Mining Sector Brochure - Cjc.dk

Mining Sector Brochure - Cjc.dk

Mining Sector Brochure - Cjc.dk

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

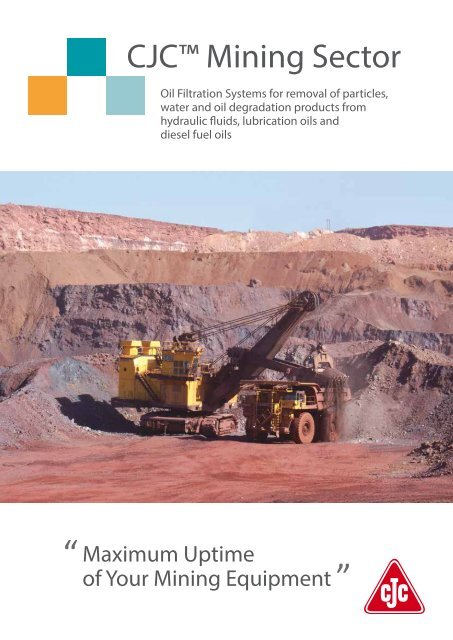

CJC <strong>Mining</strong> <strong>Sector</strong>Oil Filtration Systems for removal of particles,water and oil degradation products fromhydraulic fluids, lubrication oils anddiesel fuel oils”Maximum Uptimeof Your <strong>Mining</strong> Equipment”

Rough EnvironmentFACT: The Condition of Oil willC.C.JENSENCleaning oil for morethan 60 years.Availability& Reliability80% of all systembreakdowns are relatedto contaminated oil.Clean oil helps you avoiddowntime.Most CommonBenefits:• Cleaning oil, tanks,gearboxes andsystems while theyare in operation• Reduced downtime –less planned as wellas unscheduledshutdowns• Industry lowest costper kilo dirt removed• Short pay-back time• Reduced maintenancecosts• Enhanced processstability and efficiency• Reduced wear onpumps, cylinders,bearings, etc.• Avoid diesel bugs• Increased oil andcomponent lifetime• Significant reductionin use of in-line filters(up to several hundredpercent reduction)CrushersLube oil, gear oilhydraulic oilExtreme contaminationof the oil systemswith particles and watercauses critical downtimeand high replacementcosts for these costintensivecomponents.It is common to seecrusher shutdownsbecause dirt needsto be shovelledout of the tanks.MillsLube oil,gear oilHuge loads on bearingsand gears lead to wear.Dirt and water ingressdamage the systemcomponents. Dependingon the process, increasedtemperatures can alsoaccelerate the oil ageing.It is common to see millshutdowns because dirtneeds to be shovelledout of the tanks.Dump Trucks& ExcavatorsHydraulic oil, gear oil,lube oil, diesel fuel oilChanging operationconditions and roughenvironments entail dirtand condensate in theoil. Unclean dieseldestroys needle valvesand injector pumpsrapidly. Unclean oil andvarnish seize properoperation ofhydraulic systems.Diesel bugs block in-linepressure filters.DrillingEquipmentHydraulicoilDirt and water in the oilsystems cause wear, corrosionand erosionon pumps, cylindersand valves.Oil degradation productsresult in malfunction ofcritical components.2

