Welding Systems for Reinforcement Mesh System MG303 ... - Schlatter

Welding Systems for Reinforcement Mesh System MG303 ... - Schlatter

Welding Systems for Reinforcement Mesh System MG303 ... - Schlatter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

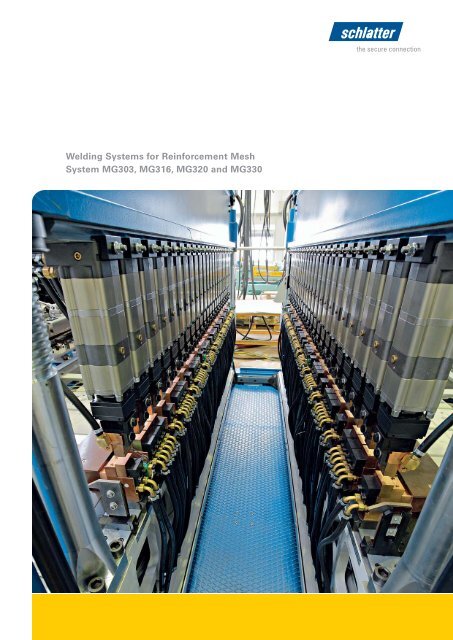

<strong>Welding</strong> <strong><strong>System</strong>s</strong> <strong>for</strong> Rein<strong>for</strong>cement <strong>Mesh</strong><br />

<strong>System</strong> <strong>MG303</strong>, MG316, MG320 and MG330

2<br />

Areas of application<br />

<strong>Welding</strong> of heavy line and cross wires<br />

Economical production systems <strong>for</strong> rein<strong>for</strong>cement mesh<br />

The <strong>Schlatter</strong> welding systems <strong>MG303</strong>, MG316, MG320 and MG330 are<br />

designed <strong>for</strong> high economic viability. The systems are distinguished<br />

by low investment costs, user friendliness and easy maintenance. A<br />

large selection of extra modules means they can be adapted to diff erent<br />

requirements, while allowing a modular setup of the automation level.

Everything from a single source<br />

The systems of the MG300 series enable<br />

the production of rein<strong>for</strong>cement mesh<br />

in diff erent geometries at competitive<br />

prices. Thanks to the modular extension<br />

options, the systems can be used<br />

in both developing and established<br />

markets.<br />

The modular principle allows customers<br />

to start with a cost-eff ective, simple yet<br />

extendible system. The wide range of<br />

extra modules and options guarantees<br />

extension up to an automatic production<br />

system with the minimum need <strong>for</strong><br />

personnel.<br />

The choice of various cross wire feeds<br />

allows the implementation of system<br />

concepts with extremely short retooling<br />

rates and high working speeds.<br />

It is not unusual <strong>for</strong> an MG300 project<br />

to result in a complete factory, planned,<br />

installed and fi nally handed over to the<br />

customer by <strong>Schlatter</strong> to be a turn-key<br />

system.<br />

Depending on your investment options<br />

and the required degree of automation,<br />

<strong>Schlatter</strong> off ers a complete solution<br />

from a single source – from a simple<br />

system through to a fully-automated<br />

plant.<br />

Line wire aligning unit with<br />

compensating mechanism<br />

3

4<br />

Extendibility with modular principle<br />

<strong>System</strong> <strong>MG303</strong><br />

Modularity<br />

This system concept is ideally suitable<br />

<strong>for</strong> the economic production of<br />

lightweight and heavy standard mesh<br />

in medium and large batches. The line<br />

wires are drawn off by spools, coils or<br />

reels. The cross wires are straightened,<br />

cut to length and fed to the welding system<br />

from a large magazine. This allows<br />

the system to be quickly retooled to<br />

another mesh type. The system concept<br />

is there<strong>for</strong>e very fl exible, a factor that is<br />

especially advantageous when supplying<br />

new markets.<br />

The right concept <strong>for</strong> individual requirements: The modular structure<br />

of the <strong>Schlatter</strong> welding systems allows you to start with minimum<br />

