March 2003 - Trench Safety

March 2003 - Trench Safety

March 2003 - Trench Safety

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

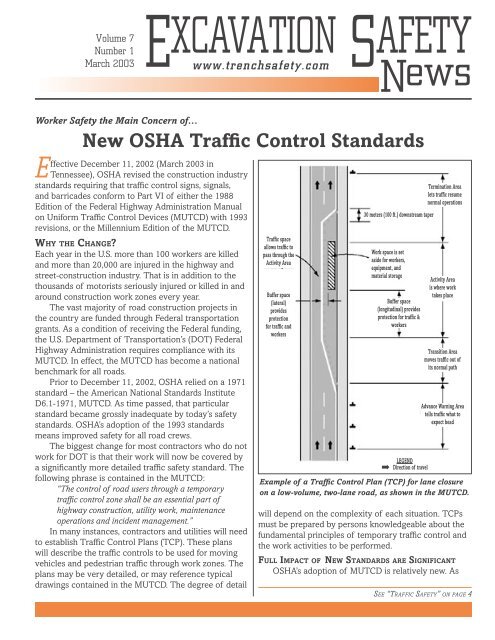

Volume 7Number 1<strong>March</strong> <strong>2003</strong>E XCAVATION S AFETYwww.trenchsafety.comNewsWorker <strong>Safety</strong> the Main Concern of…New OSHA Traffic Control StandardsEffective December 11, 2002 (<strong>March</strong> <strong>2003</strong> inTennessee), OSHA revised the construction industrystandards requiring that traffic control signs, signals,and barricades conform to Part VI of either the 1988Edition of the Federal Highway Administration Manualon Uniform Traffic Control Devices (MUTCD) with 1993revisions, or the Millennium Edition of the MUTCD.WHY THE CHANGE?Each year in the U.S. more than 100 workers are killedand more than 20,000 are injured in the highway andstreet-construction industry. That is in addition to thethousands of motorists seriously injured or killed in andaround construction work zones every year.The vast majority of road construction projects inthe country are funded through Federal transportationgrants. As a condition of receiving the Federal funding,the U.S. Department of Transportation’s (DOT) FederalHighway Administration requires compliance with itsMUTCD. In effect, the MUTCD has become a nationalbenchmark for all roads.Prior to December 11, 2002, OSHA relied on a 1971standard – the American National Standards InstituteD6.1-1971, MUTCD. As time passed, that particularstandard became grossly inadequate by today’s safetystandards. OSHA’s adoption of the 1993 standardsmeans improved safety for all road crews.The biggest change for most contractors who do notwork for DOT is that their work will now be covered bya significantly more detailed traffic safety standard. Thefollowing phrase is contained in the MUTCD:“The control of road users through a temporarytraffic control zone shall be an essential part ofhighway construction, utility work, maintenanceoperations and incident management.”In many instances, contractors and utilities will needto establish Traffic Control Plans (TCP). These planswill describe the traffic controls to be used for movingvehicles and pedestrian traffic through work zones. Theplans may be very detailed, or may reference typicaldrawings contained in the MUTCD. The degree of detailTraffic spaceallows traffic topass through theActivity AreaBuffer space(lateral)providesprotectionfor traffic andworkers30 meters (100 ft.) downstream taperWork space is setaside for workers,equipment, andmaterial storageBuffer space(longitudinal) providesprotection for traffic &workersLEGEND➡ Direction of travelTermination Arealets traffic resumenormal operationsActivity Areais where worktakes placeTransition Areamoves traffic out ofits normal pathAdvance Warning Areatells traffic what toexpect headExample of a Traffic Control Plan (TCP) for lane closureon a low-volume, two-lane road, as shown in the MUTCD.will depend on the complexity of each situation. TCPsmust be prepared by persons knowledgeable about thefundamental principles of temporary traffic control andthe work activities to be performed.FULL IMPACT OF NEW STANDARDS ARE SIGNIFICANTOSHA’s adoption of MUTCD is relatively new. AsSEE “TRAFFIC SAFETY” ON PAGE 4

