Featuring Plywood in Buildings - Engineered Wood Products ...

Featuring Plywood in Buildings - Engineered Wood Products ...

Featuring Plywood in Buildings - Engineered Wood Products ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Face Quality<strong>Plywood</strong> can be ordered with face veneers to suit the application. Veneer quality A is a high qualityappearance grade suitable for clear f<strong>in</strong>ish<strong>in</strong>g. Veneer quality S def<strong>in</strong>es an appearance grade whichpermits natural characteristics such as knots as a decorative feature. Veneer quality B is anappearance grade suitable for high quality pa<strong>in</strong>t f<strong>in</strong>ish<strong>in</strong>g. Veneer quality C is a non-appearancegrade with a sanded solid surface i.e. all open defects are filled. F<strong>in</strong>ally veneer quality D can haveopen defects and would normally be used as a back veneer on a plywood panel. Thus for a clearf<strong>in</strong>ished aesthetic application requir<strong>in</strong>g one viewed surface AD grade plywood would be specified.Under similar circumstances if a pa<strong>in</strong>ted f<strong>in</strong>ish is required then a m<strong>in</strong>imum of BD grade is thespecification. A choice of timber species other than p<strong>in</strong>e for outer veneers is also available.Quality GuaranteedFor guaranteed compliance andreliability specify that theplywood used must be brandedwith the appropriate EWPAAproduct certification stamp. Thisstamp certifies the product hasbeen manufactured under aformalised process based qualitycontrol program and is thereforefit for use as described <strong>in</strong> thisliterature.4

When you specify plywood be sure it has the PAA certification markThe EWPAA has been accredited by the Jo<strong>in</strong>t Accreditation System of Australia and New Zealand(JAS-ANZ), the peak accreditation body <strong>in</strong> both countries established by government treaty, as aproduct certification body for plywood and other glued structural veneer products. <strong>Plywood</strong>cladd<strong>in</strong>g, l<strong>in</strong><strong>in</strong>g and roof<strong>in</strong>g manufactured under the EWPAA quality brand stamp assures productconformance to the relevant product standard.5

Curv<strong>in</strong>g <strong>Plywood</strong><strong>Plywood</strong> can be safely curved forapplications such as ceil<strong>in</strong>gs and featurewalls. Table one provides guidance forthe m<strong>in</strong>imum recommended radii. Twofactors should be considered beforeselect<strong>in</strong>g the plywood thickness. Firstly,the amount of force and hence the<strong>in</strong>creased fix<strong>in</strong>gs that are required to pulland hold the panel <strong>in</strong> tight radius;thicker panels require considerable forceparticularly <strong>in</strong> thickness above 12mm.secondly, with tighter radii the change ofradii between the ends of each sheet(which tend to be straighter) and thebalance of the panel becomes morevisually obvious. Therefore for tighterradii it is best to use th<strong>in</strong>ner plywoodsand closer supports.Table 1 : Recommended m<strong>in</strong>imum bend<strong>in</strong>gradii for plywood l<strong>in</strong><strong>in</strong>gsNormalThickness(mm)Along face(m)Across face(m)4.5 1.1 0.67 1.8 1.09 2.3 1.312 3.6 2.415 4.6 3.017 6.0 4.4Acoustics and Sound Insulation<strong>Plywood</strong> is an excellent reflector of sound, an acoustic property put to good use <strong>in</strong> applicationssuch as the <strong>in</strong>ternal l<strong>in</strong><strong>in</strong>g of the Sydney Opera House. Alternatively, perforated plywood withsound <strong>in</strong>sulation beh<strong>in</strong>d can act as a sound absorb<strong>in</strong>g l<strong>in</strong><strong>in</strong>g.The most important factor determ<strong>in</strong><strong>in</strong>g the ability of a wall system or l<strong>in</strong><strong>in</strong>g to absorb transmittedsound is its mass per surface area. There is no such th<strong>in</strong>g as an ultra-lightweight, high efficiencyacoustic partition. However a double-sided plywood partition reduces the level of noisetransmitted by around 35 decibels. To achieve higher levels with timber fram<strong>in</strong>g requires staggeredor double stud wall systems fitted with sound <strong>in</strong>sulation. Another option is the <strong>in</strong>clusion of leadsheet <strong>in</strong> the wall system.7

