HIGH SPEED STEEL VWM2 - Villares Metals

HIGH SPEED STEEL VWM2 - Villares Metals

HIGH SPEED STEEL VWM2 - Villares Metals

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

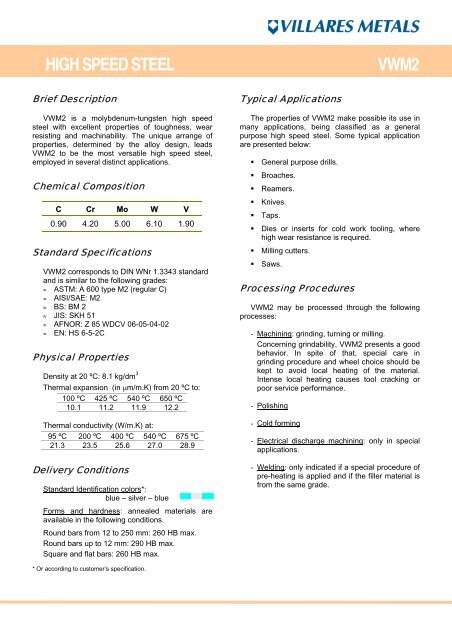

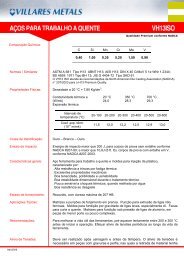

<strong>HIGH</strong> <strong>SPEED</strong> <strong>STEEL</strong><strong>VWM2</strong>Brie f Description<strong>VWM2</strong> is a molybdenum-tungsten high speedsteel with excellent properties of toughness, wearresisting and machinability. The unique arrange ofproperties, determined by the alloy design, leads<strong>VWM2</strong> to be the most versatile high speed steel,employed in several distinct applications.Chemical CompositionC Cr Mo W V0.90 4.20 5.00 6.10 1.90Standard Specifications<strong>VWM2</strong> corresponds to DIN WNr 1.3343 standardand is similar to the following grades:≈ ASTM: A 600 type M2 (regular C)≈ AISI/SAE: M2≈ BS: BM 2≈ JIS: SKH 51≈ AFNOR: Z 85 WDCV 06-05-04-02≈ EN: HS 6-5-2CPhysical PropertiesDensity at 20 ºC: 8.1 kg/dm 3Thermal expansion (in µm/m.K) from 20 ºC to:100 ºC 425 ºC 540 ºC 650 ºC10.1 11.2 11.9 12.2Thermal conductivity (W/m.K) at:95 ºC 200 ºC 400 ºC 540 ºC 675 ºC21.3 23.5 25.6 27.0 28.9Delivery ConditionsStandard Identification colors*:blue – silver – blueForms and hardness: annealed materials areavailable in the following conditions.Round bars from 12 to 250 mm: 260 HB max.Round bars up to 12 mm: 290 HB max.Square and flat bars: 260 HB max.Typical ApplicationsThe properties of <strong>VWM2</strong> make possible its use inmany applications, being classified as a generalpurpose high speed steel. Some typical applicationare presented below:• General purpose drills.• Broaches.• Reamers.• Knives.• Taps.• Dies or inserts for cold work tooling, wherehigh wear resistance is required.• Milling cutters.• Saws.Processing Procedures<strong>VWM2</strong> may be processed through the followingprocesses:- Machining: grinding, turning or milling.Concerning grindability, <strong>VWM2</strong> presents a goodbehavior. In spite of that, special care ingrinding procedure and wheel choice should bekept to avoid local heating of the material.Intense local heating causes tool cracking orpoor service performance.- Polishing- Cold forming- Electrical discharge machining: only in specialapplications.- Welding: only indicated if a special procedure ofpre-heating is applied and if the filler material isfrom the same grade.* Or according to customer’s specification.

<strong>HIGH</strong> <strong>SPEED</strong> <strong>STEEL</strong><strong>VWM2</strong>Heat H TreatmentAnnealing: soft annealing should be carried out byheating between 850 and 880 ºC for 2 hours, followedby slow cooling at 10/20 ºC per hour until 650 ºC and,then, by air cooling. In this treatment, the use ofprotective atmosphere is important to avoid surfacedecarburization.Stress relieving: Intense material removal duringmachining of tools induces considerable stress, whichmay cause distortions after heat treatment. In order toavoid this, a stress reliving is recommended to beapplied after machining and before end heat treatment.The indicated procedure is heating between 600 and700 ºC and holding until complete homogenization,followed by slow cooling (air or furnace) at least down to500 ºC.Hardening and Tempering: For improved toolperformance, hardening temperature should be chosendepending on the hardness level required, considering agiven tempering temperature around 560 ºC (see graphicbelow). The indicated hardening temperatures are:Application Hardening TemperingCutting tools 1180-1220 ºCCold work dies 1080-1160 ºC560 ºCHardening procedure must involve pre-heating at400/500 ºC followed by other at 860/880 ºC. For largetools, it is also recommended another pre-heating at1050 ºC. After pre-heating, hardening at suitableaustenitizing temperature may be conducted, followedby quenching down to room temperature. A protectiveatmosphere is absolutely necessary. Double temperingtreatments, of at least 2h, are required and after eachone tools must cool down to room temperature.Hardness (HRC)676665646362616059585756120011801160112010801220500 520 540 560 580 600 620Tempering Temperature (ºC)Tempering CurveThe austenitizing temperatures relative to each curve are indicated in italic type.Surface treatments: <strong>VWM2</strong> is an adequate substrate forPVD and CVD coatings, which normally lead toconsiderable improvements in tool life.If nitriding is applied, the treatment temperatureshould be lower than the tempering temperature, toavoid decrease of core hardness.It is important that, before all surface treatments,tools have clean surface (without oil or grease) and arefree from grinding overheating.ToughnessBend test results (below) show that increasinghardening temperature, result in decrease of bendstrength, fracture energy and deflections. This indicatesthat toughness is higher if low hardening temperatures areused. Because that, temperatures between 1080 and1160 ºC are indicated for cold work tooling, where highertoughness is required. For cutting tools, hardening shouldbe employed in the range of 1180 to 1220 ºC, to improvehardness and wear resistance; temperatures higher than1220 ºC cause a considerable loss in toughness and mustbe avoided.Bend Strength (MPa)60005500500045004000ProportionalityLimit StrengthBend StrengthFractureEnergy350033,01140 1160 1180 1200 12202,3Hardening Temperature (ºC)TotalDeflection1,50,8 PlasticDeflection0,01140 1160 1180 1200 1220Hardening Temperature (ºC)* Results for round samples of a ∅ 5,5 mm bar. Fixed tempering at 560 ºC.Relative Comparison of<strong>Villares</strong> <strong>Metals</strong> High Speed SteelsWearHotToughness Grindability Machinabilityresistance hardness<strong>VWM2</strong>VWM7VKM42VWM3CVK5EVHSSM50SINTER23 ®SINTER30 ®Deflection (mm)10987654Fracture Energy (J)All information presented are intended to provide guidelines of material use. They do not have relation to warranty of specific properties or contractual obligations.