Impact Sound Insulation - Paroc.com

Impact Sound Insulation - Paroc.com

Impact Sound Insulation - Paroc.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

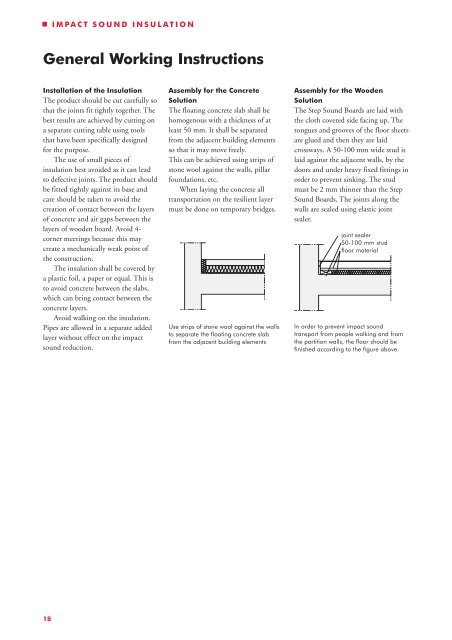

IMPACT SOUND INSULATIONGeneral Working InstructionsInstallation of the <strong>Insulation</strong>The product should be cut carefully sothat the joints fit tightly together. Thebest results are achieved by cutting ona separate cutting table using toolsthat have been specifically designedfor the purpose.The use of small pieces ofinsulation best avoided as it can leadto defective joints. The product shouldbe fitted tightly against its base andcare should be taken to avoid thecreation of contact between the layersof concrete and air gaps between thelayers of wooden board. Avoid 4-corner meetings because this maycreate a mechanically weak point ofthe construction.The insulation shall be covered bya plastic foil, a paper or equal. This isto avoid concrete between the slabs,which can bring contact between theconcrete layers.Avoid walking on the insulation.Pipes are allowed in a separate addedlayer without effect on the impactsound reduction.Assembly for the ConcreteSolutionThe floating concrete slab shall behomogenous with a thickness of atleast 50 mm. It shall be separatedfrom the adjacent building elementsso that it may move freely.This can be achieved using strips ofstone wool against the walls, pillarfoundations, etc.When laying the concrete alltransportation on the resilient layermust be done on temporary bridges.Use strips of stone wool against the wallsto separate the floating concrete slabfrom the adjacent building elementsAssembly for the WoodenSolutionThe Step <strong>Sound</strong> Boards are laid withthe cloth covered side facing up. Thetongues and grooves of the floor sheetsare glued and then they are laidcrossways. A 50-100 mm wide stud islaid against the adjacent walls, by thedoors and under heavy fixed fittings inorder to prevent sinking. The studmust be 2 mm thinner than the Step<strong>Sound</strong> Boards. The joints along thewalls are sealed using elastic jointsealer.joint sealer50-100 mm studfloor materialIn order to prevent impact soundtransport from people walking and fromthe partition walls, the floor should befinished according to the figure above.18