investment costs. This allows to convert or extend your plant in line<br />

with your requirements.<br />

<strong>System</strong> MG316<br />

An extendible system with high production<br />

capacity <strong>for</strong> a defi nite standard<br />

mesh program with lightweight and<br />

heavy mesh. Cost-eff ective system<br />

concept <strong>for</strong> starting out in mesh production<br />

with line and cross wire feed from<br />

spools, coils or reels. A cross wire feed<br />

with the option of rapidly changing<br />

between two coils or reels.<br />

<strong>System</strong> MG320<br />

The system concept <strong>for</strong> the highest<br />

production requirements, when<br />

manufacturing lightweight and heavy<br />

standard mesh. Dual-series system, two<br />

cross wire feeds, two welding machines<br />

located opposite one another. Two cross<br />

wires are welded on simultaneously.<br />

Line and cross wires from spools, coils<br />

or reels.<br />

<strong>System</strong> MG330<br />

High per<strong>for</strong>mance system <strong>for</strong> large series.<br />

The concept is particularly suitable<br />

<strong>for</strong> the manufacturing of very short,<br />

lightweight and heavy mesh at high<br />

speed and with high productivity. Dualseries<br />

system, two cross wire feeds, two<br />

welding machines located above one<br />

another. Two cross wires are welded on<br />

simultaneously. Line and cross wires<br />

from spools, coils or reels.<br />

Control<br />

The welding current control SWEP<br />

developed by <strong>Schlatter</strong> guarantees<br />

uni<strong>for</strong>m and reliable welding quality.<br />

The processes <strong>for</strong> the entire system<br />

is controlled by the process control<br />

system PLS Win. This control system is<br />

operated via a Windows interface and<br />

provides interfaces <strong>for</strong> computer-assisted<br />

work preparation.<br />

MG330<br />

Line wire feed from spools, coils or reels; straightening units; line wire pull-off and compensating<br />

mechanism; roller advance feed; two cross wire feeds from spools, coils or reels, two welding machines<br />

located above one another; simultaneous welding of cross wires, line wire shear; stacking unit

Choice of potential system confi gurations<br />

<strong>MG303</strong><br />

Line wire feed from spools, coils or reels; straightening units, line wire payoff and compensating mechanism;<br />

welding machine with roller advance feed; cross wire disc feed; line wire shear; mesh turning and stacking unit<br />

<strong>MG303</strong><br />

Line wire feed from spools, coils or reels; straightening units; line wire payoff and compensating mechanism; roller advance feed;<br />

cross wire chain insertion; welding machine; line wire cutter; mesh turning and stacking unit<br />

MG316<br />

Line wire feed from spools, coils or reels; straightening units; line wire payoff and compensating mechanism; roller advance feed;<br />

cross wire feed with disc insertion from spools, coils or reels; welding machine; line wire cutter; mesh turning and stacking unit<br />

MG316<br />

Line wire feed from spools, coils or reels; straightening units; line wire payoff and compensating mechanism; roller advance feed;<br />

cross wire feed from spools, coils or reels; welding machine; fully-automatic winding unit with roll storage system<br />

MG320<br />

Line wire feed from spools, coils or reels; straightening units; line wire payoff and compensating mechanism; roller advance feed;<br />

two cross wire feeds from spools, coils or reels; two welding machines; simultaneous welding of two cross wires, line wire cutter;<br />

mesh turning and stacking unit<br />

5

6<br />

Technical Data<br />

Product features<br />

<strong>Mesh</strong> width /<br />

Spacing of outermost line wires<br />

<strong>Mesh</strong> lengths<br />

Line wire division, infi nite beyond<br />

Cross wire division, infi nite beyond<br />

Line wire diameter<br />

Cross wire diameter<br />

Spool net weight<br />

Number of cross wires / Min.<br />

in direction of production<br />

Number of cross wires / Min.<br />

against direction of production<br />

Further dimensions on request<br />

<strong>MG303</strong>, MG316, MG320 and MG330 are fl exible mesh welding<br />

systems <strong>for</strong> the economic production of lightweight and heavy mesh<br />

