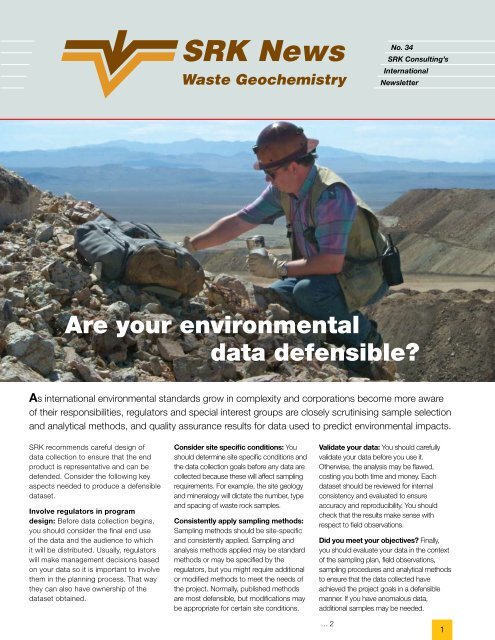

Are your environmental data defensible? - SRK Consulting

Are your environmental data defensible? - SRK Consulting

Are your environmental data defensible? - SRK Consulting

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

New porphyry copper mine approvalThe sharp rise in commodity prices anda favourable political climate have sparkeda strong interest in developing mineralproperties in western Canada and theUS. The rebirth of mining in these areasafter years of absence is an exciting andpositive occurrence for miners, operators,and the business community.The intervening years, however, have seenseveral key operational changes. In particular,scrutiny of the potential effects of new mineshas increased. This change has caused aneed for transparent and <strong>defensible</strong> waterquality predictions for mine facilities.An enviable record of accomplishmentSince the 1980s, <strong>SRK</strong> has providedclients with detailed evaluations regardingthe <strong>environmental</strong> effects of their minesites. During this time, new equipmentand reporting procedures have increasedefficiency and client benefits.Most recently, this combination of experienceand advanced testing procedures rewardedclients in Alaska and British Columbia whenour water quality predictions led to theacceptance of proposals for new mine sites.In 2004, Teck Pogo Inc. beganconstruction of the underground PogoMine, a gold mine near Fairbanks, Alaska.To secure the needed approvals, <strong>SRK</strong>prepared water chemistry predictions forthe underground mine, waste rock disposalarea, and dry-stacked tailings. Operationsat this mine are now underway.New approvalsSuccess was also achieved in BritishColumbia, where several copper porphyryproperties are being re-examined. <strong>SRK</strong>contributed to the approval of theundeveloped Red Chris Project operated bybcMetals and the mining of new zones at theMount Polley Mine owned by Imperial Metals.Aware of the need to respond quickly tomarket forces, <strong>SRK</strong> helped companiesNEMI and Western Canadian Coal beginsmall mining operations and assistedFalls Mountain Coal start a full-scalemine. These mines are located in BritishColumbia’s major coalfields in thenortheastern sector of the province.The development of a profitable miningoperation requires the desire to succeed,good people, and access to the bestinformation.With offices on six continents, our team ofgeochemists is near at hand.Stephen Day: sday@srk.combcMetals’ Red Chris porphyry copper mineStephen Day3

