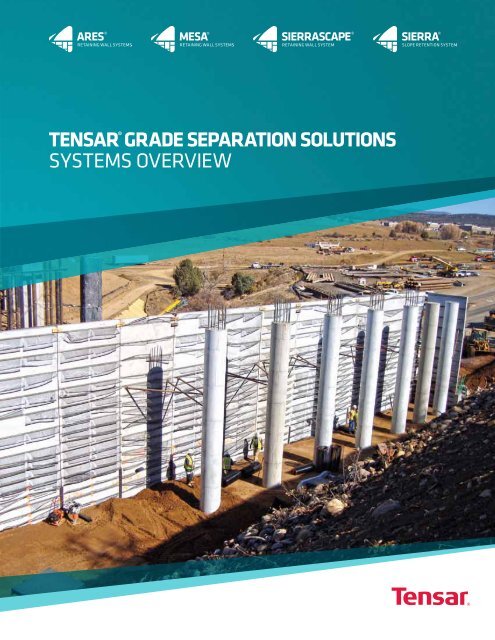

Grade Separation Solutions Overview Brochure - Tensar International

Grade Separation Solutions Overview Brochure - Tensar International

Grade Separation Solutions Overview Brochure - Tensar International

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Experience You Can Rely On<strong>Tensar</strong> delivers engineered systems that combine technology,engineering, design and products. Unique in their quality,consistency and durability, <strong>Tensar</strong>® Geogrids are composedof materials resistant to physical deterioration and loss ofstrength caused by aggressive chemical environments.<strong>Tensar</strong>® Uniaxial Geogrids<strong>Tensar</strong> UX Geogrids are manufactured using select gradesof high-density polyethylene (HDPE) resins that are highlyoriented and resist elongation when subjected to high tensileloads for long periods of time. These geogrids carry large tensileloads applied in one direction, and their open aperture structureinterlocks with natural fill materials, making them ideal formechanically stabilized earth (MSE) and reinforced soil slope(RSS) applications.The Engineered Advantage<strong>Tensar</strong> is the industry leader in internal soil reinforcement.We have developed products and technologies that have beenat the forefront of the geotechnical industry for more than twodecades. As a result, you can rely on our systems and designexpertise. Our products are backed by the most thoroughquality assurance practices in the industry. And, we can providefull engineering and construction services, including detailing,design, site assistance and final stamped drawings for each ofour grade separation solutions.For more information on all of our <strong>Grade</strong> <strong>Separation</strong> Systems,call 800-TENSAR-1, visit www.tensarcorp.com or send ane-mail to info@tensarcorp.com. We are happy to supply youwith additional information, system specifications, designdetails, conceptual designs, preliminary cost estimates andmuch more.Interstate H-3 – Oahu, HawaiiASCE recognized this Sierra® Slope project with the 1998 Outstanding CivilEngineering Achievement Award.Blackstone Valley – Millbury, MassachusettsThe SierraScape® System was chosen because it met the aesthetic demandsof the town and the Engineer’s space requirements, all while saving time andmoney by using on-site soils.3

