Extrusion of starch-based loose-fill packaging foams - ResearchGate

Extrusion of starch-based loose-fill packaging foams - ResearchGate

Extrusion of starch-based loose-fill packaging foams - ResearchGate

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

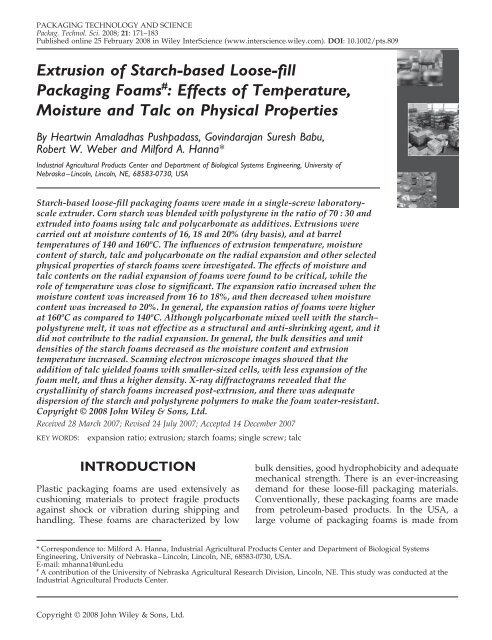

PACKAGING TECHNOLOGY AND SCIENCEPackag. Technol. Sci. 2008; 21: 171–183Published online 25 February 2008 in Wiley InterScience (www.interscience.wiley.com). DOI: 10.1002/pts.809<strong>Extrusion</strong> <strong>of</strong> Starch-<strong>based</strong> Loose-<strong>fill</strong>Packaging Foams # : Effects <strong>of</strong> Temperature,Moisture and Talc on Physical PropertiesBy Heartwin Amaladhas Pushpadass, Govindarajan Suresh Babu,Robert W. Weber and Milford A. Hanna*Industrial Agricultural Products Center and Department <strong>of</strong> Biological Systems Engineering, University <strong>of</strong>Nebraska – Lincoln, Lincoln, NE, 68583-0730, USAStarch-<strong>based</strong> <strong>loose</strong>-<strong>fill</strong> <strong>packaging</strong> <strong>foams</strong> were made in a single-screw laboratoryscaleextruder. Corn <strong>starch</strong> was blended with polystyrene in the ratio <strong>of</strong> 70 : 30 andextruded into <strong>foams</strong> using talc and polycarbonate as additives. <strong>Extrusion</strong>s werecarried out at moisture contents <strong>of</strong> 16, 18 and 20% (dry basis), and at barreltemperatures <strong>of</strong> 140 and 160ºC. The influences <strong>of</strong> extrusion temperature, moisturecontent <strong>of</strong> <strong>starch</strong>, talc and polycarbonate on the radial expansion and other selectedphysical properties <strong>of</strong> <strong>starch</strong> <strong>foams</strong> were investigated. The effects <strong>of</strong> moisture andtalc contents on the radial expansion <strong>of</strong> <strong>foams</strong> were found to be critical, while therole <strong>of</strong> temperature was close to significant. The expansion ratio increased when themoisture content was increased from 16 to 18%, and then decreased when moisturecontent was increased to 20%. In general, the expansion ratios <strong>of</strong> <strong>foams</strong> were higherat 160ºC as compared to 140ºC. Although polycarbonate mixed well with the <strong>starch</strong>–polystyrene melt, it was not effective as a structural and anti-shrinking agent, and itdid not contribute to the radial expansion. In general, the bulk densities and unitdensities <strong>of</strong> the <strong>starch</strong> <strong>foams</strong> decreased as the moisture content and extrusiontemperature increased. Scanning electron microscope images showed that theaddition <strong>of</strong> talc yielded <strong>foams</strong> with smaller-sized cells, with less expansion <strong>of</strong> thefoam melt, and thus a higher density. X-ray diffractograms revealed that thecrystallinity <strong>of</strong> <strong>starch</strong> <strong>foams</strong> increased post-extrusion, and there was adequatedispersion <strong>of</strong> the <strong>starch</strong> and polystyrene polymers to make the foam water-resistant.Copyright © 2008 John Wiley & Sons, Ltd.Received 28 March 2007; Revised 24 July 2007; Accepted 14 December 2007KEY WORDS: expansion ratio; extrusion; <strong>starch</strong> <strong>foams</strong>; single screw; talcINTRODUCTIONPlastic <strong>packaging</strong> <strong>foams</strong> are used extensively ascushioning materials to protect fragile productsagainst shock or vibration during shipping andhandling. These <strong>foams</strong> are characterized by lowbulk densities, good hydrophobicity and adequatemechanical strength. There is an ever-increasingdemand for these <strong>loose</strong>-<strong>fill</strong> <strong>packaging</strong> materials.Conventionally, these <strong>packaging</strong> <strong>foams</strong> are madefrom petroleum-<strong>based</strong> products. In the USA, alarge volume <strong>of</strong> <strong>packaging</strong> <strong>foams</strong> is made from* Correspondence to: Milford A. Hanna, Industrial Agricultural Products Center and Department <strong>of</strong> Biological SystemsEngineering, University <strong>of</strong> Nebraska – Lincoln, Lincoln, NE, 68583-0730, USA.E-mail: mhanna1@unl.edu#A contribution <strong>of</strong> the University <strong>of</strong> Nebraska Agricultural Research Division, Lincoln, NE. This study was conducted at theIndustrial Agricultural Products Center.Copyright © 2008 John Wiley & Sons, Ltd.

