 3/8 1/2 1 3 /4 9/16 5/8 5/8 1 1 15 /16 5/8 1 3 /8 1 15 /16 5 3 /4 5 13 /16 6 1 /8 6 1 /8 4 3 /41 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 1 1 3 / 8 2 5 / 16 5/ 8 1 3 / 4 2 5 / 16 6 1 / 8 6 3 / 16 6 1 / 2 6 1 / 2 5 1 / 81 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 3/ 4 1 7 / 8 2 7 / 16 6 7 / 8 6 1 / 2 7 3 / 8 6 7 / 8 5 5 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 3/ 4 2 1 / 8 2 11 / 16 7 1 / 8 6 3 / 4 7 5 / 8 7 1 / 8 5 7 / 81 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 3/ 4 1 7 / 8 2 7 / 16 6 7 / 8 6 5 / 8 7 3 / 8 7 5 5 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 3/ 4 2 1 / 8 2 11 / 16 7 1 / 8 6 7 / 8 7 5 / 8 7 1 / 4 5 7 / 8*Cushion not available head end.11

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersCap Fixed Clevis MountCap Detachable Clevis MountCap Detachable Eye Mount1-1/2" to 4" Bore SizesCap Fixed Clevis MountModel 84(NFPA MP1)YZC + STROKEP + STROKEWFLB + STROKEK1EEE SQ.CD1MRMM24LRG JFLCW3CBCWXC + STROKEFor maximum swivel angle with rear mounting plate for “84” mounting see <strong>AL4</strong> <strong>Series</strong> cylinder accessories.Cap Detachable Clevis MountModel 86(NFPA MP2)WFYZD1 + STROKEP + STROKELB + STROKEEECD E SQ.1MM24MR13K1G JFL1CWCBCWXD + STROKECap Detachable Eye MountModel 96(NFPA MP4)YZD2 + STROKEP + STROKEWFLB + STROKEK1EECD1E SQ.1MM24MR2KG JFL13CBXD + STROKE12

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BACap Fixed Clevis MountCap Detachable Clevis MountCap Detachable Eye Mount1-1/2" to 4" Bore Sizes“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting Dimensions+.000 +.002Bore CB CD CD 1CW E EE F G J K1 L L1 LR MR MR1 MR2-.002 +.004(NPTF)ADD STROKELB P1 1 /2 3/4 .501 .500 1/2 2 3/8 3/8 1 7 /16 15/16 1/8 3/8 3/4 3/4 5/8 1/2 5/8 4 2 5 /162 3/ 4 .501 .500 1/ 2 2 1 / 2 3/ 8 3/ 8 1 7 / 16 15/ 16 5/ 32 3/ 8 3/ 4 3/ 4 5/ 8 1/ 2 5/ 8 4 2 5 / 162 1 / 23/ 4 .501 .500 1/ 2 3 3/ 8 3/ 8 1 7 / 1615/ 16 5/ 32 3/ 8 3/ 4 3/ 4 5/ 8 1/ 211/ 16 4 1 / 8 2 3 / 83 1 /4 1 1 /4 .751 .750 5/8 3 3 /4 1/2 5/8 1 11 /16 1 3 /16 3/16 5/8 1 1 /4 1 15/16 3/4 7/8 4 7 /8 2 5 /84 1 1 / 4 .751 .750 5/ 8 4 1 / 2 1/ 2 5/ 8 1 11 / 16 1 3 / 16 3/ 16 5/ 8 1 1 / 4 1 15/ 16 3/ 4 7/ 8 4 7 / 8 2 5 / 8Table 2—Rod DimensionsTable 3–Envelope andMounting DimensionsRod ThreadADD STROKEStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LAF NA VF W WF Y XC XD ZC ZD1 ZD211/ 222 1 / 23 1 / 445/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 5 3 / 8 5 3 / 4 6 6 1 / 4 6 3 / 81* 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 1 1 3 / 8 2 1 / 4 5 3 / 4 6 1 / 8 6 3 / 8 6 5 / 8 6 3 / 45/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 5 3 / 8 5 3 / 4 6 6 1 / 4 6 3 / 81 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 1 1 3 / 8 2 1 / 4 5 3 / 4 6 1 / 8 6 3 / 8 6 5 / 8 6 3 / 45/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 15 / 16 5 1 / 2 5 7 / 8 6 1 / 8 6 3 / 8 6 9 / 161 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 1 1 3 / 8 2 5 / 16 5 7 / 8 6 1 / 4 6 1 / 2 6 3 / 4 6 15 / 161 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 6 7 / 8 7 1 / 2 7 13 / 16 8 1 / 4 8 3 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 7 1 / 8 7 3 / 4 8 1 / 16 8 1 / 2 8 5 / 81 7/ 8-14 3 / 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 6 7 / 8 7 1 / 2 7 13 / 16 8 1 / 4 8 3 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 7 1 / 8 7 3 / 4 8 1 / 16 8 1 / 2 8 5 / 8*Cushion not available head end.13

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersHead Trunnion Mount*Model 81(NFPA MT1)YHead Trunnion MountCap Trunnion MountIntermediate Trunnion Mount1-1/2" to 4" Bore SizesZJ + STROKEP + STROKEWFLF + STROKEUTEE1E42MMTD3TL ETLG JK1XG*Not available in 1-1/2" bore, 1" rod.Cap Trunnion MountModel 82(NFPA MT2)WFYZJ + STROKEP + STROKELF + STROKEK1UTEE1E42MMTD3TL ETLG JXJ + STROKEIntermediate Trunnion MountModel 89(NFPA MT4)YZJ + STROKEP + STROKEUM1WFLF + STROKEEEBDUV42MMTD3E SQ.G JKTLTM TLXI▲ Dimension “Xl” to be specified by customer.14

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BAHead Trunnion MountCap Trunnion MountIntermediate Trunnion Mount1-1/2" to 4" Bore Sizes“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting Dimensions+.000ADD STROKEBore BD E EE G J K K1 TD TL TM UM UT UV(NPTF)-.001LF PStyle MT4MinimumStroke1 1 /2 1 1 /4 2 3/8 1 7 /16 15 /16 1/4 1/8 1.000 1 2 1 /2 4 1 /2 4 2 1 /2 3 5 /8 2 5 /16 02 11/ 2 2 1 / 2 3/ 8 1 7 / 16 15/ 16 5/ 16 5/ 32 1.000 1 3 5 4 1 / 2 3 3 5 / 8 2 5 / 16 1/ 42 1 / 2 1 1 / 2 3 3/ 8 1 7 / 1615/ 16 5/ 16 5/ 32 1.000 1 3 1 / 2 5 1 / 2 5 3 1 / 2 3 3 / 4 2 3 / 8 1/ 83 1 /4 2 3 3 /4 1/2 1 11 /16 1 3 /16 3/8 3/16 1.000 1 4 1 /2 6 1 /2 5 3 /4 4 1 /4 4 1 /4 2 5 /8 5/84 2 4 1 / 2 1/ 2 1 11 / 16 1 3 / 16 3/ 8 3/ 16 1.000 1 5 1 / 4 7 1 / 4 6 1 / 2 5 4 1 / 4 2 5 / 8 5/ 8Table 2—Rod DimensionsTable 3–Envelope andMounting DimensionsRod Thread▲ADD STROKEBore DiaStyle5Style2 & 4+.000-.002Min.Size MM IM KK A B C D LAF NA VF W WF Y XG XI XJ ZJ1 1 / 25/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 1 3 / 4 3 3 / 16 4 1 / 8 4 5 / 81* 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 1 1 3 / 8 2 1 / 4 – 3 11 / 16 4 1 / 2 522 1 / 23 1 / 445/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 7 / 8 1 3 / 4 3 5 / 16 4 1 / 8 4 5 / 81 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 1 1 3 / 8 2 1 / 4 2 1 / 8 3 11 / 16 4 1 / 2 55/ 8 1/ 2-20 7 / 16-20 3 / 4 1.124 3/ 8 1/ 2 1 3 / 4 9/ 16 5/ 8 5/ 8 1 1 15 / 16 1 3 / 4 3 5 / 16 4 1 / 4 4 3 / 41 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 1 1 3 / 8 2 5 / 16 2 1 / 8 3 11 / 16 4 5 / 8 5 1 / 81 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 2 1 / 4 4 3 / 16 5 5 5 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 2 1 / 2 4 7 / 16 5 1 / 4 5 7 / 81 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 2 1 / 4 4 3 / 16 5 5 5 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 2 1 / 2 4 7 / 16 5 1 / 4 5 7 / 8*Cushion not available head end.▲ Dimension “Xl” to be specified by customer.15

