CMM 3_7 PROGRESS_Layout 1 - Commercial Micro Manufacturing

CMM 3_7 PROGRESS_Layout 1 - Commercial Micro Manufacturing

CMM 3_7 PROGRESS_Layout 1 - Commercial Micro Manufacturing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

What’s new in Switzerland?<br />

Novel Replication Method for Reflective<br />

Optically Variable Image Devices<br />

<strong>Micro</strong>cut Ltd<br />

C: Mr. H. Frutig<br />

T: +41 32 654 15 15<br />

E: info@microcut.ch<br />

W: www.microcut.ch<br />

<strong>Micro</strong>cut is a manufacturer of Honing machines for bores of 0.015 mm to<br />

4 mm in diameter. It provides machines, tools and job order production, as<br />

well as a sub-contract service.<br />

SARIX SA, Losone<br />

C: Franck Leleu<br />

T: +41 91 785 81 73<br />

E: sales@sarix.com<br />

W: www.sarix.com<br />

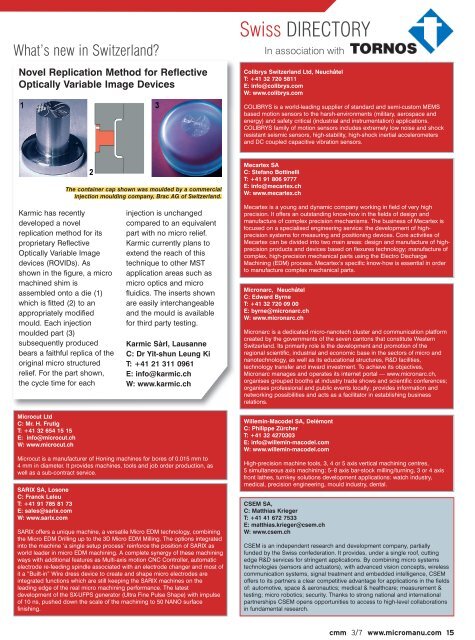

The container cap shown was moulded by a commercial<br />

injection moulding company, Brac AG of Switzerland.<br />

Karmic has recently<br />

developed a novel<br />

replication method for its<br />

proprietary Reflective<br />

Optically Variable Image<br />

devices (ROVIDs). As<br />

shown in the figure, a micro<br />

machined shim is<br />

assembled onto a die (1)<br />

which is fitted (2) to an<br />

appropriately modified<br />

mould. Each injection<br />

moulded part (3)<br />

subsequently produced<br />

bears a faithful replica of the<br />

original micro structured<br />

relief. For the part shown,<br />

the cycle time for each<br />

injection is unchanged<br />

compared to an equivalent<br />

part with no micro relief.<br />

Karmic currently plans to<br />

extend the reach of this<br />

technique to other MST<br />

application areas such as<br />

micro optics and micro<br />

fluidics. The inserts shown<br />

are easily interchangeable<br />

and the mould is available<br />

for third party testing.<br />

Karmic Sàrl, Lausanne<br />

C: Dr Yit-shun Leung Ki<br />

T: +41 21 311 0961<br />

E: info@karmic.ch<br />

W: www.karmic.ch<br />

SARIX offers a unique machine, a versatile <strong>Micro</strong> EDM technology, combining<br />

the <strong>Micro</strong> EDM Drilling up to the 3D <strong>Micro</strong> EDM Milling. The options integrated<br />

into the machine ‘a single setup process’ reinforce the position of SARIX as<br />

world leader in micro EDM machining. A complete synergy of these machining<br />

ways with additional features as Multi-axis motion CNC Controller, automatic<br />

electrode re-feeding spindle associated with an electrode changer and most of<br />

it a “Built-in” Wire dress device to create and shape micro electrodes are<br />

integrated functions which are still keeping the SARIX machines on the<br />

leading edge of the real micro machining performance. The latest<br />

development of the SX-UFPS generator (Ultra Fine Pulse Shape) with impulse<br />

of 10 ns, pushed down the scale of the machining to 50 NANO surface<br />

finishing.<br />

Swiss DIRECTORY<br />

In association with<br />

Colibrys Switzerland Ltd, Neuchâtel<br />

T: +41 32 720 5811<br />

E: info@colibrys.com<br />

W: www.colibrys.com<br />

COLIBRYS is a world-leading supplier of standard and semi-custom MEMS<br />

based motion sensors to the harsh-environments (military, aerospace and<br />

energy) and safety critical (industrial and instrumentation) applications.<br />

COLIBRYS family of motion sensors includes extremely low noise and shock<br />

resistant seismic sensors, high-stability, high-shock inertial accelerometers<br />

