as on July, 2012 - til india

as on July, 2012 - til india

as on July, 2012 - til india

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

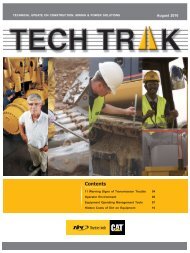

Vol. - 7, Issue - 1, <strong>2012</strong>TECHNICAL UPDATE ON CONSTRUCTION, MINING & POWER SOLUTIONSC<strong>on</strong>tentsPageThe Diesel Bug 4The Unsung Hero 6Extended Life Program 10Use Maintenance Management 12CAT

VISIBLYBETTERCAT® FLUIDS & FILTERS HELP YOU PROPERLY MAINTAINYOUR EQUIPMENTTIPL h<str<strong>on</strong>g>as</str<strong>on</strong>g> all the Cat® fluids, filters and preventive maintenance products you needto take care of your equipment. Cat Filters are manufactured to meet the most demandingengineering specs for filters — those specified by Caterpillar.Only Cat Filters provide the protecti<strong>on</strong> needed to give you the lowest owning and operatingcosts.Choose Cat Filters, get peace of mind.Call us to find out all the ways we can help you get themost from your equipment.C<strong>on</strong>tact : Mr. Pankaj Kumar +91 98310 28004Tollfree No. : 1800 345 3356, 1800 345 3355www.tipl<strong>india</strong>.inCAT

Dear Reader,TIPL is focused <strong>on</strong> ways to help customers’ profit grow: by providing hi-tech products from Caterpillar® deliveringquality service and helping bring every project to success. To this end, TechTrak remains another example of addingvalue to your business by recommending best practices that maximize equipment <str<strong>on</strong>g>as</str<strong>on</strong>g>set-life <str<strong>on</strong>g>as</str<strong>on</strong>g> well <str<strong>on</strong>g>as</str<strong>on</strong>g> profits.This issue of Techtrak covers real life stories and articles that help you derive maximum value out of your machines.The Diesel Bug story reveals interesting <str<strong>on</strong>g>as</str<strong>on</strong>g>pects of microbial c<strong>on</strong>taminati<strong>on</strong> in diesel engines – its harmful impacts ofc<strong>on</strong>taminati<strong>on</strong> and the possible soluti<strong>on</strong>s. We also c<strong>on</strong>tinue in this issue the sec<strong>on</strong>d part of the Motor Grader storytheUnsung Hero. If properly understood, operated and used, this machine can give you maximum cost saving.Through the article <strong>on</strong> Extended Life Program (ELP)–the program TIPL recently introduced, we have offered suggesti<strong>on</strong>s<strong>on</strong> getting the best value out of a product and various repair opti<strong>on</strong>s offered by us. Customers can leverage theexcellent facility of TIPL‘s 5 Star Comp<strong>on</strong>ent Rebuild Center [CRC] at Asansol with c<strong>on</strong>taminati<strong>on</strong> free repair and<str<strong>on</strong>g>as</str<strong>on</strong>g>sembly workshop. The workshop maintains highest standards of quality set by Caterpillar for a trouble free reliableperformance.Also the article <strong>on</strong> Maintenance Management is a useful read. Equipment Management h<str<strong>on</strong>g>as</str<strong>on</strong>g> positive impacts and isthe <strong>on</strong>ly way you can run your machines at peak performance.I hope you find the articles helpful to guide you <strong>on</strong> machine operati<strong>on</strong>s and management to get the intended benefits.TECHNICAL UPDATE ON CONSTRUCTION MINING & POWER SOLUTIONSWe are keen to have your feedback.G SivaramakrishnanVice President - Center of Excellence