Thermal PerformanceThe real advantage of lightweight timberconstruction <strong>in</strong> a subtropical or tropical climateis the ability to provide very liveable build<strong>in</strong>gswith wall systems hav<strong>in</strong>g low thermal mass.Thus <strong>in</strong> the cool of the even<strong>in</strong>g follow<strong>in</strong>g a hotday the wall will cool rapidly and not keepheat<strong>in</strong>g the <strong>in</strong>terior. Walls with high thermalmass hold substantially more heat thuscont<strong>in</strong>ue to radiate heat <strong>in</strong> the even<strong>in</strong>g.In cooler climates, or if the build<strong>in</strong>g is to be airconditioned, the addition of <strong>in</strong>sulation to thetimber structure can provide equivalentthermal <strong>in</strong>sulation to solid construction. Forexample the addition of R1.5 batts <strong>in</strong>to aplywood clad with reflective sisalation on90mm studs will result <strong>in</strong> a wall with anaverage R exceed<strong>in</strong>g 2.2 (see table 2).Therefore, <strong>in</strong> w<strong>in</strong>ter a lightweight timber canbe a very effective <strong>in</strong>sulator and keep thewarmth <strong>in</strong>side the build<strong>in</strong>g.Table 2 : Thermal resistance of timber framed plywood clad wallsR Value (m 2 o c/WattThroughInsulationZoneThroughStudOutdoor air film 0.04 0.0412mm <strong>Plywood</strong> Cladd<strong>in</strong>g 0.08 0.0820mm reflective air gap 0.58R1.5 Insulation 1.5090mm Stud 0.626mm <strong>Plywood</strong> L<strong>in</strong><strong>in</strong>g 0.04 0.04Indoor Air film 0.12 0.12TOTAL R VALUE 2.36 0.90Note:As a non-reflective 20mm air gap has an R value of 0.15, an <strong>in</strong>sulation wall system withoutsisalation would reduce the total r value from 2.36 to 1.93 <strong>in</strong> the above table.8

Lightweight panels<strong>Plywood</strong> is strong enough to do the job but still light enough to be <strong>in</strong>stalled by one person,sav<strong>in</strong>g time and money. The density of p<strong>in</strong>e plywood is around 590kg/m 3 , thus a 2400 x 1200 x12mm plywood panel weighs approximately 20kg. Hardwood plywood may be up to 40% moredense than p<strong>in</strong>e plywood.Fire Hazard PropertiesThe Build<strong>in</strong>g Code of Australia (BCA) is a uniform set of technical provisions for the design andconstruction of build<strong>in</strong>gs and other structures throughout Australia. The BCA <strong>in</strong>cludes a section onFire Resistance, and designers and builders must ensure that their constructions satisfy this section.There are 3 categories for plywood used <strong>in</strong> constructions :1. Floor Materials and Cover<strong>in</strong>gs2. Wall and Ceil<strong>in</strong>g L<strong>in</strong><strong>in</strong>gs3. Other materials.The follow<strong>in</strong>g tables list the properties for each of these types. For more <strong>in</strong>formation, you candownload the “EWPAA Fire Resistance” fact sheet from the EWPAA Web Site.Floor Material And Cover<strong>in</strong>gsSpecies Thickness CRFP<strong>in</strong>e, Hoop – Araucaria cunn<strong>in</strong>ghamiiP<strong>in</strong>e, Radiata – P<strong>in</strong>us RadiataP<strong>in</strong>e, Slash – P<strong>in</strong>us Elliottii15mm or greater17mm or greater17mm or greaterBetween2.2 and 4.5Smoke DevelopmentRateLess than 750percent-m<strong>in</strong>utes9