and DC coupled capacitive vibration sensors.<br />

Mecartex SA<br />

C: Stefano Bottinelli<br />

T: +41 91 806 9777<br />

E: info@mecartex.ch<br />

W: www.mecartex.ch<br />

Mecartex is a young and dynamic company working in field of very high<br />

precision. It offers an outstanding know-how in the fields of design and<br />

manufacture of complex precision mechanisms. The business of Mecartex is<br />

focused on a specialised engineering service: the development of highprecision<br />

systems for measuring and positioning devices. Core activities of<br />

Mecartex can be divided into two main areas: design and manufacture of highprecision<br />

products and devices based on flexures technology; manufacture of<br />

complex, high-precision mechanical parts using the Electro Discharge<br />

Machining (EDM) process. Mecartex’s specific know-how is essential in order<br />

to manufacture complex mechanical parts.<br />

<strong>Micro</strong>narc, Neuchâtel<br />

C: Edward Byrne<br />

T: +41 32 720 09 00<br />

E: byrne@micronarc.ch<br />

W: www.micronarc.ch<br />

<strong>Micro</strong>narc is a dedicated micro-nanotech cluster and communication platform<br />

created by the governments of the seven cantons that constitute Western<br />

Switzerland. Its primarily role is the development and promotion of the<br />

regional scientific, industrial and economic base in the sectors of micro and<br />

nanotechnology, as well as its educational structures, R&D facilities,<br />

technology transfer and inward investment. To achieve its objectives,<br />

<strong>Micro</strong>narc manages and operates its internet portal — www.micronarc.ch,<br />

organises grouped booths at industry trade shows and scientific conferences;<br />

organises professional and public events locally; provides information and<br />

networking possibilities and acts as a facilitator in establishing business<br />

relations.<br />

Willemin-Macodel SA, Delémont<br />

C: Philippe Zürcher<br />

T: +41 32 4270303<br />

E: info@willemin-macodel.com<br />

W: www.willemin-macodel.com<br />

High-precision machine tools, 3, 4 or 5 axis vertical machining centres,<br />

5 simultaneous axis machining; 5–8 axis bar-stock milling/turning, 3 or 4 axis<br />

front lathes, turnkey solutions development applications: watch industry,<br />

medical, precision engineering, mould industry, dental.<br />

CSEM SA,<br />

C: Matthias Krieger<br />

T: +41 41 672 7533<br />

E: matthias.krieger@csem.ch<br />

W: www.csem.ch<br />

CSEM is an independent research and development company, partially<br />

funded by the Swiss confederation. It provides, under a single roof, cutting<br />

edge R&D services for stringent applications. By combining micro systems<br />

technologies (sensors and actuators), with advanced vision concepts, wireless<br />

communication systems, signal treatment and embedded intelligence, CSEM<br />

offers to its partners a clear competitive advantage for applications in the fields<br />

of: automotive, space & aeronautics; medical & healthcare; measurement &<br />

testing; micro robotics; security. Thanks to strong national and international<br />

partnerships CSEM opens opportunities to access to high-level collaborations<br />

in fundamental research.<br />

cmm 3/7 www.micromanu.com 15

Swiss DIRECTORY<br />

Emissa SA, Le Locle<br />

C: Haller Jean-Francois<br />

T: +41 32 933 06 66<br />

E: info@emissa.com<br />

W: www.emissa.com<br />

The company specialises in the development and manufacture special<br />

machines. Its products are designed to stand up to the rigors of high<br />

production, as well as satisfying the demands of watch industries. Its turret<br />

heads and multi spindle heads machines, in particular, can reduce the multiple<br />

clamping required for all sizes of intricate parts. EMISSA provides solutions for<br />

increased productivity in the clients’ operations. Its products can be<br />

engineered according to the clients’ needs of all sorts and sizes. The<br />

company’s machines have been utilised in all kinds of industry, as miniature<br />

as watch making and as large as automobile or energies industries. It has<br />

enjoyed a strong relationship with the automobile industry in particular.<br />

FSRM (Swiss Foundation for Research in <strong>Micro</strong>technology), Neuchâtel<br />

