SCHIRMER DATA - Fire-Professionals.Com

SCHIRMER DATA - Fire-Professionals.Com

SCHIRMER DATA - Fire-Professionals.Com

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

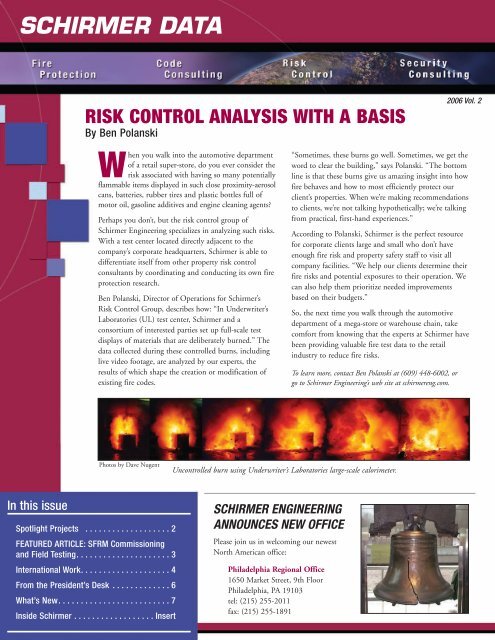

<strong>SCHIRMER</strong> <strong>DATA</strong>RISK CONTROL ANALYSIS WITH A BASISBy Ben Polanski2006 Vol. 2When you walk into the automotive departmentof a retail super-store, do you ever consider therisk associated with having so many potentiallyflammable items displayed in such close proximity-aerosolcans, batteries, rubber tires and plastic bottles full ofmotor oil, gasoline additives and engine cleaning agents?Perhaps you don’t, but the risk control group ofSchirmer Engineering specializes in analyzing such risks.With a test center located directly adjacent to thecompany’s corporate headquarters, Schirmer is able todifferentiate itself from other property risk controlconsultants by coordinating and conducting its own fireprotection research.Ben Polanski, Director of Operations for Schirmer’sRisk Control Group, describes how: “In Underwriter’sLaboratories (UL) test center, Schirmer and aconsortium of interested parties set up full-scale testdisplays of materials that are deliberately burned.” Thedata collected during these controlled burns, includinglive video footage, are analyzed by our experts, theresults of which shape the creation or modification ofexisting fire codes.“Sometimes, these burns go well. Sometimes, we get theword to clear the building,” says Polanski. “The bottomline is that these burns give us amazing insight into howfire behaves and how to most efficiently protect ourclient’s properties. When we’re making recommendationsto clients, we’re not talking hypothetically; we’re talkingfrom practical, first-hand experiences.”According to Polanski, Schirmer is the perfect resourcefor corporate clients large and small who don’t haveenough fire risk and property safety staff to visit allcompany facilities. “We help our clients determine theirfire risks and potential exposures to their operation. Wecan also help them prioritize needed improvementsbased on their budgets.”So, the next time you walk through the automotivedepartment of a mega-store or warehouse chain, takecomfort from knowing that the experts at Schirmer havebeen providing valuable fire test data to the retailindustry to reduce fire risks.To learn more, contact Ben Polanski at (609) 448-6002, orgo to Schirmer Engineering’s web site at schirmereng.com.Photos by Dave NugentUncontrolled burn using Underwriter’s Laboratories large-scale calorimeter.In this issueSpotlight Projects . . . . . . . . . . . . . . . . . . . 2FEATURED ARTICLE: SFRM <strong>Com</strong>missioningand Field Testing. . . . . . . . . . . . . . . . . . . . . 3International Work. . . . . . . . . . . . . . . . . . . . 4From the President’s Desk . . . . . . . . . . . . . 6What’s New. . . . . . . . . . . . . . . . . . . . . . . . . 7Inside Schirmer . . . . . . . . . . . . . . . . . . Insert<strong>SCHIRMER</strong> ENGINEERINGANNOUNCES NEW OFFICEPlease join us in welcoming our newestNorth American office:Philadelphia Regional Office1650 Market Street, 9th FloorPhiladelphia, PA 19103tel: (215) 255-2011fax: (215) 255-1891