The Diesel BugMicrobial Growth in DieselMicrobial c<strong>on</strong>taminati<strong>on</strong> and biodegradati<strong>on</strong> pose <str<strong>on</strong>g>as</str<strong>on</strong>g>a major problem in diesel engines which require cleanunc<strong>on</strong>taminated diesel, free from water andsuspended impurities. High pressure fuel injecti<strong>on</strong>systems in modern engines are vulnerable to fuelquality issues and hence require added protecti<strong>on</strong>.Wherever fuel and water come into c<strong>on</strong>tact in <str<strong>on</strong>g>as</str<strong>on</strong>g>torage or distributi<strong>on</strong> system, microbialc<strong>on</strong>taminati<strong>on</strong> is likely to occur. No matter how wellmaintained a storage system is, a water-bottom isalmost invariably present.This results from a number of sources:l Freshly refined fuel c<strong>on</strong>tains some water. Thisseparates out <str<strong>on</strong>g>as</str<strong>on</strong>g> the fuel cools down.lAtmospheric c<strong>on</strong>densati<strong>on</strong>: Humidity in the air instorage tank c<strong>on</strong>denses and adds to the waterbottom.Typical Microbial GrowthlRain or snow may enter the tank via sampling ports, breather vents or ill-fitting seal <strong>on</strong> floating roofs.4Water from all of these sources accumulate in the storage tank to form the water-bottom. C<strong>on</strong>sequently <str<strong>on</strong>g>as</str<strong>on</strong>g> the water-bottomdevelops a microbial populati<strong>on</strong> builds up in it. Liquid hydrocarb<strong>on</strong> fuels act <str<strong>on</strong>g>as</str<strong>on</strong>g> an excellent nutrient source resulting in a populati<strong>on</strong>explosi<strong>on</strong>: the microorganisms proliferate at the fuel/water interface, surviving in the water ph<str<strong>on</strong>g>as</str<strong>on</strong>g>e whilst feeding <strong>on</strong> the fuel.This gradually leads to development of sulphate reducing anaerobic organisms which inturn form corrosive w<str<strong>on</strong>g>as</str<strong>on</strong>g>te products such<str<strong>on</strong>g>as</str<strong>on</strong>g> hydrogen sulphide.Microbial Growth & its C<strong>on</strong>sequencesOnce a microbial populati<strong>on</strong> becomes established, fuel quality rapidly deteriorates. Problems such <str<strong>on</strong>g>as</str<strong>on</strong>g> Haziness, Failure to meetspecificati<strong>on</strong>s, Corrosi<strong>on</strong>, Filter plugging and Additive degradati<strong>on</strong> can occur. All of these problems are related directly to thepresence of microorganisms or their <str<strong>on</strong>g>as</str<strong>on</strong>g>sociated by-products.Fuel HazinessThis is a clear indicati<strong>on</strong> that fuel is out ofspecificati<strong>on</strong>. The primary cause of hazinessis an incre<str<strong>on</strong>g>as</str<strong>on</strong>g>e in the water c<strong>on</strong>tent of thefuel resulting from the producti<strong>on</strong> ofbiosurfactants. These are by-products ofmicrobial growth and alter the surface tensi<strong>on</strong>at the fuel/water interface. As a c<strong>on</strong>sequencethe solubility of water in the fuel is incre<str<strong>on</strong>g>as</str<strong>on</strong>g>ed,Samples of C<strong>on</strong>taminated & Clean Diesel Showing Fuel Hazinessthus causing diesel c<strong>on</strong>taminati<strong>on</strong>.

Degradati<strong>on</strong> of AdditivesCertain additives, especially those rich in nitrogen and/or phosphorous, encourage microbial growth. In the process theadditives are degraded and c<strong>on</strong>sequently their effect is lost.Microbially Induced Corrosi<strong>on</strong>Hydrogen sulphide is produced by sulphate reducing bacteria. Thisenters the soluti<strong>on</strong> and is highly corrosive, causing severe damagesto the fuel system parts and fuel injectors.Sludge Formati<strong>on</strong>Microbial debris is deposited <strong>on</strong> the tank bottom where it forms alayer of sludge. This sludge creates an envir<strong>on</strong>ment which favorsmicrobially induced corrosi<strong>on</strong>. It may also become c<strong>on</strong>taminated withviable microorganisms and unless removed will act <str<strong>on</strong>g>as</str<strong>on</strong>g> a reservoir ofinfecti<strong>on</strong> every time the tank is used.Filter PluggingMicrobial Debris Forming SludgeBiopolymers are formed during microbial growth. These are gummy products, which, al<strong>on</strong>g with microbial and other debris,are deposited <strong>on</strong> filters and pipes leading to reduced flow rates and blockages. For an end user, this can have seriousc<strong>on</strong>sequences causing engine damage and in extreme c<str<strong>on</strong>g>as</str<strong>on</strong>g>es complete failure.TECHNICAL UPDATE ON CONSTRUCTION MINING & POWER SOLUTIONSC<strong>on</strong>trol of Microbial C<strong>on</strong>taminati<strong>on</strong>Filtrati<strong>on</strong> systems are available for water separati<strong>on</strong> and suspended solid particles al<strong>on</strong>g with a diesel c<strong>on</strong>diti<strong>on</strong>er that preventand c<strong>on</strong>trol biodegradati<strong>on</strong> of diesel. This system effectively c<strong>on</strong>trols fuel c<strong>on</strong>taminati<strong>on</strong> and degradati<strong>on</strong> problems and willnot replace the sec<strong>on</strong>dary filtrati<strong>on</strong> of engines, but will enhance its performance in all operating envir<strong>on</strong>ment and varyingfuel quality.Bottle 1 (left): unprotected diesel from an engine fitted withstandard filtrati<strong>on</strong>Bottle 2 (right): Diesel protected with advanced pre filtrati<strong>on</strong>and c<strong>on</strong>diti<strong>on</strong>ing systemBenefits of diesel purificati<strong>on</strong> and c<strong>on</strong>diti<strong>on</strong>ing systemllllllllllllL<strong>on</strong>ger service life for fuel injecti<strong>on</strong> pump and injectorsHigh efficiency water and particulate removalPrevents frequently filter plugging and tank cleaningWater and particulates separate e<str<strong>on</strong>g>as</str<strong>on</strong>g>ily and drained offBack flushing feature for extended service lifePrevents and c<strong>on</strong>trols biodegradati<strong>on</strong> of dieselLow flow restricti<strong>on</strong>Enhances fine filter efficiencyClean diesel enhances combusti<strong>on</strong> and reduces fuel w<str<strong>on</strong>g>as</str<strong>on</strong>g>tageEngines run better with less smokeIncre<str<strong>on</strong>g>as</str<strong>on</strong>g>ed safety and reliabilitySimple maintenanceTo know more c<strong>on</strong>tactDr. Deb<str<strong>on</strong>g>as</str<strong>on</strong>g>ish Mukherjeedeb<str<strong>on</strong>g>as</str<strong>on</strong>g>ish.mukherjee@tipl<strong>india</strong>.comC<strong>on</strong>tributed byG SivaramakrishnanVice President-Center of Excellence

