RMP Underground Conduit System Installation Guide (Procedure 242)

RMP Underground Conduit System Installation Guide (Procedure 242)

RMP Underground Conduit System Installation Guide (Procedure 242)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

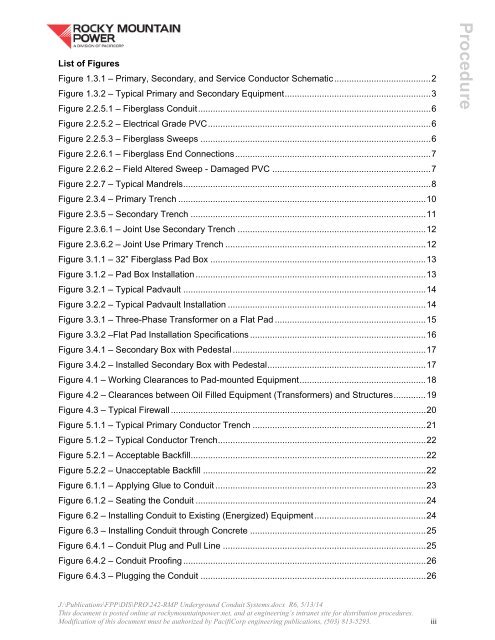

List of FiguresFigure 1.3.1 – Primary, Secondary, and Service Conductor Schematic ....................................... 2Figure 1.3.2 – Typical Primary and Secondary Equipment ........................................................... 3Figure 2.2.5.1 – Fiberglass <strong>Conduit</strong> .............................................................................................. 6Figure 2.2.5.2 – Electrical Grade PVC .......................................................................................... 6Figure 2.2.5.3 – Fiberglass Sweeps ............................................................................................. 6Figure 2.2.6.1 – Fiberglass End Connections ............................................................................... 7Figure 2.2.6.2 – Field Altered Sweep - Damaged PVC ................................................................ 7Figure 2.2.7 – Typical Mandrels .................................................................................................... 8Figure 2.3.4 – Primary Trench .................................................................................................... 10Figure 2.3.5 – Secondary Trench ............................................................................................... 11Figure 2.3.6.1 – Joint Use Secondary Trench ............................................................................ 12Figure 2.3.6.2 – Joint Use Primary Trench ................................................................................. 12Figure 3.1.1 – 32” Fiberglass Pad Box ....................................................................................... 13Figure 3.1.2 – Pad Box <strong>Installation</strong> ............................................................................................. 13Figure 3.2.1 – Typical Padvault .................................................................................................. 14Figure 3.2.2 – Typical Padvault <strong>Installation</strong> ................................................................................ 14Figure 3.3.1 – Three-Phase Transformer on a Flat Pad ............................................................. 15Figure 3.3.2 –Flat Pad <strong>Installation</strong> Specifications ....................................................................... 16Figure 3.4.1 – Secondary Box with Pedestal .............................................................................. 17Figure 3.4.2 – Installed Secondary Box with Pedestal ................................................................ 17Figure 4.1 – Working Clearances to Pad-mounted Equipment ................................................... 18Figure 4.2 – Clearances between Oil Filled Equipment (Transformers) and Structures ............. 19Figure 4.3 – Typical Firewall ....................................................................................................... 20Figure 5.1.1 – Typical Primary Conductor Trench ...................................................................... 21Figure 5.1.2 – Typical Conductor Trench .................................................................................... 22Figure 5.2.1 – Acceptable Backfill ............................................................................................... 22Figure 5.2.2 – Unacceptable Backfill .......................................................................................... 22Figure 6.1.1 – Applying Glue to <strong>Conduit</strong> ..................................................................................... 23Figure 6.1.2 – Seating the <strong>Conduit</strong> ............................................................................................. 24Figure 6.2 – Installing <strong>Conduit</strong> to Existing (Energized) Equipment ............................................. 24Figure 6.3 – Installing <strong>Conduit</strong> through Concrete ....................................................................... 25Figure 6.4.1 – <strong>Conduit</strong> Plug and Pull Line .................................................................................. 25Figure 6.4.2 – <strong>Conduit</strong> Proofing .................................................................................................. 26Figure 6.4.3 – Plugging the <strong>Conduit</strong> ........................................................................................... 26<strong>Procedure</strong>J:\Publications\FPP\DIS\PRO\<strong>242</strong>-<strong>RMP</strong> <strong>Underground</strong> <strong>Conduit</strong> <strong>System</strong>s.docx R6, 5/13/14This document is posted online at rockymountainpower.net, and at engineering’s intranet site for distribution procedures.Modification of this document must be authorized by PacifiCorp engineering publications, (503) 813-5293.iii