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersDouble Rod Models1-1/2" to 4" Bore SizesHow to Use Double Rod CylinderDimensioned DrawingsTo determine dimensions for a double rod cylinder,first refer to the desired single rod mounting stylecylinder shown on preceding pages of this catalog.After selecting necessary dimensions from thatdrawing, return to this page and supplement thesingle rod dimensions with those shown on thedrawing and dimension table below. Note that doublerod cylinders have a head (Dim. G) at both ends andthat dimension LG replaces LF and PK replaces P,etc. The double rod dimensions differ from, or arein addition to those for single rod cylinders shownon preceding pages and provide the informationneeded to completely dimension a double rodcylinder.On a double rod cylinder where the two rod endsare different, be sure to clearly state which rodend is to be assembled at which end.ZM + 2 X STROKEYPK + STROKEWFLG + STROKEEEK1MMROD END #1 ROD END #2GGAll dimensions are in inches and apply to standard rod sizes only. For alternate rodsizes, determine all envelope dimensions (within LD dim.) as described above andthen use appropriate rod end dimensions for proper rod size from single rod cylinder.RodAddDia.ADD STROKE2xBoreStrokeMM LG PK SAK XAK SSK SNK SEK XEK ZM1 / 2 5 / 8 4 1 / 8 2 3 / 8 6 1 / 8 6 1 / 8 3 3 / 8 2 1 / 4 6 3 / 8 6 1 / 4 6 1 / 82 5/ 8 41/ 8 23/ 8 61/ 8 61/ 8 33/ 8 21/ 4 63/ 4 67/ 16 61/ 82 1 /2 5/8 4 1 /4 2 3 /8 6 1 /4 6 1 /4 3 1 /2 2 3 /8 7 1 /8 6 11 /16 6 1 /43 1 / 4 1 4 3 / 4 2 5 / 8 7 1 / 4 7 3 / 8 3 3 / 4 2 5 / 8 7 3 / 4 7 5 / 8 7 1 / 24 1 43/ 4 25/ 8 71/ 4 73/ 8 33/ 4 25/ 8 8 73/ 4 71/ 2REPLACES DIMENSION LF P SA XA SS SN SE XE –ON SINGLE RODMOUNTING STYLESALL MTGSTYLES7172 74 77ALL MTGSTYLES16

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BABushing DimensionsCylinder Weight Chart“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 2—Rod DimensionsRod ThreadStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LA NA VF W WF Y5/ 8 1/ 2-20 7/ 16-20 3/ 4 1.124 3/ 8 1/ 2 1 3 / 8 9/ 16 5/ 8 5/ 8 1 1 7 /41 7/8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 1 7 / 8 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 161 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 2 5 / 8 1 5 / 16 1 1 1 5 / 8 2 11 / 161 1 / 21* 7/8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 8 15/ 16 7/ 8 1 1 3 / 882 1 / 422 1 /25/ 85/ 81/ 2-201/ 2-207/ 16-207/16-203/ 43/41.1241.1243/ 83/81/ 21/21 3 / 81 3 /89/ 169/165/ 85/85/ 85/8111 7 / 81 15 /16117/ 8-147/ 8-143/ 4-163/ 4-161 1 / 81 1 / 81.4991.4991/ 21/ 27/ 87/ 82 1 / 82 1 / 815/ 1615/ 167/ 87/ 8111 3 / 81 3 / 82 1 / 42 5 / 163 1 / 411 3 / 87/ 8-141 1 / 4-123/ 4-161-141 1 / 81 5 / 81.4991.9991/ 25/ 87/ 81 1 / 81 7 / 82 5 / 815/ 161 5 / 167/ 813/ 411 3 / 81 5 / 82 7 / 162 11 / 16*Cushion not available head end.Cylinder Weights–<strong>AL4</strong>, <strong>AL4</strong>H CylindersNo Mount Single Rod No Mount Double RodBore Rod Base Per Inch Base Per InchIn. In. Lbs. Lbs. Lbs. Lbs.1.50 .625 1.73 .20 2.16 .282.00 .625 2.40 .21 3.05 .302.00 1.00 2.99 .35 4.34 .582.50 .625 3.25 .23 3.96 .312.50 1.00 4.06 .37 5.74 .603.25 1.00 6.45 .42 7.65 .643.25 1.375 7.93 .62 11.46 1.054.00 1.00 8.80 .49 10.32 .714.00 1.375 10.29 .69 14.37 1.125.00 1.00 13.20 .61 15.84 .845.00 1.375 14.72 .81 18.89 1.246.00 1.375 20.50 .87 25.65 1.306.00 1.75 22.61 1.13 30.41 1.828.00 1.375 35.50 1.25 41.15 1.688.00 1.75 37.63 1.51 45.90 2.20Mounting Weight Adders by Model NumberBore 61, 62 81, 82 84 71, 77 89 96 72 86In. Lbs. Lbs. Lbs. Lbs. Lbs. Lbs. Lbs. Lbs.1.50 .51 .50 .15 .36 1.70 .23 .15 .202.00 .76 .50 .26 .65 2.38 .32 .15 .292.50 1.13 .50 .38 1.05 3.00 .42 .15 .413.25 2.76 .50 .98 1.38 5.35 1.26 .35 1.064.00 4.05 .50 1.35 2.20 6.75 1.62 .35 1.495.00 6.46 .50 1.20 4.29 8.77 N/A .57 2.416.00 10.74 1.22 2.91 5.88 15.52 N/A .69 11.388.00 N/A 1.22 2.91 7.84 25.01 N/A .67 17.3117

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong> - 5" through 8" BoreLightweight, Non-LubePneumatic Cylinder.Premium Quality and Economy in one.Lightweight construction and solid Non-Lube designwith proven reliability make the <strong>AL4</strong> <strong>Series</strong> Cylinderthe high performance, long lasting, economical choicefor your air cylinder applications.Heads and Caps are precision,lightweight aluminum blocks thatare anodized for maximumcorrosion resistance.Extruded AluminumLightweight cylinder body:aluminum tube with steel tie rods.PistonAluminum piston with nylon wearband increases cylinder life, eliminatesmetal-to-metal contact. Optionalmagnet* piston for use with reedor solid state switches. Anaerobicadhesive is used to permanently lockand seal the piston to the rod.* Magnet option must be specified when placingorder or piston will be equipped with wearband and seals only.Rod SealThe Nitrile rodseal is pressueenergized, wearcompensating andresists abrasion toensure long life.PortsN.P.T.F. ports arestandard.Check SealCushionRod WiperThe Urethanewiper seal wipesaway dirt that mayhave accumulatedon the rod,reducing bushingwear.Rounded lip piston seals glide onlubricant film to maximize life.Rod BushingExternally removable, high-density iron,plated rod bushing protects against sideloads. The outboard placement of the rodseal ensures lubrication over the fullbearing length.Cushion Needle Valves makeprecise adjustment quick and easy.Captive cushion design allows forsafe cushion adjusting while cylinderis under pressure. Brass material toresist corrosion.Piston-Rod - Hard chrome plated andpolished piston rod of 100,000 psiyield, high tensile strength steel, casehardened to 50-54 Rc for reliableperformance and long rod seal life,less friction.18

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersStandard Specifications• N.F.P.A. Interchangeable• Bore sizes – 5", 6" and 8"• Rod Diameters – 1", 1-3/8", and 1-3/4"• Rod Ends – three standard, specials to order.• Cushions – optional at either end or both endsof stroke.• Strokes – available in any practical stroke length.• 250 P.S.I. Air Service• 250 P.S.I. Hydraulic Service (non-cushioned only)Standard Specifications and Mounting Styles• Standard Fluid – Filtered Air• Standard Temperature – -10°F to +165°F• Fluorocarbon Seals for high temperature service –-10°F to +250°F (optional)• Single rod end or double rod end• Mounting styles – 17 standard• Non-Lube ServiceAvailable Mounting StylesTie Rods Extended Both Ends Tie Rods Extended Cap End Tie Rods Extended Head End Head Rectangular FlangeModel 515"-8"Model 525"-8"Model 535"-8"Model 615"-6"(NFPA MX1)(NFPA MX2)(NFPA MX3)(NFPA MF1)Cap Rectangular Flange No Mount Side End Angle Side LugModel 625"-6"Model 505"-8"Model 715"-8"Model 725"-8"(NFPA MF2)(NFPA MX0)(NFPA MS1)(NFPA MS2)Side Tap Head Trunnion Cap Trunnion Intermediate TrunnionModel 745"-8"Model 815"-8"Model 825"-8"Model 895"-8"(NFPA MS4)(NFPA MT1)(NFPA MT2)(NFPA MT4)Cap Fixed Clevis Cap Detachable Clevis Head SquareModel 845"-8"Model 865"-8"Model 638"Cap SquareModel 648"(NFPA MP1)(NFPA MP2)(NFPA ME3)(NFPA ME4)Sleeve NutModel 555"-8"Rod End #1Double Rod EndModel D<strong>AL4</strong> Shown5"-8"Cap Detachable EyeModel 965"-6"(NFPA MX5)(NFPA MDX0)Rod End #2(NFPA MP4)19