in large series batches.<br />

<strong>MG303</strong><br />

2500 / 2400 mm<br />

2900 / 2800 mm<br />

3300 / 3200 mm<br />

3.0 – 8.0 m<br />

min. 50 mm<br />

min. 25 mm<br />

3.4 – 12.7 mm<br />

3.4 – 12.7 mm<br />

max. 5.0 t<br />

up to 200<br />

up to 130<br />

MG316<br />

2500 / 2400 mm<br />

2900 / 2800 mm<br />

3300 / 3200 mm<br />

3.0 – 6.0 m<br />

min. 50 mm<br />

min. 25 mm<br />

3.4 – 12.7 mm<br />

3.4 – 12.7 mm<br />

max. 5.0 t<br />

up to 180<br />

up to 150<br />

Extendible level of automation<br />

The <strong>MG303</strong> system can be extended by<br />

integrating the Syrocut system in the<br />

cross wire feed, which is a straightening<br />

and cutting machine. In addition, all<br />

systems of the MG300 series can be extended<br />

with a labelling machine, a binding<br />

unit and a mesh package stacker.<br />

MG320<br />

2500 / 2400 mm<br />

2900 / 2800 mm<br />

3300 / 3200 mm<br />

3.0 – 8.0 m<br />

min. 50 mm<br />

min. 100 mm<br />

3.4 – 12.7 mm<br />

3.4 – 12.7 mm<br />

max. 5.0 t<br />

up to 300<br />

Dual welding machine<br />

MG330<br />

2500 / 2400 mm<br />

2900 / 2800 mm<br />

3300 / 3200 mm<br />

1.0 – 8.0 m<br />

min. 50 mm<br />

min. 25 mm<br />

3.4 – 8.0 mm<br />

3.4 – 8.0 mm<br />

max. 5.0 t<br />

up to 300<br />

Dual welding machine

Line wire straightening elements Electrode set<br />

Wire material<br />

• Cold-rolled, smooth or ribbed wire<br />

• Hot-rolled wire with cooling and<br />

tempering process directly after<br />

rolling (Tempcore), ribbed<br />

• Hot-rolled wire, micro-alloyed, ribbed<br />

• Hot-rolled and subsequently stretched<br />

wire, ribbed<br />

7

8<br />

Options<br />

Designed with changing needs in mind<br />

<strong>Schlatter</strong> off ers a wide range of extra modules, which can usually<br />

also be integrated in existing systems later on. The following options<br />

represent a selection of our range <strong>for</strong> the MG300 systems. We would<br />

be pleased to advise you in person should you require customized<br />

extensions.

Line wire straightening and advance feed systems<br />

Line wire monitoring<br />

The device monitors the line wires and<br />

switches the system off in the event of a<br />

wire break or at the line wire end<br />

Line wire roller advance feed<br />

The roller advance feed serves to feed<br />

the line wires in order to create the<br />

cross wire divisions; the cross wire<br />

spacing is freely programmable<br />

<strong>Welding</strong> machines<br />

<strong>Welding</strong> portal <strong>for</strong> <strong>MG303</strong> and MG316<br />