aJohn HarmanJohn is a PrincipalGroundwater/Environmentalengineer with over25 years experience.He has an M.Sc.in Hydrogeologyfrom BirminghamUniversity andoriginally qualified in John HarmanMining Engineering atthe Royal School of Mines in London.During his career John has beenextensively involved in all aspects ofwater management in mining, fromwater supply wellfield developmentthrough to mine dewatering and watermanagement, <strong>environmental</strong> managementand remediation. He has workedthroughout the world in the extremes ofboth wet and arid environments. Johncurrently heads up the Water Group in ourSantiago, Chile office.John Harman: jharman@srk.clJames LakeJames is amember of theWater departmentin Johannesburg.He has a M.Sc.in EnvironmentalGeochemistry fromthe University ofCape Town. He has9 years experience James Lakeworking on a varietyof geochemical projects, with themain focus being on mine residuemanagement. This has included wastecharacterisation and <strong>environmental</strong>impact assessment.James Lake: jlake@srk.co.za4South America: Offices bring full powerof <strong>SRK</strong> to their clients’ doorAs in other parts of the world the MiningIndustry in South America is expanding atastonishing speed. As a consequence theneed for high-level expertise in all aspectsof the mining industry has never beengreater and <strong>SRK</strong> in South America hasbeen playing a key role in support to itsclients. Our scientists and engineers in ourwell-established Santiago, Chile and newBelo Horizonte, Brazil offices are usingtheir extensive international experienceto help our clients meet the challengesof rapid growth. <strong>SRK</strong> is currentlyproviding a diverse range of geochemicalservices including characterisationand management planning for tailingsimpoundments, specialist studiesfor particular contaminants, input todue diligence assessments as part ofmergers and acquisitions, geochemicalassessments for mine closure planningand baseline studies for new mines.This newsletter is dedicated to our friend andcolleague, Ingrid Rozas Valenzuela, of Santiago, Chilewho died suddenly in July of this year. Ingrid joined<strong>SRK</strong> in September 2005. Initially, she spent sevenmonths in Vancouver working with Stephen Day,Kelly Sexsmith and others in the GeoEnvironmentalDepartment. She then returned to Santiago to developthis business area in Chile and South America; sheembarked on the project with great enthusiasm andhad begun to see the rewards of her effort by way of anumber of interesting project leads.Photo kindly authorised by Xstrata Tintaya SANew obligationsWith few exceptions, new mining legislationin Chile, Peru, and other South Americancountries requires that new projectsincorporate closure planning into theirEnvironmental Impact Assessment (EIA) andmine planning stage. Increasingly, existingoperations must also produce closure plansthat clearly define long-term liabilities.As a recognised leader in regulatory issues,<strong>SRK</strong> is actively involved in helping our clientsattain the approvals they need to operate.As each new project is rarely the same asthe previous one, our team in South Americauses the latest in technologies and itsnetwork of scientists and engineers aroundthe globe to ensure it presents clients withthe best solution to their problem.For more information call John Harmanat +56 2 269 0353or info@srk.clIn Memoriam: Ingrid Rozas ValenzuelaHer delightful personalitywas always evident and hercontribution to the team inIngrid RozasSantiago, both professionallyValenzuelaand personally, was a greatinspiration. She will be missed by all of us - herfriends in Santiago and in Vancouver - and byother members of the <strong>SRK</strong> group with whom shewas building strong working relationships. We areprivileged to have had her on our team, if only for afleeting moment.

Solving mining challenges in Africa & the Middle East<strong>SRK</strong>’s geochemists are involved insolving wide-ranging waste managementchallenges faced by mine operatorsthroughout Africa and the Middle East. Ouroffices in the region are located in SouthAfrica, Turkey and Zimbabwe. We provideexpertise in a number of areas including:Development of baseline and wastemanagement strategies: For example,the Geita Gold Mine in Tanzania, where<strong>SRK</strong> established the baseline in 1997 whichinvolved risk based site selection, liaisonwith relevant regulatory bodies, trainingof sampling personnel and developmentof a time-series <strong>data</strong>base. Subsequentmonitoring and <strong>data</strong> interpretation hasenabled <strong>SRK</strong> to demonstrate the impactof artisan workings and the occurrence ofnaturally elevated metal levels in surfaceand groundwater. As a result, a site specificbaseline was established that reflects theseCopper rich tailings atKolewezi, Zambiaprocesses that are not related to mining.This approach has allowed the regulatorsand mining company to understand theprocesses affecting water quality and theallocation of potential liabilities.Evaluation of waste re-processing: Atthe South Deep Mine in South Africa, <strong>SRK</strong>comprehensively assessed historic andmodern waste rock facilities, which resultedin re-evaluation of historic waste rock aspotential ore material. We also developed amore efficient waste rock disposal program.Development and design of mine watermanagement strategies: For example,at Grootvlei in southern Africa, high densitysludge settlement was implemented toimprove water discharge to an importantriver catchment north of Johannesburg.Assessment of closure liabilities:At the Bulyanhulu mine, in Tanzania,<strong>SRK</strong> geochemists were part of amultidisciplinary team that assessedpotential future closure liabilities.Mineral processing assessment: Duringthe design of the sulphuric acid leachprocess for the Skorpion project in Namibia,<strong>SRK</strong> studied process chemistry andmineralogy of the feed and tailings to assistin optimisation of the process. In the DRC,<strong>SRK</strong> has evaluated process chemistry forcopper and cobalt oxide, and sulfide ores.Regional water studies: In 1999 <strong>SRK</strong>participated in the review of impactsto the Zambezi River from industrialextraction and discharge of water.Groundwater remediation:At the Sukhaybarat mine, SaudiArabia, <strong>SRK</strong> identified sources ofgroundwater contamination,which led to better sitewaste management and torecommendations formitigation of presentcontamination.Rob Bowell:rbowell@srk.co.ukJames Lake:jlake@srk.co.zaRob BowellJames Lake5

