Download Metacut Abrasive Cutter / Cut-off Saw PDF Here

Download Metacut Abrasive Cutter / Cut-off Saw PDF Here

Download Metacut Abrasive Cutter / Cut-off Saw PDF Here

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

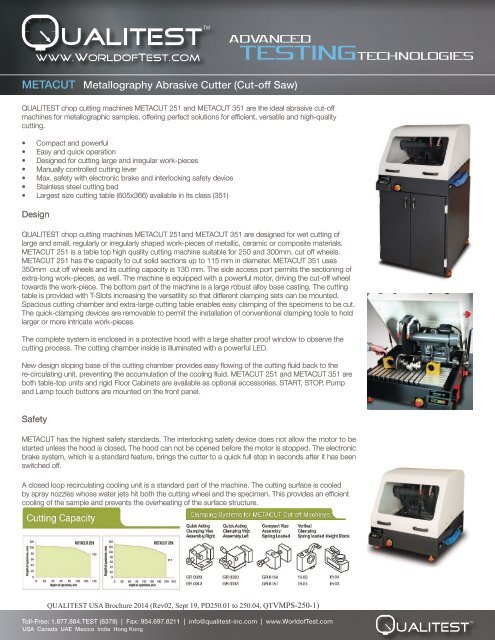

METACUT Metallography <strong>Abrasive</strong> <strong><strong>Cut</strong>ter</strong> (<strong>Cut</strong>-<strong>off</strong> <strong>Saw</strong>)ADVANCEDTESTINGTECHNOLOGIESQUALITEST chop cutting machines METACUT 251 and METACUT 351 are the ideal abrasive cut-<strong>off</strong>machines for metallographic samples, <strong>off</strong>ering perfect solutions for efficient, versatile and high-qualitycutting.• Compact and powerful• Easy and quick operation• Designed for cutting large and irregular work-pieces• Manually controlled cutting lever• Max. safety with electronic brake and interlocking safety device• Stainless steel cutting bed• Largest size cutting table (605x366) available in its class (351)DesignQUALITEST chop cutting machines METACUT 251and METACUT 351 are designed for wet cutting oflarge and small, regularly or irregularly shaped work-pieces of metallic, ceramic or composite materials.METACUT 251 is a table top high quality cutting machine suitable for 250 and 300mm. cut <strong>off</strong> wheels.METACUT 251 has the capacity to cut solid sections up to 115 mm in diameter. METACUT 351 uses350mm cut <strong>off</strong> wheels and its cutting capacity is 130 mm. The side access port permits the sectioning ofextra-long work-pieces, as well. The machine is equipped with a powerful motor, driving the cut-<strong>off</strong> wheeltowards the work-piece. The bottom part of the machine is a large robust alloy base casting. The cuttingtable is provided with T-Slots increasing the versatility so that different clamping sets can be mounted.Spacious cutting chamber and extra-large cutting table enables easy clamping of the specimens to be cut.The quick-clamping devices are removable to permit the installation of conventional clamping tools to holdlarger or more intricate work-pieces.The complete system is enclosed in a protective hood with a large shatter proof window to observe thecutting process. The cutting chamber inside is illuminated with a powerful LED.New design sloping base of the cutting chamber provides easy flowing of the cutting fluid back to there-circulating unit, preventing the accumulation of the cooling fluid. METACUT 251 and METACUT 351 areboth table-top units and rigid Floor Cabinets are available as optional accessories. START, STOP, Pumpand Lamp touch buttons are mounted on the front panel.SafetyMETACUT has the highest safety standards. The interlocking safety device does not allow the motor to bestarted unless the hood is closed, The hood can not be opened before the motor is stopped. The electronicbrake system, which is a standard feature, brings the cutter to a quick full stop in seconds after it has beenswitched <strong>off</strong>.A closed loop recirculating cooling unit is a standard part of the machine. The cutting surface is cooledby spray nozzles whose water jets hit both the cutting wheel and the specimen. This provides an efficientcooling of the sample and prevents the overheating of the surface structure.QUALITEST USA Brochure 2014 (Rev02, Sept 19, PD250.01 to 250.04, QTVMPS-250-1)Toll-Free: 1.877.884.TEST (8378) | Fax: 954.697.8211 | info@qualitest-inc.com | www.WorldofTest.comUSA Canada UAE Mexico India Hong Kong

