Literature PDF

Literature PDF

Literature PDF

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

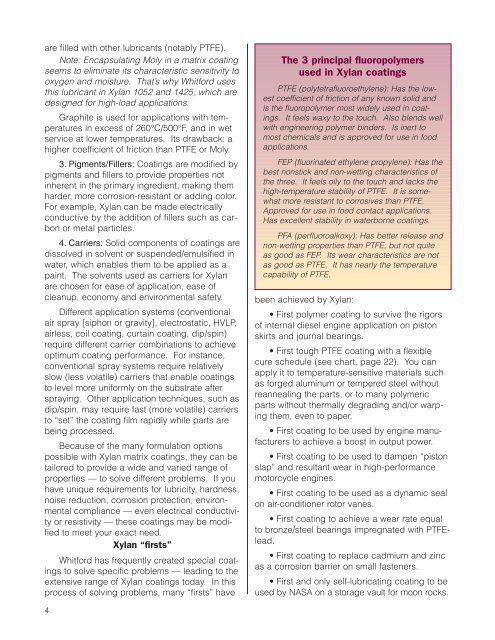

are filled with other lubricants (notably PTFE).Note: Encapsulating Moly in a matrix coatingseems to eliminate its characteristic sensitivity tooxygen and moisture. That’s why Whitford usesthis lubricant in Xylan 1052 and 1425, which aredesigned for high-load applications.Graphite is used for applications with temperaturesin excess of 260°C/500°F, and in wetservice at lower temperatures. Its drawback: ahigher coefficient of friction than PTFE or Moly.3. Pigments/Fillers: Coatings are modified bypigments and fillers to provide properties notinherent in the primary ingredient, making themharder, more corrosion-resistant or adding color.For example, Xylan can be made electricallyconductive by the addition of fillers such as carbonor metal particles.4. Carriers: Solid components of coatings aredissolved in solvent or suspended/emulsified inwater, which enables them to be applied as apaint. The solvents used as carriers for Xylanare chosen for ease of application, ease ofcleanup, economy and environmental safety.Different application systems (conventionalair spray [siphon or gravity], electrostatic, HVLP,airless, coil coating, curtain coating, dip/spin)require different carrier combinations to achieveoptimum coating performance. For instance,conventional spray systems require relativelyslow (less volatile) carriers that enable coatingsto level more uniformly on the substrate afterspraying. Other application techniques, such asdip/spin, may require fast (more volatile) carriersto “set” the coating film rapidly while parts arebeing processed.Because of the many formulation optionspossible with Xylan matrix coatings, they can betailored to provide a wide and varied range ofproperties — to solve different problems. If youhave unique requirements for lubricity, hardness,noise reduction, corrosion protection, environmentalcompliance — even electrical conductivityor resistivity — these coatings may be modifiedto meet your exact need.Xylan “firsts”Whitford has frequently created special coatingsto solve specific problems — leading to theextensive range of Xylan coatings today. In thisprocess of solving problems, many “firsts” haveThe 3 principal fluoropolymersused in Xylan coatingsPTFE (polytetrafluoroethylene): Has the lowestcoefficient of friction of any known solid andis the fluoropolymer most widely used in coatings.It feels waxy to the touch. Also blends wellwith engineering polymer binders. Is inert tomost chemicals and is approved for use in foodapplications.FEP (fluorinated ethylene propylene): Has thebest nonstick and non-wetting characteristics ofthe three. It feels oily to the touch and lacks thehigh-temperature stability of PTFE. It is somewhatmore resistant to corrosives than PTFE.Approved for use in food contact applications.Has excellent stability in waterborne coatings.PFA (perfluoroalkoxy): Has better release andnon-wetting properties than PTFE, but not quiteas good as FEP. Its wear characteristics are notas good as PTFE. It has nearly the temperaturecapability of PTFE.been achieved by Xylan:• First polymer coating to survive the rigorsof internal diesel engine application on pistonskirts and journal bearings.• First tough PTFE coating with a flexiblecure schedule (see chart, page 22). You canapply it to temperature-sensitive materials suchas forged aluminum or tempered steel withoutreannealing the parts, or to many polymericparts without thermally degrading and/or warpingthem, even to paper.• First coating to be used by engine manufacturersto achieve a boost in output power.• First coating to be used to dampen “pistonslap” and resultant wear in high-performancemotorcycle engines.• First coating to be used as a dynamic sealon air-conditioner rotor vanes.• First coating to achieve a wear rate equalto bronze/steel bearings impregnated with PTFElead.• First coating to replace cadmium and zincas a corrosion barrier on small fasteners.• First and only self-lubricating coating to beused by NASA on a storage vault for moon rocks.4