With pneumatic, soft-contact<br />

high- per<strong>for</strong>mance presses and<br />

cube electrodes<br />

Pull-off and straightening of the line<br />

wires<br />

Straightening elements centrally adjustable<br />

on two plains be<strong>for</strong>e the line wire<br />

pull-off and compensating mechanism<br />

Dual line wire roller advance feed<br />

From MG330 system<br />

<strong>Welding</strong> portal <strong>for</strong> MG320<br />

Two welding machines located opposite<br />

one another at the front with two cross<br />

wire feeds<br />

Line wire pull-off and compensating<br />

mechanism<br />

Each line wire is monitored individually<br />

Dual mesh guide from MG330 system<br />

Guides two welded wire mesh together<br />

from the cutter at the same height<br />

<strong>Welding</strong> portal <strong>for</strong> MG330<br />

Two welding levels located above<br />

one another; good accessibility to the<br />

individual elements<br />

9

10<br />

Options<br />

Cross wire feeds<br />

Cross wire disc insertion<br />

With large magazine and interim<br />

transport station with magnetic drum<br />

Cross wire feed<br />

With automatic cross wire changing<br />

system and loop storage system, a<br />

welding machine, line wire shear and<br />

roller advance feed<br />

Automatic mesh turning and stacking<br />

unit<br />

Roller or linear pull-in via grippers<br />

Cross wire feed<br />

Wire feed in direction of production;<br />

with disc insertion <strong>for</strong> high cycle speed<br />

Automatic cross wire changing system<br />

Minimum downtime when changing the<br />

spools (20–30 seconds), no time lost<br />

due to butt welding of the wire ends<br />

when changing spools<br />

Turning and stacking / Preparation and further transport of the mesh<br />

Automatic binding unit<br />

Comprising a left and right unit;<br />

automatically binds the mesh stack<br />

Magazine with magnetic drum<br />

For separating off cross wires from<br />

large wire bundles<br />

Fully automatic high-per<strong>for</strong>mance<br />

winding unit<br />

Winds the welded mesh in the set<br />

length onto the roll and cuts it automatically<br />

Automatic mesh stacker<br />

Stacks bound mesh packages

Investment certainty through long-term support<br />

Helpdesk<br />

Our multilingual Helpdesk team is available<br />

– by phone or via the Internet – to<br />

answer general technical questions and<br />

provide troubleshooting help <strong>for</strong> faults<br />

or malfunctions in your production<br />

system.<br />

Field Service<br />

For rapid on-site help, our Field Service<br />

experts off er professional support<br />

worldwide.<br />

Customer service<br />

The aim of our work is to increase the productivity of our customers<br />

and extend the service life of their systems. Our customer service<br />

will there<strong>for</strong>e continue to provide support after your system has been<br />

commissioned. We shall be pleased to arrange a personal discussion<br />

and work out a service package customised to your requirements.<br />

Repair Service<br />

<strong>Schlatter</strong> has its own workshop where<br />

they can carry out repairs and overhauls<br />

to your control units and mechanical<br />

components.<br />

Spare Parts Service<br />

Our warehouse with over 15 000 spare<br />

parts and effi cient logistics ensures<br />

a high availability and a rapid replacement<br />

of system components.<br />

Training<br />

We off er standardised courses as well<br />

as individual training measures in<br />

our welding laboratory at our training<br />

facilities in Schlieren (CH) or at your<br />

production site,<br />

11<br />

Direct contact with our customer service<br />

Helpdesk / Field Service /<br />

Training / Service Agreements<br />

T +41 44 732 74 20<br />

service@schlattergroup.com<br />

Spare Parts and Repair Service<br />

T +41 44 732 71 11<br />

ersatzteile@schlattergroup.com

12<br />

www.schlattergroup.com<br />

A reliable partner in plant construction<br />

The <strong>Schlatter</strong> group is a world leader in plant manufacturing <strong>for</strong><br />

resistance welding systems and weaving machines <strong>for</strong> special<br />

applications. With longstanding expertise in industrial engineering,<br />

innovative fl air and a reliable customer service, the company group<br />

listed in Switzerland provides production systems off ering high<br />

per<strong>for</strong>mance and quality.<br />

Core competence<br />

<strong>Schlatter</strong> has almost 100 years of<br />

expertise in plant construction,<br />

customer-oriented solutions, a worldwide<br />

presence and more than 500<br />

dedicated employees. The combination<br />

of expertise in welding and systems<br />

technology makes <strong>Schlatter</strong> a reliable<br />

partner in plant construction.<br />

Segment resistance welding<br />

<strong>Schlatter</strong> has acquired unique experience<br />

in the development and production<br />

of rein<strong>for</strong>cing and industrial mesh<br />

welding systems, mobile and stationary<br />

rail welding machines as well as<br />

systems <strong>for</strong> manufacturing radiators.<br />

Weaving segment<br />

Under the brand Jäger, the <strong>Schlatter</strong><br />

Group provides state-of-the-art weaving<br />

and fi nishing machines <strong>for</strong> the paper<br />

machine fabric industry.<br />

Contact<br />

Professional contacts <strong>for</strong> sales,<br />

technical support, customer service<br />

and administration are available worldwide<br />

in the group’s companies and<br />

at select representatives / agents of<br />

the <strong>Schlatter</strong> Group. You can fi nd the<br />

relevant contact data on our Internet<br />

site www.schlattergroup.com.<br />

<strong>Schlatter</strong> Industries AG<br />

Brandstrasse 24<br />

8952 Schlieren | Switzerland<br />

T +41 44 732 71 11<br />

F +41 44 732 45 50<br />

www.schlattergroup.com<br />

4.150EN BA<br />

Concept by www.stier.ch