PDF brochure QSTE - WINFA sro

PDF brochure QSTE - WINFA sro

PDF brochure QSTE - WINFA sro

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

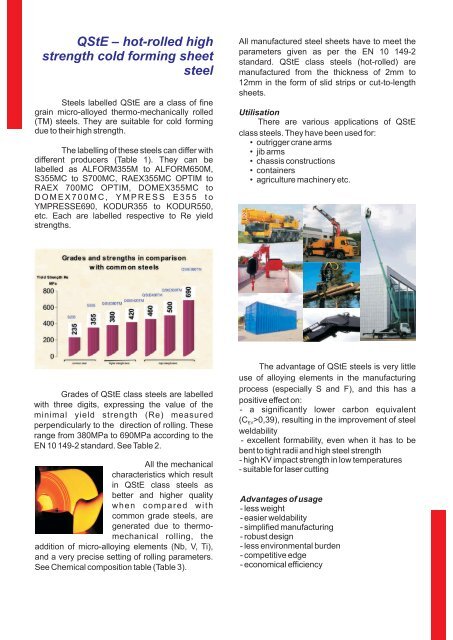

QStE – hot-rolled highstrength cold forming sheetsteelSteels labelled QStE are a class of finegrain micro-alloyed thermo-mechanically rolled(TM) steels. They are suitable for cold formingdue to their high strength.The labelling of these steels can differ withdifferent producers (Table 1). They can belabelled as ALFORM355M to ALFORM650M,S355MC to S700MC, RAEX355MC OPTIM toRAEX 700MC OPTIM, DOMEX355MC toD O M E X 7 0 0 M C , Y M P R E S S E 3 5 5 t oYMPRESSE690, KODUR355 to KODUR550,etc. Each are labelled respective to Re yieldstrengths.All manufactured steel sheets have to meet theparameters given as per the EN 10 149-2standard. QStE class steels (hot-rolled) aremanufactured from the thickness of 2mm to12mm in the form of slid strips or cut-to-lengthsheets.UtilisationThere are various applications of QStEclass steels. They have been used for:• outrigger crane arms• jib arms• chassis constructions• containers• agriculture machinery etc.Grades of QStE class steels are labelledwith three digits, expressing the value of theminimal yield strength (Re) measuredperpendicularly to the direction of rolling. Theserange from 380MPa to 690MPa according to theEN 10 149-2 standard. See Table 2.All the mechanicalcharacteristics which resultin QStE class steels asbetter and higher qualitywhen compared withcommon grade steels, aregenerated due to thermomechanicalrolling, theaddition of micro-alloying elements (Nb, V, Ti),and a very precise setting of rolling parameters.See Chemical composition table (Table 3).The advantage of QStE steels is very littleuse of alloying elements in the manufacturingprocess (especially S and F), and this has apositive effect on:- a significantly lower carbon equivalent(C EV>0,39), resulting in the improvement of steelweldability- excellent formability, even when it has to bebent to tight radii and high steel strength- high KV impact strength in low temperatures- suitable for laser cuttingAdvantages of usage- less weight- easier weldability- simplified manufacturing- robust design- less environmental burden- competitive edge- economical efficiency