When long-term performance andspeed of construction are important,ARES ® Retaining Wall Systemsoffer unmatched advantages.DOTs, contractors and engineers have long appreciated themany advantages of MSE panel walls. Their wide range ofappearances and finishes, combined with the simplicity andspeed of construction, make them attractive when comparedto other types of wall systems. Unfortunately, limitationsimposed by the behavior of steel reinforcing materials anda very narrow and expensive range of acceptable backfillproperties have restricted their use until the introductionof the ARES® Systems featuring <strong>Tensar</strong>® Geogrids. Bymechanically connecting <strong>Tensar</strong> Geogrids to the panel facing,the fully integrated ARES Retaining Wall Systems now offera long lasting, cost-effective and aesthetic solution.ARES Systems are proven MSE retaining wall solutions. They havebeen evaluated by the Highway Innovative Technology EvaluationCenter (HITEC) and millions of square feet have been installed ona variety of transportation and site development projects.No Metal – No CorrosionWith soil reinforcement that is 100% polymeric, ARESRetaining Wall Systems are proven concrete panel wallsolutions that eliminate corrosion concerns. ARES Systemsoffer the cost advantages of an MSE retaining wall without thelong-term consequences of exposure to chlorides, sulfates, lowresistivitysoils or stray electric current potential. This makesARES Systems the logical choice for “hot” backfill soils,transformer platform areas and electrified rail systems.The ARES Systems AdvantageThe ability to utilize non-metallic earth reinforcement makesthe ARES Systems inert to chemical and electrical corrosion.The inert properties of <strong>Tensar</strong> Geogrids permit the use of a widerange of backfills, including recycled materials, translating intogreater economy and the potential for a sustainable design.ARES® Systems’ ComponentsComponent<strong>Tensar</strong> GeogridsPrecast Panel FacingBodkin ConnectorFunctionHigh-density polyethylene (HDPE) structural geogrids internally reinforce the fill materials. Inertto chemical degradation, they can be used with different backfill materials, even recycled concrete.Available in standard 5 ft x 5 ft (1.5 m x 1.5 m), 5 ft x 9 ft (1.5 m x 2.75 m), or can be customized forfull height construction.HDPE Connector for high connection efficiency without the concern for corrosion.Full Engineering and Construction ServicesDetailing, design, site assistance and stamped drawings for each ARES project upon request.4

All in all, ARES ® Systems providea structurally dependable solutionfor a variety of grade changerequirements, while saving timeand money during installation.Structural StabilityCombined withAesthetic AppealAn Economical AdvantageARES® modular and full-height panelsoffer designers a choice of texturesand patterns to fit the architectural,structural and budgetary needsof your next retaining wall project.The panels are cast with polymertabs embedded in the rear face of eachpanel and then connected to the <strong>Tensar</strong>®reinforcing geogrid. The 100% polymerconnection assures load transfer to thereinforcement with no loss in designstrength for the project’s life.Memorial Causeway – Clearwater, FloridaThe non-corrosive properties associated with <strong>Tensar</strong>Geogrids allowed the ARES System to be used in thissalt water application.King Kamehameha – Oahu, HawaiiARES Full-Height Panels permit the use of a wide rangeof architectural finishes.In addition to the various aestheticoptions available, contractors will alsobenefit by saving time and labor costswhen installing ARES Systems. TheARES panels contain significantface area while the reinforcement islightweight and easy to connect –no nuts or bolts to tighten.All in all, ARES Systems provide astructurally dependable solution for avariety of grade change requirements,while saving time and money duringinstallation.ARES wallReinforced fill<strong>Tensar</strong> geogridprimary reinforcementRetainedfillARES wallReinforced fill<strong>Tensar</strong> geogridprimary reinforcementRetainedfillFoundationFoundation6

West Reynolds Road – Lexington, KentuckyBy using the ARES® Full-Height Panels, the contractorand government saved a significant amount of timeand expense on installation.Third Street – Auburn, WashingtonFaced with constructing an embankment of very softsoils, the ARES 2-stage wall system was utilized toallow for anticipated post-construction settlement.San Diego Light Rail – San Diego, CaliforniaProject specifications required that metal not be incontact with the earth backfill. The <strong>Tensar</strong>® Geogridreinforcement used with the ARES System providedthe ideal solution.Galvanized weldedwire formSupport strutTrack<strong>Tensar</strong> geogridprimary reinforcementARES wallReinforced fillRetainedfillARES wallReinforced fillRetainedfillARES wallRetainedfill<strong>Tensar</strong> geogridprimary reinforcement<strong>Tensar</strong> geogridprimary reinforcementReinforced fillFoundationFoundationFoundation

