mechanical properties of recycled cfrp by injection ... - Takahashi

mechanical properties of recycled cfrp by injection ... - Takahashi

mechanical properties of recycled cfrp by injection ... - Takahashi

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

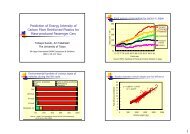

16 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALSMECHANICAL PROPERTIES OF RECYCLED CFRPBY INJECTION MOLDING METHODJun <strong>Takahashi</strong> *, Nobukuni Matsutsuka *, Tetsuya Okazumi *, Kiyoshi Uzawa *,Isamu Ohsawa *, Koji Yamaguchi ** and Akihiko Kitano *** Department <strong>of</strong> Environmental and Ocean Engineering, The University <strong>of</strong> Tokyo, Japan,** Toray Industries, Inc., JapanKeywords: CFRP, Recycle, Injection Molding, Crush, ABS, PPAbstractEnergy consumption <strong>of</strong> the running stage <strong>of</strong>automobiles can be drastically reduced <strong>by</strong>lightening their weight <strong>by</strong> CFRP (carbon fiberreinforced plastics). However, energy consumption<strong>of</strong> the CFRP manufacturing is so big to cancel theenergy saving <strong>of</strong> the running stage. To reduceenergy consumption and cost <strong>of</strong> CFRPmanufacturing, reuse <strong>of</strong> carbon fiber is the mosteffective. Then, the objective <strong>of</strong> this study is todevelop CFRTP (carbon fiber reinforcedthermoplastics) <strong>by</strong> using waste CFRP, and the target<strong>of</strong> the <strong>mechanical</strong> <strong>properties</strong> <strong>of</strong> the <strong>recycled</strong> CFRPis more than those <strong>of</strong> secondary structural parts <strong>of</strong>current automobile.1 IntroductionFor more than a century, population, foodproduction, industrial production, consumption <strong>of</strong>resources and pollution are all growing. Amongthem, we have been studying the increase <strong>of</strong> energyconsumption <strong>by</strong> car-orientated society [1-4]. Figure1 shows sectional energy consumption in the world.Comparing sectional energy consumption, that <strong>of</strong>transport sector has too much depended on oil for along time, and been increasing firmly. Consideringthe motorization <strong>of</strong> non-OECD countries, inespecially BRICs, it is easy to predict that energyconsumption <strong>of</strong> transport sector will more and moregrow from now on. For example, as shown in figure2, energy consumption in transport sector <strong>of</strong> Chinawill become equal level to the current world energyconsumption in transport sector in the future withoutany drastic measurement [3, 4]. So, we need todevelop effective measurements as soon as possible.Although fuel cell technology is now underdevelopment, it takes much time to be practicalapplication.From such a background, we have focused onlightening the weight <strong>of</strong> automobile <strong>by</strong> using CFRP(carbon fiber reinforced plastics). CFRP is used forthe aircraft or space field since their high specificstrength, specific rigidity and lightweight. Howevercurrent CFRP is not suitable to mass productionbecause <strong>of</strong> its high cost and recyclability [5]. In thispaper we investigated recyclability <strong>of</strong> CFRP formass production.2 Recycle Method in This StudyAs a method <strong>of</strong> CFRP recycling, heat recoveryand material recycling have been investigated, andmaterial recycling is better from a viewpoint <strong>of</strong> LCA(life cycle assessment) since carbon fiber should bereused as not just carbon but carbon fiber. Figure 3shows the energy intensity <strong>of</strong> parts manufacturing <strong>by</strong>using steel, CFRTS (carbon fiber reinforcedthermosetting resin) and CFRTP (carbon fiberreinforced thermoplastics) [6, 7]. As a result,recycling <strong>of</strong> CFRP contributes to reduce not onlywaste but life cycle energy consumption as shown infigure 4. Furthermore, considering that the cost <strong>of</strong><strong>recycled</strong> CFRP must be very cheap as shown infigure 3, establishment <strong>of</strong> the recycling technology<strong>of</strong> CFRP will drastically contribute to lower-pricing<strong>of</strong> CFRP products. Hence, the recycling technology<strong>of</strong> CFRP is indispensable in the mass-productionapplication, in especially passenger automobile, tocontribute global energy saving.As a method <strong>of</strong> taking out carbon fiber fromwaste CFRP, evaporation [8] and a chemicaldepolymerization <strong>of</strong> thermosetting resin [9] arereported as shown in figure 5. According to thesemethods, there is a possibility that a high1