Wall and Ceil<strong>in</strong>g L<strong>in</strong><strong>in</strong>gs<strong>Plywood</strong>SpeciesM<strong>in</strong>imumThickness (mm)GroupNo.Average SpecificExt<strong>in</strong>ction Area(m 2 /kg)P<strong>in</strong>e, Radiata – P<strong>in</strong>us Radiata 6mm or greater 3 < 250Lauan – Shorea agsaboensis 6mm or greater 3 < 250P<strong>in</strong>e, Hoop 6mm or greater 3 82.4P<strong>in</strong>e, Slash 6mm or greater 3 96.0Other MaterialsFace Veneer CommonNameBotanical NameSpread of FlameIndex (0-10)SmokeDeveloped Index(0-10)Kl<strong>in</strong>kii p<strong>in</strong>e Aurancaria hunste<strong>in</strong>ii 8 4Radiata P<strong>in</strong>e P<strong>in</strong>us radiata 8 2Radiata P<strong>in</strong>e (scorchedand brushed surface)P<strong>in</strong>us radiata 7 2Energy Costs of Construction<strong>Plywood</strong> is manufactured from a natural, renewable resource; wood. The energy requirements forthe manufacture of plywood are relatively low when compared to most other competitive build<strong>in</strong>gproducts. A comparison of process<strong>in</strong>g energy used to manufacture cladd<strong>in</strong>g materials is provided <strong>in</strong>table 3Table 3: Process energy for various cladd<strong>in</strong>gsCladd<strong>in</strong>g MaterialProcess<strong>in</strong>g Energy(mJ/m 2 )19mm timber weatherboards 9012mm plywood 114150mm concrete blocks 3000.6mm galvanised steel sheet 308100mm bricks 100010

<strong>Plywood</strong> Exterior Cladd<strong>in</strong>gPreservative treated structural or exteriorplywood applied direct to studs as exteriorcladd<strong>in</strong>g can provide a cost efficient,modern architectural look for the mostbasic or elaborate build<strong>in</strong>g project.Significant costs sav<strong>in</strong>gs are possible if thecladd<strong>in</strong>g is structural plywood as it can alsoact as brac<strong>in</strong>g to protect the structure fromw<strong>in</strong>d and earthquake forces. In addition tobrac<strong>in</strong>g the structure, structural plywoodcladd<strong>in</strong>g provides tie down of the top plateto the bottom plate aga<strong>in</strong>st w<strong>in</strong>d uplift-refer to the EWPAA “Structural <strong>Plywood</strong> Wall Brac<strong>in</strong>g Manual” for details, available from theEWPAA Web Site. Additional cost sav<strong>in</strong>g can be made with structural plywood clad fram<strong>in</strong>g fromelim<strong>in</strong>at<strong>in</strong>g the need to use a ribbon top plate to strengthen the top plate for trusses or rafters thatdon’t co<strong>in</strong>cide with the stud location.Durability RequirementsThe two most important characteristics forguaranteed long term performance ofplywood as exterior cladd<strong>in</strong>g are treatmentaga<strong>in</strong>st fungal and <strong>in</strong>sect attack, and thepanel be manufactured with permanentType A bonds. The preservation treatmentshould be a m<strong>in</strong>imum of hazard level H3“outdoors above ground” as def<strong>in</strong>ed byAS/NZS1604.3. The preservative treatmentcurrently available are Ruply andAmmoniacial Copper QuaternaryCompounds (ACQ) , veneer treatmentsystems, and a number of pressuretreatments for f<strong>in</strong>ished panels, <strong>in</strong>clud<strong>in</strong>gCopper Chrome Arsenate (CCA) and LightOrganic Solvent Preservatives (LOSP) .Structural plywood to AS/NZS2269 has a Type A bond, and exterior plywood to AS/NZS2271 can beordered with Type A bonds. For maximum cost effectiveness it is good practice to use structuralplywood as a wall brac<strong>in</strong>g as well as cladd<strong>in</strong>g.For maximum long term performance to exposed face of the plywood cladd<strong>in</strong>g should be f<strong>in</strong>ishedwith a water repellent or a 100% acrylic latex pa<strong>in</strong>t system. Additionally, the edges of the plywoodpanel should be sealed to m<strong>in</strong>imise water uptake <strong>in</strong> the end gra<strong>in</strong>. The edge seal<strong>in</strong>g can be doneus<strong>in</strong>g a water repellent or the same primer used on the face, and is most readily applied while theplywood is <strong>in</strong> a pack, before <strong>in</strong>stallation. Some plywood cladd<strong>in</strong>g products presently available <strong>in</strong> themarketplace have a mach<strong>in</strong>ed or textured face veneer which provides a good surface to hold pa<strong>in</strong>t,11