The Unsung HeroCat ® Motor Grader - Part IIMotor Graders are very versa<strong>til</strong>e and mostly used in building roads from start tofinish, from close tolerance to finish grading. A high percentage of Motor Gradersare used in road maintenance, repair and rebuilding work <strong>on</strong> provincial and townshiproads. In our previous issue we discussed about the relevant terms and modes ofoperati<strong>on</strong> that are comm<strong>on</strong>ly used while operating a Motor Grader. In this article,we will share the best practices for maintenance, clearing, building city townshiptype roads. This includes smoothing, shaping the travel surface, and providingdrainage to prevent road deteriorati<strong>on</strong> in inclement weather.6Road Maintenance TipsThe best time to dress a road is when moisture is present:after a rain or after the road h<str<strong>on</strong>g>as</str<strong>on</strong>g> been sprayed by a waterwag<strong>on</strong>. Maintain straight cutting edges by trimming themwith a torch or, if wear is not severe, by dragging thecutting edges <strong>on</strong> a smooth c<strong>on</strong>crete surface. Replace edgesbefore wear occurs <strong>on</strong> the bottom of the moldboard andreduces cutting edge support. Drag the surface when hardand dry, with the cutting edge near 90 degrees to thesurface. Cut to the depth of major potholes and d<strong>on</strong>'t fillthese holes with loose dry material, because traffic willquickly displace the loose material and the holes will reappear.Maintenance work is normally d<strong>on</strong>e with the centershiftlock pin in the center positi<strong>on</strong>, and the drawbar and circlecentered under the mainframe. For maximum machinestability, the mainframe should be straight or articulatedslightly. Articulating the rear frame toward the toe of themoldboard approximately 2 to 5 degrees (1 to 1.5 timesthe width of the tire) will frequently help reduce themachine's tendency to bounce. Start with the moldboardtop 2 inches (5.1 centimeters) ahead of the cutting edge.Then adjust to the material and c<strong>on</strong>diti<strong>on</strong>s. Use of full reartip could cause material penetrati<strong>on</strong> problems and damagethe moldboard bottom or pivot area, especially if the cuttingedges are worn.Use <strong>on</strong>ly enough down pressure to accomplish the t<str<strong>on</strong>g>as</str<strong>on</strong>g>k.Excessive down pressure <strong>on</strong> a hard dry surface causesrapid cutting edge wear, requires more horsepower andfuel and reduces productivity. Sliding and tire spinningincre<str<strong>on</strong>g>as</str<strong>on</strong>g>e fr<strong>on</strong>t and rear tire wear. In extreme c<str<strong>on</strong>g>as</str<strong>on</strong>g>es,excessive down pressure may cause the cutting edges tosplinter causing tire damage.In road maintenance, cutting edges will wear quicker inthe center than at the ends. Three secti<strong>on</strong> edges aresometimes used: carbide edges in the center, hardenededges at the ends. Check edge wear frequently to preventmoldboard damage..To Extend Cutting Edge Life in RoadMaintenance, Maintain a C<strong>on</strong>stant TipPositi<strong>on</strong>Side View of moldboard cutting edge1. FootprintThe cutting edge tip angle can affect cutting edge lifewhen maintaining roads. The tip angle should positi<strong>on</strong> thecutting edge at 90 degrees to the road surface. In thispositi<strong>on</strong>, down pressure <strong>on</strong> the moldboard places less stress<strong>on</strong> the cutting edge and retaining bolts. The edges willhave a tendency to ride over objects possibly preventingmachine damage.The fixed tip angle presents a c<strong>on</strong>stant edge thickness tothe wear surface for l<strong>on</strong>ger life. If you change the tip angleoften in this applicati<strong>on</strong>, the sharpened edge will wearquickly, shortening its life.