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersNo Mount BasicModel 50(NFPA MX0)YNo Mount (Basic)Head Rectangular Flange MountCap Rectangular Flange Mount5" to 8" Bore SizesZJ + STROKEP + STROKEWFLF + STROKEEE1E SQ.42MMAA3R SQ.K G JHead Rectangular Flange Mount (5" and 6" bore sizes)Model 61(NFPA MF1)YZJ + STROKEP + STROKEWLB + STROKEUFEE1R42EMM3ETFFB4 HOLESF G JKCap Rectangular Flange Mount (5" and 6" bore sizes)Model 62(NFPA MF2)YZF + STROKEP + STROKEWFLB + STROKEEEUF1MMR24EK3G JZJ + STROKEFETFFB4 HOLES20

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSFRONT FLANGEThread Style 2(NFPA Style SM)Small MaleAKKCLAFLAWWFVFNA MM BFD WRENCH FLATSFRONT FLANGEThread Style 5(NFPA Style IM)Intermediate MaleNAIMACLAFLAWWFVFFMM BD WRENCH FLATSFRONT FLANGEThread Style 4(NFPA Style SF)Short FemaleNAKKCLAWFAWVFNo Mount (Basic)Head Rectangular Flange MountCap Rectangular Flange Mount5" to 8" Bore SizesFMM B“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsBore AA EEEF FB G J K R TF UF(NPTF)5 5.8 5 1 / 2 1/ 2 5/ 8 9/ 16 1.66 1.228 9.1 8 1 / 2 3/ 4 3/ 4 — 1.81 1.446 6.9 6 1 / 2 3/ 4 3/ 4 9/16 1.91 1.417/ 164.107/ 16 4.889/ 16 —6 5 / 87 5 / 8—7 5 /88 5 / 8—ADD STROKELB LF P5 1 /85 3 / 45 7 / 84 1 / 255 1 / 82 7 /83 1 / 83 1 / 4Table 2—Rod DimensionsRod ThreadStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LA NA VF W WF Y568Table 3–Envelopeand MountingDimensionsADD STROKEZF ZJ1 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 1 7 / 8 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 6 1 / 2 5 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 2 5 / 8 1 5 / 16 1 1 1 5 / 8 2 11 / 16 6 3 / 4 6 1 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 2 1 / 2 1 5 / 16 1 7/ 8 1 5 / 8 2 13 / 16 7 3 / 8 6 5 / 81 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 1 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 1 / 16 7 5 / 8 6 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 2 1 / 2 1 5 / 16 1 7/ 8 1 5 / 8 2 3 / 4 — 6 3 / 41 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 1 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 — 721

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersHead Square MountCap Square Mount8" Bore SizeHead Square MountModel 63(NFPA ME3)WFYZJ + STROKEP + STROKELF + STROKEEE1E SQ.42TEMM3TEEB4 HOLESG JKCap Square MountModel 64(NFPA ME4)YZJ + STROKEP + STROKEWFLF + STROKEEE1MME SQ.24TEKG J3TEEB4 HOLESXK + STROKE22

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BAHead Square MountCap Square Mount8" Bore Size“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsBore E EBEEADD STROKEG J K TE(NPTF) LF P8 8 1 /2 11/16 3/4 1.81 1.44 9/16 7.57 5 1 /8 3 1 /4Table 2—Rod DimensionsRod ThreadStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LAF NA VF W WF Y8Table 3—Envelopeand MountingDimensionsADD STROKEXK ZJ1 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 3 / 4 5 5 / 16 6 3 / 41 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 5 9 / 16 723

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersTie Rods Extended Head End MountModel 53(NFPA MX3)DDTie Rods Extended Head End MountTie Rods Extended Cap End MountTie Rods Extended Both Ends MountSleeve Nut Mount5" to 8" Bore SizesYZJ + STROKEP + STROKEWF LF + STROKEEE1E SQ.42MMAA3R SQ.KBBGJTie Rods Extended Cap End MountModel 52(NFPA MX2)YWFZJ + STROKEP + STROKELF + STROKEEEDD1E SQ.42MMAA3R SQ.KG JBBTie Rods Extended Both Ends MountModel 51(NFPA MX1)DDWFYZJ + STROKEP + STROKELF + STROKEEEDD1E SQ.42MMAA3R SQ.KKBBGJBBSleeve Nut MountModel 55(NFPA MX5)WFYZJ + STROKEP + STROKELF + STROKEEE1E SQ.42MMAA3R SQ.BGBGGJ24

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCTie Rods Extended Head End MountTie Rods Extended Cap End MountTie Rods Extended Both Ends MountSleeve Nut Mount5" to 8" Bore SizesWFVFNA MM BA“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsBore AA BB BG DD EEEADD STROKEG J K R(NPTF) LF P5 5.8 1 13 / 16 .50 1/ 2-20 5 1 / 2 1/ 2 1.66 1.22 7/ 16 4.10 4 1 / 2 2 7 / 86 6.9 1 13 / 16 .50 1/ 2-20 6 1 / 2 3/ 4 1.91 1.41 7/ 16 4.88 5 3 1 / 88 9.1 2 5 / 16 .62 5/ 8-18 8 1 / 2 3/ 4 1.81 1.44 9/ 16 6.44 5 1 / 8 3 1 / 4Table 2—Rod DimensionsRod ThreadADDStyle Style +.000STROKEBore Dia 5 2 & 4 -.002Size MM IM KK A B C D LAF NA VF W WF Y ZJ5681 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 5 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 6 1 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 13 / 16 6 5 / 81 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 1 / 16 6 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 3 / 4 6 3 / 41 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 7Table 3–Envelopeand MountingDimensions25

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersSide End Angle Mount5" to 8" Bore SizesSide End Angle MountModel 71*(NFPA MS1)ZA + STROKEXA + STROKEYP + STROKEEWFLF + STROKEEEAB6 HOLES4E31MMSATAH2ATAO ALFGJ ALKAO*Maximum recommended pressure of 150 PSIAESA + STROKE26

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BASide End Angle Mount5" to 8" Bore Sizes“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsEE ADD STROKEBore AB AE AH AL AO AT E (NPTF) F G J K R SLF P SA5 11/ 16 2 2 3 / 4 1 3 / 8 5/ 8 3/ 16 5 1 / 2 1/ 2 5/ 8 1.66 1.22 7/ 16 4.10 4 1 / 4 4 1 / 2 2 7 / 8 7 7 / 86 13/ 16 2 1 / 8 3 1 / 4 1 3 / 8 5/ 8 3/ 16 6 1 / 2 3/ 4 3/ 4 1.91 1.41 7/ 16 4.88 5 1 / 4 5 3 1 / 8 8 1 / 28 13/ 16 1 13 / 16 4 1 / 4 1 13 / 1611/ 16 1/ 4 8 1 / 2 3/ 4— 1.81 1.44 9/ 16 6.44 7 1 / 8 5 1 / 8 3 1 / 4 8 3 / 4Table 2—Rod DimensionsTable 3—Envelope andMounting DimensionsRod Thread ADD STROKEStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LAF NA VF W WF Y XA ZA5681 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 7 1 / 4 7 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 7 1 / 2 8 1 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 5/ 8 2 13 / 16 8 8 5 / 81 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 1 / 16 8 1 / 4 8 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 3 / 4 8 9 / 16 9 1 / 41 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 8 13 / 16 9 1 / 227