Mesa ® Walls provide the dependability engineersrequire, the efficient installation contractors havecome to expect, and the aesthetics owners andarchitects demand in the industry today.A Single-Source SolutionFor over a decade, the Mesa® Retaining Wall Systems have beenthe retaining wall solution of choice for many architects andengineers. One of the only concrete segmental retaining wall(SRW) systems with a proven, positive, mechanical connection,the Mesa Systems offer superior and cost-effective solutionsfor your structural and landscaped retaining wall needs in thecommercial, industrial, residential and transportation markets.With a network of licensed independent block manufacturersthroughout the United States, Canada and Latin America,the Mesa Systems have become a new standard in SRWtechnology. Designed as a truly integrated solution, they arethe only SRW system where the block, geogrid and connectorhave been developed by one company. Unlike other SRWs, thecomponents of a Mesa Wall have been specifically designedto work together for optimum efficiency and performance.High-strength, low-absorption concrete units, high-shearstrength connectors and <strong>Tensar</strong>® Geogrids all work togetherto form a mechanically stabilized earth (MSE) system that canmeet or exceed the industry standard. In fact, as a result of thehigh connection strength and reliability of the system,* core fillis rarely needed. Using less core fill results in greater projectsavings through less imported stone and less labor.If you’re looking for long-term durability, increased structuralintegrity and simplified construction, all at lower costs thanmost conventional alternatives, specify the Mesa RetainingWall Systems on your next project.*Core fill is defined as the aggregate fill within the open void space of anSRW Block. Core fill is suggested for wall segments that form convex curveswith a radius less than 25 ft (7.6 m) and 90° outside corner units.Mesa® Systems’ ComponentsComponent<strong>Tensar</strong> GeogridsMesa Segmental UnitsMesa ConnectorsFunctionHigh-density polyethylene (HDPE) structural geogrids internally reinforce the fill materials. Inert tochemical degradation, they can be used with non-select fill or even recycled concrete.High-strength concrete block with a compressive strength that exceeds the National Concrete MasonryAssociation (NCMA) standards (>4,000 psi) (27.6 MPa).Unique locking connectors are designed to mechanically connect the <strong>Tensar</strong> Geogrids to the Mesa Units.Provide a low-strain, end-bearing connection that is not dependent on friction for structural integrityand allow walls to be built near vertical or with a 5 ⁄8" (1.6 cm) setback.Full Engineering and Construction ServicesDetailing, design, site assistance and stamped drawings for each Mesa project upon request.8

The Connection You Can Count OnTested Transportation <strong>Solutions</strong>The long-term performance of any retaining wall system istested most rigorously in the public transportation market.Differential settlement, traffic barriers and seismic loads cantest the strength of any retaining wall, so connection strengthmust be reliable. The Mesa® Connectors were specificallydesigned to meet these long-term performance demands,providing a mechanical connection where it’s needed most –at the face. The system and connection components are largelyunaffected by abrasion, tearing or hydrolysis – factors that canundermine the performance of frictional systems using awoven polyester reinforcement. When specifying a Mesa Wall,you are assured that the system’s structural components arereliable and designed for long-term performance.Mesa Systems –Segmental Retaining WallCreative Commercial ApplicationsWhen designing for commercial applications, the need tocombine creative looks with practical installations becomes anecessity, while at the same time maintaining the bottom line.That’s where the Mesa Systems can help. By coexisting withboth nature and industry, a Mesa Wall combines creativity withstructural stability, providing the ideal solution for almost anycommercial application.Reliable Residential ProjectsWhether you’re increasing useable land or improving propertyvalue, the Mesa Systems can solve your most challenging gradechange requirements with a full line of segmental retaining wallproducts. From building large structural walls for multi-familyhomes to tiered garden walls in your own backyard, Mesa Unitsblend effortlessly with the natural surroundings of most any site.<strong>Tensar</strong> Uniaxial Geogrid12" (min.) (30.5 cm)granular fillMesa® standardconnectorLeveling padMesastandard unitThe Mesa Systems’ Standard Connector holdsthe <strong>Tensar</strong>® Geogrid securely to the Mesa Blockand provides block facing alignment.9