Cross secti<strong>on</strong> of moldboard cutting edge1. M Secti<strong>on</strong> Reinforcement 2. Slide Rails 3. Cutting EdgeNew moldboards are designed to give support to cuttingedges. To maintain this support, the edges must be replacedbefore wear occurs <strong>on</strong> the bottom edge of the moldboard(shown in grey at bottom of above illustrati<strong>on</strong>). Wear in thisarea reduces cutting edge support. Bent ends of themoldboard also reduce edge support. Repair damage beforeinstalling new edges. Cutting edges have good support in theforward directi<strong>on</strong>, but use cauti<strong>on</strong> when back-draggingmaterial or backing up with the moldboard close to the ground.For l<strong>on</strong>g life in road maintenance, use the thickest edges thatallow you to do the job. In hard material if you use excessivedown pressure, the machine's fr<strong>on</strong>t end appears light. Ifpenetrati<strong>on</strong> is a problem use thinner cutting edges, a serratededge or a scarifier to loosen the material.Cutting edges with carbide tipped replaceable teeth areoffered by several manufacturers. They generally give l<strong>on</strong>gerlife than standard hardened edges. The Cat GraderBitsSystem provides four types of tips: Standard, Wide,Penetrati<strong>on</strong> and Sharp. The teeth can be individually replacedor repositi<strong>on</strong>ed for wear. They can be placed in a solid orserrated c<strong>on</strong>figurati<strong>on</strong> depending <strong>on</strong> job needs.Wide bitStandard bits are used <strong>on</strong> larger units where penetrati<strong>on</strong>is not a problem but the material is abr<str<strong>on</strong>g>as</str<strong>on</strong>g>ive.Wide bits are used <strong>on</strong> each end of the standard arrangement.Use of all wide bits supplies a c<strong>on</strong>tinuous edge. (Note widebit in photo.)Penetrati<strong>on</strong> bits are used <strong>on</strong> mid sized Graders and wherepenetrati<strong>on</strong> is a problem.Sharp bits are used <strong>on</strong> smaller Motor Graders and wherepenetrati<strong>on</strong> is a problem. Bit types can be mixed to customizethe edge to material or c<strong>on</strong>diti<strong>on</strong>s. Cutting edge c<strong>on</strong>diti<strong>on</strong> isvery important for keeping the proper road profile. Cuttingedges c<strong>on</strong>stitute major expense in this applicati<strong>on</strong>, so checktheir c<strong>on</strong>diti<strong>on</strong> frequently.Know Your Job’s Cutting EdgeRequirements and Select the ProperType for Your C<strong>on</strong>diti<strong>on</strong>sFor the best machine stability in road maintenance, use thewidest possible p<str<strong>on</strong>g>as</str<strong>on</strong>g>s width. Keep the moldboard angle <str<strong>on</strong>g>as</str<strong>on</strong>g>square to the frame <str<strong>on</strong>g>as</str<strong>on</strong>g> possible. If material starts to flowaround the leading end of the moldboard, incre<str<strong>on</strong>g>as</str<strong>on</strong>g>e the bladeangle. Keep machine travel speed <str<strong>on</strong>g>as</str<strong>on</strong>g> high <str<strong>on</strong>g>as</str<strong>on</strong>g> possible formaximum productivity but low enough to prevent machinebounce. The cutting width of a p<str<strong>on</strong>g>as</str<strong>on</strong>g>s will depend <strong>on</strong> the lengthof the moldboard and the moldboard angle used. The chartbelow shows the width of coverage for different lengthmoldboards and several blade angles.TECHNICAL UPDATE ON CONSTRUCTION MINING & POWER SOLUTIONSMOLDBOARD LENGTH12Feet 14 Feet 16 Feet3.7 meters 4.3 meters 4.9 meters30o blade angle 10.3 ft 12.25 ft 13.7 ft3.1 m 3.7 m 4.2 m45o blade angle 8.5 ft 9.9 ft 11.3 ft2.6 m 3 m 3.4 m