- Smooth FiltrationDetermine Uptime and Life of Machinery!If You Think...• You have to shut down your systemthree times or more per year toshovel out dirt from tanks, or• You change in-line filters almost daily, or• You have to change bearings two orthree times per year... then we have News for You!!!What do we dodifferently thanother filtrationsystems?• We clean oil, tanks,gearboxes and systemswhile they are inoperation• We remove particles,water and varnish• We filter down to0.8 micron• Our filters haveindustry highest dirtholding capacity• Filter insert can bechanged withoutsystem shutdown• We do not onlyclean the oil, but alsoremove dirt fromyour tanks, pipes,gearbox, etc.• Since our filters alsoclean the entiresystem, we typicallyeliminate up to 80%of shutdowns becausecleaning tanks is nolonger neededTransformersConveyorBeltsMineralProcessingStorageTanksTap changer oil,transformer cooling oilGear oil,hydraulic oilHydraulicoilLube oil, hydraulic oil,and diesel fuel oilToo high soot level in thetap changer reduces theoil’s resistivity whichenables electric shortcircuits. Too high waterlevel in the transformercooling oil indicatessignificantly higher waterlevel in the paper insulation.Water destroys theinsulation paper whichwill force the transformerto be taken out of service.In addition to the dirtingress from the environment,gear and hydraulicoil systems in conveyorbelts are contaminatedwith wear particles andoil degradation products.In every stage of mineralprocessing, maintenanceof the fluid systems canenhance process stabilityand efficiency.Oil and fuel are alreadycontaminated with particlesand condensate bytransportation and transferring.During storage,diesel can additionally bepolluted with microbesdue to high condensationfrom transfer andtransportation. Diesel willduring storage form watercondensate, which willcreate microbes(diesel bugs).3

Risk of Failure on YourNowhere are the level of contamination andThe Main Cause for Equipment Breakdown80% of all breakdowns, machinery repair and maintenance costs are caused by too highly contaminatedsystem oils and fluids. Hydraulic fluids, lube oil and fuel carry destructive solids, corrosive sediments andwater to the various sensitive components of the system. Since mining is an extremely dirty and roughenvironment, proper oil care will have significant impact on reliability and lifetime of equipment and fluids CrushersThe key equipment for effective production in a mine are the primary,secondary and tertiary crushers.This equipment operates under extreme environmental conditions whichcan lead to badly contaminated system with ISO cleanliness levels as highas 29/27/25. The recommended level should be 18/16/14 (100 timeslower) if the crushers are to operate reliably and efficiently.Seal failures cause water and particle contamination and oil degradation.The combination of all contaminants results in wear of system parts andcomponent failure and frequent oil changes.These failures lead to unscheduled stoppages and unbudgeted replacementof parts. This is particularly relevant for sensitive components suchas bushings, socket liners and bevel gears. Most importantly, the effect ofcontaminated oil is down-time and lost production!CJC PTU327/81CJC HDU2x27/108When CJC Offline Oil Filters have beeninstalled on crushers, there is no need toshovel dirt out of the tanks!!MillsMills in mines operate under extremely rough environmental conditionsOperating under extremely rough environmental conditions leads to verycontaminated oil resulting in high ISO classes. The recommended ISOcleanliness level of the oil is 19/16/13, if the mills are to work reliably andeffectively, and thereby add to a profitable production. Typically, the CJCFine Filters, Filter Separators, and Desorbers are installed on the lube oilsystems containing 400-10,000 L of oil, in order to match recommendedcleanliness.The lube oil system is most often contaminated by oil degradationproducts, silica dust, and water. The result of this contamination canbe extremely expensive repair and downtime. The most sensitivecomponents are bearings and bronze bushings found in the system.4CJC HDU27/108CJC DesorberD30<strong>Mining</strong> companies, who have installedCJC Oil Filters on their mills,have saved 50% in maintenance costsdue to longer lifetime of equipmentand critical parts!