SPOTLIGHT PROJECTSPATRICK HENRY BUILDING – Richmond, VirginiaSchirmer Engineering’s Washington, DC office was proud to serve as the fireprotection engineer and code consultant for the renovation of the PatrickHenry Building in Richmond, VA. The project was McGraw Hill’s Mid-Atlantic Project of the Year and Best Adaptive Re-Use project. The $32-millionproject involved the transformation of the building formerly known as theRichmond Old State Library from the offices of Virginia’ Supreme Court andState Library to the new home for Virginia’sgovernment during the renovation of the VirginiaState Capitol Building, another of SchirmerEngineering’s projects. Schirmer Engineering offeredthe Hillier Architecture lead design team fullyengineeredfire protection design and constructiondocuments as well as comprehensive buildingcode consulting. Schirmer’s experts providedvaluable insights about the building codes alongwith fire protection strategies to help accomplish themonumental transformation of this historic structure.PENTAGON KICK-OFF OF WEDGE4 DESIGN – Arlington, VirginiaSchirmer Engineering’s Washington,DC office continues to provide fireprotection design services for theworld’s largest office building.Schirmer Engineering has recentlybegun the design of the fire protectionsystems for Wedge 4 of the Pentagonin Arlington, VA. Schirmer Engineering has been partof the Pentagon Renovation team since 2001. Whiledesigning the automatic sprinkler and standpipesystems for the 1.1 million square feet of Wedge 4,our work in Wedges 2 & 3 continues with thepreparation of 3-dimensional record documents andconstruction administration services.NOvA EXPERIMENT FACILITY – MinnesotaSchirmer Engineering’s Chicago team, led by Rick Glenn, P.E., recently completed a fire protection/lifesafety analysis for the new NOvA Experiment Facility to be constructed by Fermilab in Minnesota. The$160 million project includes the construction of a 43,000 sq. ft. structure that will be used to house a430'L x 60'W x 55'H Detector for a physics experiment. The Detector, and most of the facility, will belocated underground and will contain 7.5 million gallons of a Class IIIB combustible liquid in 23,000rigid PVC containers.Schirmer Engineering prepared a report documenting its fire protection/life safety analysis for this newfacility, and provided recommendations based on DOE Order 420.1, the International Building Code(IBC), and applicable NFPA Standards. The report addressed construction type, compartmentation,means of egress, smoke control, fire suppression, fire detection/alarm, standby power, emergency power, and emergency preparedness. It isanticipated that construction of the facility will begin in November, 2006 and that the facility, including the experiment equipment, will becompleted and in operation in 2011.A TIP THAT COULD SAVE YOUR LIFEfrom <strong>Fire</strong>Safety.govIn 2003, fire departments responded to 388,500 home structurefires in the United States that claimed the lives of an estimated3,145 people. Working smoke alarms greatly reduce the likelihoodof a residential fire-related fatal injury by providing occupantswith early warning and giving them additional time to escape.Smoke alarms are still missing in 4% of US homes. This groupaccounts for 39% of reported home fires and nearly half of all thereported home fire deaths. They representjust over 4 million housing units.An estimated 20% of US homes havesmoke alarms present but none that areworking. Nearly all of this 20% involvesdead or missing batteries, as opposed toproblems with AC power.Please don’t become a statistic. If you don’t have a smoke alarm,please install one right away. And, if you do have one, check tomake sure the batteries are charged and it is working properly.2