Four p<str<strong>on</strong>g>as</str<strong>on</strong>g>ses are normally required to maintain a 28-ft. (8.5-meters) wide road (24-ft. [7.3 meters] wide traffic laneswith 2-ft. [0.6 meters] shoulders). In this applicati<strong>on</strong>, <strong>on</strong>wider roads, blade extensi<strong>on</strong>s are frequently used <strong>on</strong> <strong>on</strong>eor both ends of the moldboard to incre<str<strong>on</strong>g>as</str<strong>on</strong>g>e p<str<strong>on</strong>g>as</str<strong>on</strong>g>s width andreduce the number of machine p<str<strong>on</strong>g>as</str<strong>on</strong>g>ses required. Theseextensi<strong>on</strong>s are of lighter c<strong>on</strong>structi<strong>on</strong> than the parentmoldboard.8Moldboard fitted with blade extensi<strong>on</strong>sWhen backsloping, the extensi<strong>on</strong> must be installed <strong>on</strong> thetoe to obtain the heel clearance required.CAUTION: Using it <strong>on</strong> the leading end in tough or rockymaterial may damage the extensi<strong>on</strong>.When two extensi<strong>on</strong>s are installed, they should be used <strong>on</strong>lyin light maintenance work and will need to be removed forsome jobs, <str<strong>on</strong>g>as</str<strong>on</strong>g> their length restricts blade positi<strong>on</strong>ing. Inrocky are<str<strong>on</strong>g>as</str<strong>on</strong>g> where c<strong>on</strong>trol of the moldboard is desirable butthere is a need to reduce vertical stress into the drawbar,circle and main frame, use a blade cushi<strong>on</strong> arrangement forreduced maintenance and l<strong>on</strong>ger circle and drawbarcomp<strong>on</strong>ent life. An important feature in snow plowing orother high impact are<str<strong>on</strong>g>as</str<strong>on</strong>g> is the circle slip clutch. It will relievehoriz<strong>on</strong>tal impacts <strong>on</strong> the moldboard and circle and canreduce maintenance costs.Maintaining Road and Existing Ditchesand ShouldersFor maximum machine stability when maintaining the travelsurface, the Motor Grader's main frame should be straightwith the drawbar and circle centered under the frame. Forthe widest possible p<str<strong>on</strong>g>as</str<strong>on</strong>g>s width <strong>on</strong> the travel surface, keepthe moldboard angle <str<strong>on</strong>g>as</str<strong>on</strong>g> square to the frame <str<strong>on</strong>g>as</str<strong>on</strong>g> possible. Ifmaterial starts to flow around the leading end of themoldboard, or the rolling acti<strong>on</strong> dies, incre<str<strong>on</strong>g>as</str<strong>on</strong>g>e the bladeangle. Keep machine travel speed <str<strong>on</strong>g>as</str<strong>on</strong>g> high <str<strong>on</strong>g>as</str<strong>on</strong>g> possible formaximum productivity but low enough to prevent machinebounce (4-7 mph [6-11 km/h]). On straight secti<strong>on</strong>s, steerthe machine <str<strong>on</strong>g>as</str<strong>on</strong>g> straight <str<strong>on</strong>g>as</str<strong>on</strong>g> possible to maintain a straightshoulder and uniform crown to the road.Aerial view of articulating rear frame toward toe of moldboardArticulating the rear frame toward the toe of the moldboard2 to 5 degrees frequently reduces the machine's tendencyto bounce. This crab mode is extremely effective whencutting w<str<strong>on</strong>g>as</str<strong>on</strong>g>hboards from the travel surface with themoldboard. When the Motor Grader is in the crab mode, thefr<strong>on</strong>t axle is no l<strong>on</strong>ger running perpendicular to the directi<strong>on</strong>of travel. This places <strong>on</strong>e fr<strong>on</strong>t tire slightly ahead of theother and allows <strong>on</strong>e tire to be <strong>on</strong> top of a corrugati<strong>on</strong> whilethe other is at the bottom. As the tires roll up and downthrough the w<str<strong>on</strong>g>as</str<strong>on</strong>g>hboard, the fr<strong>on</strong>t axle will pivot up anddown keeping the fr<strong>on</strong>t mainframe stable. The degree ofarticulati<strong>on</strong> required to make this technique work effectivelywill vary with the space between corrugati<strong>on</strong>s.CAUTION: Do not use the crab mode when scarifyingw<str<strong>on</strong>g>as</str<strong>on</strong>g>hboarded are<str<strong>on</strong>g>as</str<strong>on</strong>g>. Crab mode could bend the scarifiershanks and/or linkage.Regular traffic forces the shoulders to mushroom aroundwhen roads are soft, widening the road. Ditches may requirecleaning to restore drainage <str<strong>on</strong>g>as</str<strong>on</strong>g> gravels fall off the road <strong>on</strong>to road shoulder and ditch slope. Spring road maintenancenormally includes repairing these problems.Use straight or articulated frame for this work.Cleaning Ditches using Linkbar & Drawbar Operati<strong>on</strong>s

Two modes of operati<strong>on</strong>s are:1. Move the linkbar to its maximum positi<strong>on</strong> toward theditch. Side shift the drawbar to its maximum positi<strong>on</strong>.With the frame in straight mode, positi<strong>on</strong> the Motor Grader<strong>on</strong> the road shoulder. Circle the moldboard and side shiftit to obtain the desired blade angle and desired reach intothe ditch. Raise the heel of the moldboard to match theditch slope angle. Move the material up <strong>on</strong>to the roadshoulder or <strong>on</strong>to the ditch slope <str<strong>on</strong>g>as</str<strong>on</strong>g> desired. When theshoulders are soft, using articulati<strong>on</strong> to offset the heavyrear frame away from the shoulder will prevent ruttingand trap water that cause shoulder damage.Re-opening culvert with Crab SteerMove slowly forward to remove the blocking material,then rotate the circle to pull the material up <strong>on</strong>to the roadshoulder. Several short forward-reverse p<str<strong>on</strong>g>as</str<strong>on</strong>g>ses may berequired to reach the bottom of the culvert. C<strong>on</strong>tinue <strong>on</strong>using <strong>on</strong>e of the ditch cleaning techniques describedpreviously. In shallow ditches, this operati<strong>on</strong> can also beaccomplished with the machine <strong>on</strong> the road travel surfaceand the frame straight. It is very important to maintainthe proper road crown for drainage. In many c<str<strong>on</strong>g>as</str<strong>on</strong>g>es whilemaintaining the road surface, operators will cut below theexisting shoulders leaving a ridge <strong>on</strong> each side of the road.In other are<str<strong>on</strong>g>as</str<strong>on</strong>g> a windrow of material is left <strong>on</strong> the roadshoulder so material is available for the next maintainingp<str<strong>on</strong>g>as</str<strong>on</strong>g>s. Both of these have undesirable effects like theyblock drainage by holding water <strong>on</strong> the shoulder causingit to become soft.TECHNICAL UPDATE ON CONSTRUCTION MINING & POWER SOLUTIONSCleaning Ditches using Crab Steer mode2. Using crab steer will allow running <strong>on</strong>e fr<strong>on</strong>t wheelin the road ditch or <strong>on</strong> the road shoulder slope to recovermaterial moved there by traffic or snow plowing. Use crabsteer to narrow shoulders, to maintain the desired roadwidth, and to clean wet ditches. The rear tandems canbe kept <strong>on</strong> the road travel surface away from the shoulder.Extend the blade into the ditch to open a drainage path.This reduces standing water and possible road damage.Crab steer can be used to reopen culverts blocked bymaterial. If the ditch bottom is solid, place the fr<strong>on</strong>t wheelsin the ditch with the rear frame <strong>on</strong> the road travel surface.Shift the circle toward the toe of moldboard, with themoldboard square to the mainframe and tipped to nearlytwo-thirds of its maximum forward tip capability. Placethe moldboard cutting edge into the ditch at the blockedend of the culvert, and set the blade angle to match theshoulder slope. Be careful not to damage the end ofculvert.1. Shoulder Undercut, 2. Shoulder WindrowNOTEThe windrow of material should be processed andspread across the road evenly with <strong>on</strong>ly the oversizerocks or chunks of sod to kick over the slope.Source:Cat ® Motor Grader Applicati<strong>on</strong> Guide