Page 2 Excavation <strong>Safety</strong> News – <strong>March</strong> <strong>2003</strong>Slide Rail Shoring Systems Continue toGrow in PopularitySlide rail shoring systems continue to grow inpopularity in the U.S. They have proven to becast-in-place concrete structures, tank installations,pump installations, etc. These systems were specificallydesigned for pit applications, andwere substantially heavier in theirconstruction. The end result was shoringsystems that were quick and easy toinstall using mid-sized excavators, weresafe and cost-effective, and met OSHA’srequirements.Everything now seems to havecome “full circle.” Slide rail shoringsystems today are used in more andmore linear-applications in the UnitedStates – just like in Europe.particularly cost-effective for pit-applications(where contractors and utilities havetraditionally used sheet piling) and in situationswith particularly poor soil conditions.Slide rail shoring systems were firstdeveloped in Europe almost 30 years ago. Thesystems were used heavily in linear applicationsin which contractors laid storm drain andsewer pipe between manholes in congestedenvironments. Contractors would shore theentire trench, leaving the shoring in place untilall pipe was in place and tested. They wouldthen backfill the trench and restore the surface.In contrast, U.S. contractors havetraditionally used trench shields in the situationssuch as this. <strong>Trench</strong> shields are usuallypulled through trenches as pipe is laid. Once the pipeis properly installed, trenches are backfilled almostimmediately.SLIDE RAIL NOT POPULAR EARLY ONEarly slide rail shoring systems were not readilyaccepted in the U.S. for at least a couple of reasons.First, trench shields worked quite well, and manycontractors saw little reason to change systems. Second,U.S. contractors tend to be rougher on equipment,compared to their European counterparts. Early sliderail systems did not hold up under the rigors of thejob site.In the early 1990s, several shoring systemdistributors in the northeast U.S. began promotingslide rail systems for manholes, pre-cast structures,Excavation <strong>Safety</strong> NewsPublished by<strong>Trench</strong><strong>Safety</strong> and Supply, Inc.www.trenchsafety.com3000 Ferrell Park Cove • Memphis, TN 38116(910) 346-5800 • (800) 856-5801 • FAX (901) 346-1060North Little Rock, AR(501) 955-3800 • (800) 243-6408 • FAX (501) 955-2044This newsletter provides a brief overview of safety regulations andsystems. It is not intended to provide specific legal or engineeringadvice. Please refer to OSHA CFR29, Part 1926, Subpart P,“Excavation and <strong>Trench</strong>es,” and to other governmental regulations,and to manufacturers’ instructions for specific information.Copyright © <strong>2003</strong>, <strong>Trench</strong><strong>Safety</strong> and Supply, Inc.

Excavation <strong>Safety</strong> News – <strong>March</strong> <strong>2003</strong>10 STEPS IN SLIDE RAILINSTALLATION…<strong>Trench</strong> Boxes Save Lives…Page 312After initial excavation, firstouter panel and corner postis put into place.Second panel and corner postform a right [90º] angle.3 4With the outer panels andcorner posts in position……excavation continues…At least two people’s lives were saved by this trenchshield when a massive chunk of soil gave way, slammingthe side of this trench box.5 6…But They Must Be In Place…while outer panels andcorner posts are pushedto proper depth with theexcavator.7 8Excavation is deepened andpanels are lowered into insidetracks on the posts.Excavator continues to digand push the inside panelsand corner posts……until the desired depth isreached.910Removal begins by extractinginner panels, as back-fillingand compaction are started.Outer panels and posts areextracted as back-filling andcompaction are completed.The workers in this trench were not so fortunate.Two men lost their lives here because sensible – andrequired – protection was not provided in the form ofproper, life-saving shoring or shielding.