FEATURED ARTICLESFRM COMMISSIONING AND FIELD TESTINGBy Mike Rzeznik, P.E.Sprayed <strong>Fire</strong>-Resistive Material (SFRM),more commonly referred to as sprayappliedfireproofing, is a passive fireprotection material intended for directapplication to structural building members.The fire resistive qualities of SFRM materialsdiffer with their composition, as well as themanner in which they are prepared andapplied. Further, the ability of SFRM toprotect a given structural assembly varies with the characteristics ofthe members being protected. Therefore, laboratory testing is usedto evaluate fire resistance ratings for complete assemblies ofstructural members.The relative fire resistance of an assembly is measured by itsperformance during the ASTM E119 standard fire endurance test.However, the method used to verify that the field installation isconsistent with the intention of the manufacturer and laboratorytesting is outlined in ASTM E 605 and ASTM E 736.Because the controlled environment and care associated withpreparing a structural test assembly for the laboratory fire endurancetest can vary greatly with the amount of time and attention availableduring the field application of SFRM, field verification of SFRMinstallation is critical to the building commissioning process.THICKNESSProper SFRM thickness is critical to ensure that sufficient insulationis available to mitigate the passage of heat from a fire to thestructure being protected. The level of thermal protection providedby the installed SFRM must be at least equivalent to that providedfor the test assembly during the ASTM E 119 test. ASTM E 605,Standard Test Methods for Thickness and Density of Sprayed <strong>Fire</strong>-Resistive Material (SFRM) Applied to Structural Members (ASTME 605) specifies procedures and methods with which to evaluateSFRM thickness, while taking into consideration the realities offield installations.The thickness of SFRM as installed on a structural member shouldbe measured with a calibrated thickness gauge, consisting ofa needle or pinfor penetratingthe SFRM,and a slidingdisk orientedperpendicular tothe needle.ASTM E 605 requires that the gauge be graduated to takemeasurements in minimum 1/16-inch intervals.ASTM E 605 also requires that thickness tests be conductedrandomly at a rate of one bay per floor or 10,000 square feet,whichever is greater, for each structural member being tested. Aseries of point thickness measurements are to be collected in each ofthese locations.Once these measurements are taken, an identical series ofmeasurements must be taken at 12 inches from that point. Thesemeasurements represent the field thickness testing for this one bayor 10,000 square foot area.With regard to pass/fail criteria, the thickness of SFRM protecting agiven member is considered deficient if any individual measurementis more than 6mm less, or more than 25% less, than the requiredfire resistance design thickness of the listed assembly, or if thecalculated average thickness of the SFRM is less that that requiredfor the design.DENSITYThe frequency outlined by ASTM E 605 for density testing is thesame as that required for thickness testing. For density testing,however, a 48 square inch specimen, with no dimension less than 3inches, is measured in place for thickness. The average thickness ofthe sample is taken as the thickness of the specimen. After carefullycutting and removing the specimen from the substrate, thespecimen should be allowed to cure at no greater than 60%humidity for a period of time until successive weight readings differby less than 1%. Once the dried weight of the specimen isstabilized, the density of the specimen can be calculated using thefollowing formula,where,D= W / (l x w x t)D = density, (kg/m3)W = constant weight of dried material (kg)l = length (m)w = width (m)t = average thickness (m)A density failure is recorded whenever the calculated density fallsbelow the minimum individual density value of the fire resistancerated design assembly, which it is being tested against.SFRM Depth Gauge Continued on page 73

INTERNATIONAL WORKINTRODUCING DUBAI...By Jim Bychowski, P.E.It is safe to say that if you haven’t heardof Dubai yet, you soon will. Located onthe Eastern coast of the Arabian Peninsula,Dubai is one of the fastest growing citiesin the world.The city’s significant development is mainlydue to the bold decision making ofgovernment officials who, knowing thatDubai’s oil reserves could be depleted by 2010,have launched a massive effort to diversify its economy byexpanding commercial and corporate activity. The government’saggressive economicdevelopment plan focuseslargely on trade and tourism,which has led to the recentconstruction of Dubailand,as well as massive shoppingmalls, theme parks, resorts,Rendering of Dubai Marina Sitestadiums and othertourist attractions.As a result of the city’s economic shift, the skyline of Dubai hasresembled a sea of construction equipment for the past 6 years.In fact, experts estimate that somewhere around 20% of theworld’s construction cranes are currently located in the city.Dubai Municipality statisticsindicated that Dubai has added morethan 560 buildings to its skyline sincethe beginning of 2006. According topublished figures, the total spent oncompleted buildings in the first threemonths of this year was morethan 770 million US dollars.Bruce Wienand overlookingBurj Dubai Marina siteIn addition to being one of the largestdevelopment efforts in the world today, the city of Dubai is alsoone of the fastestgrowingcities,progressing at amuch quicker ratethan the growth ofany Westerncountry. By 2010,it is anticipated that The Palm, man-made islands in Dubaithe city’s unique architecture and attractions will draw 15 millionhotel guests every year, and by 2017, Dubai’s population of 1.1million is expected to nearly quadruple to 4 million.While many investorshave been drawn toDubai for the real estateopportunities, the city’smassive constructionefforts also posed a hugeopportunity for SchirmerEngineering to applyits fire engineering andsercurity expertise on alarge-scale, international level.Rendering of Sports City in DubaiFor the past three years, Schirmer Engineering has been workingwith the world’s top multinational design and construction firms,offering guidance in the application of US and UK building codesand standards for a diverse group of construction projects in thecity. We have offered fire strategy and security design and consultingfor a variety of unique structures including high rise buildings,sports arenas, residential and commercial complexes, hotels, andshopping malls. Schirmer Engineering has even been involved in thedesign of what will be the world’s tallest building.In 2004, we officially named Martin J. Kealy, PEng, our Directorof International Practices. “Schirmer’s in-depth knowledge of fireContinued on next pageDirector of International Practices, Martin Kealy, and DubaiConsultant, Bruce Wienand, evaluate a new security console4