Extended Life Program (ELP)Earn profit from extended equipment life10The Indian Mining Industry h<str<strong>on</strong>g>as</str<strong>on</strong>g> traditi<strong>on</strong>ally used machines fora life span of 7-10 years or 30,000 hours of operati<strong>on</strong>, dependingup<strong>on</strong> the machine’s capacity and the depreciati<strong>on</strong> cost. Theaverage u<strong>til</strong>izati<strong>on</strong> across public and private sectors especiallyfor the lower capacity mining trucks have been around 40% ofthe scheduled hours. Thus the major structures of these equipmentdo not experience the stress cycles that are comm<strong>on</strong> to highu<strong>til</strong>izati<strong>on</strong>, leaving a scope for machine rebuild and extended lifefor additi<strong>on</strong>al periods of operati<strong>on</strong>.In the present scenario, the growth in mining industry h<str<strong>on</strong>g>as</str<strong>on</strong>g> causeda rise in the market demand for new machines which is not beingmet due to demand supply gaps from the manufacturers. Thusmining companies in public and private sectors both face achallenge to meet up to their producti<strong>on</strong> plans and are exploringopti<strong>on</strong>s that can keep their old machines available and productiveat minimum costs.To support the customers and their producti<strong>on</strong> plans, TIPL cameup with the “Extended Life Program” (ELP) to rebuild the machinesfor an additi<strong>on</strong>al period of 30,000 hours at a re<str<strong>on</strong>g>as</str<strong>on</strong>g><strong>on</strong>able cost.Backed by years of experience, TIPL h<str<strong>on</strong>g>as</str<strong>on</strong>g> all the resources such<str<strong>on</strong>g>as</str<strong>on</strong>g> the 5 star Comp<strong>on</strong>ent Rebuild Center (CRC) at Asansol inWest Bengal to refurbish the machines ensuring quality andtimelines demanded by customers.TIPL CRC - Asansol

Once a machine for rebuild is received at the CRC, theprocess starts through cleaning of the equipment in orderto remove every bit of dirt, gre<str<strong>on</strong>g>as</str<strong>on</strong>g>e, sludge, oil etc. Thisprocess is then followed by complete dismantling of theimplements and checking through specialized instrumentsto <str<strong>on</strong>g>as</str<strong>on</strong>g>certain the reusability of parts and comp<strong>on</strong>ents. Aftera comp<strong>on</strong>ent is repaired, CRC provides the facility of testingthe performance of the comp<strong>on</strong>ent <str<strong>on</strong>g>as</str<strong>on</strong>g> per Cat specificati<strong>on</strong>.Some of the multiple values customers derive through ELP, are highlighted below:llllLower cost of repair vis-à-vis capital costAvailability and producti<strong>on</strong> being equitable with that of a machine rebuilt through ELP enables achievement of producti<strong>on</strong>target <str<strong>on</strong>g>as</str<strong>on</strong>g> per scheduleFor specific models, the cycle of machine repair is far less than new equipment delivery lead timeExtended life of costly machine to achieve lower cost per t<strong>on</strong> of producti<strong>on</strong>TECHNICAL UPDATE ON CONSTRUCTION MINING & POWER SOLUTIONSTIPL’s Extended Life Program – a soluti<strong>on</strong> from TIPL which h<str<strong>on</strong>g>as</str<strong>on</strong>g> addressed the demand supply gap and customer producti<strong>on</strong>growth enhancing customer loyalty.C<strong>on</strong>tributed byBiswajit MukherjeeHead - West Bengal & Sikkim - Territory E<str<strong>on</strong>g>as</str<strong>on</strong>g>t - TIPL