METACUT Metallography <strong>Abrasive</strong> <strong><strong>Cut</strong>ter</strong> (<strong>Cut</strong>-<strong>off</strong> <strong>Saw</strong>)ADVANCEDTESTINGTECHNOLOGIESClamping DevicesMany sample preparation applications require the sectioning of specimen from a small or irregularly shapedsample or component part. The small size or irregular sample shape can create positioning and clampingdifficulties for the operator. To overcome these difficulties QUALITEST <strong>off</strong>ers a number of special clampingdevices for use with METACUT abrasive cutters which are equipped with stainless T - slotted clampingtables. All clamping devices are made of stainless steel and can be attached to the cutters T-Slot beds inseconds for fast, positive clamping of parts having virtually any configuration.METACUT 251 <strong>Abrasive</strong> <strong><strong>Cut</strong>ter</strong> (<strong>Cut</strong>-<strong>off</strong> <strong>Saw</strong>)<strong>Abrasive</strong> <strong>Cut</strong>ting Machine, Microprocessor controlled, front panel with touch-pad controls, 3 KW compactpowerful motor, electronic brake system, cutting capacity up to 90/115 mm solid stock, for cut-<strong>off</strong> wheelsup to Ø 250/300 mm, twin T-slotted clamping table 255x250 mm made of stainless steel, bottom partas rugged alloy base casting, GRP protective hood, 80 lit. re-circulating cooling unit with connectionhoses and ready for operation.Includes a standard set of cutting consumables composed of an assortment of 20 cut-<strong>off</strong> wheels with 250mm dia. and 5 Lt. of cooling fluid.METACUT 351 <strong>Abrasive</strong> <strong><strong>Cut</strong>ter</strong> (<strong>Cut</strong>-<strong>off</strong> <strong>Saw</strong>)<strong>Abrasive</strong> <strong>Cut</strong>ting Machine, Microprocessor controlled, front panel with touch-pad controls, 5.5 KWcompact powerful motor, electronic brake system, cutting capacity up to 130 mm solid stock, for cut-<strong>off</strong>wheels up to Ø 350 mm, extra large T-slotted clamping table 605x366 mm made of stainless steel, bottompart as rugged alloy base casting, 100 lit. re-circulating cooling unit with connection hoses and ready foroperation.Includes a standard set of cutting consumables composed of; An assortment of 20 cut-<strong>off</strong> wheels with350 mm dia. and 5 lit. of cooling fluid.METACUT 351METACUT 251QUALITEST USA Brochure 2014 (Rev02, Sept 19, PD250.01 to 250.04, QTVMPS-250-1)Toll-Free: 1.877.884.TEST (8378) | Fax: 954.697.8211 | info@qualitest-inc.com | www.WorldofTest.comUSA Canada UAE Mexico India Hong Kong