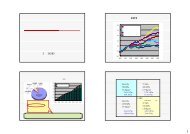

MECHANICAL PROPERTIES OF RECYCLED CFRP BY INJECTION MOLDING METHOD<strong>mechanical</strong> <strong>properties</strong> <strong>by</strong> using the <strong>injection</strong> moldedplates to understand an actual performance <strong>of</strong><strong>injection</strong> molded automotive parts. The <strong>injection</strong>gate <strong>of</strong> the metal mold <strong>of</strong> the panel is designed asone place so that anisotropy similar to actual<strong>injection</strong> molded parts might appear to the moldedpanels. Then, in order to examine the directional<strong>properties</strong>, flexural test specimens are cut out fromthese panels in both the direction <strong>of</strong> <strong>injection</strong> and thevertical direction.4 Experimental Results <strong>of</strong> Panel SpecimensThe size <strong>of</strong> the flexural test specimens werelength 80 mm * width 15 mm * thickness 3 mm, andthree points bending test and Izot impact energyabsorption test were performed. Five times testswere performed for every condition; thermoplasticswithout CF, longitudinal and transversal specimens<strong>of</strong> CFRTP with Vf = 30 % <strong>of</strong> fresh CF, longitudinaland transversal specimens <strong>of</strong> CFRTP with Vf = 7, 15,24 and 30 % <strong>of</strong> <strong>recycled</strong> CF.The result <strong>of</strong> these tests is summarized in figures7 and 8, where “F” means the specimen made <strong>by</strong>fresh CF, “L” means longitudinal specimen and “T”means transversal specimen, and the number meansvolume fraction <strong>of</strong> <strong>recycled</strong> CF respectively. Brittlefracture occurred in compressive side in everyspecimen.In the same manner, we investigated theinfluence <strong>of</strong> the repetition <strong>of</strong> recycling. RecycledCF/PP specimens whose fiber volume fraction is15 % were crushed and remolded <strong>by</strong> <strong>injection</strong>molding method to obtain the second, third andfourth <strong>recycled</strong> specimens. The results aresummarized in figures 9.5 Discussions5.1 JIS Standard SpecimensIn case <strong>of</strong> the flexural test shown in figure 6,there is little difference in <strong>mechanical</strong> <strong>properties</strong>between Fresh 30 and Recycle 30, hence thedegradation may be quite little in recycling process.In terms <strong>of</strong> the flexural strength, the specimens withthe fiber volume fraction <strong>of</strong> 24 % show higherstrength than those with the fiber volume fraction <strong>of</strong>30 %. It may be caused <strong>by</strong> the poor impregnation <strong>of</strong>thermoplastics into <strong>recycled</strong> CF in the cases that thefiber volume fraction is larger than 24 %. Then, theappropriate volume fraction at this recycle methodmay be around 24 % or less.In case <strong>of</strong> the tensile test, fresh material hadhighest <strong>mechanical</strong> property. Difference from theflexural test was that the fracture occurred at theweakest point <strong>of</strong> the specimen in tensile test. Andthe weak point may caused <strong>by</strong> the poor impregnation<strong>of</strong> thermoplastics into <strong>recycled</strong> CF.In case <strong>of</strong> the Izot impact energy absorption test,even in the CFRTP made <strong>by</strong> fresh CF, energyabsorption ability fell down drastically due to themixture <strong>of</strong> CF in thermoplastics.5.2 Specimens Cut Out From The InjectionMolded PanelAs shown in figures 7 (a) and 8 (a), a bigdifference between longitudinal and transversaldirection was shown especially in flexural modulus.The flexural modulus <strong>of</strong> longitudinal directionbecame large almost in proportion to the fibervolume fraction like JIS standard specimen, howeverthose <strong>of</strong> transversal direction showed low and almostconstant regardless <strong>of</strong> fiber volume fraction.Consequently, when the fiber volume fractionbecame larger, anisotropy became stronger.Furthermore, although the influence <strong>of</strong> fiber volumefraction on the flexural modulus <strong>of</strong> longitudinaldirection showed almost the same tendency as JISstandard specimens, the values were about 70 % <strong>of</strong>JIS standard specimens. This is because theanisotropy <strong>of</strong> JIS standard specimen was muchstronger.Although the failure strain <strong>of</strong> transversaldirection was larger than that <strong>of</strong> longitudinaldirection, there was not so much difference whichwas shown in flexural modulus. When the fibervolume fraction becomes smaller, failure strain <strong>of</strong>both transversal and longitudinal direction becomeslarger, which is the same tendency <strong>of</strong> JIS standardspecimens. However, it should be noted that eventhe failure strain <strong>of</strong> the longitudinal direction is morethan twice <strong>of</strong> the JIS standard specimens.As a result, like JIS standard specimens,recommended fiber volume fraction is about 24 %since a peak value <strong>of</strong> the strength was shown around24 %. However, since almost the same strengthholds to the fiber volume fraction <strong>of</strong> 15 %, <strong>recycled</strong>CFRTP with fiber volume fraction <strong>of</strong> about 15 % isalso recommended for a purpose <strong>of</strong> larger failurestrain if the rigidity is not so serious requirement.By the way, the strength <strong>of</strong> longitudinaldirection shows approximately 20 % smaller thanthat <strong>of</strong> JIS standard specimens. To a contrary,<strong>injection</strong> molded CF/PP parts whose fiber volumefraction is between 15 to 24 % are expected the3