Use Maintenance ManagementRun your machines at peak performance12Equipment management is the <strong>on</strong>ly wayyou can keep your machines running atpeak performance. It helps you makemaintenance decisi<strong>on</strong>s, reduce owningand operating costs and maximizecomp<strong>on</strong>ent life.As a Cat ® dealer we have beenc<strong>on</strong>tinuously providing value - b<str<strong>on</strong>g>as</str<strong>on</strong>g>edinformati<strong>on</strong> to our customers. Theseinclude equipment management processthat h<str<strong>on</strong>g>as</str<strong>on</strong>g> positive impact and improvesoverall business profitability.An efficient equipment maintenancemanagement process will schedule theentire repair cycle of various systems andcomp<strong>on</strong>ents <strong>on</strong> the equipment al<strong>on</strong>g withthe filter and oil changes at appropriatehours. Maximizing comp<strong>on</strong>ent life wouldmean ensuring a c<strong>on</strong>taminant free systemand checking the c<strong>on</strong>taminants in betweenoil changes especially if the intervalsexceed 1000 hours.Scheduled Oil Sampling (S O S SM ) willl lidentify and provide early warnings <strong>on</strong>defects arising inside major comp<strong>on</strong>ents.S O S SMis a highly essential m<strong>on</strong>itoringl ltool for aligning with Repair Before Failurec<strong>on</strong>cept and ensuring designed comp<strong>on</strong>entlife and managing <str<strong>on</strong>g>as</str<strong>on</strong>g>sociated coststhereof. Machine system audits atscheduled intervals will help in correctingthe minor problems before they becomemajor. It also indicates the actualcomp<strong>on</strong>ent change <strong>on</strong> overhaul timelinesand ensures that maintenance costs d<strong>on</strong>ot exceed budgets; thus c<strong>on</strong>trolling lifecycle costs. It also tracks individualcomp<strong>on</strong>ent life irrespective of machineclocked hours, b<str<strong>on</strong>g>as</str<strong>on</strong>g>ed <strong>on</strong> the m<strong>on</strong>itoringof the comp<strong>on</strong>ent during each comp<strong>on</strong>entchangeout (comp<strong>on</strong>ent tracking).TIPL offers a host of such supportagreements to choose from, of whichS O S SM c<strong>on</strong>diti<strong>on</strong> m<strong>on</strong>itoring and machinel lsystem audits being critical to machineperformance at lowest costs.While walk-arounds before every shift areimportant, they d<strong>on</strong>'t let you see insideof your engine. Regular fluid analysis doesgive you that glimpse inside, so you not<strong>on</strong>ly avoid failures but also find problemsearly to keep repair costs low. Torecognize the value of regular fluidanalysis, you need <strong>on</strong>ly c<strong>on</strong>sider two facts:l80% of hydraulic system failures aredue to c<strong>on</strong>taminati<strong>on</strong>.l50% of engine problems are linked tocooling system faults.Cat S O S SMServices is a good idea forl lcompetitive <str<strong>on</strong>g>as</str<strong>on</strong>g> well <str<strong>on</strong>g>as</str<strong>on</strong>g> Cat machines,helping you manage downtime moreeffectively. Regular S O S SMsamplingl lindicates trends so you can schedulerepairs with a minimum loss of producti<strong>on</strong>.There are primarily four types of S O S ltesting and possible causes of problems.1. Wear Rate AnalysisIn EngineslSMSilic<strong>on</strong> - air inducti<strong>on</strong> system/filter dirtc<strong>on</strong>taminati<strong>on</strong>.Ir<strong>on</strong> - abnormal operating temperatures,oil degradati<strong>on</strong>, rust, broken rings, lackof lubricati<strong>on</strong>.Chrome - blowby, oil c<strong>on</strong>sumpti<strong>on</strong> ordegradati<strong>on</strong>.Lead - lack of lubricati<strong>on</strong>, coolant or fuelc<strong>on</strong>taminati<strong>on</strong>.In HydraulicsSilic<strong>on</strong> - dirt c<strong>on</strong>taminati<strong>on</strong>.Copper - oil degradati<strong>on</strong>, c<strong>on</strong>taminati<strong>on</strong>.In Transmissi<strong>on</strong>sAluminum or Copper - abnormaloperating temperatures, lack of lubricati<strong>on</strong>,rust, c<strong>on</strong>taminati<strong>on</strong>.In Final DrivesSilic<strong>on</strong> - dirt or clay soil c<strong>on</strong>taminati<strong>on</strong>.Ir<strong>on</strong> - water entry, preload loss.When analyzing the trend, d<strong>on</strong>'t look at <str<strong>on</strong>g>as</str<strong>on</strong>g>ingle metal, observe the wear rate of acombinati<strong>on</strong> of metals. For example,c<strong>on</strong>tinuous high ir<strong>on</strong> and chromiumreadings al<strong>on</strong>g with high soot will indicateliner and ring wear with incre<str<strong>on</strong>g>as</str<strong>on</strong>g>e ofblowby. So<strong>on</strong>er the problem is rectified,lesser will be the c<strong>on</strong>sequential damages.

2. Oil C<strong>on</strong>diti<strong>on</strong>Soot - plugged air filter element,excessive idling, cool engine temperatures,blowby, rapid accelerati<strong>on</strong>, l<strong>on</strong>goil drain intervals.Sulfati<strong>on</strong> - excess sulfur in fuel, lowTBN (Total B<str<strong>on</strong>g>as</str<strong>on</strong>g>e Number, whichneutralizes sulfur), machine operating inhigh humidity and temperature, l<strong>on</strong>g oildrain intervals.Oxidati<strong>on</strong> - high operating temperatures,glycol or copper c<strong>on</strong>taminants, inefficientantioxidant oil additives, l<strong>on</strong>g oil drainintervals.Nitrati<strong>on</strong> - nitrogen chemicallycombining with oil.3. Oil C<strong>on</strong>taminati<strong>on</strong>Water - water p<str<strong>on</strong>g>as</str<strong>on</strong>g>sing through a matingsurface. You'll receive an alert whenyour sample exceeds 0.5% waterc<strong>on</strong>tent.Fuel Diluti<strong>on</strong> - leak in transfer pump orbad fuel nozzle. You'll receive an alertwhen fuel diluti<strong>on</strong> reaches 4%.ISO CodeOil viscosity is decre<str<strong>on</strong>g>as</str<strong>on</strong>g>ed.Glycol - leak from the cooling systemthrough the heat exchanger into the oil,leading to accelerated oil oxidati<strong>on</strong> andincre<str<strong>on</strong>g>as</str<strong>on</strong>g>ed oil viscosity.Silic<strong>on</strong> - dirt entry.4. Oil CleanlinessParticle Count detects additi<strong>on</strong>al signsof abnormal wear and dirty oil that othertests may not find, such <str<strong>on</strong>g>as</str<strong>on</strong>g> gear androller bearing failures or n<strong>on</strong>metallicmaterials.The chart below shows the levels of c<strong>on</strong>taminati<strong>on</strong> identified by ISO codes in your S l O l S SM Services reportsParticles per milliliter20........................................................ 5000 - 1000019........................................................ 2500 - 500018........................................................ 1300 - 250017........................................................ 640 - 130016........................................................ 320 - 64015........................................................ 160 – 32TECHNICAL UPDATE ON CONSTRUCTION MINING & POWER SOLUTIONS