METACUT Metallography <strong>Abrasive</strong> <strong><strong>Cut</strong>ter</strong> (<strong>Cut</strong>-<strong>off</strong> <strong>Saw</strong>)ADVANCEDTESTINGTECHNOLOGIESSpecifications10 05 METACUT 251<strong>Abrasive</strong> <strong>Cut</strong>ting Machine, Microprocessor controlled, front panel with touch-pad controls, 3 KW compact powerfulmotor, electronic brake system, cutting capacity up to 90/115 mm solid stock, for cut-<strong>off</strong> wheels up to Ø 250/300 mm,twin T-slotted clamping table 255x250 mm made of stainless steel, bottom part as rugged alloy base casting, GRPprotective hood, 80 lit. re-circulating cooling unit with connection hoses and ready for operation.Without clamping devices.400V, 3 phase, 50 HzIncludes a standard set of cutting consumables composed of;- An assortment of 20 cut-<strong>off</strong> wheels with 250 mm dia.- 5 Lit. of cooling fluid.Clamping Devices for METACUT 251GR 0012 Quick Acting Clamping Vise Assembly, Right (Stainless Steel)GR 0013 Quick Acting Clamping Vise Assembly, LeftGR 0151 Compact Vise Assembly, Spring Loaded.15 01 MBU 1011 Vertical Clamping Device with clamping shoe, clamping height upto 90 mm.GR 0453 Fastener vise for longitudinal sectioning of screws, fasteners tubes, etc. from 12 to 45 mm. in lengthGR 0937Accessories for METACUT 251Cabinet for floor mode.12 05 METACUT 351<strong>Abrasive</strong> <strong>Cut</strong>ting Machine, Microprocessor controlled, front panel with touch-pad controls, 5.5 KW compact powerfulmotor, electronic brake system, cutting capacity up to 130 mm solid stock, for cut-<strong>off</strong> wheels up to Ø 350 mm, extralarge T-slotted clamping table 605x366 mm made of stainless steel, bottom part as rugged alloy base casting, 100lit. re-circulating cooling unit with connection hoses and ready for operation.Without clamping devices.400V, 3 phase, 50 HzIncludes a standard set of cutting consumables composed of;- An assortment of 20 cut-<strong>off</strong> wheels with 350 mm dia.- 5 Lit. of cooling fluid.10 02-V As above (10 02) and having variable cutting speed with 3 different fixed speeds (2400-3000-3600 RPM)GR 0029GR 0030GR 0154Clamping Devices for METACUT 351Quick Acting Clamping Vise Assembly, RightQuick Acting Clamping Vise Assembly, Left.Compact Vise Assembly, Spring Loaded15 02 MBU 1011 Vertical Clamping Device with clamping shoe, clamping height up to 115 mm.15 04 MK 10 Height Block, 70 mm 22GR 0938Accessories for METACUT 351Cabinet for floor mode, MTC-351QUALITEST USA Brochure 2014 (Rev02, Sept 19, PD250.01 to 250.04, QTVMPS-250-1)Toll-Free: 1.877.884.TEST (8378) | Fax: 954.697.8211 | info@qualitest-inc.com | www.WorldofTest.comUSA Canada UAE Mexico India Hong Kong

METACUT Metallography <strong>Abrasive</strong> <strong><strong>Cut</strong>ter</strong> (<strong>Cut</strong>-<strong>off</strong> <strong>Saw</strong>)ADVANCEDTESTINGTECHNOLOGIESMETACUT 251 METACUT 351Order No 10 05 12 05<strong>Cut</strong>ting Power kW (S1) 3 5.5<strong>Cut</strong>ting Power kW (S3) 4.6 7,9Wheel speed, (rpm) 2800 2200Operation Manual ManualWheel diameter, (mm) Ø250 / Ø300 Ø 350<strong>Cut</strong>ting Capacity ø (mm) Ø90 / Ø115 Ø130<strong>Cut</strong>ting Capacity, # (mm) 50 x 165 / 50 x 195 84 x 236T-Slot table dimensions, (mm) 255 x 250 605 x 366T-Slot dimension, (mm) 12 12Size WxDxH (cm) 58 x 68 x 49 68 x 81 x 62Weight, (kg) 132 165Cooling unit, (Lit.) 80 100Mains, (V) 3 phase 400V, 50Hz AC 3 phase 400V, 50Hz ACNote: Other voltages and frequencies available upon request. Please state before ordering.Please download our complete technical brochure at www.WorldofTest.com/pdf/metacut.pdfQUALITEST USA Brochure 2014 (Rev02, Sept 19, PD250.01 to 250.04, QTVMPS-250-1)Toll-Free: 1.877.884.TEST (8378) | Fax: 954.697.8211 | info@qualitest-inc.com | www.WorldofTest.comUSA Canada UAE Mexico India Hong Kong