PowerTorq ™ Precision Ball Spline Assemblies

PowerTorq ™ Precision Ball Spline Assemblies

PowerTorq ™ Precision Ball Spline Assemblies

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

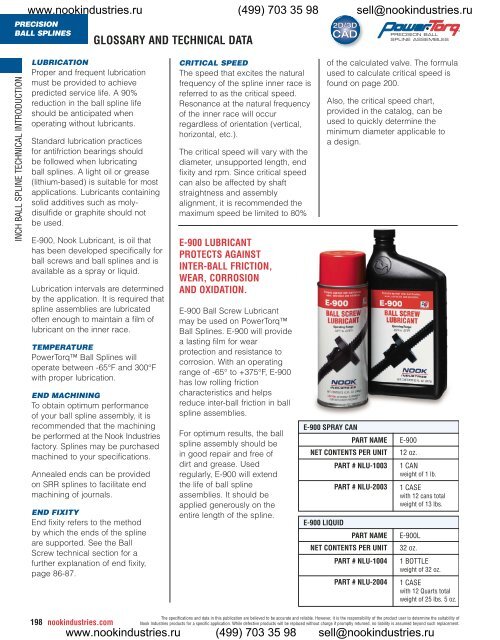

www.nookindustries.ru (499) 703 35 98 sell@nookindustries.ruPRECISIONBALL SPLINESGLOSSARY AND TECHNICAL DATAPRECISION BALLSPLINE ASSEMBLESINCH BALL SPLINE TECHNICAL INTRODUCTIONLUBRICATIONProper and frequent lubricationmust be provided to achievepredicted service life. A 90%reduction in the ball spline lifeshould be anticipated whenoperating without lubricants.Standard lubrication practicesfor antifriction bearings shouldbe followed when lubricatingball splines. A light oil or grease(lithium-based) is suitable for mostapplications. Lubricants containingsolid additives such as molydisulfideor graphite should notbe used.E-900, Nook Lubricant, is oil thathas been developed specifically forball screws and ball splines and isavailable as a spray or liquid.Lubrication intervals are determinedby the application. It is required thatspline assemblies are lubricatedoften enough to maintain a film oflubricant on the inner race.TEMPERATURE<strong>PowerTorq</strong> <strong>Ball</strong> <strong>Spline</strong>s willoperate between -65°F and 300°Fwith proper lubrication.END MACHININGTo obtain optimum performanceof your ball spline assembly, it isrecommended that the machiningbe performed at the Nook Industriesfactory. <strong>Spline</strong>s may be purchasedmachined to your specifications.Annealed ends can be providedon SRR splines to facilitate endmachining of journals.END FIXITYEnd fixity refers to the methodby which the ends of the splineare supported. See the <strong>Ball</strong>Screw technical section for afurther explanation of end fixity,page 86-87.CRITICAL SPEEDThe speed that excites the naturalfrequency of the spline inner race isreferred to as the critical speed.Resonance at the natural frequencyof the inner race will occurregardless of orientation (vertical,horizontal, etc.).The critical speed will vary with thediameter, unsupported length, endfixity and rpm. Since critical speedcan also be affected by shaftstraightness and assemblyalignment, it is recommended themaximum speed be limited to 80%E-900 LUBRICANTPROTECTS AGAINSTINTER-BALL FRICTION,WEAR, CORROSIONAND OXIDATION.E-900 <strong>Ball</strong> Screw Lubricantmay be used on <strong>PowerTorq</strong><strong>Ball</strong> <strong>Spline</strong>s. E-900 will providea lasting film for wearprotection and resistance tocorrosion. With an operatingrange of -65° to +375°F, E-900has low rolling frictioncharacteristics and helpsreduce inter-ball friction in ballspline assemblies.For optimum results, the ballspline assembly should bein good repair and free ofdirt and grease. Usedregularly, E-900 will extendthe life of ball splineassemblies. It should beapplied generously on theentire length of the spline.of the calculated valve. The formulaused to calculate critical speed isfound on page 200.Also, the critical speed chart,provided in the catalog, can beused to quickly determine theminimum diameter applicable toa design.E-900 SPRAY CANPART NAMENET CONTENTS PER UNITE-900 LIQUIDPART # NLU-1003PART # NLU-2003PART NAMENET CONTENTS PER UNITPART # NLU-1004PART # NLU-2004E-90012 oz.1 CANweight of 1 lb.1 CASEwith 12 cans totalweight of 13 lbs.E-900L32 oz.1 BOTTLEweight of 32 oz.1 CASEwith 12 Quarts totalweight of 25 lbs. 5 oz.198nookindustries.comThe specifications and data in this publication are believed to be accurate and reliable. However, it is the responsibility of the product user to determine the suitability ofNook Industries products for a specific application. While defective products will be replaced without charge if promptly returned, no liability is assumed beyond such replacement.www.nookindustries.ru (499) 703 35 98 sell@nookindustries.ru