Cathodic Protection of Aluminium Hulls in Sea Water - MGDUFF

Cathodic Protection of Aluminium Hulls in Sea Water - MGDUFF

Cathodic Protection of Aluminium Hulls in Sea Water - MGDUFF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

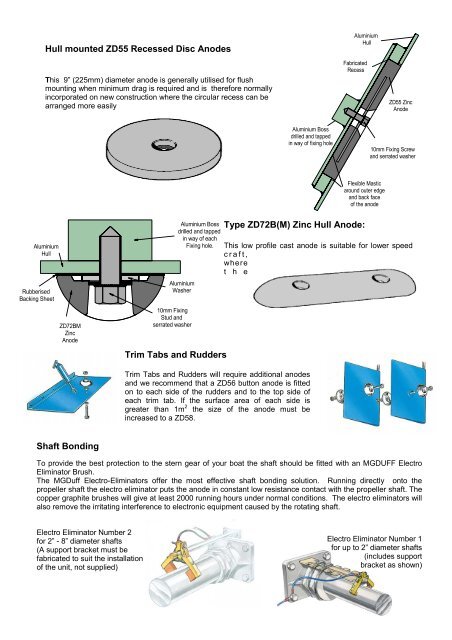

Hull mounted ZD55 Recessed Disc AnodesThis 9” (225mm) diameter anode is generally utilised for flushmount<strong>in</strong>g when m<strong>in</strong>imum drag is required and is therefore normally<strong>in</strong>corporated on new construction where the circular recess can bearranged more easily<strong>Alum<strong>in</strong>ium</strong>HullFabricatedRecessZD55 Z<strong>in</strong>cAnode<strong>Alum<strong>in</strong>ium</strong> Bossdrilled and tapped<strong>in</strong> way <strong>of</strong> fix<strong>in</strong>g hole10mm Fix<strong>in</strong>g Screwand serrated washerFlexible Masticaround outer edgeand back face<strong>of</strong> the anode<strong>Alum<strong>in</strong>ium</strong>HullRubberisedBack<strong>in</strong>g SheetZD72BMZ<strong>in</strong>cAnode<strong>Alum<strong>in</strong>ium</strong>Washer10mm Fix<strong>in</strong>gStud andserrated washer<strong>Alum<strong>in</strong>ium</strong> Bossdrilled and tapped<strong>in</strong> way <strong>of</strong> eachFix<strong>in</strong>g hole.Trim Tabs and RuddersType ZD72B(M) Z<strong>in</strong>c Hull Anode:This low pr<strong>of</strong>ile cast anode is suitable for lower speedcraft,wheret h eTrim Tabs and Rudders will require additional anodesand we recommend that a ZD56 button anode is fittedon to each side <strong>of</strong> the rudders and to the top side <strong>of</strong>each trim tab. If the surface area <strong>of</strong> each side isgreater than 1m 2 the size <strong>of</strong> the anode must be<strong>in</strong>creased to a ZD58.Shaft Bond<strong>in</strong>gTo provide the best protection to the stern gear <strong>of</strong> your boat the shaft should be fitted with an <strong>MGDUFF</strong> ElectroElim<strong>in</strong>ator Brush.The MGDuff Electro-Elim<strong>in</strong>ators <strong>of</strong>fer the most effective shaft bond<strong>in</strong>g solution. Runn<strong>in</strong>g directly onto thepropeller shaft the electro elim<strong>in</strong>ator puts the anode <strong>in</strong> constant low resistance contact with the propeller shaft. Thecopper graphite brushes will give at least 2000 runn<strong>in</strong>g hours under normal conditions. The electro elim<strong>in</strong>ators willalso remove the irritat<strong>in</strong>g <strong>in</strong>terference to electronic equipment caused by the rotat<strong>in</strong>g shaft.Electro Elim<strong>in</strong>ator Number 2for 2” - 8” diameter shafts(A support bracket must befabricated to suit the <strong>in</strong>stallation<strong>of</strong> the unit, not supplied)Electro Elim<strong>in</strong>ator Number 1for up to 2” diameter shafts(<strong>in</strong>cludes supportbracket as shown)