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersSide Lug MountModel 72(NFPA MS2)YZJ + STROKESide Lug MountSide Tap Mount5" to 8" Bore SizesP + STROKEWF LF + STROKEEEE1AB4 HOLESE42MMSTLH3SW SWKSW TSSWGJUSSWSWXSSS + STROKESide Tap MountModel 74(NFPA MS4)YZJ + STROKEP + STROKEWFLF + STROKEEEK11E SQ.42MMTH3TNNT THREAD, ND DEEP4 TAPPED MTG. HOLESG JXT SN + STROKE28

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BASide Lug MountSide Tap Mount5" to 8" Bore Sizes“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsBore AB EEE LH TH ADD STROKEG J KNT ST SW TN TS US(NPTF)±.003±.003 LF P SN SS5 13/ 16 5 1 / 2 1/ 2 1.66 1.22 7/ 16 2.743 5/ 8-11 1 11/ 16 2.743 2 11 / 16 6 7 / 8 8 1 / 4 4 1 / 2 2 7 / 8 2 7 / 8 3 1 / 86 13/ 16 6 1 / 2 3/ 4 1.91 1.41 7/ 16 3.243 3/ 4-10 1 11/ 16 3.243 3 1 / 4 7 7 / 8 9 1 / 4 5 3 1 / 8 3 1 / 8 3 5 / 88 13/ 16 8 1 / 2 3/ 4 1.81 1.44 9/ 16 4.243 3/ 4-10 1 11/ 16 4.243 4 1 / 2 9 7 / 8 11 1 / 4 5 1 / 8 3 1 / 4 3 1 / 4 3 3 / 4Table 2—Rod DimensionsTable 3—Envelope andMounting DimensionsRod Thread ADD STROKEStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LAF NA VF W WF Y ND XS XT ZJ5681 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 15/ 16 2 1 / 16 2 7 / 16 5 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 15/ 16 2 5 / 16 2 11 / 16 6 1 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 13 / 16 1 1 / 8 2 5 / 16 2 13 / 16 6 5 / 81 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 1 / 16 1 1 / 8 2 9 / 16 3 1 / 16 6 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 3 / 4 1 1 / 8 2 5 / 16 2 13 / 16 6 3 / 41 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 1 1 / 8 2 9 / 16 3 1 / 16 729

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersCap Fixed Clevis MountCap Detachable Clevis MountCap Detachable Eye Mount5" to 8" Bore SizesCap Fixed ClevisModel 84(NFPA MP1)WFYZC + STROKEP + STROKELB + STROKEEECD1MMLRMRE SQ. 24KG JFLCW3CBCWXC + STROKEFor maximum swivel angle with rear mounting plate for Model 84 mounting see <strong>Series</strong> <strong>AL4</strong> cylinder accessories.Cap Detachable ClevisModel 86(NFPA MP2)YZD + STROKEP + STROKEWFLB + STROKEEECD1MR1MME SQ. 24KG JFL1CW3CBCWXD + STROKECap Detachable Eye Mount (5" and 6" bore sizes)Model 96(NFPA MP4)YZD1 + STROKEP + STROKEWFLB + STROKEEECD11MR2MME SQ. 24FL13KG JCBXD + STROKE30

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BACap Fixed Clevis MountCap Detachable Clevis MountCap Detachable Eye Mount5" to 8" Bore Sizes“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting DimensionsBore CB+.000 +.002EE ADD STROKECD▲ CD1▲ CW EF G J K L L1 LR M MR1 MR2(NPTF)-.002 +.004 LB P5 1 1 / 4 .751 .750 5/ 8 5 1 / 2 1/ 2 5/ 8 1.66 1.22 7/ 16 5/ 8 1 1 / 4 1 15/ 16 3/ 4 7/ 8 5 1 / 8 2 7 / 86 1 1 / 2 1.001 1.00 3/ 4 6 1 / 2 3/ 4 3/ 4 1.91 1.41 7/ 16 3/ 4 1 1 / 2 1 1 / 4 1 1 / 8 1 1 1 / 8 5 3 / 4 3 1 / 88 1 1 / 2 1.001 — 3/ 4 8 1 / 2 3/ 4 3/ 4 1.81 1.44 9/ 16 3/ 4 1 1 / 2 1 1 / 4 1 1 / 8 1 — 5 7 / 8 3 1 / 4▲Dimension CD is pin diameter.Table 2—Rod DimensionsRod Thread ADD STROKEStyle Style +.000Bore Dia 5 2 & 4 -.002Size MM IM KK A B C D LAF NA VF W WF Y XC XD ZC ZD ZD1568Table 3—Envelope andMounting Dimensions1 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 2 15/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 7 1 / 8 7 3 / 4 8 1 / 16 8 1 / 2 8 5 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 7 3 / 8 8 8 5 / 16 8 3 / 4 —1 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 13 / 16 8 1 / 8 8 7 / 8 9 1 / 4 9 7 / 8 101 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 1 / 16 8 3 / 8 9 1 / 8 9 1 / 2 10 1 / 8 —1 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 3 / 4 8 1 / 4 9 9 3 / 8 10 —1 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 8 1 / 2 9 1 / 4 9 5 / 8 10 1 / 4 —31

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersHead Trunnion MountModel 81(NFPA MT1)YHead Trunnion MountCap Trunnion MountIntermediate Trunnion Mount5" to 8" Bore SizesZJ + STROKEP + STROKEWFLF + STROKEUTEE1E42MMTD3TLETLG JKXGCap Trunnion MountModel 82(NFPA MT2)YZJ + STROKEP + STROKEWFLF + STROKEKUTEE1E42MMTD3TL ETLG JXJ + STROKEIntermediate Trunnion MountModel 89(NFPA MT4)YZJ + STROKEP + STROKEUM1WFLF + STROKEEEBDUV42MMTD3E SQ.G JKTLTM TLXI▲Dimension “XI” to be specified by customer.32

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersRod End Dimensions—Basic CylinderD WRENCH FLATSThread Style 2(NFPA Style SM)Small MaleACKKLAFWFVFNA MM BD WRENCH FLATSThread Style 5(NFPA Style IM)Intermediate MaleIMACLAFWFVFNA MM BD WRENCH FLATSThread Style 4(NFPA Style SF)Short FemaleKKCWFVFNA MM BAHead Trunnion MountCap Trunnion MountIntermediate Trunnion Mount5" to 8" Bore Sizes“SpecialThread”Style XSpecial thread,extension, rod eye,blank, etc., arealso available.To order specify“Style X” and givedesired dimensionsfor KK, Aand W or WF. Ifotherwise special,furnish dimensionedsketch.Table 1—Envelope and Mounting Dimensions+.000EEADD STROKE Model 89Bore BD EG J K TD TL TM UM UT UV(NPTF)Minimum-.001 LF P Stroke5 2 5 1 /2 1/2 1.66 1.22 7/16 1.000 1 6 1 /4 8 1 /4 7 1 /2 6 4 1 /2 2 7 /8 3/86 2 1 /2 6 1 /2 3/4 1.91 1.41 7/16 1.375 1 3 /8 7 5 /8 10 3 /8 9 1 /4 7 5 3 1 /8 7/88 2 1 / 2 8 1 / 2 3/ 4 1.81 1.44 9/ 16 1.375 1 3 / 8 9 3 / 4 12 1 / 2 11 1 / 4 9 1 / 2 5 1 / 8 3 1 / 4 5/ 8Table 2—Rod DimensionsRod Thread ADD STROKEStyle Style +.000 ▲Bore Dia 5 2 & 4 -.002 Min.Size MM IM KK A B C D LAF NA VF W WF Y XG XI XJ ZJ568Table 3—Envelope andMounting Dimensions1 7/ 8-14 3/ 4-16 1 1 / 8 1.499 1/ 2 7/ 8 2 1 / 215/ 16 7/ 8 3/ 4 1 3 / 8 2 7 / 16 2 1 / 4 4 3 / 16 5 1 / 4 5 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 1 1 5 / 8 2 11 / 16 2 1 / 2 4 7 / 16 5 1 / 2 6 1 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 13 / 16 2 5 / 8 4 15 / 16 5 7 / 8 6 5 / 81 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 1 / 16 2 7 / 8 5 3 / 16 6 1 / 8 6 7 / 81 3 / 8 1 1 / 4-12 1-14 1 5 / 8 1.999 5/ 8 1 1 / 8 3 1 / 4 1 5 / 16 1 7/ 8 1 5 / 8 2 3 / 4 2 5 / 8 4 15 / 16 6 6 3 / 41 3 / 4 1 1 / 2-12 1 1 / 4-12 2 2.374 3/ 4 1 1 / 2 3 7 / 8 1 11 / 16 1 1 / 8 1 1 / 8 1 7 / 8 3 2 7 / 8 5 3 / 16 6 1 / 4 7▲Dimension “XI” to be specified by customer.33