educes and disguises any surface check<strong>in</strong>g of the face veneer effectively by dispers<strong>in</strong>g or reflect<strong>in</strong>gthe <strong>in</strong>cidence of solar radiation.InstallationTypically, plywood cladd<strong>in</strong>gproducts are manufactured to suit1200mm cover with shiplapped orother mach<strong>in</strong>es jo<strong>in</strong>ts, thus thestuds need to be at 600mm or400mm centres. These shiplapjo<strong>in</strong>ts allow for some panelmovement. If square edged panelsare used, leave a 2-3mm gapbetween jo<strong>in</strong>ts on studs toaccommodate panel movement dueto moisture changes.The length of standard plywood cladd<strong>in</strong>g products available are 2440mm, 2700mm, 2745mm with3050mm sheets hav<strong>in</strong>g limited availability. Other panel sizes are available subject to specialenquiry.<strong>Plywood</strong> cladd<strong>in</strong>gs are normally <strong>in</strong>stalled vertically, but may also be placed horizontally (i.e. longdimension across the studs) if horizontal studs are nogged and detailed to prevent water <strong>in</strong>gressthrough the jo<strong>in</strong>ts. Nogg<strong>in</strong>gs are not required for vertical <strong>in</strong>stallation of plywood cladd<strong>in</strong>g, unless itis under a horizontal jo<strong>in</strong>t. The m<strong>in</strong>imum plywood thickness for external cladd<strong>in</strong>g are given <strong>in</strong> table4 , and the m<strong>in</strong>imum recommended fastener sizes are given <strong>in</strong> table 5.<strong>Plywood</strong>Stress GradeTable 4: M<strong>in</strong>imum plywood thickness (mm) for external cladd<strong>in</strong>gStud Spac<strong>in</strong>g (mm)<strong>Plywood</strong> face gra<strong>in</strong> runn<strong>in</strong>g <strong>Plywood</strong> face gra<strong>in</strong> runn<strong>in</strong>gverticallyhorizontally400/450 600 900 400/450 600 900F11 12 12 17 8 8 12F14 12 12 16 7 7 12Table 5: m<strong>in</strong>imum recommended fastener sizes<strong>Plywood</strong> Thickness Up to 7mm Up to 21mmNails to timber 2.8mm dia x 40mm 2.8mm dia x 50mmScrews to timber No.8 x 30mm No.8 x 40mmScrews to steel No.10 x 45mm No.10 x 45mmNotes:1. Nails are flathead, and screws are self drill<strong>in</strong>g countersunk head.2. Fasteners must be no-sta<strong>in</strong><strong>in</strong>g and corrosion protected. For some applications sta<strong>in</strong>less steelor silicon bronze fasteners may be required.12

It is essential <strong>in</strong> plywood cladd<strong>in</strong>g <strong>in</strong>stallation that all jo<strong>in</strong>ts are weatherproofed us<strong>in</strong>g shiplappedjo<strong>in</strong>ts, battened jo<strong>in</strong>ts, caulk<strong>in</strong>g, flash<strong>in</strong>g timber or elastomeric sealants. Shiplap jo<strong>in</strong>ts are best<strong>in</strong>stalled fac<strong>in</strong>g away from the prevail<strong>in</strong>g weather. The use of sisalation or build<strong>in</strong>g paper isoptional, however, when butt or horizontal jo<strong>in</strong>ts are utilised, or the fram<strong>in</strong>g is steel, the use of thisextra protection is recommended. Where used, sisalation must be of the vapour permeable type.To allow for movement <strong>in</strong> the panel due to excessive wett<strong>in</strong>g dur<strong>in</strong>g ra<strong>in</strong>y periods, a 2-3mm gapmust be provided at all panel edges.Brac<strong>in</strong>g Resistance of<strong>Plywood</strong> Exterior Cladd<strong>in</strong>g<strong>Plywood</strong> cladd<strong>in</strong>g fixed to timberstud walls, <strong>in</strong> accordance with allof the requirements of theEWPAA “Structural <strong>Plywood</strong> WallBrac<strong>in</strong>g Manual” (available fromthe EWPAA Web Site) willprovide, depend<strong>in</strong>g on spac<strong>in</strong>g’sand connection to the sub floor,from 3.0kN/m of brac<strong>in</strong>gresistance per 900mm of cladwall length.13

Typical Jo<strong>in</strong>t Details for <strong>Plywood</strong> Exterior Cladd<strong>in</strong>gVertical Jo<strong>in</strong>t DetailsHorizontal Jo<strong>in</strong>t Details14