EXTRUSION OF STARCH FOAMSPackaging Technologyand ScienceRelative Intensity1000090008000700060005000400030002000100000 5 10 15 20 25 30 35 40Angle 2Figure 9. X-ray diffractograms <strong>of</strong>: (a) native corn <strong>starch</strong>;(b) PS; and (c) <strong>starch</strong>-PS foam.cabConcentration <strong>of</strong> CO2,%6.005.004.003.002.001.000.000 6 12 18 24 30 36Time, daysFigure 10. Aerobic biodegradation <strong>of</strong> <strong>starch</strong>–PS <strong>foams</strong>extruded from <strong>starch</strong> containing (a) 16% moistureand (b) 18% moisture.abcrystalline regions were from PS. Therefore, fromthe loss <strong>of</strong> the characteristic <strong>starch</strong> pattern and thegain in crystallinity in the extruded <strong>foams</strong>, it wasconcluded that <strong>starch</strong> and PS formed a homogenousand well-grafted matrix during extrusion.This fact could be strengthened from the separatetests done for the water absorption and watersolubility indices <strong>of</strong> the <strong>foams</strong>, which indicatedthat the <strong>starch</strong>-<strong>based</strong> <strong>foams</strong> were highly waterresistant,making them suited for <strong>loose</strong>-<strong>fill</strong> <strong>packaging</strong>applications. It is evident that the <strong>starch</strong> <strong>foams</strong>were made hydrophobic due to the addition <strong>of</strong> PSand by the proper binding between the two polymers.These results vindicated the addition <strong>of</strong> 30%PS to <strong>starch</strong> to make the <strong>starch</strong> foam water-resistant.However, it would be interesting to knowhow far the PS content can be reduced withoutcompromising the hydrophobicity and otherdesired physical or mechanical properties <strong>of</strong> the<strong>foams</strong>.BiodegradabilityThe generation <strong>of</strong> CO 2 from the compost is presentedin Figure 10. It can be seen that the CO 2emitted reached a peak value before starting todecrease, regardless <strong>of</strong> the (sample) extrusion conditions.At the end <strong>of</strong> 30 days, the CO 2 productionreached a plateau, suggesting that the <strong>foams</strong> haddecomposed biologically. Foams made from <strong>starch</strong>containing 16% moisture content had a minimumsurface area due to reduced radial expansion, andhence took longer to reach the peak degradationrate. At the end <strong>of</strong> composting, the <strong>foams</strong> had afibrous and crumbly texture, presumably consisting<strong>of</strong> only PS. Pure PS is supposed to have ahalf-life period <strong>of</strong> 400–1000 years. However, thestructural rigidity <strong>of</strong> PS was lost due to the transformationsinside the extruder. It is presumed thatthe PS remaining in the compost will degrademuch faster, owing to the increased surface area(due to extrusion expansion) to degradation, aswell as the loss <strong>of</strong> structural rigidity.CONCLUSIONSWater-resistant <strong>starch</strong>-<strong>based</strong> <strong>foams</strong> can be preparedby replacing 70% PS with a <strong>starch</strong> biopolymer.The specific independent variables selected toevaluate the <strong>foams</strong> in this study were chosen asa result <strong>of</strong> discussions <strong>of</strong> the most critical foamproperties during commercialization activities.The expansion ratio and densities <strong>of</strong> the <strong>starch</strong><strong>foams</strong> depended on the initial moisture content,extrusion temperature and talc content. However,the effects <strong>of</strong> moisture content and talc on theradial expansion and densities <strong>of</strong> the <strong>foams</strong> weredominant over extrusion temperatures. SEMimages showed an increase in cell size with theincrease in moisture content <strong>of</strong> <strong>starch</strong>. In contrast,Copyright © 2008 John Wiley & Sons, Ltd. 181 Packag. Technol. Sci. 2008; 21: 171–183DOI: 10.1002/pts