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersDouble Rod Models5" to 8" Bore SizesHow to Use Double Rod CylinderDimensioned DrawingsTo determine dimensions for a double rod cylinder,first refer to the desired single rod mounting stylecylinder shown on preceding pages of this catalog.After selecting necessary dimensions from thatdrawing, return to this page and supplement thesingle rod dimensions with those shown on thedrawing and dimension table below. Note that doublerod cylinders have a head (Dim. G) at both ends andthat dimension LG replaces LF and PK replaces P,etc. The double rod dimensions differ from, or arein addition to those for single rod cylinders shownon preceding pages and provide the informationneeded to completely dimension a double rodcylinder.On a double rod cylinder where the two rod endsare different, be sure to clearly state which rodend is to be assembled at which end.ZM + 2 X STROKEYPK + STROKEWFLG + STROKEEEKMMROD END #1ROD END #2GGBoreRodAddDia.ADD STROKE2XStrokeMM LG PK SAK XAK SSK SNK ZM5 1 4 15 / 16 2 13 / 16 7 11 / 16 7 11 / 16 3 9 / 16 2 13 / 16 7 11 / 166 1 3 / 8 5 1 / 2 3 1 / 8 8 1 / 4 8 1 / 2 4 1 / 8 3 1 / 8 8 3 / 48 1 3 /8 5 1 /2 3 1 /4 9 1 /8 8 15 /16 4 1 /8 3 1 /8 8 3 /4REPLACES DIMENSION LF P SA XA SS SN —ON SINGLE RODALL MTGALL MTGMOUNTING STYLES STYLES 71 72 74 STYLESAll dimensions are in inches and apply to standard rod sizes only. Foralternate rod sizes, determine all envelope dimensions (within LD dim.) asdescribed above and then use appropriate rod end dimensions for properrod size from single rod cylinder.34

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersCylinder AccessoriesRod end accessories can be selected by cylinder rod end thread size from Table A & B below. Matingparts for rod end accessories are listed just to the right of the rod eye or clevis selected. Eye bracketsand clevis brackets for models 84 and 96 cylinder mounts are selected by bore size from Table C.TABLE A TABLE B TABLE CRodMating Parts Mating Parts Mounting PlateEnd For ForThread Rod Eye Pivot Rod Clevis Pivot Bore Model 84 Model 96Size Clevis Bracket Pin Eye Bracket Pin Size Cylinder Cylinder17/16-20057-RC001- 057-EB001- 057-PP006- 057-RE001- 170-MB86A- 057-PP006-1 057-EB001- 170-MB86A-/250 150-5044-20 50 50 44-20 150-50 502057-EB001- 170-MB86A-50 150-502 1 057-EB001- 170-MB86A-3 /2/4-16 057-RC001- 057-EB001- 057-PP006- 057-RE001- 170-MB86A- 057-PP006- 50 150-5075-16 75 75 75-16 250-75 7531057-EB001- 170-MB86A-/475 250-754057-EB001- 170-MB86A-1-14 057-RC001- 057-EB001- 057-PP006- 057-RE001- 170-MB86A- 057-PP006- 75 250-75100-14 100 100 100-14 325-100 1005057-EB001-—756057-EB001-—1 1 /4-12 057-RC001- 057-EB001- 057-PP006- 057-RE001- 170-MB86A- 057-PP006- 100125-12 138 138 125-12 400-138 138 8057-EB001-—100Cylinder AccessoriesBore 1 1 /2 2 2 1 /2 3 1 /4 4 5 6 8Angle A 52 43 29 50 49 45 42 42Pivot PinSymbol 057-PP006-50 057-PP006-75 057-PP006-100 057-PP006-138CD1/23/4 1 1 3 /8CL 1 7 /8 2 5 /8 3 1 /8 4 1 /4ShearCap. 8600 19300 34300 65000Lbs.Note: Pivot Pin must be ordered separately forsingle lug pivot mounting.CLCD+.001-.002AM RCW CB CWCBM R CACDCDCEASymbol 057-RC001-44-20 057-RC001-75-16 057-RC001-100-14 057-RC001-125-12A 3/4 1 1 /8 1 5 /8 2CB 3/4 1 1 /4 1 1 /2 23/4 1 1 3 /8CD 1/2CE 1 1 /2 2 1 /4 2 15 /16 3 3 /4CW 1/2M 1/2Rod Clevis5/8KK THD3/4 13/4 1 1 3 /8KK 7/16-20 3/4-16 1-14 1 1 /4-12LoadCapacity 4250 11200 19500 33500Lbs.Rod EyeSymbol 057-RE001-44-20 057-RE001-75-16 057-RE001-100-14 057-RE001-125-12A 3/4 1 1 /8 1 5 /8 2CA 1 1 /2 2 1 /16 2 13 /16 3 7 /16CB 3/4 1 1 /4 1 1 /2 23/4 1 1 3 /8CD 1/2M 1/2KK3/4 1 1 3 /8KK 7/16-20 3/4-16 1-14 1 1 /4-12LoadCapacity 5000 12100 21700 33500Lbs.AFCFLEA SQ.CW CB CWFEFMEA SQ.CBM R CDM RCDDE THD.RADB BOLT DIA.RAClevis BracketSymbol 170-MB86A-150-50 170-MB86A-250-75 170-MB86A-325-100 170-MB86A-400-138CB 3/4 1 1 /4 1 1 /2 23/4 1 1 3 /8CD 1/2CW 1/25/83/4 1DE 3/8-24 1/2-20 5/8-18 5/8-18EA 2 1 /2 3 1 /2 4 1 /2 5FC 3/85/8FL 1 1 /8 1 7 /8 2 1 /4 3M 1/23/4 1 1 3 /8RA 1.63 2.55 3.25 3.82LoadCapacity 5000 11000 17000 30000Lbs.3/47/8Eye BracketSymbol 057-EB001-50 057-EB001-75 057-EB001-100 057-EB001-138CB 3/4 1 1 /4 1 1 /2 23/4 1 1 3 /8CD 1/2DB 3/81/2EA 2 1 /2 3 1 /2 4 1 /2 5FE 3/85/8FM 1 1 /8 1 7 /8 2 1 /4 3M 1/23/4 1 1 3 /8RA 1.63 2.55 3.25 3.82LoadCapacity 3600 11000 17000 21000Lbs.5/83/45/87/835

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersStop TubingLong stroke cylinders, fixed or pivot mounted, tend tojackknife or buckle on push load applications, resulting inhigh bearing loading at the rod bushing or piston. Use of astop tube to lengthen the distance between the bushingand piston when cylinder rod is fully extended is recommendedto reduce these bearing loads. The drawing belowshows stop tube construction for fluid power cylinders.Refer to chart on next page to determine stop tube length.When specifying cylinders with long stroke and stop tube,be sure to call out the net stroke and the length of the stoptube. Machine design can be continued without delayby laying in a cylinder equivalent in length to the NETSTROKE PLUS STOP TUBE LENGTH, which is referredto as GROSS STROKE.Refer to the next page to determine stop tube length.(HEAD END)CUSHIONSLEEVEUNTHREADEDPISTONSPACERPISTON(CAP END)Stop TubingMounting ClassesMounting ClassesStandard mountings for fluid power cylinders fall into threebasic groups. The groups can be summarized as follows:Group 1 – Straight Line Force Transfer with fixed mountswhich absorb force on cylinder centerline.Group 2 – Pivot Force Transfer. Pivot mountings permit acylinder to change its alignment in one plane.Group 3 – Straight Line Force Transfer with fixed mountswhich do not absorb force on cylinder centerline.Because a cylinder’s mounting directly affects the maximumpressure at which the cylinder can be used, the chartsbelow should be helpful in the selection of the propermounting combination for your application. Stroke length,piston rod connection to load, extra piston rod length overstandard, etc. should be considered for thrust loads. Alloysteel mountingbolts are recommendedfor all mountingstyles, and thrustkeys are recommendedfor Group 3.GROUP 1FIXED MOUNTS which absorbforce on cylinder centerline.NETSTROKETOTAL STOPTUBE LENGTHGROSS STROKELF + GROSS STROKEDouble piston design is supplied on air cylinders withcushion head end or both ends.HEAVY-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____MEDIUM-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____LIGHT-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____Mtg. Model 52Mtg. Model 53Mtg. Model 62, 64Mtg. Model 61, 63Mtg. Model 62, 64Mtg. Model 61, 63GROUP 2PIVOT MOUNTS which absorbforce on cylinder centerline.(HEAD END)STOP TUBENET STROKEGROSS STROKELF + GROSS STROKEThis design is supplied on cushioned cap ornon-cushioned cylinders.PISTON(CAP END)STOP TUBELENGTHCushion SelectionCushions are required when cylinder piston rod speedexceeds 4" per second.HEAVY-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____MEDIUM-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____HEAVY-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____MEDIUM-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____LIGHT-DUTY SERVICEFor Thrust Loads _____For Tension Loads ____Mtg. Models 89, 81Mtg. Models 84, 86, 89, 81, 82Mtg. Models 84, 86, 96Mtg. Models 84, 86, 96GROUP 3FIXED MOUNTS which do notabsorb force on the centerline.Mtg. Model 72Mtg. Model 72Mtg. Model 74Mtg. Model 74Mtg. Model 71*Mtg. Model 71**Mounting model 71 recommended for maximum pressure of 150 p.s.i.36