The SierraScape ® Retaining WallSystem offers a more affordablealternative to concrete for variousgrade change requirements.Engineers and architects are constantly under pressure tofind cost-effective alternatives to traditional wall systems. Ina range of applications, they are finding that the best solution– in terms of appearance, performance and overall value – is theSierraScape® Wire-Formed Retaining Wall System. Backed byover two decades of engineering experience and over 10 millionsquare feet of installations worldwide, the SierraScape Systemis a complete retaining wall solution which includes materials,design, specifications and technical assistance when needed.The Positive ConnectionThe SierraScape System combines <strong>Tensar</strong>® Geogrids witha positive mechanical connection, providing a dependableand cost-effective solution for the most challenging gradechange projects. This connection better withstands differentialsettlement, offers exceptional performance in areas whereseismic activity or heavy external loads are a concern andvirtually eliminates surficial stability problems oftenassociated with other alternatives. The SierraScape Connectionalso provides a visual construction quality control checkduring installation.Inside and Out –No Other Wall System ComparesWhen it comes to structural stability, no other wire-formedretaining wall compares. The SierraScape System adapts to avariety of project conditions, design requirements and aestheticoptions. When compared to concrete, the system can be a morecost-effective solution. Its unique wire forms ease installationand help speed up construction time. Better yet, the SierraScapeSystem’s resistance to environmental degradation, lowmaintenance and design versatility help make it the rightchoice for almost any retaining wall application.SIERRASCAPE® Systems’ ComponentsComponent<strong>Tensar</strong> GeogridsSierraScape Facing ElementsLocking Tail StrutFunctionHigh-density polyethylene (HDPE) structural geogrids internally reinforce the fill materials. Inert tochemical degradation, they can be used with non-select fill or even recycled concrete.Galvanized wire-form baskets that provide permanent facial stability during placement and compactionof fill material, and simplify facing alignment.Locking struts secure the geogrid to the SierraScape basket tail, and help stiffen the facing elementto maintain alignment.Geotextiles<strong>Separation</strong> filter fabric provides a barrier between the backfill material and the stone fill at the face.Turf Reinforcement MatsFull Engineering andConstruction ServicesPermanent, erosion-control products that aid in vegetation establishment and provide long-termturf reinforcement. Only used in vegetated face applications.Detailing, design, site assistance and stamped drawings for each SierraScape project upon request.12

A Complete Retaining Wall SolutionUnlike the stark appearance of most concrete wall systems,the SierraScape® System offers many different facing optionsto meet your design needs.SierraScape facing options include:˴˴Stone – facing filled with native or imported stone thatcan be color and size specified for a desired look and feel˴˴Vegetated – designed with a vegetated face for a naturalappearance and usually incorporates local plant speciesto blend the wall into the existing environment˴˴Architectural – veneer treated with stacked stoneor a shotcrete sculpted face providing a unique,traditional finishEase of Installation Keeps Costs DownIntegrating SierraScape components create durable,yet simple-to-build structures. With a small number ofcomponents, project assembly moves quickly and withoutspecialized equipment or labor. Welded-wire forms stack easilyto create a uniform wall face, and unlike geotextile wrap walls,stiff <strong>Tensar</strong>® Geogrids and the unique SierraScape LockingTail Strut help maintain facing alignment. And, because thesystem can be backfilled with general embankment fills oron-site soils, cost savings for fill materials and disposal costscan also be realized.SierraScape System –Vegetated Face Option<strong>Tensar</strong> BiaxialGeogrid<strong>Tensar</strong> Uniaxial GeogridSierraScape System –Stone Face Option<strong>Tensar</strong> Uniaxial GeogridTurfreinforcementmatLockingtail strutLockingtail strutSierraScapefacing unitSierraScapeconnectionGalvanizedSierraScapefacing unitSierraScapeconnection13