Packaging Technologyand Scienceupon the addition <strong>of</strong> talc, the radial expansiondecreased, and the density <strong>of</strong> the <strong>foams</strong> increased.In general, 18% moisture content and 1% talc at anextrusion temperature <strong>of</strong> 160ºC was found to beoptimum for obtaining the maximum radial expansionand desirable physical properties <strong>of</strong> the <strong>foams</strong>.Polycarbonate did not affect the radial expansionor the physical properties <strong>of</strong> the <strong>foams</strong>. Hence, theuse <strong>of</strong> polycarbonate as a structural and antishrinkingagent is not recommended in the extrusion<strong>of</strong> <strong>starch</strong>-<strong>based</strong> <strong>foams</strong>. The loss <strong>of</strong> the peaks<strong>of</strong> native <strong>starch</strong> and the formation <strong>of</strong> new crystallineregions in <strong>starch</strong> <strong>foams</strong> indicated the fusion <strong>of</strong><strong>starch</strong> and PS in the extruded <strong>foams</strong>. The <strong>starch</strong><strong>foams</strong> are recommended for <strong>loose</strong>-<strong>fill</strong> <strong>packaging</strong>applications due to their better biodegradability,hydrophobicity and comparable bulkdensity.ACKNOWLEDGEMENTSThe authors are grateful to Dr David Marx, pr<strong>of</strong>essor,Statistics Department <strong>of</strong> University <strong>of</strong> Nebraska – Lincoln,for formulating the fractional composite statisticaldesign to reduce the number <strong>of</strong> extrusion trials. Thisresearch paper is a contribution <strong>of</strong> the University <strong>of</strong>Nebraska Agricultural Research Division, supported inpart by funds provided through the Hatch Act. Mention<strong>of</strong> trade names, proprietary products or company namesis for presentation clarity and does not imply endorsementby the authors or the University <strong>of</strong> Nebraska.REFERENCES1. Miladinov VD, Hanna MA. Physical and molecularproperties <strong>of</strong> <strong>starch</strong> acetates extruded with waterand ethanol. Ind. Eng. Chem. Res. 1999; 38: 3892–3897.2. Fang Q, Hanna MA. Functional properties <strong>of</strong> polylacticacid <strong>starch</strong>-<strong>based</strong> <strong>loose</strong>-<strong>fill</strong> <strong>packaging</strong> <strong>foams</strong>.Cereal Chem. 2000; 77: 779–783.3. Bhatnagar S, Hanna MA. Physical, mechanical, andthermal properties <strong>of</strong> <strong>starch</strong>-<strong>based</strong> plastic <strong>foams</strong>.Trans. ASAE 1995; 38: 567–571.4. Hutchinson RJ, Siodlak GDE, Smith AC. Influence<strong>of</strong> processing variables on the mechanical properties<strong>of</strong> extruded maize. J. Mater. Sci. 1987; 22: 3956–3962.5. Wang L, Shogren RL. Preparation and properties <strong>of</strong>corn <strong>starch</strong>-<strong>based</strong> <strong>loose</strong>-<strong>fill</strong> <strong>foams</strong>. In Proceedings <strong>of</strong>the 6th Annual Meeting <strong>of</strong> the Bio/EnvironmentallyDegradable Polymer Society, St. Paul, MN, 1997.H. A. PUSHPADASS ET AL.6. Cha J, Chung DS, Seib