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersPiston RodSelection Chart and DataPiston Rod Selection Chart and DataROD DIAMETERBASIC LENGTH — INCHES30020010090807060504030201 3 /815 /81 /21 3 /4INCHES OF7STOP TUBECONSULT FACTORY65432110100 2 3 4 5 6 7 8 1000 2 3 4 5 6 7 8 910,0002 3 4How To Use The ChartTHRUST — POUNDSThe selection of a piston rod for thrust (push) conditions requires thefollowing steps:1. Determine the type of cylinder mounting style and rod end connectionto be used. Then consult the chart below and find the “strokefactor” that corresponds to the conditions used.2. Using this stroke factor, determine the “basic length” from theequation:a) The correct piston rod size is read from the diagonally curvedline labeled “Rod Diameter” next above the point of intersection.b) The required length of stop tube is read from the right of thegraph by following the shaded band in which the point ofintersection lies.c) If required length of stop tube is in the region labeled “consultfactory,” submit the following information for an individual analysis.Basic= Actual xStroke1) Cylinder mounting style.Length Stroke Factor2) Rod end connection and method of guiding load.The graph is prepared for standard rod extensions beyond the faceof the bushing retainer. For rod extensions greater than standard,add the increase to the stroke in arriving at the “basic length.”3. Find the load imposed for the thrust application by multiplying the fullbore area of the cylinder by the system pressure.4. Enter the graph along the values of “basic length” and “thrust” asfound above and note the point of intersection:3) Bore, required stroke, length of rod extension (Dim. “LA”) ifgreater than standard, and series of cylinder used.4) Mounting position of cylinder. (Note: if at an angle or vertical,specify direction of piston rod.)5) Operating pressure of cylinder if limited to less than standardpressure for cylinder selected.Recommended Mounting Styles for Maximum Strokeand Thrust LoadsGroups 1 or 3Long stroke cylinders for thrust loads should be mountedusing a heavy-duty mounting style at one end, firmly fixedand aligned to take the principal force. Additional mountingshould be specified at the opposite end, which should beused for alignment and support. An intermediate supportmay also be desirable for long stroke cylinders mountedhorizontally.Group 2Model 81 - Trunnion on HeadModel 89 - Intermediate TrunnionModel 82 - Trunnion on Cap orModel 84 - Clevis on CapRod EndConnectionFIXEDANDRIGIDLYGUIDEDPIVOTEDANDRIGIDLYGUIDEDSUPPORTEDBUTNOT RIGIDLYGUIDEDPIVOTEDANDRIGIDLYGUIDEDPIVOTEDANDRIGIDLYGUIDEDPIVOTEDANDRIGIDLYGUIDEDIIIIIIIVVVICaseStrokeFactor.50.702.001.001.502.0037

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersBumper Seal OptionBumper Seal Piston OptionImpact dampening Bumper Seals are now optional on all<strong>Miller</strong> <strong>AL4</strong> air cylinders from 1-1/2" to 4" bore. TheBumper Seal piston combines the features of lowfriction,round lipseals and impact-dampening bumpersto provide reduced noise and smoother end-of-strokedeceleration. At pressures greater than 80 psi, thecompressible Buna Nitrile Bumper Seal has a minimaleffect on stroke loss. When specified, Bumper Seals willbe supplied on both ends of the piston, eliminating theneed to specify head end or cap end only.Specifying the Bumper Seal piston feature on <strong>Miller</strong> <strong>AL4</strong> cylinders provides many benefits, such as:Advantage BenefitReduced noise upon piston impactQuieter operating environmentMinimal loss of stroke (or added piston thickness)Space-efficient design for applying cylinders in tight spacesSmoother end-of-stroke deceleration when used in combination with cushions Efficient cushioning increases cylinder and machine lifeRounded sealing lip is rated for non-lube serviceLong seal life without the need for external lubrication38

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersBumper Seal OptionSummary ofAccelerometerTest ResultsBoreSize1.50"2.00"2.50"Piston Cushioning Efficiency Cushioning TimeType (Maximum G’s of deceleration (Ms)force created)Standard Piston 13.4 22Bumper Seal Piston 5.1 22Standard Piston 12.6 33Bumper Seal Piston 7.8 26Standard Piston 12.2 36Bumper Seal Piston 5.2 24Bumper Seals Reduce NoiseThe special profile of the Bumper Sealprevents the piston from banging into theend cap at the end of stroke. Independenttesting shows that the Bumper Seal, whencombined with cushions, will absorb thefinal piston inertia and reduce the strokenoise by as much as 20 dB. The SoundLevel Comparison graph illustrates thenoise-reducing effects of the Bumper Sealpiston when combined with cushions.Impact noise was recorded at a distance of 3 feetfrom the front of the cylinder, inside a semi-anechoicchamber. Cylinders were operating at 95 psi.Sound Level dB12010080Sound Level ComparisonNo Bumpers or CushionsWith Bumper Seals and Cushions601.50 Bore2.00 Bore3.25 BoreBumper Seals Have Minimum Effect on Stroke LengthThe accompanying chart depicts typicalamounts of overall stroke loss incurred atvarious system pressures. The amount ofstroke loss may vary slightly due to designtolerances of seal size, variance in sealdurometer, and compression set associatedwith cylinder wear.To determine the total stroke loss at eitherend of the cylinder, divide the values by two.Typical Overall Stroke Loss by Bore Size (in.)Pressure(psi)1.50 2.00 2.50 3.25 4.000 .16" .13" .19" .22" .22"20 .12" .11" .12" .18" .18"40 .10" .08" .09" .12" .12"60 .08" .07" .07" .09" .09"80 .06" .05" .05" .06" .06"100 .05" .03" .02" .04" .04"39