A PositiveConnection withan EconomicalAdvantageThe Solution of Choice14The SierraScape® System hasincreasingly become the systemof choice for residential, commercialand transportation applications.By combining beauty and elegancewith efficiency and performance,SierraScape Walls are built to standthe test of time.˴˴Stone:Components stack quickly andevenly to create a more uniformwall face. Their flexibility andconnection capabilities helpresist differential settlement.˴˴Vegetated:SierraScape Vegetated Wallsprovide a versatile soil retainingwall structure where differentnative vegetated covers blendnaturally with the surroundinggreen space.˴˴Pressure Relief:Structurally equivalent totraditional approaches, SierraScapePressure Relief walls effectivelyreinforce surrounding fill so lateralsoil loads against the below gradestructure are eliminated.Vulcan Materials Plant – Columbia, South CarolinaThe stone-filled SierraScape wall and superspanstructure allow heavy trucks easy and stablepassage to and from the quarry.GalvanizedSierraScapefacing unitCulvert<strong>Tensar</strong> geogridprimary reinforcementGeotextileReinforced fillFoundationRetainedfillPost River Apartments – Atlanta, GeorgiaEnvironmental impact, budget and aesthetics wereconcerns when selecting a retaining wall for thisapartment complex, the natural choice was theSierraScape System with a vegetated face.Plantablefill<strong>Tensar</strong> geogridprimary reinforcementTurf reinforcement matLocking tail strut<strong>Tensar</strong> UVstabilized geogridReinforced fillFoundationRetainedfill

Brentwood Towne Square – Pittsburgh, PennsylvaniaTo eliminate lateral soil loads, a SierraScape® PressureRelief Wall was selected as a cost-effective alternativeto traditional below-grade construction.Quail Ridge – Kelowna, British ColumbiaThe combination of stone face walls for drainageand vegetated walls for a “green” natural face providedthe ideal configuration at this upscale golf coursecommunity.Webb Gin – Gwinnett County, GeorgiaA multi-system design combined a Mesa Wall with bothvegetated and stone face SierraScape Walls, providing aunique and aesthetic solution.6" min. void space (15.24 cm)<strong>Tensar</strong> geogridprimary reinforcement<strong>Tensar</strong> geogrid primary reinforcement<strong>Tensar</strong> UV stabilized geogridMesa wall<strong>Tensar</strong> geogridprimary reinforcementGeotextileRetainedfill=TopsoilTurf reinforcement matLimit of reinforced fill#57 stoneReinforced fillRetainedfillSierraScape vegetated wallGranular fill2"-4" rock (7.6 cm - 10 cm)Turf reinforcement matReinforced fillFoundation=<strong>Tensar</strong> UV stabilized geogridReinforced fillRetainedfillDrainage pipeLocking tail strutFoundationSierraScape stone face wallFoundation

The Sierra ® Slope RetentionSystem provides an economicaland aesthetic alternative toconventional retaining walls.The Sierra® Slope Retention System, a premier reinforcedsoil slope (RSS) retention system, was introduced by <strong>Tensar</strong>in 1982.The Sierra Slope Retention System is a complete and fullyintegrated mechanically stabilized earth (MSE) system.Each mechanical component has been designed to worktogether for optimum efficiency in a variety of challengingsite and loading conditions.The cost effectiveness of the Sierra System, coupledwith a natural aesthetic appeal, provides an RSS retentionsystem that is routinely specified by government agencies,developers, engineers and architects for a varietyof applications:˴˴Commercial, industrial and retail˴˴Single- and multi-family residential housing˴˴Transportation infrastructure˴˴Recreation facilities˴˴Municipal water and storm water managementThe Sierra System significantly reduces material andinstallation costs by virtually eliminating limitations imposedby soil conditions, minimizing fill requirements and allowingthe use of on-site fills. The economic benefits of Sierra Slopeshave led cost-conscious transportation agencies around theworld to select them for landslide repairs, overpasses androadway widenings.These same cost advantages have led to the use of theSierra System by site developers concerned with enhancingproperty values and preserving the natural beauty of theirsites. Sierra Slopes can be graded so that the appearanceof these reinforced earth retention structures is almostindistinguishable from the native terrain.Sierra® Systems’ ComponentsComponentFunction<strong>Tensar</strong> Uniaxial (UX) GeogridsPrimary reinforcement that internally reinforces the soil structure and fill materials.<strong>Tensar</strong> Biaxial (BX) GeogridsSecondary reinforcement that provides surficial stability of the slope structure.Site-Specific Facing SystemProvides aesthetic value by offering multiple facing options, including bioengineering.Full Engineering andConstruction ServicesDetailing, design, site assistance and stamped drawings for each Sierra project upon request.16

