"A castle in the making!" N°3 (PDF - 778 Ko) - Guédelon

"A castle in the making!" N°3 (PDF - 778 Ko) - Guédelon

"A castle in the making!" N°3 (PDF - 778 Ko) - Guédelon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

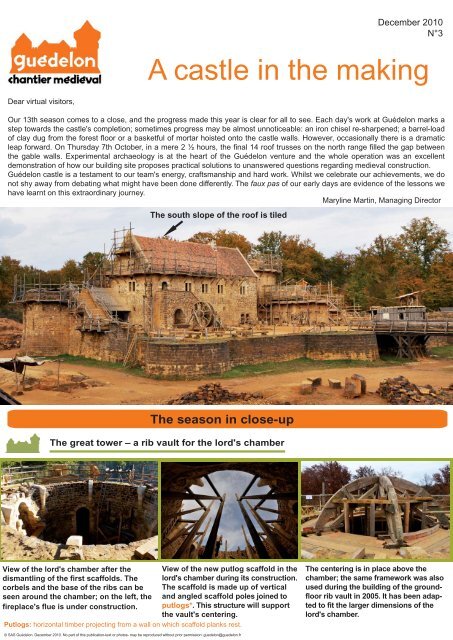

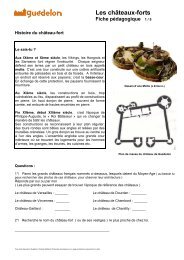

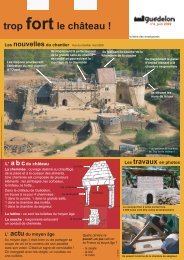

December 2010<strong>N°3</strong>A <strong>castle</strong> <strong>in</strong> <strong>the</strong> mak<strong>in</strong>gDear virtual visitors,Our 13th season comes to a close, and <strong>the</strong> progress made this year is clear for all to see. Each day's work at <strong>Guédelon</strong> marks astep towards <strong>the</strong> <strong>castle</strong>'s completion; sometimes progress may be almost unnoticeable: an iron chisel re-sharpened; a barrel-loadof clay dug from <strong>the</strong> forest floor or a basketful of mortar hoisted onto <strong>the</strong> <strong>castle</strong> walls. However, occasionally <strong>the</strong>re is a dramaticleap forward. On Thursday 7th October, <strong>in</strong> a mere 2 ½ hours, <strong>the</strong> f<strong>in</strong>al 14 roof trusses on <strong>the</strong> north range filled <strong>the</strong> gap between<strong>the</strong> gable walls. Experimental archaeology is at <strong>the</strong> heart of <strong>the</strong> <strong>Guédelon</strong> venture and <strong>the</strong> whole operation was an excellentdemonstration of how our build<strong>in</strong>g site proposes practical solutions to unanswered questions regard<strong>in</strong>g medieval construction.<strong>Guédelon</strong> <strong>castle</strong> is a testament to our team's energy, craftsmanship and hard work. Whilst we celebrate our achievements, we donot shy away from debat<strong>in</strong>g what might have been done differently. The faux pas of our early days are evidence of <strong>the</strong> lessons wehave learnt on this extraord<strong>in</strong>ary journey.Maryl<strong>in</strong>e Mart<strong>in</strong>, Manag<strong>in</strong>g DirectorThe south slope of <strong>the</strong> roof is tiledThe season <strong>in</strong> close-upThe great tower – a rib vault for <strong>the</strong> lord's chamber© F. FolcherView of <strong>the</strong> lord's chamber after <strong>the</strong> View of <strong>the</strong> new putlog scaffold <strong>in</strong> <strong>the</strong>dismantl<strong>in</strong>g of <strong>the</strong> first scaffolds. The lord's chamber dur<strong>in</strong>g its construction.corbels and <strong>the</strong> base of <strong>the</strong> ribs can be The scaffold is made up of verticalseen around <strong>the</strong> chamber; on <strong>the</strong> left, <strong>the</strong> and angled scaffold poles jo<strong>in</strong>ed tofireplace's flue is under construction. putlogs*. This structure will support<strong>the</strong> vault's center<strong>in</strong>g.Putlogs: horizontal timber project<strong>in</strong>g from a wall on which scaffold planks rest.The center<strong>in</strong>g is <strong>in</strong> place above <strong>the</strong>chamber; <strong>the</strong> same framework was alsoused dur<strong>in</strong>g <strong>the</strong> build<strong>in</strong>g of <strong>the</strong> groundfloorrib vault <strong>in</strong> 2005. It has been adaptedto fit <strong>the</strong> larger dimensions of <strong>the</strong>lord's chamber.© SAS <strong>Guédelon</strong>. December 2010. No part of this publication-text or photos- may be reproduced without prior permission: guedelon@guedelon.fr