Jun <strong>Takahashi</strong>, N. Matsutsuka, T. Okazumi, K. Uzawa, I. Ohsawa, K. Yamaguchi and A. KitanoFlexural modulus (GPa)2520151050Fresh 30 24 15 7ABS(a) Flexural modulusFlexuralmodulus(GPa)181614121086420FL FT30L30T24L24T15L15T7L 7TABS(a) Flexural modulusFlexural strength (MPa)200180160140120100806040200Fresh 30 24 15 7 ABS(b) Flexural strengthFlexuralstrength(MPa)180160140120100806040200FL FT30L30T24L24T15L15T7L 7T ABS(b) Flexural strengthFlexural strain (%)3.02.52.01.51.00.50.0Fresh 30 24 15 7 ABS(c) Flexural failure strainFlexuralfailurestrain(%)3.02.52.01.51.00.50.0FL FT 30L30T24L24T15L15T 7L 7T ABS(c) Flexural failure strainIZOD Impact energyabsorption (kJ/m 2 )140120100806040200Vf7 Vf15 Vf24 Vf30 Fresh ABS(d) Izod impact energy absorptionFig. 6. Flexural <strong>properties</strong> <strong>of</strong> the <strong>recycled</strong> CF/ABSJIS standard specimens.Izodimpactenergyabsorption(kJ/m 2 )8070605040302010030L 30T 24L 24T 15L 15T 7L(d) Izod impact energy absorption7T ABSFig. 7. Flexural <strong>properties</strong> <strong>of</strong> the <strong>recycled</strong> CF/ABSspecimens cut out from the <strong>injection</strong> molded plate.4

MECHANICAL PROPERTIES OF RECYCLED CFRP BY INJECTION MOLDING METHODFlexuralmodulus(GPa)18161412108642030L 30T 24L24T15L15T 7L 7T PP(a) Flexural modulusFlexuralmodulus(GPa)876543210F L F T 1 st L 1 st T 2 nd L 2 nd T 3 rd L 3 rd T 4 th L 4 th T(a) Flexural modulusFlexuralstrength(MPa)Flexuralfailurestrain(%)Izodimpactenergyabsorption(kJ/m 2 )12010080604020030L 30T 24L24T15L15T 7L 7T PP(b) Flexural strength7654321030L 30T 24L 24T15L 15T 7L 7T(c) Flexural failure strain35302520151050PP30L 30T 24L 24T 15L 15T 7L 7T PP(d) Izod impact energy absorptionFig. 8. Flexural <strong>properties</strong> <strong>of</strong> the <strong>recycled</strong> CF/PPspecimens cut out from the <strong>injection</strong> molded plate.Flexuralstrength(MPa)Flexuralfailurestrain(%)10090807060504030201003210Izodimpactenergyabsorption(kJ/m 2 )F L F T 1 st L 1 st T 2 nd L 2 nd T 3 rd L 3 rd T 4 th L 4 th T(b) Flexural strengthF L F T 1 st L 1 st T 2 nd L 2 nd T 3 rd L 3 rd T 4 th L 4 th T302520151050(c) Flexural failure strainF L F T 1 st L 1 st T 2 nd L 2 nd T 3 rd L 3 rd T 4 th L 4 th T(d) Izod impact energy absorptionFig. 9. Influence <strong>of</strong> the repetition <strong>of</strong> recycling on theflexural <strong>properties</strong> <strong>of</strong> the CF/PP.5