A Complete and Proven SystemEconomical˴˴Create usable land in previously undeveloped areas˴˴Save up to 60% versus conventional concreteretaining walls˴˴May allow for lower quality fills so on-site soils areusually acceptable˴˴Installs quickly and without specialized equipmentFlexible˴˴Create slopes from 26° to 70° to fit sitedevelopment conditions˴˴Use a smaller footprint while maximizing landfor development˴˴Create curved slopes and varying face anglesfor a more natural look˴˴Specify a variety of facing options from erosionblanket to professionally landscaped vegetationAttractive˴˴Blends naturally with the surrounding environment˴˴Not subject to facial distortions and cracking likeconcrete walls˴˴Resists the effects of differential settlement andseismic activityProven˴˴Over 40 million square feet of Sierra® Slopes havebeen installed˴˴Stands up to the most critical loading situations:railways, bridge abutments and building foundations˴˴Sierra Slopes have adapted to extreme conditions andwithstood multiple seismic events exceeding 0.4 g˴˴Constructed with high performance <strong>Tensar</strong>® GeogridsSierra ® System –Welded Wire Formwith Plantable Fill<strong>Tensar</strong> BX Geogrid<strong>Tensar</strong> Uniaxial GeogridOffset varies to suitrequired slope angle6" (min.)Turf reinforcement matTopsoilBlack steelwelded wirefacing unitSupport strut17

Optimal DesignsBased on SiteConstraintsSite Specific <strong>Solutions</strong>The <strong>Tensar</strong>® Sierra® Slope Systemwas developed to provide designersand specifiers countless layout andslope angle options. The flexibilityof the Sierra Slope System makesit an ideal choice when solving gradeseparation challenges.Designers and owners are continuallyfaced with different property and siteconstraints that require innovativesolutions. Some projects may requirea very steep grade change in whicha green, vegetative face is the rightsolution. Other projects may utilizecomplementary grade separationsystems, such as the Mesa® RetainingWall System, to create an aestheticand cost-effective alternative.Bridge Street – Irwin, PennsylvaniaDepartments of Transportation use the Sierra Systemto stay within the restricted rights-of-way whilemaximizing land use.<strong>Tensar</strong> geogridprimary reinforcement<strong>Tensar</strong> GeogridPrimary ReinforcementRight Plantable ofway limit FillErosion Control MatLocking Tail Strut<strong>Tensar</strong> UV Stabilized GeogridFoundationAdditional land availablefor highway wideningRetainedfillPrevious slopeLimit of excavationRetainedFillPoland Spring Plant Expansion –Poland Spring, MaineFlower or grass seed installs quickly and is a low-costalternative for many projects, including overpassesand roadways.Turf reinforcement mat1 (Min.)1<strong>Tensar</strong> geogridsecondary reinforcementReinforced fillFoundationRetained fill<strong>Tensar</strong> geogridprimaryreinforcementReinforced FillFoundation18

Marriott Riverchase – Hoover, AlabamaThe Sierra® System easily adapts to a wide range of slopeand slope/wall combinations, but the 1H:1V remains themost commonly specified Sierra Slope solution.Pearl Street – Braintree, MassachusettsCombine Sierra Slopes and Mesa® Retaining Walls onprojects where vertical retention along with reducedmaterial and labor costs are essential.Banks County Landfill – Banks County, GeorgiaThe Sierra System was used to create 1H:1V inboardslopes and 1H:6V outboard slopes to increase disposalcapacity at this landfill without expanding the footprint.<strong>Tensar</strong> geogridprimary reinforcement<strong>Tensar</strong> geogridprimary reinforcementTurf reinforcement mat<strong>Tensar</strong> geogridsecondaryreinforcement1 (Min.)1ReinforcedfillRetainedfillSierraSlopeMesa wall1 (Min.)1Reinforced fillRetainedfillWeldedwire form<strong>Tensar</strong> geogridprimary reinforcement<strong>Tensar</strong> UV stabilized geogridFoundationFoundationReinforced fillRetainedfillFoundation