14S O S SMsamples should be taken for alll lfluids. When it’s performed regularly,coupled with expert interpretati<strong>on</strong>, itwill help lower maintenance costs.Combined with S O S SM , effectivel lc<strong>on</strong>taminati<strong>on</strong> c<strong>on</strong>trol reduces breakdownsand <str<strong>on</strong>g>as</str<strong>on</strong>g>sociated costs. Keeping machinesystem clean eliminates comp<strong>on</strong>ent wearand improves system efficiency andresp<strong>on</strong>se under varying loads.Because 80% of hydraulic system failurescan be traced to c<strong>on</strong>taminati<strong>on</strong>, here aresome tips that will help you focus <strong>on</strong>cleanliness.Types of C<strong>on</strong>taminantsllllAbr<str<strong>on</strong>g>as</str<strong>on</strong>g>ive particles like aluminium andsilica cause sticky valves and poorpump performance.Water in hydraulic fluid forms bubblesthat pit internal comp<strong>on</strong>ent surfaces.Air in the system causes jerky moti<strong>on</strong>.Heat reduces the lubricity of hydraulicfluid, accelerating comp<strong>on</strong>ent wear.Sources of C<strong>on</strong>taminantsllllExposure to external envir<strong>on</strong>ment viaworn seals, faulty g<str<strong>on</strong>g>as</str<strong>on</strong>g>kets, leakyvalves or defects in cylinder rods.Internal wear due to insufficientlubricati<strong>on</strong> or improper clearances.Installing new comp<strong>on</strong>ents, like dirtyhoses.Adding fluids that were stored in dirtyc<strong>on</strong>tainers.C<strong>on</strong>trolling C<strong>on</strong>taminantsllUse particle counter to <str<strong>on</strong>g>as</str<strong>on</strong>g>sess thecleanliness of the fluid before and afterfiltrati<strong>on</strong>.Flush a dirty system and fill it withnew fluid.Use these simple t<str<strong>on</strong>g>as</str<strong>on</strong>g>ks and derivesignificant impact <strong>on</strong> your hydraulic systemefficiency.C<strong>on</strong>taminati<strong>on</strong> c<strong>on</strong>trol and SlOlS SM analysisare two very effective ways you canc<strong>on</strong>sider to improve your machineavailability and performance. Performedat regular intervals these take minimumtime and cost but have huge returns <strong>on</strong>your investment.lllllCheck the machine for leaksduring daily walkaround inspecti<strong>on</strong>.Use proper filters and change themregularly.Use proper hydraulic fluid, filtering itwhen transferred between storagelocati<strong>on</strong>s.Use desiccant breathers <strong>on</strong> fluidstorage c<strong>on</strong>tainers to prevent waterand c<strong>on</strong>taminant ingressi<strong>on</strong> inside thesystem.Remove c<strong>on</strong>taminants from a dirtysystem with kidney loop mobilefiltrati<strong>on</strong>.C<strong>on</strong>tributed byDr. Deb<str<strong>on</strong>g>as</str<strong>on</strong>g>ish MukherjeeIn-charge-Scheduled Oil Sampling Lab, TIPL

THE FASTEST GROWINGCONSTRUCTION EQUIPMENT COMPANY9TH CONSTRUCTION WORLD AWARDS 20111, Taratolla Road, Garden Reach, Kolkata 700 024Tel: (91) (33) 2469 3732-36, 6633 2000Fax: (91) (33) 2469 2143/3731www.<strong>til</strong><strong>india</strong>.in

“We make ourcustomers moreprofitable”lA quarterly journal from TIPL l For private circulati<strong>on</strong> <strong>on</strong>ly l Edited & Published by Corporate Communicati<strong>on</strong>s l Printed at CDC Printers (P) Ltd. l Copyright © TIPL <strong>2012</strong>CAT1, Taratolla Road, Garden Reach, Kolkata 700 024Tel: (91) (33) 2469 3732-36, 6633 2000, Fax: (91) (33) 2469 2143/3731Our Toll Free Nos.: 1800-345-3356 (Sales) 1800-345-3355 (Service)Visit our website: www.tipl<strong>india</strong>.in