Ultra EU - Yachtpaint.com

Ultra EU - Yachtpaint.com

Ultra EU - Yachtpaint.com

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

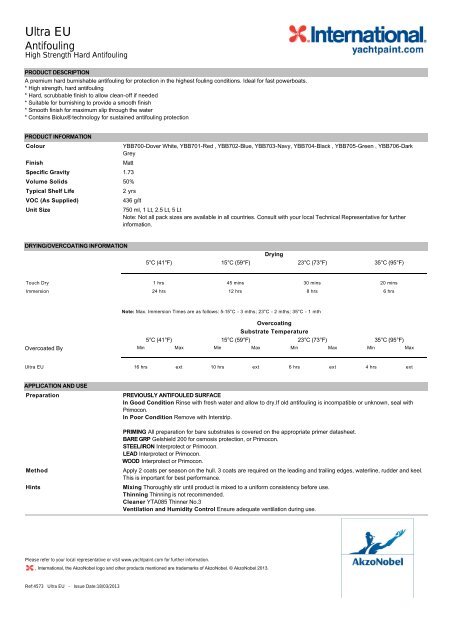

<strong>Ultra</strong> <strong>EU</strong>AntifoulingHigh Strength Hard AntifoulingPRODUCT DESCRIPTIONA premium hard burnishable antifouling for protection in the highest fouling conditions. Ideal for fast powerboats.* High strength, hard antifouling* Hard, scrubbable finish to allow clean-off if needed* Suitable for burnishing to provide a smooth finish* Smooth finish for maximum slip through the water* Contains Biolux® technology for sustained antifouling protectionPRODUCT INFORMATIONColourFinishYBB700-Dover White, YBB701-Red , YBB702-Blue, YBB703-Navy, YBB704-Black , YBB705-Green , YBB706-DarkGreyMattSpecific Gravity 1.73Volume Solids 50%Typical Shelf LifeVOC (As Supplied)Unit Size2 yrs436 g/lt750 ml, 1 Lt, 2.5 Lt, 5 LtNote: Not all pack sizes are available in all countries. Consult with your local Technical Representative for furtherinformation.DRYING/OVERCOATING INFORMATIONDrying5°C (41°F) 15°C (59°F) 23°C (73°F) 35°C (95°F)Touch Dry 1 hrs 45 mins 30 mins 20 minsImmersion 24 hrs 12 hrs 8 hrs 6 hrsNote: Max. Immersion Times are as follows: 5-15°C - 3 mths; 23°C - 2 mths; 35°C - 1 mthOvercoatingSubstrate Temperature5°C (41°F) 15°C (59°F) 23°C (73°F) 35°C (95°F)Overcoated By Min Max Min Max Min Max Min Max<strong>Ultra</strong> <strong>EU</strong> 16 hrs ext 10 hrs ext 6 hrs ext 4 hrs extAPPLICATION AND USEPreparationMethodHintsPREVIOUSLY ANTIFOULED SURFACEIn Good Condition Rinse with fresh water and allow to dry.If old antifouling is in<strong>com</strong>patible or unknown, seal withPrimocon.In Poor Condition Remove with Interstrip.PRIMING All preparation for bare substrates is covered on the appropriate primer datasheet.BARE GRP Gelshield 200 for osmosis protection, or Primocon.STEEL/IRON Interprotect or Primocon.LEAD Interprotect or Primocon.WOOD Interprotect or Primocon.Apply 2 coats per season on the hull. 3 coats are required on the leading and trailing edges, waterline, rudder and keel.This is important for best performance.Mixing Thoroughly stir until product is mixed to a uniform consistency before use.Thinning Thinning is not re<strong>com</strong>mended.Cleaner YTA085 Thinner No.3Ventilation and Humidity Control Ensure adequate ventilation during use.Please refer to your local representative or visit www.yachtpaint.<strong>com</strong> for further information., International, the AkzoNobel logo and other products mentioned are trademarks of AkzoNobel. © AkzoNobel 2013.Ref:4573 <strong>Ultra</strong> <strong>EU</strong> - Issue Date:18/03/2013

<strong>Ultra</strong> <strong>EU</strong>AntifoulingHigh Strength Hard AntifoulingSome Important PointsCompatibility/SubstratesNumber of CoatsCoverageRe<strong>com</strong>mended DFTRe<strong>com</strong>mended WFTApplication MethodsAirless Spray Pressure: 176-210 bar. Tip Size: 2180.Other For Airmix spray application: Pressure: 2.5 bar.Tip Size: 20-113.True colour will develop after immersion.To prevent premature failure, ensure the correct amount of paint is applied using the coverage as a guide. Producttemperature should be minimum 5°C/41°F and maximum 35°C/95°F. Ambient temperature should be minimum 5°C/41°F andmaximum 35°C/95°F. Substrate temperature should be minimum 1°C above dew point and maximum 35°C.GRP, Wood, Steel/Iron, Lead. Not suitable for use over Aluminium/Alloy substrates or zinc sprayed surfaces. Can beapplied direct over most types of antifoulings, provided they are in sound condition.Apply 2 coats per season. Apply an extra stripe coat in areas of high wear such as chines, rudders, sterngear and anyleading edges.(Theoretical) - 10 m²/lt by brush, 5 m²/lt by spray(Practical) - 9 m²/lt by brush, 3 m²/lt by spray50 microns dry by brush / roller, 100 microns dry by spray100 microns wet by brush / roller, 200 microns wet by sprayAirless Spray, Airmix, Brush, RollerTRANSPORTATION,STORAGE AND SAFETY INFORMATIONStorageSafetyGENERAL INFORMATION:Exposure to air and extremes of temperature should be avoided. For the full shelf life of <strong>Ultra</strong> <strong>EU</strong> to be realised ensurethat between use the container is firmly closed and the temperature is between 5°C/41°F and 35°C/95°F. Keep out ofdirect sunlight.TRANSPORTATION:<strong>Ultra</strong> <strong>EU</strong> should be kept in securely closed containers during transport and storage.GENERAL:Contains biocides. Antifoulings should only be wet sanded. Never dry sand or burn-off old antifoulings. Read the labelsafety section for Health and Safety Information, also available from our Technical Help Line.IMPORTANT NOTESDISPOSAL:Do not discard tins or pour paint into water courses, use the facilities provided. It is best to allow paints to harden beforedisposal.Remainders of <strong>Ultra</strong> <strong>EU</strong> cannot be disposed of through the municipal waste route or dumped without permit. Disposal ofremainders must be arranged for in consultation with the authorities.The information given in this sheet is not intended to be exhaustive. Any person using the product without first makingfurther written enquiries as to the suitability of the product for the intended purpose does so at their own risk and wecan accept no responsibility for the performance of the product or for any loss or damage (other than death or personalinjury resulting from negligence) arising out of such use. The information contained in this sheet is liable tomodification from time to time in the light of experience and our policy of continuous product development.Please refer to your local representative or visit www.yachtpaint.<strong>com</strong> for further information., International, the AkzoNobel logo and other products mentioned are trademarks of AkzoNobel. © AkzoNobel 2013.Ref:4573 <strong>Ultra</strong> <strong>EU</strong> - Issue Date:18/03/2013