PA. Effects <strong>of</strong> extrusion temperatureand moisture content on mechanical properties<strong>of</strong> <strong>starch</strong>-<strong>based</strong> <strong>foams</strong>. Trans. ASAE 1999; 42:1765–1770.7. Cha J, Chung DS, Seib PA. Rheological properties<strong>of</strong> blend melts for <strong>starch</strong>-<strong>based</strong> <strong>foams</strong> in extrusionprocessing. Trans. ASAE 1999; 42: 1801–1807.8. Guan J, Fang Q, Hanna MA. Functional properties<strong>of</strong> extruded <strong>starch</strong> acetate blends. J. Polym. Environ.2004; 12: 57–63.9. Nabar Y, Narayan R, Schindler M. Twinscrewextrusion production and characterization <strong>of</strong><strong>starch</strong>-foam products for use in cushioning andinsulation applications. Polym. Eng. Sci. 2006; 46:438–451.10. Bhatnagar S, Hanna MA. Starch-<strong>based</strong> plastic <strong>foams</strong>from various <strong>starch</strong> sources. Cereal Chem. 1996; 73:601–604.11. Chinnaswamy R, Hanna MA. Macromolecular andfunctional properties <strong>of</strong> native and extrusion-cookedcorn <strong>starch</strong>. Cereal Chem. 1990; 67: 490–499.12. Bhatnagar S, Hanna MA. <strong>Extrusion</strong> processing conditionsfor amylose-lipid complexing. Cereal Chem.1994; 71: 587–593.13. Zhou J, Hanna MA. Effects <strong>of</strong> the properties <strong>of</strong>blowing agents on the processing and performance<strong>of</strong> extruded <strong>starch</strong> acetate. J. Appl. Polym. Sci. 2005;97: 1880–1890.14. Hwang MP, Hayakawa KI. Bulk densities <strong>of</strong> cookiesundergoing commercial baking process. J. Food Sci.1980; 45: 1400–1402, 1407.15. Bhatnagar S, Hanna MA. Effect <strong>of</strong> Lipids on PhysicochemicalProperties <strong>of</strong> Extruded Corn Starch. ASAE(now ASABE) Paper No. 916541. St. Joseph, MI,1991.16. ASTM D5338-98. Standard test method for determiningaerobic biodegradation <strong>of</strong> plastic materialsunder controlled composting conditions. In AnnualBook <strong>of</strong> ASTM Standards. American Society forTesting and Materials: Philadelphia, PA, 2007;Section 8.03: 114–119.17. McLean RA, Anderson VL. Applied Factorialand Fractional Designs. Marcel Dekker: New York,1984.18. SAS. Proprietary S<strong>of</strong>tware Release v. 9.1, SAS Institute:Cary, NC, 2005.19. Chinnaswamy R, Hanna MA. Optimum extrusioncookingconditions for maximum expansion <strong>of</strong> corn<strong>starch</strong>. J. Food Sci. 1988; 53: 834–836, 840.20. Lin S, Huff HE, Hsieh F. <strong>Extrusion</strong> process parameters,sensory characteristics, and structural properties<strong>of</strong> a high moisture soy protein meat analog.J. Food Sci. 2002; 67: 1066–1072.21. Alvarez-Martinez L, Kondury KP, Harper JM. Ageneral model for expansion <strong>of</strong> extruded products.J. Food Sci. 1988; 53: 609–615.22. Faubion JM, Hoseney RC. High-temperature shorttimeextrusion cooking <strong>of</strong> wheat <strong>starch</strong> and flour. I.Effect <strong>of</strong> moisture and flour type on extrudateproperties. Cereal Chem. 1982; 59: 529–533.Copyright © 2008 John Wiley & Sons, Ltd. 182 Packag. Technol. Sci. 2008; 21: 171–183DOI: 10.1002/pts