By utilizing less expensive materials,unskilled labor and lightweightequipment, the <strong>Tensar</strong> ® Systemprovides a low-cost alternativefor temporary wall applications.Temporary walls are a necessity for many types of stagedconstruction, but conventional means of constructing them areexpensive and require heavy lifting and pile driving equipment.Fortunately, there is a proven technology that allows you tobuild temporary walls without the difficulties and expenseof conventional techniques – the <strong>Tensar</strong> Temporary RetainingWall System.A <strong>Tensar</strong>® Temporary Retaining Wall can change theconstruction parameters for applications, such as bridgeimprovements, road widening projects, phased or stagedconstruction or the construction of surcharge load cells. <strong>Tensar</strong>Geogrids internally reinforce the fill within the wall and utilizean inexpensive wire-form facing system. Construction oftemporary walls is no longer restricted to sheet pile or soldierpile and lagging walls. Both of these typically require toepenetration equal to or greater than the wall height and/or theuse of secondary bracing or deadmen to safely retain the fill.Pile systems have been the temporary wall of choice for manyyears. These walls require the use of expensive equipment andlabor, resulting in significant project costs.By utilizing less expensive materials, unskilled labor andlightweight equipment, the <strong>Tensar</strong> Temporary Wall Systemprovides a low-cost alternative for temporary wall applications.Additionally, the materials may be left in place or easilyremoved as required.Temporary Welded Wire Form –with BX and Fabric<strong>Tensar</strong> BX Geogrid<strong>Tensar</strong> Uniaxial GeogridOffsetvariesAASHTO M288Class 1 GeotextileTemporary Welded Wire Form –with FabricAASHTO M288Class 1 Geotextile<strong>Tensar</strong> Uniaxial GeogridBlack steel WWFfacing unitOffsetvariesSupportstrut20Black steel WWFfacing unitSupport strut

The John Paul Jones Arena at the University of Virginiacombined the Geopier System in lieu of drilled shaftfoundations, with a SierraScape® Pressure Relief Wallto eliminate costly concrete foundation walls.<strong>Tensar</strong>® Corporation Provides Complete Site <strong>Solutions</strong><strong>Tensar</strong>® Corporation is a premier provider of technology-drivensite solutions. We believe that the synergies inherent incombining two or more of our Company’s products, services,applications and systems will create faster, stronger, andmore economical solutions that save time and money whencompared to conventional alternatives. Through <strong>Tensar</strong>Corporation’s Subsidiary units – <strong>Tensar</strong> <strong>International</strong>, GeopierFoundation Company and North American Green, we are ableto offer high-performance solutions for a wide range ofconstruction site challenges.An example of these synergies is found in the Southlandsof Orchard project in Denver, Colorado. Existing conditionsrequired the use of a Rammed Aggregate Pier® design toreinforce soft soils found on the site. The Geopier® Systemprovided total and differential settlement control and increasedbearing support for the proposed Mesa Retaining Wall System.By bringing together two systems from within the samecompany, <strong>Tensar</strong> is able to provide a complete site solutionpackage, all from a single source.Our systems are based on advanced soil reinforcementtechnologies that incorporate high-performance patentedproducts. It is the synergies within our company that allow usto be well positioned to provide customized, engineering-basedsolutions for common site development applications.Reinforced fill<strong>Tensar</strong> geogridprimary reinforcement<strong>Tensar</strong> geogridreinforcementRetainedfillSouthlands Orchard Road – Denver, Colorado. This Mesa® Wall used withGeopier System Foundation provided a complete site solution.Rammed Aggregate Pier® system21