Corner Jo<strong>in</strong>t Details15

F<strong>in</strong>ish<strong>in</strong>gThe plywood surface must be protected to avoid mechanical breakdown (surface check<strong>in</strong>g) andmaximise its appearance and durability. High quality oil based exterior wood sta<strong>in</strong>s or 100% acryliclatex pa<strong>in</strong>t systems are recommended. Always use a reputable pa<strong>in</strong>t brand as cheaper alternativesdo not always perform. Light colours are recommended <strong>in</strong> preference to darker colours as they givesuperior performance. In humid areas where mould may grow on the pa<strong>in</strong>t surface the use ofquality mouldicide <strong>in</strong> the pa<strong>in</strong>t is recommended.16

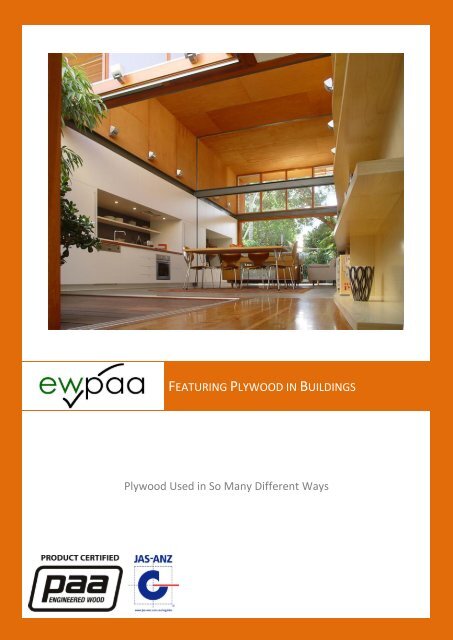

<strong>Plywood</strong> Interior Wall & Ceil<strong>in</strong>g L<strong>in</strong><strong>in</strong>g<strong>Plywood</strong> with a high quality real wood face veneer can be clear f<strong>in</strong>ished to give a real timberappearance to walls, to ceil<strong>in</strong>gs or as an eaves l<strong>in</strong><strong>in</strong>g on verandahs. The plywood face can betraditional rotary peeled or sliced veneer. Alternatively, the plywood can be V grooved thus prov<strong>in</strong>ga l<strong>in</strong><strong>in</strong>g hav<strong>in</strong>g a traditional planked effect to V jo<strong>in</strong>ted boards.<strong>Plywood</strong> SpecificationIf the l<strong>in</strong><strong>in</strong>g is designed to have a secondaryas a brac<strong>in</strong>g or a structural diaphragm theplywood must be structural plywood toAS/NZS2269. However, for non structurall<strong>in</strong><strong>in</strong>g applications completely protected fromthe weather any plywood product withappropriate face veneer is acceptable. Theplywood must be manufactured to am<strong>in</strong>imum of AS/NZS2270.The appearance of decorative veneer variesconsiderably depend<strong>in</strong>g on species, timbersource and the method of veneer<strong>in</strong>g andplywood manufacturer. Most plywood l<strong>in</strong><strong>in</strong>g<strong>in</strong> the marketplace has attractive rotarypeeled p<strong>in</strong>e veneer faces; however, somesliced veneers are available and can bespecially matched for colour and figure. Theface veneers are sanded smooth ready forthe selected surface f<strong>in</strong>ish. The back side ofthe decorative plywood normally is nondecorativeand is of reduced quality.For ceil<strong>in</strong>gs, 9mm and 12mm plywood l<strong>in</strong><strong>in</strong>gsare available with tongued and groovededges to negate the need for nogg<strong>in</strong>g underthe panel sides. If square edged panels areused fram<strong>in</strong>g is required to support all edges.Recommended m<strong>in</strong>imum plywood thicknesses are given <strong>in</strong> table 6. Standard panel size is 2400mmx 1200mm. 2700mm x 1200mm panels are not as readily available.InstallationTo m<strong>in</strong>imise shr<strong>in</strong>kage or expansion of panels after <strong>in</strong>stallation, it is good practice to let theplywood panels acclimatise to room temperature and humidity for several days before f<strong>in</strong>al fix<strong>in</strong>g.This is best achieved by break<strong>in</strong>g open the packs and lay<strong>in</strong>g out the panels to allow air to circulatearound them.17

