Download full report - Toyota Motor Europe

Download full report - Toyota Motor Europe

Download full report - Toyota Motor Europe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Special feature<br />

<strong>Toyota</strong> <strong>Motor</strong> Manufacturing UK –<br />

towards the ultimate Eco-Factory<br />

<strong>Toyota</strong> in the UK has been recognised by Cleangreencars.<br />

co.uk as the first automotive manufacturer in the UK to<br />

achieve CO 2 emissions averaging below 130 g/km across<br />

the model range, already meeting the 2013 <strong>Europe</strong>an Union<br />

target set for automotive manufacturers. TMUK began<br />

manufacturing cars in 1992. Since that time, it has placed<br />

environmental considerations at the forefront of its business<br />

planning and sought to minimise its environmental impact.<br />

The company was the first UK automotive manufacturer to<br />

achieve ISO14001 in 1996 for its manufacturing operations<br />

and the first to achieve zero waste to landfill in 2002.<br />

Leading by example<br />

This commitment is demonstrated by the following<br />

reductions that have been achieved :<br />

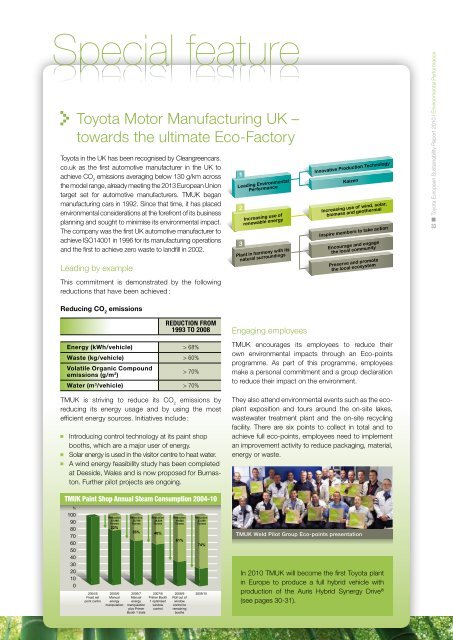

Reducing CO 2 emissions<br />

TMUK is striving to reduce its CO 2 emissions by<br />

reducing its energy usage and by using the most<br />

efficient energy sources. Initiatives include :<br />

Introducing control technology at its paint shop<br />

booths, which are a major user of energy.<br />

Solar energy is used in the visitor centre to heat water.<br />

A wind energy feasibility study has been completed<br />

at Deeside, Wales and is now proposed for Burnaston.<br />

Further pilot projects are ongoing.<br />

%<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

2004/5<br />

Fixed set<br />

point contro<br />

Reduction<br />

15,468<br />

Tonnes<br />

22%<br />

2005/6<br />

Manual<br />

energy<br />

manipulation<br />

Reduction<br />

25,760<br />

Tonnes<br />

36%<br />

2006/7<br />

Manual<br />

energy<br />

manipulation<br />

plus Primer<br />

Booth 1 trials<br />

Reduction<br />

28,024<br />

Tonnes<br />

40%<br />

2007/8<br />

Primer Booth<br />

1 optimised<br />

window<br />

control<br />

rEDuction from<br />

1993 to 2008<br />

Energy (kWh/vehicle) > 68%<br />

Waste (kg/vehicle) > 60%<br />

Volatile Organic Compound<br />

emissions (g/m 2 )<br />

Reduction<br />

44,902<br />

Tonnes<br />

61%<br />

2008/9<br />

Roll out of<br />

window<br />

control to<br />

remaining<br />

booths<br />

> 70%<br />

Water (m 3 /vehicle) > 70%<br />

TMUK Paint Shop Annual Steam Consumption 2004-10<br />

Reduction<br />

53,299<br />

Tonnes<br />

74%<br />

2009/10<br />

1<br />

Leading Environmental<br />

Performance<br />

2<br />

3<br />

Increasing use of<br />

renewable energy<br />

Plant in harmony with its<br />

natural surroundings<br />

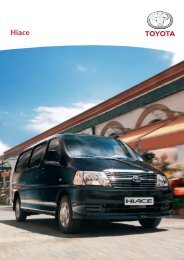

Engaging employees<br />

Innovative Production Technology<br />

Kaizen<br />

Increasing use of wind, solar,<br />

biomass and geothermal<br />

Inspire members to take action<br />

Encourage and engage<br />

the local community<br />

Preserve and promote<br />

the local ecosystem<br />

TMUK encourages its employees to reduce their<br />

own environmental impacts through an Eco-points<br />

programme. As part of this programme, employees<br />

make a personal commitment and a group declaration<br />

to reduce their impact on the environment.<br />

They also attend environmental events such as the ecoplant<br />

exposition and tours around the on-site lakes,<br />

wastewater treatment plant and the on-site recycling<br />

facility. There are six points to collect in total and to<br />

achieve <strong>full</strong> eco-points, employees need to implement<br />

an improvement activity to reduce packaging, material,<br />

energy or waste.<br />

TMUK Weld Pilot Group Eco-points presentation<br />

In 2010 TMUK will become the first <strong>Toyota</strong> plant<br />

in <strong>Europe</strong> to produce a <strong>full</strong> hybrid vehicle with<br />

production of the Auris Hybrid Synergy Drive ®<br />

(see pages 30-31).<br />

<strong>Toyota</strong> <strong>Europe</strong>an Sustainability Report 2010 I Environmental Performance<br />

33