Stephen DaySteve leads a groupof five geochemistsin the Vancouveroffice. Steve has aM.Sc. in geologyand geochemistryfrom the Universityof British Columbia,and 17 years ofexperience working Stephen Dayon mine wastegeochemistry. He specialises in wastedisposal facilities at proposed, operating,and closed mines, and has experience atnumerous sites where commodities haveincluded metals, coal, diamonds, andrare earths.Stephen Day: sday@srk.comRobert J. BowellThe United Kingdom has thousands ofabandoned metal minesThe United Kingdom has thousands ofabandoned metal mines stretching frombase metal mines in Scotland to gold andcopper mines in the Cambrian mountainsof Wales to tin mines in Cornwall. Metalmining has occurred since 500 BC or over2500 years.Mining in the UK peaked in the 18th and19th centuries with more than 2000 activemines, all of which are now abandoned.The mines have left a legacy of derelictland and contamination of surface waterby metals.<strong>SRK</strong> has completed several commissionsto develop risk assessment criteria andreclamation plans for metal and coalmines in Cornwall, Ireland, and Walesand for coal mines in Scotland. In somecases these plans involve removal of minewaste, recontouring topography and watermanagement techniques such as drainagecontrol, adit plugs and installation ofpassive treatment schemes.At other mines, little or no surfacereclamation is required. Remediationstrategies were based on identificationof various contaminant sources,minimisation of water movement throughsource areas and treatment of residualcontaminated flows.<strong>SRK</strong> has also worked with tourist andarchaeological specialists and with localstakeholders to ensure the cultural value offormer mining areas is maintained.Rob Bowell: rbowell@srk.co.ukThe Ale and Cake mine began operation in the 1490s and produced ore for over 400 yearsRob is a principalgeochemist with18-years experienceand is head of thegeo-<strong>environmental</strong>department in Cardiff,Wales. He holds anhonours degree ingeochemistry, anda Ph.D. Rob is the Rob Bowellcurrent presidentof the International Association ofApplied Geochemists. He specialises inmineral processing and the geochemicaltreatment of arsenic-rich waste, minewaste, and water including wastecyanide solutions, acid rock drainage andsaline water.Rob Bowell: rbowell@srk.co.uk6