Wall l<strong>in</strong><strong>in</strong>gs may be fixed to the wall fram<strong>in</strong>g withstructural elastomeric adhesives and/or panelp<strong>in</strong>s. Ceil<strong>in</strong>g l<strong>in</strong><strong>in</strong>g panels must be <strong>in</strong>stalled withthe face gra<strong>in</strong> runn<strong>in</strong>g across or at right angles tothe ceil<strong>in</strong>g battens. For ceil<strong>in</strong>g panels the nailsused normally have flat heads, or the screws havecountersunk heads, to avoid head pull through.<strong>Wood</strong> coloured putty can be used to stop fastenerholes if required. Alternatively, the use of siliconebronze, copper or copper coloured flathead nailsor countersunk screws can look very effective <strong>in</strong>clear f<strong>in</strong>ished timber.If the plywood l<strong>in</strong><strong>in</strong>g is fixed to exterior masonry walls, battens are recommended and the masonrywall must be waterproofed. Waterproof<strong>in</strong>g can be achieved by us<strong>in</strong>g a polythene vapour barrier.<strong>Plywood</strong> Thickness and Support Spac<strong>in</strong>g’sTable 6: Recommended m<strong>in</strong>imum plywood thickness and support spac<strong>in</strong>g’sStud/support spac<strong>in</strong>g (mm) Wall L<strong>in</strong><strong>in</strong>g Ceil<strong>in</strong>g l<strong>in</strong><strong>in</strong>g450 4mm 6mm600 6mm 6mm900 9mm1200 12mmNote: for ceil<strong>in</strong>g l<strong>in</strong><strong>in</strong>g the face gra<strong>in</strong> must run across the span.18

Brac<strong>in</strong>g Resistance of <strong>Plywood</strong> Wall L<strong>in</strong><strong>in</strong>gStructural plywood wall l<strong>in</strong><strong>in</strong>g of a m<strong>in</strong>imum 6mm thick F11 (<strong>in</strong>clud<strong>in</strong>g panels grooved at 100mmcentres), fixed to timber and stud walls <strong>in</strong> accordance with Table 7 can provide brac<strong>in</strong>g resistanceaga<strong>in</strong>st w<strong>in</strong>d and earthquakes. The bullet head nails may be punched just below the plywoodsurface.Table 7: Limit State Brac<strong>in</strong>g Resistance of Structural <strong>Plywood</strong> Wall L<strong>in</strong><strong>in</strong>g (6mm F11 m<strong>in</strong>imum)Fix<strong>in</strong>g DetailsNailed at 100mm centres around all edges and butt jo<strong>in</strong>ts and at200mm on the <strong>in</strong>termediate studsGlued along all edges and <strong>in</strong>termediate supports with a cont<strong>in</strong>uous6mm bead of elastomeric adhesive and nailed at 200mm centresBrac<strong>in</strong>g Resistance2.1kN/m5.3kN/mNotes:1. Nails a m<strong>in</strong>imum of 2.5mm diameter x 40mm bullet head.2. Studs spaced at a maximum of 600mm centres.3. Structural elastomeric adhesive that meets American <strong>Plywood</strong> Association Standard AFG-01.4. Brac<strong>in</strong>g Resistance applies to panels a m<strong>in</strong>imum of 900mm width and a maximum wall heightof 2700mm.5. Fix<strong>in</strong>g of the bottom plate to the sub-floor can be nom<strong>in</strong>al nail<strong>in</strong>g for the 2.1 kN/m system butfor the 5.3kN/m system the fix<strong>in</strong>g must be strapped or bolted at a m<strong>in</strong>imum of 1200mmcentres as detailed <strong>in</strong> the EWPAA “Structural <strong>Plywood</strong> Wall Brac<strong>in</strong>g Manual” which is availablefrom the EWPAA Web Site.F<strong>in</strong>ish<strong>in</strong>gHigh quality pa<strong>in</strong>ts, sta<strong>in</strong>s, or clearf<strong>in</strong>ishes are recommended for plywoodl<strong>in</strong><strong>in</strong>gs. T<strong>in</strong>ted clear f<strong>in</strong>ishes e.g. lim<strong>in</strong>ggrey, allow decorators to create amodern coloured key timber décor.The use of high gloss f<strong>in</strong>ishes andpa<strong>in</strong>ts tend to highlight naturallyoccurr<strong>in</strong>g and manufactur<strong>in</strong>gcharacteristics of plywood such aschanges <strong>in</strong> gra<strong>in</strong> and beat marks fromthe sand<strong>in</strong>g. Matt f<strong>in</strong>ishes and pa<strong>in</strong>tsare recommended to provide a naturaltimber f<strong>in</strong>ish.19

