MOV CHOKES - cedip

MOV CHOKES - cedip

MOV CHOKES - cedip

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

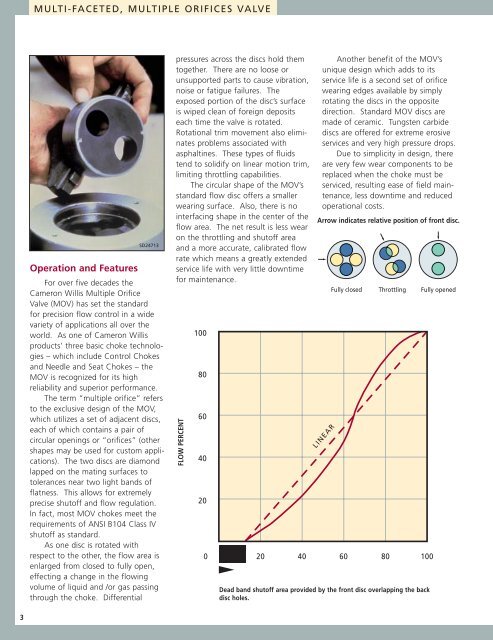

MULTI-FACETED, MULTIPLE ORIFICES VALVEOperation and FeaturesSD24713For over five decades theCameron Willis Multiple OrificeValve (<strong>MOV</strong>) has set the standardfor precision flow control in a widevariety of applications all over theworld. As one of Cameron Willisproducts’ three basic choke technologies– which include Control Chokesand Needle and Seat Chokes – the<strong>MOV</strong> is recognized for its highreliability and superior performance.The term “multiple orifice” refersto the exclusive design of the <strong>MOV</strong>,which utilizes a set of adjacent discs,each of which contains a pair ofcircular openings or “orifices” (othershapes may be used for custom applications).The two discs are diamondlapped on the mating surfaces totolerances near two light bands offlatness. This allows for extremelyprecise shutoff and flow regulation.In fact, most <strong>MOV</strong> chokes meet therequirements of ANSI B104 Class IVshutoff as standard.As one disc is rotated withrespect to the other, the flow area isenlarged from closed to fully open,effecting a change in the flowingvolume of liquid and /or gas passingthrough the choke. Differentialpressures across the discs hold themtogether. There are no loose orunsupported parts to cause vibration,noise or fatigue failures. Theexposed portion of the disc’s surfaceis wiped clean of foreign depositseach time the valve is rotated.Rotational trim movement also eliminatesproblems associated withasphaltines. These types of fluidstend to solidify on linear motion trim,limiting throttling capabilities.The circular shape of the <strong>MOV</strong>’sstandard flow disc offers a smallerwearing surface. Also, there is nointerfacing shape in the center of theflow area. The net result is less wearon the throttling and shutoff areaand a more accurate, calibrated flowrate which means a greatly extendedservice life with very little downtimefor maintenance.FLOW PERCENT100806040200Another benefit of the <strong>MOV</strong>’sunique design which adds to itsservice life is a second set of orificewearing edges available by simplyrotating the discs in the oppositedirection. Standard <strong>MOV</strong> discs aremade of ceramic. Tungsten carbidediscs are offered for extreme erosiveservices and very high pressure drops.Due to simplicity in design, thereare very few wear components to bereplaced when the choke must beserviced, resulting ease of field maintenance,less downtime and reducedoperational costs.Arrow indicates relative position of front disc.LINEARFully closedThrottling20 40 60 80 100Dead band shutoff area provided by the front disc overlapping the backdisc holes.Fully opened3