Selective handling of wastes can reduce futuretreatment costs<strong>SRK</strong> has helped numerous miningclients limit non-compliant discharge ofcontaminants by identifying major sourcesof contamination. This work enablesselective handling of specific wastes, andequally important, lowers future costssubstantially.For modern mine operators, thepossibility of <strong>environmental</strong> impact is aprimary consideration. Very often, thegreatest <strong>environmental</strong> risks are posedby the leaching of heavy elements,the generation of Acid Rock Drainage(ARD) and discharge to the surroundingenvironment, and the possibility of landcontamination.Finding a better course of actionHistorically, mine operators waited untilimpact occurred and then designedremediation. In addition to the high costsof retro-active waste management, thisapproach often resulted in an incompletemitigation that was not satisfactory.In recent years, laboratory test work hasbeen used to estimate waste reactivity.This information was then used to predictthe chemistry of mine discharges.Unfortunately, in many instances, thepredictions do not match reality. As aconsequence, unnecessary costs wereincurred at a range of levels and theproject risked delays and additionalregulatory consultation.Getting it right from the startWhat is missing? The key to solving thispuzzle is in understanding the typesof minerals occurring in the ore andwaste. Major advances in other scientificdisciplines now allow us to characterisemineralogy at a level not available untilrecently. This knowledge allows mineoperators to identify mineable rock unitsand segregate potentially problematicrocks from those that are benign. As aresult, the overall volume of waste rockthat requires special handling or storage isgreatly reduced.Reduced expenditures<strong>SRK</strong>’s method begins with a detailedgeological and geochemical assessmentat an early stage in development of oredeposits.At Turquoise Ridge in Nevada, <strong>SRK</strong> usedthis technique to estimate the proportionsof different waste rock types to be mined.Our geochemists worked with the projectgeologists to develop a resource blockmodel for waste rock.This process enabled us to determinewhich waste rock was likely to causemetal leaching. It also allowed thecompany to put in place appropriatepreventative measures.<strong>SRK</strong> helped to create an operationalstrategy to segregate the waste rockthat was predicted to cause ARD. Thecompany then effectively disposed ofthis rock.Benefits you can build onThese actions substantially reduced theoverall cost of monitoring and disposal ofARD generating waste. Equally important,the mine operators could confidentlyuse non-ARD generating waste rock forconstruction of structures at the site.Rob Bowell: rbowell@srk.co.uk7

John T. ChapmanJohn is a principalin our Brisbaneoffice with over 15years experiencethroughout NorthAmerica, LatinAmerica, Africa,Australasia, andEurope. He holds aM.Sc. in chemical John Chapmanengineering from theUniversity of Cape Town and specialisesin acid drainage assessment, water qualityprediction, and water management.John has been the project principal forseveral reclamation projects and the leadgeochemist for impact assessment andpermitting projects.John Chapman: jchapman@srk.com.au<strong>SRK</strong> expands its geochemical servicesin AustraliaTwo senior staff members of ANSTO,Andrew Garvie and Claire Linklater, havejoined our Sydney office. Their specificexpertise centres on ARD assessment,waste rock and stockpile managementplanning. Both have experience in themeasurement and modelling of relevantprocesses and will expand <strong>SRK</strong>’s abilityto predict the behaviour of waste rockdumps and heap leach piles.Andrew has been responsible for numerousinnovative developments. These includea proof of concept instrument for rapidlymeasuring the intrinsic oxidation rate ofsmall waste rock samples, such as drillcore, and the development of a techniqueto measure the in situ diffusion coefficientof waste rock and cover materials at minesites. He has extensive experience indetermining physical parameters of sulfidicpiles, e.g. oxygen and heat distribution.This information is determined via fieldmeasurements and used to estimate theoverall rates of sulfide oxidation.Andrew Garvie and Claire LinklaterClaire has applied the numerical code,SULFIDOX, to help with interpretationof field <strong>data</strong> and to predict the futurebehaviour of sulphide-bearing piles.SULFIDOX was developed at ANSTO tomodel sulfide oxidation, heat, gas andwater transport and incorporates anequilibrium chemistry module for calculatingeffluent quality. <strong>SRK</strong> will be acquiringthe rights to SULFIDOX. Claire also hasconsiderable experience in assessingthe geochemical behaviour of aqueouscontaminants, mineral-water interactionsand dissolution of waste forms.Andrew Garvie: agarvie@srk.com.auClaire Linklater: clinklater@srk.com.auFor more information, visit us at: www.srk.comIssue No. 348