INTRODUCING DUBAI...Continued from previous page.clients. Schrimer holds a Professional License in Dubai under thename Schirmer Safety Consultants.Emirates Towers and the Al Burj Hotel lobby and exteriorscience, international code basis and alternative approaches usingperformance-based design gives us the ability to produce costeffectiveresults for our international clients,” Kealy noted last year.And clearly, Kealy was right.Schirmer Engineering’s reputation for delivering high-quality,cost-effective solutions has earned our company the respect andthe business of many local Dubai firms. Just this year, as a showof our dedication to the growing city, we opened a local office inDubai. With the help of our new Consultant, Bruce Wienand,Schirmer Engineering has come to be known as the local fireengineering and security experts. We are certified by the DubaiCivil Defense as a House of Expertise and can certify fire strategieson behalf of Dubai Civil Defense, which expedites projects for ourAlthough the staggering growth in Dubai has made it one of themost talked about cities in the world, Schirmer Engineering’sinternational expertise stretches far beyond the UAE. Ourinternational portfolio currently includes unique and large scaleprojects located in Bahrain, Qatar, Egypt, Chile, Korea, China,Kenya, Mexico, Australia, Canada, Uzbekistan, the UnitedKingdom and Jakarta.In coming years, armed with our expertise and internationalexperience, our intention will be to develop a stronger presencein other Emirates and Middle East countries. Through ourrelationships with multinational and global firms we will continueto build on Schirmer Engineering’s status as one of the mostrespected names in the industry.To learn more, contact Jim Bychowski at (847) 272-8340, x227, or go toSchirmer Engineering’s web site at schirmereng.com.Rendering of Bahrain Financial HarborRendering of Doha International Airport in Qatar“Schirmer’s in-depth knowledge of fire science, international code basis and alternativeapproaches using performance-based design gives us the ability to produce cost-effectiveresults for our international clients.”—Martin J. Kealy, PEng5

FROM THE PRESIDENT’S DESKFROM THE LAB TO YOUR FACILITIES: HOW OUR RESEARCH BENEFITS OUR CLIENTSBy Carl F. Baldassarra, P.E.The cover article of the last issue of <strong>DATA</strong>, Volume 12006, by Daniel J. O'Connor, P.E., described howSchirmer Engineering was contracted by the National<strong>Fire</strong> Protection Association’s (NFPA) <strong>Fire</strong> Protection ResearchFoundation to conduct an extensive study of the spacing rulesfor smoke detectors included in the NFPA’s internationallyrecognizedStandard 72, National <strong>Fire</strong> Alarm Code. The spacingrules included in NFPA 72 have been the subject of frequentquestions and interpretations by designers and the codeenforcement community, particularly with respect to ceilingconfigurations involving beams and other ceiling-level “pocket” designs. Schirmerwas contracted by the NFPA’s <strong>Fire</strong> Protection Research Foundation as part of itsmission to advance the implementation of fire protection technology throughscientifically-based research and education programs.The Schirmer Engineering team evaluated the prescriptive spacing provisionsincluded in NFPA 72 to determine the validity of the rules for the various ceilinggeometries. Using hundreds of sophisticated <strong>Com</strong>putational Fluid Dynamics (CFD)fire simulations, Schirmer was able to determine the validity of the rules and “bust”at least one previously accepted myth. It was found that deep beam configurations onceilings up to 18 feet in height above the floor do not negatively affect smokedetector performance as compared to that of smooth ceilings, and in corridors thereis no significant difference in detector performance if it is mounted either on thebottom of the beam or on the ceiling between beams. In addition, the study foundthat the concern for keeping smoke detectors 12 inches below or away from aceiling-wall corner is unsubstantiated. These and other findings from the study werepresented last Fall at the 10th Annual <strong>Fire</strong> Suppression and Detection ResearchApplication Symposium in Orlando, Florida, byMr. O'Connor. Moreover, the research projectled to a number of changes in the latest editionof the NFPA 72 standard which now clarifiesthese previous misconceptions and allows morecost-effective system designs for owners andoperators of buildings worldwide.This project is one of the latest examples of how studies and research projectsconducted by Schirmer have benefited our clients and society in general by bringinglaboratory findings to application in the field with new and more affordableprotection products and installation methods, improving life safety and propertyprotection in the built environment.Many of our current projects involve computer fire simulations as opposed toconducting full-scale fire tests in a laboratory. But some things do not change. Ourengineers love solving problems—the more challenging the better. Developingsolutions that improve the level of life safety and property protection in society isespecially rewarding. For that reason, Schirmer Engineering’s staff will continue to beinvolved in research and testing, as well as codes and standards development, toassure continuous improvement in fire and life safety methods for our clients andultimately society.6<strong>Fire</strong> Testing and Research Contributions1960s• Schirmer was a principal participant in rack storagetests, specifically on tall rack storage protection,conducted at Factory Mutual Research Center. Theresults were incorporated in the NFPA rack storagedesign standards in the 1970’s that are routinelyused today.1970s• Former Schirmer president Chester W. Schirmer,P.E. developed the concept of light hazardautomatic sprinkler spacing for the Sears Tower.In addition, the project employed the “systemsconcept” of fire protection, which was widelyadopted into the model building codes in themid-1970s and remains a viable concept in ourbuilding codes today.• Schirmer participated in a number of studies,including two for the US <strong>Fire</strong> Administration,which led to the economical installation ofautomatic sprinklers in residential occupancies.• Schirmer served as a consultant to themanufacturer of the raw materials used in theproduction of plastic sprinkler pipe and assistedin the development of fire test criteria andperformance standards for listing and use ofplastic pipe in automatic sprinkler systems.• Schirmer developed test criteria and performancestandards for first listed delayed egress doorhardware devices.1980s• Schirmer, in conjunction with a major sprinklermanufacturer, developed multiple retrofit side-wallsprinkler applications for protection of existinghotel rooms.1990s• Schirmer developed test criteria and participatedin full-scale fire tests for flammable liquids, poolchemicals and other common home center andretail storage configurations to economizeinstallations and improve fire protection overtraditional design methods.