<strong>Mining</strong> Equipmentcost of downtime as high as within mining! The main cause is wear induced by contamination through solid particles, water and oil degradation products.Oil degradation products - “soft contaminants” - are precursors to the sticky varnish that deposits on metalsurfaces. It is a common perception that in-line oil filtration is sufficient. However it is the smaller particles -below 10 micron - which do most harm to a system. You will only see the real effect of oil filtration once youremove the small particles.Clean Oil is a Must!Dump Trucks & ExcavatorsEarth moving equipment operates under extreme operating conditionsThe exposure to extreme weather, a dusty environment and highvibration can severely stress the sensitive system components.The particle contamination in the oil is often very high.Moisture and condensate is formed due to frequent start/stops.Furthermore, the harsh operation conditions cause oil degradation,leading to reliability issues and lost production.By installing CJC Filters these problems will be reduced to a minimum.Sensitive components such as hydraulic pumps, motors, transmission gears,steering systems and injector pumps will operate more efficiently and forlonger hours, thus increasing reliability and equipment lifetime.For all systems, it is possible to reduce oil changes and maintenance costs,thereby achieving fast pay back on investment!In cases where a permanent filter cannot be installed, a mobile flushing unitcan clean the vehicle’s oil systems while it is in for service.CJC Heavy Duty Series:For all systems, it is possible to reduce oilchanges and maintenance costs, therebyachieving fast pay back on investment!CJC HDHDU 15/12CJC HDHDU 15/25CJC MFUMobile FlushingUnitStorage TanksOil cleanliness levels of ISO 23/21/19 are commonOil delivered to storage tanks is generally contaminated with particles, water andsludge. Oil cleanliness levels of ISO 23/21/19 are common. This is above therecommended cleanliness level of most equipment manufacturers, andoil filtration needs to take place before being put into operation.Many mines change in-line filters every day which is expensive- it does not have to be this way.Installation of a CJC Offline Oil Filtration System will clean the oil in the tanksto the cleanliness level required by the machine manufacturers (trucks, dozers,excavators). The recommended ISO cleanliness level is 19/16/13, which enhancesthe performance of the machinery immediately.The above mentioned facts are also applicable to diesel oil storage,where the diesel bugs (microbial contamination) are a major problem.The key to reliable machinery & effective production is clean oil and diesel!The key to reliable machinery & effectiveproduction is clean oil and diesel!CJC PTU32x27/108CJC HDU427/1085

Satisfied CustomersProblem solving & preventive maintenance arekeywords in the mining industryKumba Iron Ore’s Sishen Mine, South AfricaA CJC FilterSeparatorinstalled onone of thecrushers atKumba IronOre’s SishenMine in theNorthern Cape,South AfricaSenior tribologist at Anglo American,Mr. Dave J. Gamble“The CJC Filter will give benefits such as reduced downtime for maintenance,greatly reduced wear and consequent failures, increased availability,utilisation, and production. Together, this results in extended oil lifetime”6ProblemSignificant ingress of contaminated particles into thelube oil system through a water flow seal under thecrusher head, also causing significant water ingressinto the lube oil system.The particle and water contamination of the oil inturn significantly contributed to component wearand subsequently large volumes of metallic particlesbeing suspended in the lube oil as a result.Savingsin bronze bushings:EUR 35,000per crusher/yearSolutionA CJC Filter Separator was installed with 4 x CJCFilter Inserts, capable of retaining up to 16 kg ofparticles.The CJC Oil Filter removed 13 L of water in the first24 hours, continuing to remove water for another 2weeks. Within 3 months, the ISO level was broughtdown from 24/22 to an astounding 16/11.The installation of the CJC Filter provided numerousbenefits in wear reduction. Replacement of bronzebushings for each crusher alone costs around EUR35,000, and are replaced up to twice a year. A reductionof 50% in wear reduces the cost by EUR 35,000per crusher - and Kumba Iron Ore’s Sishen Mine has19 of these machines in their production.