Evaluate Every <strong>Tensar</strong> ® <strong>Grade</strong><strong>Separation</strong> System with aProven Design Application<strong>Tensar</strong> is a global site development solutions provider. And themore we grow, the more we’re able to offer unique tools thatmake the design of grade separation systems simpler, fasterand more cost-efficient.That is why we now offer <strong>Tensar</strong>Soil Software to engineersand designers of retaining walls and reinforced soil slopes herein North America. Successfully used in Europe, Asia and otherregions for more than a decade, the latest version of <strong>Tensar</strong>SoilSoftware has been expanded to evaluate the feasibility,potential performance and cost benefits of each of ourgeogrid-reinforced systems, including:˴˴ARES® Retaining Wall Systems˴˴Mesa® Retaining Wall Systems˴˴SierraScape® Retaining Wall Systems˴˴Sierra® Slope Retention System˴˴<strong>Tensar</strong>® Temporary Retaining WallsIn addition, <strong>Tensar</strong>Soil Software may be used with large precastblock systems that incorporate <strong>Tensar</strong>® Uniaxial Geogrid intotheir design.<strong>Tensar</strong>Soil Software is Compatible withAll Major Design Methodologies<strong>Tensar</strong>Soil Software offers a versatile technology thatenables you to design <strong>Tensar</strong> Systems in accordance withall major industry-standard protocols including:˴˴National Concrete Masonry Association – (NCMA) 1997˴˴Federal Highway Administration – DemonstrationProject 82 (1997)˴˴Federal Highway Administration – National HighwayInstitute (FHWA NHI 043) 2001 (AASHTO ASD) 2002˴˴American Association of State Highway andTransportation Officials – Load and Resistance FactorDesign (AASHTO LRFD) 200722<strong>Tensar</strong>Soil Software allows you to design and compare costs for different<strong>Tensar</strong> Systems.Several windows can be simultaneously displayed on a full screen.Windows can be re-dimensioned or repositioned for graphicemphasis, presentation purposes, etc.

<strong>Tensar</strong>Soil Software has been used to designthousands of critical structures across the globe,like the Al Mawaleh Bridge in Muscat, Oman.<strong>Tensar</strong>Soil Software is programmed with data on all <strong>Tensar</strong>®wall and slope systems. Fully interactive, it allows you to inputand easily alter wall/slope geometry, geogrid grade or layout,surcharge load and/or soil characteristics – all on a singlescreen image – to determine stability data and material costsinstantaneously. With each change, results are updated in realtime. For <strong>Tensar</strong> walls, that means that any underdesignedarea is immediately revealed, with no need to back-tracethrough previous screens and then recalculate. Once internaland external stability parameters have been determined,wall or slope design results can be exported to <strong>Tensar</strong>SlopeSoftware, our slope stability application, for a comprehensive,compound and global stability analysis.Experience You Can Rely On<strong>Tensar</strong>, the leader in geosynthetic soil reinforcement, offersa variety of solutions for retaining wall and steepened slopeprojects. Our products and technologies, backed by the mostthorough quality assurance practices, are at the forefrontof the industry. Our support services include site evaluation,design consulting and site construction assistance. Forinnovative solutions to your engineering challenges, rely onthe experience, resources and expertise that have set theindustry standard for more than two decades.No other program offers the capabilities you’ll find with<strong>Tensar</strong>Soil Software. To sign-up for a training workshopnear you, call us at 800-TENSAR-1. For more information onour <strong>Grade</strong> <strong>Separation</strong> <strong>Solutions</strong>, visit www.tensarcorp.com, orcall the number above to speak with a <strong>Tensar</strong> representative.23

<strong>Tensar</strong> <strong>International</strong> Corporation2500 Northwinds Parkway, Suite 500Alpharetta, Georgia 30009800-TENSAR-1tensarcorp.comDistributed by:©2011, <strong>Tensar</strong> <strong>International</strong> Corporation. Certain products and/or applications described or illustrated herein are protected under oneor more U.S. patents. Other U.S. patents are pending, and certain foreign patents and patent applications may also exist. Trademarkrights also apply as indicated herein. Final determination of the suitability of any information or material for the use contemplated,and its manner of use, is the sole responsibility of the user. Printed in the U.S.A.GSS_BRO_1.11