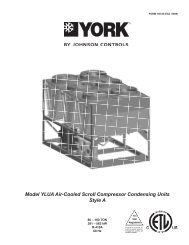

Model YCUL Air-Cooled Scroll Compressor ... - Usair-eng.com

Model YCUL Air-Cooled Scroll Compressor ... - Usair-eng.com

Model YCUL Air-Cooled Scroll Compressor ... - Usair-eng.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Options and AccessoriesFORM 150.68-EG1 (1109)ELECTRICAL OPTIONS:COMPRESSOR POWER CONNECTIONS – Single-pointterminal block connection(s) are provided as standard.The following power connections are available as options.(See electrical data for specific voltage and options availability.)(Factory-Mounted.)SINGLE-POINT SUPPLY TERMINAL BLOCK – (standardon <strong>YCUL</strong> models). Includes enclosure, terminal-blockand interconnecting wiring to the <strong>com</strong>pressors. Separateexternal protection must be supplied, by others, in thein<strong>com</strong>ing <strong>com</strong>pressor-power wiring. (Do not include thisoption if either the SinglePoint NonFused DisconnectSwitch or Single-Point Circuit Breaker options have beenincluded.)SINGLE-POINT NON-FUSED DISCONNECT SWITCH– Unit-mounted disconnect switch with external, lockablehandle (in <strong>com</strong>pliance with Article 440-14 of N.E.C.), canbe supplied to isolate the unit power voltage for servicing.Separate external fusing must be supplied, by others inthe power wiring, which must <strong>com</strong>ply with the NationalElectrical Code and/or local codes.SINGLE-POINT CIRCUIT BREAKER – A unit mountedcircuit breaker with external, lockable handle (in <strong>com</strong>pliancewith N.E.C. Article 440-14), can be supplied to isolatethe power voltage for servicing. (This option includes theSingle-Point Power connection.)CONTROL TRANSFORMER – Converts unit power voltageto 115-1-60 or 115-1-50 for 50Hz units (0.5 or 1.0KVA capacity). Factory mounting includes primary andsecondary wiring between the transformer and the controlpanel. (Factory-Mounted.)POWER FACTOR CORRECTION CAPACITORS – Willcorrect unit <strong>com</strong>pressor power factors to a 0.90-0.95.(Factory-Mounted.)CONTROL OPTIONS:AMBIENT KIT (LOW) – Units will operate to 25°F (-4°C).This accessory includes all necessary <strong>com</strong>ponents topermit chiller operation to 0°F (-18°C). (This option includesthe Discharge Pressure Transducer / ReadoutCapability option.) For proper head pressure control inapplications below 25°F (-4°C), where wind gusts mayexceed five mph, it is re<strong>com</strong>mended that Optional CondenserLouvered Enclosure Panels also be included.(Factory-Mounted.)AMBIENT KIT (HIGH) – Required if units are to operatewhen the ambient temperature is above 110°F (43°C).Includes discharge pressure transducers. (This optionincludes the Discharge Pressure Transducer / Readout-Capability option.) (Factory-Mounted.)BUILDING AUTOMATION SYSTEM INTERFACE – Thefactory addition of a Printed Circuit Board to accept a4-20 milliamp, 0-10VDC or contact closure input to resetthe leaving chiller liquid temperature from a Building AutomationSystem. (Only one of following options can beoffered on a unit at a time: BAS, Remote Control Panel orMulti-unit Sequence Control.) (Factory-Mounted.) (Thestandard unit capabilities include remote startstop, remotewater temperature reset via a PWM input signal or up totwo steps of demand (load) limiting depending on model.The standard control panel can be directly connected toa Johnson Controls Building Automated System via thestandard onboard RS485 <strong>com</strong>munication port.)LANGUAGE LCD AND KEYPAD DISPLAY – Spanish,French, and German unit LCD controls and keypad displayavailable. Standard language is English.DISCHARGE PRESSURE TRANSDUCERS AND READ-OUT CAPABILITY – The addition of pressure transducersallows models to sense and display discharge pressure.This is re<strong>com</strong>mended for brine chilling applications. (Thisoption is included with either the low or high ambient kits.)(Factory-Mounted.)Suction Pressure Transducers – Permits unitto sense and display suction pressure. This capability isstandard on <strong>YCUL</strong> models.MOTOR CURRENT MODULE – Capable of monitoring<strong>com</strong>pressor motor current. Provides extra protectionagainst <strong>com</strong>pressor reverse rotation, phase-loss andphase imbalance. Option consists of one module perelectrical system. (Factory-Mounted.)OPTIVIEW REMOTE CONTROL PANEL – Graphicalinterface panel to remotely control and monitor up to 8different units. (Refer to form 201.18-SG4 for detailedinformation)MULTI-UNIT SEQUENCING – A separate sequencingcontrol center is provided to handle sequencing control ofup to eight chillers in parallel based on mixed liquid temperature(interconnecting wiring by others). (Only one offollowing options can be offered on a unit at a time: BAS,Remote Control Panel or Multi-Unit Sequence Control.)JOHNSON CONTROLS