DisDisputada de Las Condes CMD, ChileSAG MillDisputada de LasCondes CMD, <strong>Mining</strong>Company, ChileMr. Fernando Cavassa C,Grinding MaintenanceChief - CMD L.B.:“The equipment wasinstalled just to cleanthe oil periodically.However, due to theout-standing results, ithas been installed tooperate continuously.”ProblemThe main lubricating system of 6,000 litres of oil was highly contaminatedwith pulp (ore-silica-water). The contamination caused numerousproduction stoppages.SolutionA CJC Fine Filter with a dirt holding capacity of 8 kg was installed.The oil was passed through the filter only once. After seeing theinstant visual improvements of the oil, CMD installed two additionalCJC Filters.After 5 days, the oil and storage tank was clean, avoiding anyproduction stoppages, costing in the region of USD 90,000 per stop.CMD's investment costs including spares were USD 10,000.Minera El Tesoro, ChileCJC Oil Filtersinstalled onstorage tanks,Minera El TesoroChileESSO Chile“Benefits of a filtersystem maintainingclean oil can be seenin the extended lifetimeof mechanical componentsof earth movingequipment.This is partially due tothe substantial reductionof particles greater than6 micron”.ProblemThe Minera El Tesoro has four tanks for storage of new oil, with a capacityof 10,000 litres each. Every 15 days, the tanks are topped-up with 5,000litres of new oil. When the oil arrives in trucks it is highly contaminatedfrom the transportation process. Caterpillar and other manufacturers ofearth moving equipment recommend a cleanliness level of ISO 19/16/13,with the purpose of maintaining reliability and economical operation oftheir equipment, i.e. drilling machines, dumpers, etc.SolutionA CJC Fine Filter was installed on each tank, operating with a filtration of3 µm absolute and 0.8 µm nominal. Each CJC Filter Insert has a dirt holdingcapacity of 4 kg and a water absorption capacity of 2 litres. The CJCFine Filters absorb sludge/resin and oil degradation products as well.Talvivaara Mine, FinlandDisE. Hartikainen Oy,Talvivaara Mine, FinlandAtlas Copco, Drill RigMr. Ari-PekkaJormanainen,Project ManagerE. Hartikainen Oy“We have used CJC OfflineFilters for many years.We now have 20-30 filtersin operation. We take oilsamples after installation ofa filter and follow up withrandom samples – and theoil is always very clean.”ProblemGeneral repair needs, erosion in pumps and cylinders.Frequent oil changes and downtime.SolutionAfter installation of CJC Offline Oil Filters, the benefits of improvedcleanliness levels are a noticeable reduction in repairs and reducederosion of pumps and cylinders. As a result, the expense of oil changesand service intervals is reduced.The CJC Filter Inserts are generally changed twice a year, at the sametime as when other service is needed. The pressure gauge on the filtermakes it easy to supervise the dirt holding capacity.The CJC Filters do not need any service other than the change of thefilter inserts.7

Your Challenge80% of all breakdowns in oil systems are related to contamination of the oilMilliporemembrane- sample takenbeforeinstallation ofoffline filtrationOptimum oil cleanliness can rarely be achieved by in-line filtrationContamination of an oil system leads to various problems which can result in machinedowntime, frequent repairs of equipment and reduced oil lifetime. All of which meansinefficient production and unnecessary expenses spent on repair and oil change.Oil systemhydraulic oilgear oillube oildiesel fuel oiletc.In-line FiltrationIn-line filterSystem pumpContaminationExternal EnvironmentWater from the externalenvironment enters the systemvia the elements, high-pressurewater blasting, washing, etc.Wear & Tear ParticlesWear particles are generatedinside the oil system.Air VentParticles and water ingressthrough the air vent.Internal EnvironmentWater condensation in the oilreservoir, due to temperaturevariations.Acid Produced by OxidationHigh temperature + contaminated oil= acid and resin.Rust/CorrosionWater initiates the formation ofrust particles which are veryhard and abrasive particles.Cooler Leaking WaterA leaking cooler results in wateringress to the oil reservoir.Varnish/ResinOil degradation products,micro particles and water areaccumulated in the bottomof the oil reservoir.Most Common Types of Contamination8Abrasive WearWhen clearance sized hard particles are wedgedbetween movable metal parts, they destroy themetal surface further and can result in additionalwear.Cavitation & PittingOccurs in areas where water is present and oil iscompressed; the water implodes, causing the metalsurfaces to crackle and release more particles.Oil DegradationOxygen, water and high temperatures lead to oildegradation, which is the precursor of varnish/resin.This results in sticky varnish that deposits on metalsurfaces.

