Hydraulic Diver LARS (Diving Launch & Recovery System)

Hydraulic Diver LARS (Diving Launch & Recovery System)

Hydraulic Diver LARS (Diving Launch & Recovery System)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

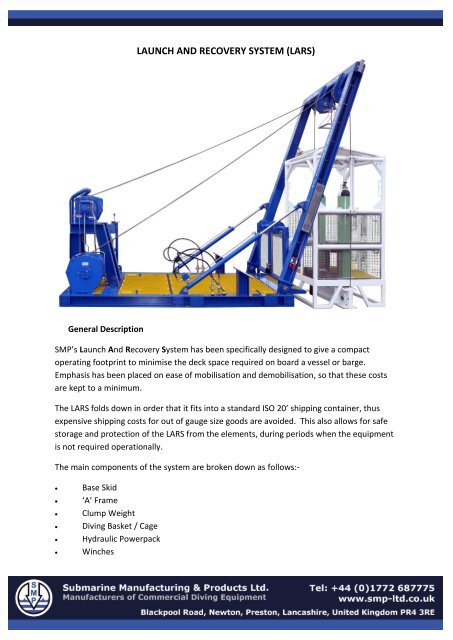

LAUNCH AND RECOVERY SYSTEM (<strong>LARS</strong>)General DescriptionSMP’s <strong>Launch</strong> And <strong>Recovery</strong> <strong>System</strong> has been specifically designed to give a compactoperating footprint to minimise the deck space required on board a vessel or barge.Emphasis has been placed on ease of mobilisation and demobilisation, so that these costsare kept to a minimum.The <strong>LARS</strong> folds down in order that it fits into a standard ISO 20’ shipping container, thusexpensive shipping costs for out of gauge size goods are avoided. This also allows for safestorage and protection of the <strong>LARS</strong> from the elements, during periods when the equipmentis not required operationally.The main components of the system are broken down as follows:-Base Skid‘A’ FrameClump Weight<strong>Diving</strong> Basket / Cage<strong>Hydraulic</strong> PowerpackWinches

<strong>LARS</strong><strong>Hydraulic</strong> ‘A’ Frame ModelFixed Arm ‘A’ Frame ModelTwin <strong>Hydraulic</strong> Power UnitBase SkidPart Nos.SMP000667SMP001044SMP004601The Base skid is constructed of heavy section ‘I’ Beam with theVertical ‘A’ Frame section situated at one end. Protective Stopsare incorporated into the base skid fabrication, which supportsthe ‘A’ Frame in the lowered position to avoid contact with thewinches and controls. The hydraulic Cylinders are fixed to thebase clevises with quick release pins in order that they can bedisconnected and retracted for transit.The base frame is covered with a light weight, non-slip, corrosionproof composite material grating. Additionally there is a controlpedestal which incorporates the proportional hydraulic controlvalve assembly.There are two hydraulic man-riding winchesprovided and positioned at the opposite end ofthe base skid. The winches are integrally pipedin 316 Stainless Steel to the hydraulic controlvalve block via quick connects, which in turn areconnected directly to the supply and returnhydraulic supplies.The base skid is additionally fitted with twoinward opening safety gates, which haveintegrated 316 stainless steel multi rollers fittedfor umbilical handling.‘A’ FrameThe ‘A’ Frame is moved by hydraulic cylinders to the inboard or outboard positions byoperation of the hydraulic control. The ‘A’ Frame is fitted with a main central sheave, wherethe lift wire is positioned for lifting and lowering the divers’ basket. Additionally at each endof the top beam of the ‘A’ Frame there is a sheave for the clump weight wire and a stop endfor connection of the clump weight wire end termination.

The head of the ‘A’ Frame also incorporates a spotlight for illumination during hours ofdarkness and an electrically interlocked chandelier which activates a failsafe lock-out systemwhen the basket is raised above the preset level.Clump WeightThis is a pre-fabricated Clump Weight which allows the Clump Weight wire to be doubledweaved through the sheaves situated at each end of the Clump Weight. This allows the freetravel of the Clump Weight in the event of an emergency recovery of the two diver basket.<strong>Diving</strong> Basket / CageThis is a 1.2 m x 1.2 m <strong>Diving</strong> Cage with overhead protective frame. It incorporates 2 x 50litre high pressure emergency air cylinders, Clump weight wire guides, diver access pointsfrom both sides of the cage and seating for both divers. Hand hold points are situatedwithin the cage and the base of the basket is fitted with a light weight, non-slip corrosionproof composite type material grating.The basket is also fitted with a base structure that incorporates the Clump Weight when inthe stowed position. Stainless steel mesh cladding is used to enclose the top and sides ofthe basket. Stainless steel chains, carabiners and nuts and bolts are used as standard for theassembly of this basket.The main structure of the basket is made up of a heavy duty tubular section. The main liftwire connection point incorporates two additional emergency lift points.Twin <strong>Hydraulic</strong> Power Unit (HPU)This is a twin <strong>Hydraulic</strong> Powerpack is mounted within anoffshore crash frame. The twin <strong>Hydraulic</strong> Powerpack isequipped with two separate hydraulic reservoirs, with separateinspection hatches, return line filters, sight glasses and fill point.The skid is fitted with twin electric 22 kW motors with variabledisplacement, axial piston pumps complete with constantpressure control. This allows 100% redundancy and acts asprimary and secondary units in the event of failure.The hydraulic circuitry is fitted with non-return valves and overpressurisationsafety valves which operate as and when required during the operation of thediver’s <strong>LARS</strong> system.

The unit is fitted with a unique single one lever change over valve, which is switched verysimply from the primary to the secondary hydraulic system circuits, without the need todisconnect or operate multiple changeover valves.Manriding WinchesBoth hydraulic Manriding Winches are planetarytype Winches of high performance with many yearsof service. The Winches are powered by highefficiency gear motors designed specifically forapplications to provide smooth application. Themotor torque is transmitted and multiplied by thehigh efficient gear train within the Winch drums.All rotating components are supported by highanti-friction bearings and run in oil to minimisefriction.The load control system is maintained by a patented brake valve. The brake valve is alsobacked up by an internal multi-disc hydraulic release safety brake. Additionally an overrunclutch permits a free rotation through the brake in the hoisting direction with immediatelock-up when the hoisting operation is completed.Two hydraulic Manriding Winches are fitted to the SMP <strong>LARS</strong>. Both Winches are fitted withBridon Dyform rotational resistant wire ropes, which are crush resistant and reduce sheavewear.Technical SpecificationDepth CapabilityDesignCertificationBasket / Cage CylindersLengthWidthHeightWeightHPU Electrical RequirementsOil CapacityOil Delivery<strong>Hydraulic</strong> Oil Cooling<strong>Hydraulic</strong> Working PressureMain Lift WireClump Weight Wire: 75 mtrs: Lloyds Register Rules for Offshore lifting: IMCA DO23 Design & IMCA DO18: 2 x 50 Litre @ 300 Bar: 3500 mm: 2100 mm: 3690 mm: 4800 kgs (HPU Not Included): 380-440 V 3PH 50/60 Hz: 2 x 200 Litre (Per Twin Tank): 90 litres / min @ 1450 RPM max: 2 x Tube and Shell Seawater Oil Coolers: 100 Bar: 13 mm dia Length 80 metres Anti Rotational: 13 mm dia Length 160 metres Anti Rotational