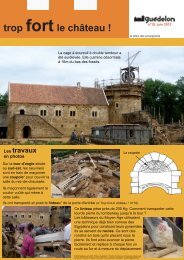

The North Range – rais<strong>in</strong>g <strong>the</strong> roofThe first roof trusses* were positioned <strong>in</strong> 2008 and a fur<strong>the</strong>rseries <strong>in</strong> 2009. The roof timbers were first made up <strong>in</strong> <strong>the</strong>carpenters' lodge, <strong>the</strong>n each piece was hoisted up us<strong>in</strong>g <strong>the</strong>treadmill w<strong>in</strong>ch, and <strong>the</strong> trusses were re-assembled on a temporaryfloorboard at eaves* level and <strong>the</strong>n hauled up <strong>in</strong>to position.An unanswered question rema<strong>in</strong>ed: how would <strong>the</strong> carpentersmanage to pull <strong>the</strong> last trusses up <strong>in</strong>to position, as <strong>the</strong>y wouldbe blocked by <strong>the</strong> west gable*?roof truss: a framework of rafters.eaves: <strong>the</strong> junction of wall and roof, usually overhang<strong>in</strong>g a support<strong>in</strong>g wall.gable: <strong>the</strong> triangular end of an exterior wall of a double-sloped roof.<strong>Guédelon</strong>’s head-carpenter, Nicolas, suggested <strong>the</strong> idea of assembl<strong>in</strong>g all <strong>the</strong> rema<strong>in</strong><strong>in</strong>g trusses and <strong>the</strong>n slid<strong>in</strong>g <strong>the</strong>m<strong>in</strong>to position along a specially constructed rail. Thanks to this technique, <strong>the</strong> f<strong>in</strong>al 14 trusses slid – like files <strong>in</strong> a fil<strong>in</strong>gcab<strong>in</strong>et – along <strong>the</strong> rail and <strong>in</strong>to <strong>the</strong>ir permanent positions. This remarkable operation was closely observed by FrédéricEpaud – archaeologist and member of <strong>Guédelon</strong>'s scientific committee: "There is no def<strong>in</strong>itive answer to <strong>the</strong> questionof how medieval roof timbers were fitted <strong>in</strong> position. At <strong>Guédelon</strong> - <strong>the</strong> pace of work, <strong>the</strong> rhythm of <strong>the</strong> constructionsite, <strong>the</strong> different technical operations - have allowed us to test a range of <strong>the</strong>ories, and filled gaps <strong>in</strong> our knowledge."A worker kicks <strong>the</strong> truss along <strong>the</strong> rail9 assembled rooftrusses wait<strong>in</strong>g fortransfer.The 5th isbe<strong>in</strong>g moved.4 roof trussesare already <strong>in</strong>placeTwo carpenters push <strong>the</strong>truss with large forks1 The worker sat up on <strong>the</strong> collar beam had a dual role:he was <strong>the</strong>re to kick <strong>the</strong> roof truss along <strong>the</strong> rail and alsoto help guide <strong>the</strong> truss with a rope as <strong>the</strong> carpentersbelow move it along.2 Once <strong>the</strong> truss is mov<strong>in</strong>g, two carpenters armed withforks, push it easily along <strong>the</strong> rail. The truss is l<strong>in</strong>ed upwith <strong>the</strong> jo<strong>in</strong>ts.The tenon be<strong>in</strong>g fitted <strong>in</strong>to <strong>the</strong> mortise.A peg will fix <strong>the</strong> jo<strong>in</strong>t toge<strong>the</strong>r.3 The forks are used to lift one side of <strong>the</strong> roof truss <strong>in</strong>order to fit <strong>the</strong> tenon* at <strong>the</strong> end of <strong>the</strong> rafter <strong>in</strong>to <strong>the</strong>mortise*. The carpenters <strong>the</strong>n nail a board between tworoof trusses to temporarily keep <strong>the</strong>m <strong>in</strong> place.Tenon: a project<strong>in</strong>g piece of wood made for <strong>in</strong>sertion <strong>in</strong>to mortise.Mortise: a hole designed to receive <strong>the</strong> tenon.The curved angle braces are fitted.4 The carpenters <strong>the</strong>n fit curved angle braces to eachrafter. They can <strong>the</strong>n check <strong>the</strong> distances between <strong>the</strong>roof trusses. Battens* are <strong>the</strong>n nailed to <strong>the</strong> rafters and<strong>the</strong> tiles hung <strong>in</strong> place.Batten: strips of timber on which tiles are held <strong>in</strong> place.© SAS <strong>Guédelon</strong>. December 2010. No part of this publication-text or photos- may be reproduced without prior permission: guedelon@guedelon.fr