C: Annette Locher<br />

T: +41 32 720 09 00<br />

E: fsrm@fsrm.ch<br />

W: www.fsrm.ch<br />

The FSRM is an international leader for in-service training in micro and nano<br />

technologies. It currently offers over 30 state-of-the-art courses held at various<br />

locations throughout Europe. The courses cover most of the commonly used<br />

technologies, suitable design methods and the most typical fields of<br />

applications. Course topics are, for example: biomedical engineering,<br />

cantilever-based sensors, carbon nanotubes, micro fabrication, micro fluidics,<br />

micro optics, packaging, reliability, etc. FSRM courses specifically address<br />

engineers and researchers. Over 4,000 people, of whom 80% work in industry,<br />

have already gone to the FSRM to update their skills. Companies particularly<br />

appreciate the practice-oriented approach and the fact that FSRM courses are<br />

limited in duration to one or two days. The consistently high quality of the<br />

FSRM courses is assured through a broad network of over 40 specialists.<br />

These instructors, coming directly from both the private sector and academic<br />

institutions, bring professional knowledge that can be directly put into practice<br />

by the participants.<br />

Karmic Sàrl, Lausanne<br />

C: Dr Yit-shun Leung Ki<br />

T: +41 21 311 0961<br />

E: info@karmic.ch<br />

W: www.karmic.ch<br />

Karmic develops and supplies anti-counterfeiting devices based on the<br />

proprietary ROVID technology, in-line solution (no labels), customisable to the<br />

client’s production, fast turnaround, suitable for all plastic products.<br />

Maxon Motor, Sachseln<br />

C: Albert Bucheli<br />

T: +41 41 666 15 00<br />

E: info@maxonmotor.com<br />

W: www.maxonmotor.com<br />

Maxon Motor is reportedly the world’s leading supplier of high-precision drives<br />

and systems of up to 500 Watts power output. The company develops and<br />

manufactures brushless and brushed DC motors with the unique ironless<br />

maxon winding, in addition to iron-cored brushless flat motors. The modular<br />

product range is further complemented by planetary, spur and special<br />

gearheads, feedback devices and control electronics. The design and<br />

production of high-tech CIM and MIM components are achieved at a special<br />

competence centre. maxon motor stands for high quality, innovation,<br />

competitive prices and a worldwide distribution network.<br />

<strong>Micro</strong>Précis SA, Genève<br />

C: Charles Egli<br />

T: +41 22 301 77 71<br />

E: microprecis@yahoo.com<br />

W: www.microprecis.ch<br />

<strong>Micro</strong>Précis Corp. is a young, innovative company that distinguishes itself by<br />

an extremely rigorous finish. The company specialises in rapidly<br />

manufacturing high-end small and micro parts for the medical, space and<br />

watch making fields (famous Geneva Hallmark). It produces numerous pieces<br />

— such as surgical screws, dental implants, covers, abutments, micro screws<br />

— that require thin and long holes (e.g. 0.30 mm in diameter, 4 mm length),<br />

and many other parts that demand the highest quality of finish and precision<br />

to microns.<br />

FISBA OPTIK AG, St. Gallen<br />

C: Monique Tomaselli<br />

T: +41 71 282 31 31<br />

E: info@fisba.com<br />

W: www.fisba.com<br />

From simple lenses to complex optical components, the solutions created by<br />

FISBA are always perfectly tailored to the specific demands. FISBA develops<br />

and manufactures lenses, laser modules, micro optics and advanced optical<br />

components for industrial applications. Further areas of expertise comprise<br />

metrological applications as well as the development of completely<br />

customised solutions.<br />

Huntsman Advanced Materials GmbH, Basel<br />

C: Benjamin Wiekenberg<br />

T: +41 61 299 11 11<br />

E: advanced_materials@huntsman.com<br />

W: www.huntsman.com/advanced_materials<br />

Huntsman is a leading global supplier of synthetic and formulated polymer<br />

systems for customers requiring high-performance materials which outperform<br />

the properties, functionality and durability of traditional materials. Over 2,300<br />

associates at 13 locations worldwide work to fulfil this promise day by day.<br />