Lightweight Roof<strong>in</strong>g SystemT&G structural plywood <strong>in</strong> comb<strong>in</strong>ation with sh<strong>in</strong>gles or overlayed waterproof membranes canprovide a safe, lightweight, flat or curved roof system <strong>in</strong> residential, light commercial and <strong>in</strong>dustrialbuild<strong>in</strong>gs. Thickness/span details for a structural, non-trafficable plywood roof system to supportlightweight roof<strong>in</strong>g are given <strong>in</strong> table 9. If the roof is to be trafficable, then the plywood must betreated as a floor and design data sourced from the EWPAA design manual “T&G Structural<strong>Plywood</strong> for Residential Floor<strong>in</strong>g” available from the EWPAA Web Site. The T&G plywood providesa structural diaphragm and elim<strong>in</strong>ates the need for other forms of brac<strong>in</strong>g <strong>in</strong> the roof system. Thedesign of plywood diaphragms is covered <strong>in</strong> Appendix J of AS/NZS1720.1 Timber Structure Code.Installation of Structural <strong>Plywood</strong> Roof<strong>in</strong>g System<strong>Plywood</strong> SpecificationThe plywood to be used is CD or DD grade T&G structural plywood to AS/NZS2269. Specialised T&Gplywood with a decorative underside, usually V grooved to give a planked effect, can be used as acomb<strong>in</strong>ed structural roof and decorative ceil<strong>in</strong>g. Square edged plywood can be used but will requirenogg<strong>in</strong>g under the side jo<strong>in</strong>ts.Roof<strong>in</strong>g OverlayThe roof<strong>in</strong>g overlay must be waterproof and durable. It may be decorated asphalt or fibreglasssh<strong>in</strong>gles, timber shakes or sh<strong>in</strong>gles, rubber, acrylic or bitumen membranes or metal tiles or deck<strong>in</strong>g.InstallationThe two major requirements for the T&G structural plywood are the face must run across i.e.perpendicular to, the rafters or trusses, and the plywood must be cont<strong>in</strong>uous over two or morespans. The plywood should be <strong>in</strong>stalled with 2-3mm gap at all sheet edges, the appropriate fix<strong>in</strong>gsare given <strong>in</strong> Table 8, and the m<strong>in</strong>imum plywood thickness relative to truss or rafter spac<strong>in</strong>g arelisted <strong>in</strong> Table 9.20

Table 8: Fix<strong>in</strong>g of T&G Structural <strong>Plywood</strong> to Non Trafficable RoofsDesign speed(permissibleStress)33 metres/second41 metres/secondNon CyclonicM<strong>in</strong>imum Fastener2.8mm dia. X 50mmFlathead NailsNo. 8 x 40mmCountersunk selfdrill<strong>in</strong>g wood screws3.05mm dia. X 50mmFlathead NailsNo.8 x 40mmCountersunk selfdrill<strong>in</strong>g wood screwsFastener Spac<strong>in</strong>g at End and Intermediate Supports (mm)General roofs areasWith<strong>in</strong> 1200mm of RoofPerimeters150 100150 100100(for 1200mm spans)150(for 900mm & 800mm spans)50(for 1200mm spans)75( for 900 & 800mm spans)150 100Notes:1. The above fix<strong>in</strong>gs are applicable to timber species with jo<strong>in</strong>t strength J4 and JD4 and to plywood up to21mm <strong>in</strong> thickness.2. For higher w<strong>in</strong>d speeds or cyclone sites fix<strong>in</strong>gs are to be designed for uplift <strong>in</strong> accordance withAS/NZS1170.2 “w<strong>in</strong>d actions”.Table 9: Allowable structural plywood thickness and rafter spac<strong>in</strong>g for plywood non-trafficableroofs support<strong>in</strong>g light weight roof<strong>in</strong>g systems (20kg/m 2 max.)Rafter or TrussSpac<strong>in</strong>g (mm)M<strong>in</strong>imum Allowable <strong>Plywood</strong> Thickness (mm)F8 F11 F14800 13 12 12900 16 15 151200 19 17 1621