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersBrownBlueLoadReed Switch AssemblyDCorACSwitch SpecificationsSolid State Switch AssemblySwitching Logic Normally Open, SPST NPN or PNPSupply Voltage Range 5 to 125 V AC/DC 5 TO 30 VDCMax. Switching Power 10 Watts (Resistive) 5 Watts (Inductive) 6 WattsMax. Switching Current 300 mA (Resistive) 150 mA (Inductive) 200 mA at 24 VDCCircuit Current Consumption — Max 14 mA at 24 VDCShort Circuit Interruption Current — 370 mALeakage Current — 10 µA MaximumResidual Voltage Maximum 3 V 1.5 V Maximum"On" State Voltage Drop 1.7V Maximum See BelowResponse 1000 Hz Maximum 1000 Hz MaximumShock Resistance 30G Non-Repeated Shock 30G Non-Repeated ShockDegree Of Protection IEC IP 67 IEC IP 67CircuitsReed SwitchL074860000Part No. ................ L074870000NOTE:Polarity must be observedfor DC operation only.NPN Sinking OutputL074800000Part No. ............................................... L074900000Color of Cable ................................................ Black“On” State Voltage Drop ................. 0.7V MaximumBrownBlackBlueLOADSwitch SpecificationsReed Switch Assembly Solid State Switch AssemblyOperating Temperature 14° to 140°F (-10° to 60°C) 14° to 158°F (-10° to 70°C)Storage Temperature -4° to 158°F (-20° to 70°C) -4° to 176°F (-20° to 80°C)LED Indicator Red, Target Present When On Red, Target Present When OnMinimum Current To Light LED 18 mA 1 mALead Wire Lengths 39 Inches, 1 Meter 39 Inches, 1 Meter1 Polarity is restricted to DC operation: (+) to Brown (-) to BlueIf these connections are reversed the contacts will close, but the LED will not light.Note: For switches with connectors and cordsets, see catalog.For 1-1/2" to 4" bore intermediate trunnion mounts, tandem and duplex cylinders,see Bulletin M0830-M2 for applicable switch part number.(+)5 to 30 VDC()PNP Sourcing OutputL075910000Part No. ............................................... L074920000Color of Cable ................................................. Gray“On” State Voltage Drop ................. 0.2V MaximumBrownBlackBlueLOAD(+)5 to 30VDC()Circuit for Switching Contact Protection (Inductive Loads)(Required for proper operation 24V DC)Put Diode parallel to loads following polarity as shown below.Put a resistor and capacitor in parallel with the load. Select the resistor and capacitoraccording to the load.BrownBlueLoadDD: Diode: select a Diode with the breakdown voltage and current rating according tothe load.Typical Example—100 Volt, 1 Amp DiodeLoad: Relay coil (under 0.5W coil rating)(Recommended for longer life 125 VAC)DCTypical Example:BrownLoad: Relay coil (under 2W coil rating)LoadR: Resistor 1 KΩ - 5 KΩ, 1/4 WC: Capacitor 0.1 µF, 600 V R CBlueACSwitchMounting DataA1 1 /2"-4" Bores A1.005"-8" BoresBB1.0040Note: For switches with connectors and cordsets, see Complementary Products Section.Piston Travel at Minimum Activation DistanceBoreSolid State Switch AssemblyMidstroke (Inches) from End of Stroke (Inches)Size Reed Switch Assembly NPN Sinking PNP Sourcing A B (Switch On) (±.01) Head Cap1 1 /2 L074860000 L074880000 L074910000 1.46 2.12 .37 .06 .062 L074860000 L074880000 L074910000 1.68 2.57 .40 .12 .122 1 /2 L074860000 L074880000 L074910000 1.90 2.99 .41 .07 .073 1 /4 L074870000 L074900000 L074920000 2.24 3.73 .43 .13 .134 L074870000 L074900000 L074920000 2.55 4.37 .44 .11 .115 L074860000 L074880000 L074910000 2.88 5.25 .44 .06 .066 L074860000 L074880000 L074910000 3.25 6.12 .50 .06 .068 L074870000 L074900000 L074920000 4.06 8.00 .50 .06 .06! Caution– Current capabilities are relative to operational temperatures.– Use an ampmeter to test reed switch current. Testing devices such as incandescent light – Use relay coils for reed switch contact protection.bulbs may subject the reed switch to high in-rush loads.– The operation of some 120 VAC PLC's (especially some older Allen-Bradley PLC's) can– NOTE: When checking an unpowered reed switch for continuity with a digital ohmmeter the overload the reed switch. The switch may fail to release after the piston magnet hasresistance reading will change from infinity to a very large resistance (2 M ohm) when the passed. This problem may be corrected by the placement of a 700 to 1K OHM resistorswitch is activated. This is due to the presence of a diode in the reed switch.between the switch and the PLC input terminal. Consult the manufacturer of the PLC for– Anti-magnetic shielding is recommended for reed switches exposed to high external RF or appropriate circuit.magnetic fields.– Switches with long wire leads (greater than 15 feet) can cause capacitance build-up and– The magnetic field strength of the piston magnet is designed to operate with our switches. sticking will result. Attach a resistor in series with the reed switch (the resistor should beOther manufacturers’ switches or sensors may not operate correctly in conjunction with installed as close as possible to the switch). The resistor should be selected such that Rthese magnets.(ohms) >E/0.3.– NOTE: On 5"-8" bores switch will not lay flush with cylinder body.

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersLinear Position Sensor OptionLinear PositionSensor Option for<strong>AL4</strong> <strong>Series</strong> CylinderPrecise Position FeedbackNon-Contact SensingAnalog or Digital OutputsBore Sizes 2" - 8"Available in Eleven Mounting StylesApplicationsPneumatic Cylinders Tooling and Tool Handling PressesFoundries Casting and Rolling Mills Injection MoldingLeveling Machines Transport Systems Lift ControlsLevel Monitoring Tunnel Boring Equipment Die CastingPortal Robots Wood Working Machinery Flight SimulatorsConveying Cutting/Slitting Machinery WindmillsElevators Packaging Machines X-Y Tables-Anywhere linear motion must be monitored -41

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersLinear Position Sensor OptionGeneration of the ultrasonic torsion pulse ina metallic conductor based on the principleof magnetostriction.ElectromagneticfieldDampingMechanicalwaveMechanicalwaveWaveguideInitial pulsePosition markerwith magnetsCopperconductorSignal converter coil (patented process)ReceiverPrinciples of OperationThe measuring element ("waveguide"), consists of aspecial nickel-alloy tube.A copper conductor is introduced through the length ofthis tube. The start of measurement is initiated by a shortcurrent pulse.This current generates a circular magnetic field whichrotates around the waveguide. A permanent magnet atthe point of measurement is used as the marker element,whose lines of field run at right angles to the electromagneticfield. In the area on the waveguide where thetwo fields intersect, a magneto-strictive effect causes anelastic deformation of the waveguide, which propagatesalong the wave guide in both directions in the form of amechanical wave.The propagation velocity of this wave in the waveguide is2830 m/s, and is nearly insensitive to environmentaleffects (e.g., temperature, shock, contamination).The component of the wave which reaches the far end ofthe waveguide is damped there, whereas the componentwhich arrives at the signal converter is changed into anelectrical signal by reversing the magnetostrictive effect.The wave travel time from its point of origin to the signalconverter is directly proportional to the distance betweenthe permanent magnet and the signal converter. A timemeasurement then allows the distance to be determinedwith extremely high accuracy.DesignThe transducers are made to the same safety andreliability standards for use in the harshest conditions:– The electronics unit is compactly designed using SMDtechnology. The boards are protected in a space-saving,rugged aluminum extruded housing.– The waveguide is protected in the extruded aluminumhousing.QualityEach and every transducer undergoes a speciallydesigned, computer-controlled testing procedure whichincludes 100% checking of all specified data.42

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersLinear Position Sensor OptionThe drawings below show that the Linear Position Sensoris longer than the cylinder of the same stroke length. Thesensor overhang on the head end of the cylinder, asindicated by dimension A, may be eliminated by addingstop tubing, which effectively increases the gross strokeof the cylinder. The recommended stop tube lengths areprovided in the table below for each bore size. TheWITH STOP TUBE2.75(DAMPING ZONE)0.50ELECTRICAL STROKE "XXX"examples show that the electrical stroke of the sensor willalways match the net stroke of the cylinder.As a result of the limited sensing range of the sensor, itwill overhang at the cap end of the cylinder by theamount of dimension B. For rear clevis and eye mounts,rotation is limited due to sensor interference.4.103.733.10(NULL ZONE)0.14STOP TUBE INCLUDEDBNO STOP TUBE2.75(DAMPING ZONE)ELECTRICAL STROKE "XXX"4.103.733.10(NULL ZONE)2.251.681.360.14A0.500.151.171.73B2.50Example B: To eliminate sensor overhang on the head end of a 2.0" bore cylinder, add 1.0" of recommended stop tube length.The cylinder gross stroke becomes 13" and the net stroke remains 12". Specify a sensor with an electrical stroke of 12".Note that the electrical stroke equals cylinder net stroke length.Example C: To eliminate sensor overhang on the head end of a 5.0" bore cylinder, add .625" of recommended stop tube length.The cylinder gross stroke becomes 12.625" and the net stroke remains 12". Specify a sensor with an electrical stroke of 12".Note that the electrical stroke equals cylinder net stroke length.No Stop TubeWith Stop TubeBore Rod Diameter A B Stop Tube Length A1 B25/81.95 1.3 1.0 0 1.32 1/25/81.90 1.25 1.0 0 1.253 1/411 3/8.64 1.0 .75 0 1.0411 3/8.63 .99 .75 0 .99511 3/8.55 .79 .625 0 .7961 3/81 3/4.47 .46 .50 0 .4581 3/81 3/4.28 .44 .375 0 .4443