INSIDE <strong>SCHIRMER</strong>AWARDS & ACHIEVEMENTSCongratulations to all Schirmer team members!Special AchievementsMargaret Andrews–Margaretwas recently promoted toExecutive Assistant in theSan Diego office.Brian Hall–Brian, of the Dallas office, justpublished his first book, Operation IraqiFreedom II (OIFII). The bookis all about his first-hand Armyexperience in Iraq in 2004.Brian’s book is available forpurchase at authorhouse.com.Garrett Kaye, P.E.–Garrett, of theSan Diego office, was recentlypromoted to Senior Consultant.Bill Kerbein–Bill, of the SanDiego office, was recentlypromoted to Designer.Vidar Landa–Vidar, of the LosAngeles office, recently passedhis P.E. Exam.Steve Thomas, A.E.T.–Steve,of the San Diego office,was recently promoted toAssociate Designer.Employment AnnouncementsPatricia Brown–Patricia wasrecently hired as an AdministrativeAssistant in the Las Vegas office.Joel Bouma–Joel, a Consultant,recently transferred from theCharlotte office to the LosAngeles office.William Burrus–William wasrecently hired as a Senior Consultant in thenew San Antonio office.Lauren Curley–Laurenwas recently hired as aMarketing Coordinator inthe San Diego office.Mike Clemetsen–Mike wasrecently hired as a ProjectManager in the Chicago office.Paul Elliott–Paul was recentlyhired as an Associate Consultantin the New York office.Matthew Gummersall–Matthew, has rejoined theSchirmer team, in the Chicagooffice, as an Associate Consultant.David Loucks–David wasrecently hired as a SeniorDesigner in the San Diego office.Frank Molnar–Frank was recentlyhired as a Senior Consultant inthe San Francisco office.Jay Paquet–Jay was recentlyhired as a Technician in theLos Angeles office.Jonathan Sikes–Jonathanwas recently hired as aConsultant in the LosAngeles office.Zeqiang (Zeke) Sun–Zeke wasrecently hired as a Consultantin the Chicago office.Mark Suski–Mark wasrecently hired as a Senior<strong>Fire</strong> Alarm Designer in theChicago office.Dan Varney, S.E.T.–Dan was recently hired asa Senior Designer in the LosAngeles office.Tom Waldron–Tomwas recently hired as aSenior Consultant in theSan Francisco office.Frank Wang–Frank wasrecently hired as a Consultantin the Los Angeles office.<strong>SCHIRMER</strong> WELCOMES SCIENTISTSAND SCHOLARS FROM CHINASchirmer recently hosted a visit of scholars and scientists fromChina’s Tsinghau University and the State Key Laboratory of<strong>Fire</strong> Science at the University of Science and Technology toexchange ideas and to compare notes on current fire sciencetechnology. The Chinese entourage’s primary reason for comingto the United States was to visit the National Institute ofStandards and Technology (NIST) and UnderwritersLaboratories Inc. (ULI). Not pictured: Professor WeichengFan, head of the State Key Laboratory of <strong>Fire</strong> Science at theUniversity of Science and Technology.