Shell Omala S4 WE Brochure

Shell Omala S4 WE Brochure

Shell Omala S4 WE Brochure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

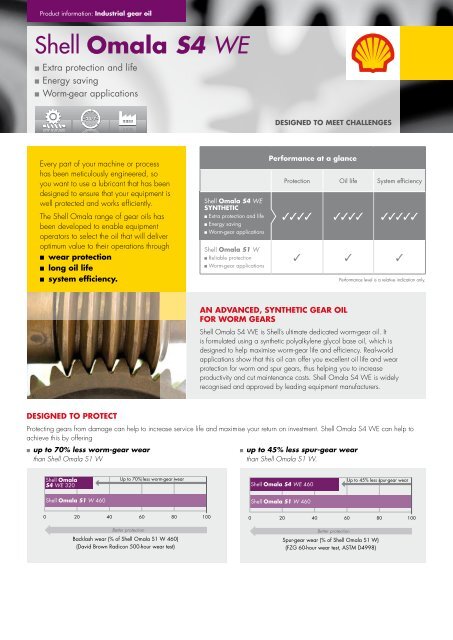

Product information: Industrial gear oil<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong>n Extra protection and lifen Energy savingn Worm-gear applicationsDesigned to meet challengesEvery part of your machine or processhas been meticulously engineered, soyou want to use a lubricant that has beendesigned to ensure that your equipment iswell protected and works efficiently.The <strong>Shell</strong> <strong>Omala</strong> range of gear oils hasbeen developed to enable equipmentoperators to select the oil that will deliveroptimum value to their operations throughn wear protectionn long oil lifen system efficiency.<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong>SYNTHETICn Extra protection and lifen Energy savingn Worm-gear applications<strong>Shell</strong> <strong>Omala</strong> S1 Wn Reliable protectionn Worm-gear applicationsPerformance at a glanceProtection Oil life System efficiency✓✓✓✓ ✓✓✓✓ ✓✓✓✓✓✓ ✓ ✓Performance level is a relative indication only.AN ADVANCED, SYNTHETIC GEAR OILFOR WORM gears<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> is <strong>Shell</strong>’s ultimate dedicated worm-gear oil. Itis formulated using a synthetic polyalkylene glycol base oil, which isdesigned to help maximise worm-gear life and efficiency. Real-worldapplications show that this oil can offer you excellent oil life and wearprotection for worm and spur gears, thus helping you to increaseproductivity and cut maintenance costs. <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> is widelyrecognised and approved by leading equipment manufacturers.Designed to protectProtecting gears from damage can help to increase service life and maximise your return on investment. <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> can help toachieve this by offeringn up to 70% less worm-gear wearthan <strong>Shell</strong> <strong>Omala</strong> S1 Wn up to 45% less spur-gear wearthan <strong>Shell</strong> <strong>Omala</strong> S1 W.<strong>Shell</strong> <strong>Omala</strong><strong>S4</strong> <strong>WE</strong> 320Up to 70% less worm-gear wear<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> 460Up to 45% less spur-gear wear<strong>Shell</strong> <strong>Omala</strong> S1 W 460<strong>Shell</strong> <strong>Omala</strong> S1 W 4600 2040 6080100Better protectionBacklash wear (% of <strong>Shell</strong> <strong>Omala</strong> S1 W 460)(David Brown Radicon 500-hour wear test)0 2040 6080100Better protectionSpur-gear wear (% of <strong>Shell</strong> <strong>Omala</strong> S1 W)(FZG 60-hour wear test, ASTM D4998)

Designed for long oil lifeLimiting fluid degradation can help to prolong oil life. <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> is designed to help you operate for longer without interruption –for reduced maintenance requirements and enhanced productivity. In an industry-standard oil life test, <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> hasn over twice the oil lifecompared with conventional oils such as <strong>Shell</strong> <strong>Omala</strong> S1 W.<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> 460<strong>Shell</strong> <strong>Omala</strong> S1 W 460Over twice the oil life0 50 100150 200250Longer lifeOil life (% of <strong>Shell</strong> <strong>Omala</strong> S1 W)(RPVOT – modified ASTM D2272 test at 120°C)Designed for high efficiencyA gear oil needs to protect and lubricate efficiently. <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> is designed to increase productivity by helping equipment to meetor exceed its design capabilities. <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> hasn over 10% greater worm-gear efficiencythan a standard mineral oiln a 75% lower friction coefficientthan conventional oils such as <strong>Shell</strong> <strong>Omala</strong> S1 W.<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> 320<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> 46075% lowerMineral oilOver 10% greater efficiency<strong>Shell</strong> <strong>Omala</strong> S1 W 4600 20 40 60 80 100Greater efficiencyWorm gear efficiency (%)(David Brown Radiconworm-gear efficiency test)0 0.01 0.02 0.03 0.04Lower is betterFriction coefficient20% slide/roll ratiosimulating typical gearcontact conditionsSpecifications and approvals<strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> meets the requirements of a wide range of industrial bodies andequipment manufacturers, and is available in viscosity grades from ISO 150 to 680.Claims and approvalsFully approved by BonfiglioliApplicationsMeets requirementsANSI/AGMA 9005-E02 (EP)David Brown S1.53.105 GISO 12925-1 Type CKEIndustrial worm-drive reduction systems – for use in severe operatingconditions such as high load under extreme temperature conditions.Compared with conventional oils, <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> can significantlyreduce energy loss in worm drives.Extended life operations – for long-life applications, particularly whereexceptional protection is required for inaccessible locations, for example,in wind turbine yaw bearings or where high temperatures or pressures maybe encounteredSuitable for bearings and other components in splash-lubricated systemsContains polyalkylene glycols and is not compatible with mineral oilsor many synthetic oils. Contact your <strong>Shell</strong> representative for changeoverprocedures.Real-world value deliveryCustomers around the world are benefiting fromswitching to <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong>. For instance:n one tyre manufacturer extended its oil-drainintervals from three months to three years incuring press gearboxes to increase productivityn customers operating worm gears, in particularbronze/steel gear sets, have increased gear lifeby using <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong> dedicated wormgearoiln crane and winch operators have benefited fromthe superior protection of <strong>Shell</strong> <strong>Omala</strong> <strong>S4</strong> <strong>WE</strong>and increased the life of their systems.FULL PRODUCT ANDSERVICE PORTFOLIOWhatever your needs or application, we can providea full range of oils and greases, including synthetic,high-performance products and additional services.For more information, please contactshell.com/lubricants