Our SolutionClean oil and guaranteed success through offline filtration- you avoid expenses on repairs and oil changesOne Filter - 4 SolutionsCJC Filter Inserts have a 3 µm absolute filtration ratio and will remove particles, water and oil degradationproducts in one and the same operation. The CJC Filter Insert has a very large dirt holdingcapacity. The CJC products are almost maintenance free and have a very low cost of operation.Offline FiltrationOil systemhydraulic oilgear oillube oildiesel fuel oiletc.Clean oilClean oil isreturnedto the oilreservoirIn-line filterSystem pumpContamination- now under ControlExternal EnvironmentWater ingress from the environmentis continuously removed from thesystem with CJC Filters.Wear & Tear ParticlesWear and tear particles are stillbeing created, but are removedby the CJC Oil Filter.Air VentIngress of contamination can bereduced by installing a breatherwith fine filtration and waterabsorbing media (silica gel).Internal EnvironmentWater still condensates in the oilreservoir, but with the CJC Filtersinstalled, the water is removed beforeit reaches critical system components.Acid Produced by OxidationThe risk of developing acids andoxidation by-products has beenconsiderably reduced.Rust/CorrosionContamination is still being createdbut is removed by the CJC Oil Filter.Cooler Leaking WaterThe leaking cooler can be repairedat scheduled overhauls as theCJC Oil Filters continuouslyremove water in large volumes.Milliporemembrane- sample takenafterinstallation ofofflinefiltrationCJC OfflineOil FilterVarnish/ResinOil degradation products andmicro particles have now practicallydisappeared from the bottom ofthe oil reservoir.generated at BeQRious.comContamination CapacitiesAll CJC Filter Inserts have outstanding oil filtration capabilities withfiltration degrees of 3 µm (micron) absolute. This means that 98.7%of all solid particles larger than 3 µm and approximately 50% of allparticles larger than 0.8 µm are retained - in one single pass.Capacities: 15/25 series: 27/27 Series:Particles 2-4 kg 4-8 kgWater 0,75 L 2 LVarnish 1 L 4 LDirty and cleanCJC Filter Inserts9

Our ProductsCJC Oil Filters - user-friendly design with low maintenance- and we offer highly qualified technical back-upKey Figures of the CJC Oil FiltersThe CJC Oil Filters are offline depth filters forhydraulic oils, lube oils and diesel fuel oils.CJC Oil Filters have a very high dirt holdingcapacity, and remove particles, water and oildegradation products, all in one and the sameoperation.Our product range covers tailor made solutionsfor all system volumes.The cleanliness level achieved and maintainedby offline filtration means that the predictedlifetime of machine components and oil isexpected to be extended 2-10 times!Using CJC Offline Filters will have a positiveeffect on your maintenance budget as well asincrease your productivity and reduce yourenergy consumption.- all Advantages in Terms of Your total Economy!CJC HDU SeriesCJC Fine Filters are offline oil filtration systems with integratedcirculating pumps for off-line installation. The filtersare recognized around the world as highly efficient purificationsystems for mining applications.CJC Fine Filters have a 3 µm absolute filtration ratio andremove particles, water and oil degradation products fromhydraulic oils and lube oils - in one and the same operation.CJC Heavy DutyHD HDU 15/12CJC HDU 15/25CJC Heavy DutyHD HDU 15/25CJC MFUMobile Flushing UnitCJC HDU 27/27CJC HDU 27/54 CJC HDU 27/108CJC HDU 2x27/108CJC HDU 427/10810C.C.JENSEN will back you up- we have more than 60 years of experience!

CJC PTU SeriesThe CJC Filter Separators combine depth filtration withwater separation and are used for water contaminated dieselfuel oils, hydraulic and lubricating oils.The CJC PTU Series continuously remove water from oil inlarge volumes.CJC PTU3 27/81CJC PTU3 2x27/108CJC DesorbersThe CJC Desorbers provide solutions forremoval of water in mineral, synthetic andhigh viscosity oils.The Desorbers remove water even fromstable emulsions and from oils with adensity above 1.CJC Desorber D10CJC Desorber D30CJC Filter InsertsAll CJC Filter Inserts have a 3 µm absolute filtration ratio and will removeparticles, water and oil degradation products. Particles down to 0.8 µm are retained in theunique CJC Filter Insert cellulose mass. Water is removed either by absorption or separationaccording to oil system requirements. Oil degradation products are removed by theattraction to the polar fibers.Modular build-upThe modular build-up of theCJC Filter Inserts meansthat a CJC Fine Filter canbe designed to fit anyapplications andrequirementsCJCFilter Insertafter useATEX Explosion ProofCJC Oil Filters can be supplied as ATEX units for installation in explosive atmospheres.We are able to supply equipment for installation in Zone 1 and 2, gas group IIB and IIC.The individual layout of the filter units is based on the actual zone classification wherethe filter unit will be installed. Various voltages are available upon request.Simple, effective and low maintenance- will guarantee your success!11