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersOutput signalTransducer interfaceInput interfaceanalogAanalogLinear Position Sensor OptionanalogEanalogOrdering codeOutput voltageOutput currentLoad currentmax. ripple.Load resistanceSystem resolutionBTL5-A11-M_ _ _ _-R-S320...10 Vmax. 10 mA≤5 mV≤0.1 mVBTL5-E1_-M_ _ _ _-R-S324...20 mA or 20...4mA≤500 Ohm≤0.2 µAHysteresisRepeatabilityOutput update ratemax. non-linearityTemperature coefficient Voltage outputCurrent outputShock loadingVibrationTraverse velocity of magnetOperating voltageCurrent drawPolarity reversal protectedOvervoltage protectionDielectric constantOperating temperatureStorage temperature-4 µm≤6 µm (hysteresis + resolution)STANDARD = 1 ms≤1400 mm±100 µm to 500 mm stroke±0.02 % 501...3606 mm stroke[150 µV/°C + (5 ppm/°CxPxU/L)]xDT[0.6 µA/°C + (10 ppm/°CxPxI/L)]x DT100 g/11 ms per IEC 68-2-2712 g, 10...2000 Hz per IEC 68-2-6any24 V DC ± 20%≤150 mAyesTranszorb protection diodes500 V (Ground to housing)–40...185°F (-40...85°C)–40...212°F (-40...100°C)S32 Pin assignments Pin ColorOutput signals 1 YE2 GY3 PK5 GNSupply voltage 6 BU7 BN8 WHConnect shield to housing.BTL5-A11...not usedsignal GND10...0 V0...10 VGND+24 V DC(GND)BTL5-E1...BTL5-E1...4...20 mA 20...4 mA0 V output20-4 mA4-20 mAGND+24 V DC(GND)Specifications subject to change.Please enter code for output signal andnominal stroke in ordering code.Ordering Sample:BTL5-A11-M_ _ _ _-R-SU 022-S32BTL transducers with analog outputs are available in theranges of 0...10V, 4...20mA with rising or falling signal.Output signal1 increasing anddecreasing (for A)0 increasing7 decreasing (for E)Standard strokelengths (mm)44

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersLinear Position Sensor OptionM InterfaceDifferential START/STOPcontrol-specific interface.P InterfaceCompatible with BTA processors and various OEM controls. Reliable signal transmission,even over cable lengths up to 500 m (1640 ft.) between BTA and BTL, is assured by theespecially noise-immune RS485 differential drivers and receivers. Noise signals areeffectively suppressed.<strong>Series</strong>Transducer interfaceUser interfaceBTL5 Low Profilepulse Mpulse MBTL5 Low Profilepulse Ppulse POrdering codeBTL5-M1-M_ _ _ _-R-S 32BTL5-P1-M_ _ _ _-R-S 32System resolutionRepeatabilityResolutionHysteresisStandard sampling ratemax. non-linearityTemperature coefficient of overall systemTraverse velocity of magnetOperating voltageCurrent drawOperating temperatureStorage temperatureProcess-dependent/control dependentHysteresis + Resolution≤2 µm≤4 µmfSTANDARD = 1 kHz 1400 mm±100 µm to 500 mm nominal stroke±0.02 % 501...3750 mm nominal stroke(6 µm + 5 ppm x L)/°Cany24 V DC ±20 % or ±15V DC ±2% (optional)≤100 mA–40...185°F (-40...85°C)–40...212°F (-40...100°C)≥S32 Pin assignments Pin ColorInput/output signals Input 1 YEOutput 2 GYInput 3 PKOutput 5 GNSupply voltage 6 BU7 BN8 WHShield connected to housingBTL5-M1-M...INITSTART/STOPINITSTART/STOPGND+24 V DC(GND)BTL5-P1-M...INITSTART/STOPINITSTART/STOPGND+24 V DC(GND)Specifications subject to change.Please enter code for nominal stroke inordering code.Ordering Sample:BTL5-P1-M_ _ _ _-R-SU 022-S32Output signalStandard strokelengths (mm)45

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersLinear Position Sensor OptionOrdering CodeTransducer - LinearGeneration 5Output SignalA = 0...10VE = 4...20 mAM = differential Start/Stop - leading edge activeP = differential Start/Stop - trailing edge activeSupply Voltage1 = 24 V ±20%Output Signal Used for analog only.Leave position #9 blank for digital.If A in position 71 = Vmin or Vmax at connector end, i.e. user selectablerising or fallingIf E in position 70 = Imin at connector end (rising towards opposite end)7 = Imax at connector end (falling towards opposite end)Nominal stroke in mm0 3 0 5 = 305 mm active electrical stroke.See chart below for std. stroke length.Note: Electrical stroke = Net Cylinder StrokeHousing geometryR = Low Profile extrusionConnection typeS 3 2K A 0 5= 8 pin quick disconnect metal connector= integral axial cable (with 5 m cable; specify length)Cable Required = BKS – 532M - 05 (straight connector), 5 meter cable lengthBKS – 533M - 05 (right angle, 90° connector), 5 meter cable lengthStandard LengthsElectrical Strokeinches mm2 00513 00774 01025 01276 01527 01788 02039 023010 025411 028012 030513 0330inches mm15 038116 040718 045720 050822 056024 061026 066128 071130 076232 081336 091440 1016inches mm42 106748 122050 127060 152470 177880 203290 2286100 2540110 2794120 304846

<strong>Miller</strong> <strong>AL4</strong> <strong>Series</strong>Air CylindersTransducer InformationTransducer InformationSpecial Sensor ModificationWhen specifying the Linear Position Option, the <strong>Series</strong> letter “S” (example - <strong>AL4</strong>S) must be used and the cylinder part number must include amagnet, along with the number “9” in the “modified” identification. Please include the following information in the Special Modifications:1. Sensor part number from the previous page.2. Sensor position.3. Port position (not position 1).4. Length of stop tubing, gross stroke and net stroke (if required). Ordering Example: <strong>AL4</strong>S 72 B 2N 00400-00800 0100 N 22 M 9Table A – Cylinder Mounting Styles without Stop Tube OptionMountingMountingStyle N.F.P.A. Mounting Description Style N.F.P.A. Mounting DescriptionCode Style Code Style81 MT1 Head Trunnion50 MX0 No Mount (Basic) 82 MT2 Cap Trunnion96****† MP4 Detachable Pivot Eye72 MS2 Side Lug 84****† MP1 Cap Fixed Clevis71 MS1 Single End Angle 86****† MP2 Cap Detachable Clevis74 MS4 Side Tapped77 MS7 End Lug Mount62 MF2 Cap Rectangular Flange (6" only)**** Mounting styles with asterisks (****) can be ordered assembled to the cylinder or as a basic no-mount cylinder with a bolt on mounting kit as a separateitem (1-1/2" to 4" only). † For rear clevis mounts, 84, 86 and 96, rotation is limited due to sensor interference.Table B – Cylinder Mounting Styles with Stop Tube OptionMountingMountingStyle N.F.P.A. Mounting Description Style N.F.P.A. Mounting DescriptionCode Style Code Style50 MX0 No Mount (Basic)61**** MF1 Head Rectangular Flange (2"-6")62**** MF2 Cap Rectangular Flange (6"-8" only)53 MX3 Tie Rods Extended Head End81 MT1 Head Trunnion82 MT2 Cap Trunnion55 MX5 Sleeve Nut Mount 96****† MP4 Detachable Pivot Eye72 MS2 Side Lug 84****† MP1 Cap Fixed Clevis71**** MS1 Side End Angle 86****† MP2 Cap Detachable Clevis74 MS4 Side Tapped 63 ME3 Head Square (8")77 MS7 End Lug Mount**** Mounting styles with asterisks (****) can be ordered assembled to the cylinder or as a basic no-mount cylinder with a bolt on mounting kit as a separateitem (1-1/2" to 4" only). † For rear clevis mounts, 84, 86 and 96, rotation is limited due to sensor interference.Transducer WarrantyThe Company’s products are guaranteed to be free from defect in material and workmanship for the period defined below:The Company offers a standard 2-year warranty from the date of shipment for magnetostrictive transducers.The Company will repair or replace, without charge, any unit, which fails because of defective workmanship or material, during thisguarantee period and which is returned to The Company, transportation prepaid. The guarantee will not apply if, in the judgementof The Company, damage or failure has resulted from accident, alteration, misuse, abuse, or operation on an incorrect powersupply. The guarantee expressly does not include any other costs such as the cost of removal of the defective part, installation,labor or consequential damages of any kind. The Company assumes no responsibility for selection and installation of its products.The foregoing is in lieu of all other guarantees expressed, implied or statutory and The Company neither assumes nor authorizesany person to assume for it any other obligation or liability in connection with said products.47