Revision HistoryRevision Changes Date Who5 Fixed a m<strong>in</strong>or error <strong>in</strong> the table of the curv<strong>in</strong>g plywood section 28-10-13 MB4 Updated logos and member list 07-02-12 MB Updated to <strong>in</strong>clude latest JAS-ANZ Logos3.0 Fixed miss<strong>in</strong>g fastener description for <strong>in</strong>stallation of exteriorcladd<strong>in</strong>g. Reformatted.2.0 Updated several pictures. Updated Fire resistance <strong>in</strong>formation1.0 Initial Release18-12-08 MB28-10-08 MB22

EWPAA Members<strong>Plywood</strong> and Lam<strong>in</strong>ated Veneer Lumber (LVL)Member Name Location Phone Fax WebAusply NSW +61 2 6926 7300 +61 2 6922 7824 www.ausply.comAustral <strong>Plywood</strong>s Pty Ltd QLD +61 7 3426 8600 +61 7 3848 0646 www.australply.com.auBig River Group Pty Ltd NSW +61 2 6644 0900 +61 2 6643 3328 www.bigrivergroup.com.auCarter Holt Harvey <strong>Wood</strong>products Australia(<strong>Plywood</strong>) – MyrtlefordVIC +61 5751 9201 +61 3 5751 9296 www.chhwoodproducts.com.auCarter Holt Harvey <strong>Wood</strong>products Australia –Nangwarry LVLSA +61 8 8739 7011 www.chhwoodproducts.com.auCarter Holt Harvey <strong>Wood</strong>products - MarsdenPo<strong>in</strong>t LVLNZ +64 9 432 8800 +64 9 432 8830 www.chhfuturebuild.co.nzCarter Holt Harvey <strong>Wood</strong>products (<strong>Plywood</strong>) -TokoroaNZ +64 7 885 5999 +64 7 885 5614 www.chhwoodproducts.co.nzFiji Forest Industries FIJI +67 9 881 1088 +67 9 881 3088IPL (West Coast) Ltd NZ +64 3 762 6759 +64 3 762 6789Juken New Zealand Ltd (Gisborne) NZ +64 6 869 1100 +64 6 869 1130 www.jnl.co.nzJuken New Zealand Ltd (Wairarapa) NZ +64 6 370 0650 +64 6 370 0653 www.jnl.co.nzNelson P<strong>in</strong>e Industries Ltd NZ +64 3 543 8800 +64 3 543 8890 www.nelsonp<strong>in</strong>e.co.nzPNG Forest <strong>Products</strong> Ltd PNG +67 5 472 4944 +67 5 472 6017 www.pngfp.comRH (PNG) Ltd PNG +67 5 325 5600 +67 5 325 6165 www.rhpng.com.pgValebasoga Tropikboards Ltd FIJI +67 9 881 4286 +67 9 881 4154Wesbeam Pty Ltd WA +61 8 9306 0400 +61 8 9306 0444 www.wesbeam.comParticleboard and MDFMember Name Location Phone Fax WebAlp<strong>in</strong>e MDF Industries Pty Ltd VIC +613 5721 3522 +61 3 5721 3588 www.alp<strong>in</strong>emdf.com.auBorg Panels Pty Ltd NSW + 61 2 6339 6111 + 61 2 6339 6220 www.borgs.com.auCarter Holt Harvey <strong>Wood</strong>products Australia NSW 1800 891 881 +61 2 9468 5793 www.chhwoodproducts.com.auD & R Henderson Pty Ltd NSW +612 4577 4033 +61 2 4577 4759 www.drhenderson.com.auLam<strong>in</strong>ex VIC + 61 9848 4811 www.thelam<strong>in</strong>exgroup.com.auTasmanian <strong>Wood</strong> Panels (Aust) TAS +613 9460 7766 +61 3 9460 7268Weathertex Pty Ltd NSW 1800 040 080 www.weathertex.com.auVisit the EWPAA Website to get the latest <strong>in</strong>formation. www.ewp.asn.auVisit www.ewp.asn.au/register to ensure your products carry genu<strong>in</strong>e EWPAA certification23