Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

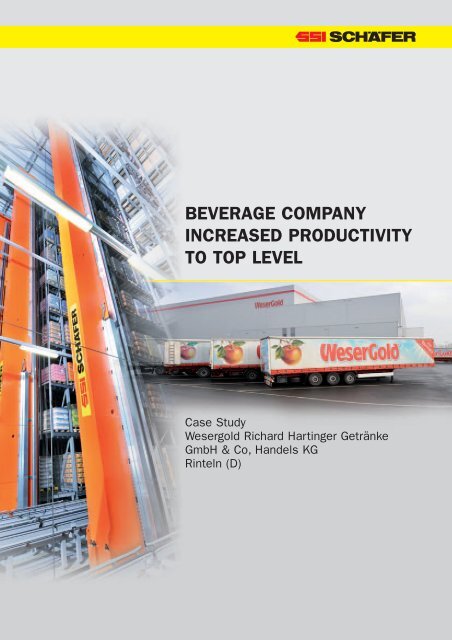

BEVERAGE COMPANYINCREASED PRODUCTIVITYTO TOP LEVELCase StudyWesergold Richard Hartinger GetränkeGmbH & Co, Handels KGRinteln (D)

WESERGOLD, RINTELNProject Objective Increase of throughput Meeting peak demand Guarantee of delivery itself and ability to deliverthrough processes that are more efficient Improved utilisation of space Optimized allocationAt a height of approximately 15 meters a transport bridge with electro Monorail connectsthe production lines with the warehouse facilities (top right)Our Scope of Supply and Services Simulation Planning of realisation Turn-key creation (roof/wall sprinkler) Pallet conveyor system Electro Monorail with transfer bridge 14 Storage and Retrieval Machines Rack construction and steel platforms Visualisation Material flow computer Warehouse management and control systemMit einem Twister V Lastaufnahmemittel können die RBG zwei verschiedene Ladeeinheiten doppelt tiefein- und auslagern.High Bay Warehouse (HBW)L x W x H114 x 64 x 36 mStorage aidEuro- and industrial palletsStorage positions 38,700 (Euro pallets)Weight1,000 kg/palletType of storage single deepHBW – Storage and Retrieval Machine (SRM)Number SRMs / aisles 14Load accepting device 2 telescopic forks per SRMTraveling speed 190 m/min.Hoisting speed 70 m/min.Handling capacity 45 double- or70 single-cycles per SRMNarrow aisles, high racks. Almost 39,000 pallet storage positions are available in the HBW

WESERGOLD, RINTELNIncrease of Throughput to EnsureMeeting Peak DemandsReduction of inventory, higher storage capacity,increased loading volume – by concentrating fourwarehouses in one new central distribution warehouseat the largest production location of theRichard Hartinger Beverage Group in Rinteln, thebeverage company Wesergold raised its’ distribution-and intra-logistics to a trend-setting andfuture oriented level.Center piece of the system: A modern, high performancehigh bay warehouse that is connecteddirectly to the production lines through a transportbridge with an electro Monorail.With a choice of approximately 1000 differentjuice and mineral water products, the Riha beveragegroup is one of the leading producers inGermany. The long-established company has sixproduction locations throughout Europe.The electro Monorail transports the pallets with beverages from the production lineto the warehouse complexMonorail (EHB)Length875 mNumber of vehicles 76Transfers approx. 620/hPallet Conveyor SystemComponents:Roller conveyors, chain conveyors,feed-in/acceptance stations, vertical conveyors,lifting transfer units, rotary tables 90°,double-shuttle vehicles, pallet stacker/de-stacker,accessible chain link conveyors as acceptancestations, de-stacking units for Duesseldorf andindustrial palletsControl of Material FlowHardwareHP/Compaq Deskpro-LineOperating system Windows 2003Data base system ORACLEThe pallets that need to be loaded are allocated on a link-belt according to demandFunctions:Warehouse management, goods receiving/issuing,order picking, control of material flow, visualisation,radio frequency data transmission system,automatic door scannerOutside view of transport bridge with MonorailThe double shuttle vehicle forwards theshipping pallets from the HBW to thedispatch conveyors

No. 270511en, © <strong>SSI</strong> SCHÄFER Giebelstadt.Printed in Germany. Any liability for misprints excluded.General contractorPlanning and consultingWarehouse Management SystemControl systemsSteel structure/racking systemsStorage and Retrieval MachinesConveyor systemService and maintenance<strong>SSI</strong> SCHÄFER NOELL GMBHi_Park Klingholz 18/19D-97232 GiebelstadtPhone +49 / (0) 93 34 / 9 79-0Fax +49 / (0) 93 34 / 9 79-100info@ssi-schaefer-noell.comwww.ssi-schaefer.com