C.C.JENSEN- Contact us Today!Manufacturing & HeadquartersC.C.JENSEN A/SLøvholmen 13 | DK - 5700 Svendborg | DenmarkTel. +45 6321 2014 | Fax: +45 6222 4615sales@cjc.<strong>dk</strong> | www.cjc.<strong>dk</strong>C.C.JENSEN Subsidiaries and Sales OfficesBelgiumC.C.JENSEN BelgiumTel.: +32 484 25 36 96ccjensen.be@cjc.<strong>dk</strong>www.ccjensen.<strong>dk</strong>FranceC.C.JENSEN FranceTel: +33 3 59 56 16 58ccjensen.fr@cjc.<strong>dk</strong>www.ccjensen.frItalyKARBERG & HENNEMANN srlTel: +39 059 29 29 498info@cjc.itwww.cjc.itUnited KingdomC.C.JENSEN Ltd.Tel.: +44 1 388 420 721filtration@cjcuk.co.ukwww.ccjensen.co.ukBeneluxC.C.JENSEN Benelux B.V.Tel.: +31 182 37 90 29ccjensen.nl@cjc.<strong>dk</strong>www.ccjensen.nlChileC.C.JENSEN S.L. LimitadaTel.: +56 2 739 2910ccjensen.cl@cjc.<strong>dk</strong>www.ccjensen.clChinaC.C.JENSEN FiltrationEquipment (Tianjin) Co. Ltd.Tel: +86 10 6436 4838ccjensen.cn@cjc.<strong>dk</strong>www.ccjensen.cnDenmarkC.C.JENSEN DanmarkTel: +45 7228 2222ccjensen.<strong>dk</strong>@cjc.<strong>dk</strong>www.cjc.<strong>dk</strong>GermanyKARBERG & HENNEMANNGmbH & Co. KGTel: +49 (0)40 855 04 79 0kontakt@cjc.dewww.cjc.deGreeceC.C.JENSEN Greece Ltd.Tel.: +30 210 42 81 260ccjensen.gr@cjc.<strong>dk</strong>www.ccjensen.grIndiaC.C.JENSEN IndiaTel.: +91 4426241364ccjensen.in@cjc.<strong>dk</strong>www.ccjensen.inIrelandC.C.JENSEN IrelandTel.: +353 86 827 1508ccjensen.ie@cjc.<strong>dk</strong>www.ccjensen.iePolandC.C.JENSEN Polska Sp. z o.o.Tel.: +48 22 648 83 43ccjensen@ccjensen.com.plwww.ccjensen.plSpainC.C.JENSEN Ibérica, S. L.Tel.: +34 93 590 63 31ccjensen.es@cjc.<strong>dk</strong>www.cjc.<strong>dk</strong>SwedenC.C.JENSEN ABTel.: +46 8 755 4411sales@ccjensen.sewww.ccjensen.seUnited Arab EmiratesC.C.JENSEN Middle EastTel.: +971 4 447 2886ccjensen.uae@cjc.<strong>dk</strong>www.cjc.aeUSAC.C.JENSEN Inc.Tel.: +1 770 692 6001ccjensen@ccjensen.comwww.ccjensen.comgenerated at BeQRious.comYour local C.C.JENSEN Distributor:C.C.JENSEN A/S | Ver. 002 | 01.14Scan the QR code and findyour nearest distributorsat www.cjc.<strong>dk</strong>- or give us a call!