A door for <strong>the</strong> great towerThe <strong>castle</strong>'s third door has been fitted. The wood for <strong>the</strong> entrance to <strong>the</strong> great tower is made from cleft oak planks. Thedoor itself took 3 weeks for <strong>the</strong> carpenters to prepare; <strong>the</strong> iron strapwork represents a month of work at <strong>the</strong> forge; ittook a fur<strong>the</strong>r week to fit <strong>the</strong> strapwork and hang <strong>the</strong> door. The strapwork is <strong>in</strong> part defensive and <strong>in</strong> part a show ofwealth and prestige.The door was not made from sawnplanks, but from cleft logs. The faceswere f<strong>in</strong>ished with a side-axe. Theadvantage of us<strong>in</strong>g cleft wood ra<strong>the</strong>rthan sawn wood is that it works with<strong>the</strong> gra<strong>in</strong> of <strong>the</strong> wood ra<strong>the</strong>r thancutt<strong>in</strong>g across it, it ma<strong>in</strong>ta<strong>in</strong>s <strong>the</strong> strengthand reduces its exposure to rot.Meanwhile <strong>the</strong> blacksmiths forged <strong>the</strong>door's h<strong>in</strong>ges and decorativestrapwork. The ma<strong>in</strong> h<strong>in</strong>ges are <strong>the</strong>nfixed to <strong>the</strong> door.With <strong>the</strong> help of <strong>the</strong> carter, <strong>the</strong> doorwas <strong>the</strong>n transported from <strong>the</strong> carpenters'lodge to <strong>the</strong> base of <strong>the</strong> greattower.Experimental archaeology<strong>in</strong> actionTo recreate a 13th century <strong>castle</strong> door isquite a feat; very few examples exist fromthis period. In design<strong>in</strong>g and mak<strong>in</strong>g <strong>the</strong>strapwork, <strong>Guédelon</strong>’s blacksmiths,Olivier and Adrien, respected <strong>the</strong> spirit ofearly 13th century blacksmiths, but alsoreplicated <strong>the</strong> production techniques ofthat age, and referred to precise archaeologicalmodels: church doors from Lignac,Jaleyrac, Ydes and Serandon <strong>in</strong> <strong>the</strong>centre of France.The new door is <strong>the</strong> third to be fitted at<strong>Guédelon</strong>. A door from <strong>the</strong> lord's chamberto <strong>the</strong> wall-walk was hung at <strong>the</strong> end of<strong>the</strong> 2009 season and <strong>the</strong> first door was<strong>in</strong>stalled on <strong>the</strong> ground-floor of <strong>the</strong> chapeltower <strong>in</strong> 2003. We realise now that,strictly speak<strong>in</strong>g, this first door has noplace <strong>in</strong> a 13th century <strong>castle</strong>: it is madefrom sawn planks of wood; it lacksdefensive iron strapwork and anyassailants would be delighted to f<strong>in</strong>d <strong>the</strong>lock on <strong>the</strong> outside!The carpenters could make last m<strong>in</strong>uteadjustments and <strong>the</strong> blacksmithscould <strong>the</strong>n fix <strong>the</strong> strapwork <strong>in</strong> place.At <strong>the</strong> end of each branch are forgedgrotesque heads. There are 20 <strong>in</strong> alland not one is <strong>the</strong> same.The first door may well be modified later<strong>in</strong> <strong>the</strong> build<strong>in</strong>g programme; however it willrema<strong>in</strong> <strong>in</strong> <strong>the</strong> <strong>castle</strong>. It is an importantpart of our story and is evidence of <strong>the</strong>steep learn<strong>in</strong>g curve we faced when wetook on this monumental task.© SAS <strong>Guédelon</strong>. December 2010. No part of this publication-text or photos- may bereproduced without prior permission: guedelon@guedelon.frFrom <strong>the</strong> courtyard From <strong>the</strong> corridor