Vertical Lamp - Kim Lighting

Vertical Lamp - Kim Lighting

Vertical Lamp - Kim Lighting

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

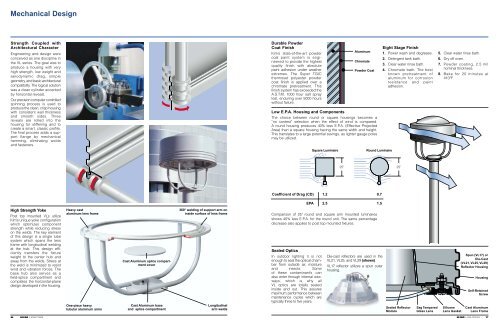

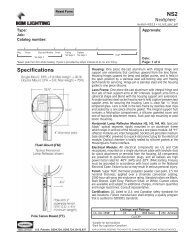

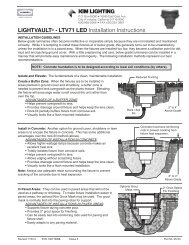

Mechanical DesignStrength Coupled withArchitectural CharacterEngineering and design wereconceived as one discipline inthe VL series. The goal was toproduce a housing with veryhigh strength, low weight andaerodynamic drag, simplegeometry, and basic architecturalcompatibility. The logical solutionwas a clean cylinder accentedby horizontal reveals.Our precision computer controlledspinning process is used toproduce the clean, crisp housingwith consistent wall thicknessand smooth sides. Threereveals are rolled into thehousing for stiffening and tocreate a smart, classic profile.The final process adds a supportflange by mechanicalhemming, eliminating weldsand fasteners.Durable PowderCoat Finish<strong>Kim</strong>’s state-of-the-art powdercoat paint system is engineeredto provide the highestquality finish with absolutepaint adhesion under weatherextremes. The Super TGICthermoset polyester powdercoat finish is applied over achromate pretreatment. Thisfinish system has exceeded theA.S.T.M. 1000 hour salt spraytest, enduring over 5000 hourswithout failure.•••AluminumChromatePowder CoatLow E.P.A. Housing and ComponentsThe choice between round or square housings becomes a“no contest” selection when the effect of wind is compared.A round housing produces 40% less E.P.A. (Effective ProjectedArea) than a square housing having the same width and height.This translates to a large potential savings, as lighter gauge polesmay be utilized.Square LuminaireRound LuminaireEight Stage Finish1. Power wash and degrease.2. Detergent tank bath.3. Clear water rinse bath.4. Chromate bath. The bestknown pretreatment ofaluminum for corrosionresistance and paintadhesion.5. Clear water rinse bath.6. Dry off oven.7. Powder coating, 2.5 milnominal thickness.8. Bake for 20 minutes at410°F.25" 25"Coefficient of Drag (CD) 1.2 0.7EPA 2.5 1.5High Strength YokePost top mounted VLs utilize<strong>Kim</strong>’s unique yoke configurationwhich optimizes componentstrength while reducing stresson the welds. The key elementof this design is a single tubesystem which spans the lensframe with longitudinal weldingat the hub. This design efficientlytransfers the fixtureweight to the center hub andaway from the welds. Stress atthe weld is minimized to resistwind and vibration forces. Thebase hub also serves as afield-splice compartment andcompletes the horizontal-planedesign developed in the housing.Heavy castaluminum lens frameOne-piece heavytubular aluminum armsCast Aluminum splice compartmentcoverCast Aluminum baseand splice compartment360° welding of support arm oninside surface of lens frameLongitudinalarm weldsComparison of 25" round and square arm mounted luminairesshows 40% less E.P.A. for the round unit. The same percentagedecrease also applies to post top mounted fixtures.Sealed OpticsIn outdoor lighting it is notenough to seal the optical chamberfrom outside air, moistureand insects. Someof these contaminant’s canalso enter through internal wireways,which is why allVL optics are totally sealedinside and out. This assuresmaximum performance betweenmaintenance cycles which aretypically three to five years.Die-cast reflectors are used in theVL21, VL25, and VL29 (shown).VL17 reflector utilizes a spun outerhousing.Sealed ReflectorModuleSag TemperedGlass LensSiliconeLens GasketSpun (VL17) orDie-Cast(VL21, VL25, VL29)Reflector HousingHousingSelf-RetainedScrewCast AluminumLens Frame6 KIM LIGHTINGKIM LIGHTING 7