EXTRUSION OF STARCH FOAMS23. Owusu-Ansah J, van de Voort FR, Stanley DW.Physicochemical changes in corn <strong>starch</strong> as a function<strong>of</strong> extrusion variables. Cereal Chem. 1983; 60:319–324.24. Guy R, Horne AW. <strong>Extrusion</strong> and co-extrusion <strong>of</strong>cereals. In Food Structure: Its Creation and Evaluation,Blanshard JMV, Mitchell JR (eds). Butterworths:London, 1988; 331–349.25. Mercier C, Feillet P. Modification <strong>of</strong> carbohydratecomponents by extrusion-cooking <strong>of</strong> cereal products.Cereal Chem. 1975; 52: 283–297.26. Colonna P, Tayeb J, Mercier C. <strong>Extrusion</strong> cooking <strong>of</strong><strong>starch</strong> and <strong>starch</strong>y products. In <strong>Extrusion</strong> Cooking,Mercier C, Linko P, Harper JM (eds). AACC: St.Paul, MN, 1989; 247–319.27. Blanche S, Sun X. Physical characterization <strong>of</strong> <strong>starch</strong>extrudates as a function <strong>of</strong> melting transitions andextrusion conditions. Adv. Polym. Technol. 2004; 23:277–290.28. Bhattacharya M, Hanna MA. Textural properties <strong>of</strong>extrusion-cooked corn <strong>starch</strong>. Lebensm.-Wiss. Technol.1987; 20: 195–201.29. Brummer T, Meuser F, van Lengerich B, NiemannC. Expansion and functional properties <strong>of</strong> corn<strong>starch</strong> extrudates related to their molecular degradation,product temperature and water content.Starch/Stärke 2002; 54: 9–15.30. Colonna P, Doublier JL, Melcion JP, de MonredonF, Mercier C. <strong>Extrusion</strong> cooking and drum drying <strong>of</strong>Packaging Technologyand Sciencewheat <strong>starch</strong>. I. Physical and macromolecular modifications.Cereal Chem. 1984; 61: 538–543.31. Choudhury GS, Gautam A. Screw configurationeffects on macroscopic characteristics <strong>of</strong> extrudatesproduced by twin-screw extrusion <strong>of</strong> rice flour.J. Food Sci. 1999; 64: 479–487.32. Kadan RS, Bryant RJ, Pepperman AB. Functionalproperties <strong>of</strong> extruded rice flours. J. Food Sci. 2003;68: 1669–1672.33. Yacu WA. Modeling a twin screw co-rotatingextruder. J. Food Eng. 1985; 8: 1–21.34. Lawton BT, Henderson GA, Derlatka EJ. The effects<strong>of</strong> extruder variables on gelatinization <strong>of</strong> corn <strong>starch</strong>.Can. J. Chem. Eng. 1972; 50: 168–172.35. Fan J, Mitchell JR, Blanshard JMV. The effect <strong>of</strong>sugars on the extrusion <strong>of</strong> maize grits. I. The role <strong>of</strong>the glass transition in determining product densityand shape. Int. J. Food Sci. Technol. 1996; 31: 55–65.36. Naguib HE, Park CB, Lee PC. Effect <strong>of</strong> talc contenton the volume expansion ratio <strong>of</strong> extruded pp <strong>foams</strong>.J. Cell. Plast. 2003; 39: 499–511.37. Xu Y, Hanna MA. Effect <strong>of</strong> eggshell powder asnucleating agent on the structure, morphology andfunctional properties <strong>of</strong> normal corn <strong>starch</strong> <strong>foams</strong>.Packag. Technol. Sci. 2007; 20: 165–172.38. Takamine K, Bhatnagar S, Hanna MA. Effect <strong>of</strong> eggshellon properties <strong>of</strong> corn <strong>starch</strong> extrudates. CerealChem. 1995; 72: 385–388.Copyright © 2008 John Wiley & Sons, Ltd. 183 Packag. Technol. Sci. 2008; 21: 171–183DOI: 10.1002/pts

![()] 1](https://img.yumpu.com/45117883/1/190x143/-1.jpg?quality=85)