More than 9,000 companies around the world use Huntsman Advanced<br />

Materials technologies in key markets such as adhesives and inks, aerospace,<br />

automotive, coatings, construction, electronics, medical, marine, power<br />

transmission and distribution, sports equipment and wind power generation.<br />

Locatis SA<br />

C: Alain Pilloud<br />

T: +41 32 427 04 40<br />

E: alain.pilloud@locatis.ch<br />

W: www.locatis-electronics.ch<br />

Based in Switzerland, the electronic division of LOCATIS aims to be the partner<br />

of the manufacture of electronic products as the subcontractor. A<br />

comprehensive set of benefits may be offered, clients can have a single<br />

interlocutor. The company can meet the needs so responsive and reliable<br />

including: production teams on the spot, a strong solid experience; production<br />

tools and controls at the cutting edge of current technology; central<br />

purchasing; dual certification ISO 9001/ISO 13485; compliance with delivery;<br />

technical process control that will ensure complete satisfaction. Thanks to its<br />

know-how and that of its partners and suppliers, LOCATIS is able to design<br />

products with the customer. It offers: advice on the choice of electronic<br />

components (analysis of the client’s nomenclature); studying the feasibility of<br />

the PCB and plastic parts; services of a network of developers<br />

hardware/software specialist; design and production of the PCB.<br />

<strong>Micro</strong>cube Sàrl, Crissier<br />

C: Jérôme Orteu<br />

T: +41 21 6358220<br />

E: info@microcube.ch<br />

W: www.microcube.ch<br />

<strong>Micro</strong>cube distributes Alicona InfiniteFocus, a high-resolution 3D Optical<br />

system for Form and Roughness measurement in Switzerland.<br />

<strong>Micro</strong>Vu Swiss, Gland<br />

C: Franck Zollinger<br />

T: +41 22 301 45 47<br />

E: mce@microvueurope.com<br />

W: www.microvu.ch<br />

<strong>Micro</strong>waterjet AG, Aarwangen<br />

C: Maurer Walter<br />

T: +41 62 9192090<br />

E: info@microwaterjet.ch<br />

W: www.microwaterjet.ch<br />

The company does wicro waterjet cutting.<br />

In association with<br />

<strong>Micro</strong>Vu manufactures video and multisensor measuring machines since 1959.<br />

These non-contact and contact measurement systems use video, touch probe<br />

and laser inputs to perform high-precision 2D and 3D measurements. <strong>Micro</strong>Vu<br />

measurement systems are used for quality assurance and incoming inspection<br />

applications — www.microvu.com/appl.html — to inspect high-precision parts<br />

for micro moulding, and the watch, medical devices, aerospace and<br />

automotive industries.<br />

cmm 3/7 www.micromanu.com 17

Swiss DIRECTORY<br />

Mimotec SA, Sion<br />

C: Adrian Häubi<br />

T: +41 27 329 09 09<br />

W: www.mimotec.ch<br />

Mimotec, a Swiss company, was founded in November 1998. The company is<br />

recognised both in Switzerland and abroad as a leader in the fields of micro<br />

technique and micro mechanics. So far, Mimotec has made a name for itself in<br />

the world of luxury watches and would now also like to put this experience and<br />

knowledge to use in other professional sectors, such as biomedical. The<br />

process used for the manufacture of micro components, as well as mould<br />

inserts for plastic injection, was inspired by Liga technology (lithography,<br />

electroplating, moulding); the difference being that Mimotec uses an ultraviolet<br />

luminous source rather than x-ray.<br />

Nanosurf AG<br />

C: Dr. Björn Pietzak<br />

T: +41 61 9275646<br />

E: info@nanosurf.com<br />

W: www.nanosurf.com<br />

Nanosurf is a leading provider of easy-to-use atomic force microscopes (AFM)<br />

and scanning tunneling microscopes (STM). Its products and services are<br />

trusted by professionals worldwide to help them measure, analyse and<br />

present 3D surface information. Its microscopes excel through their compact<br />

and elegant design, their easy handling and their absolute reliability.<br />

Polydec SA, Biel-Bienne<br />

C: Yolanda Marcote<br />

T: +41 32 344 10 00<br />

E: info@polydec.ch<br />

W: www.polydec.ch<br />

Polydec, founded in 1985, specialises in micro turned parts. The company has<br />

over 40 staff and an annual turnover exceeding CHF 13 million. Polydec also<br />

has a sales office in Chicago, Polydec International. More than 80% of<br />

production is exported, mainly to the US and Germany. Certified ISO 9001,<br />

ISO/TS 16949, ISO 14001 and OHSAS 18001, the company focuses on the<br />

quality of its products, as well as on the well-being of its employees. Polydec<br />

caters for: automotive — with an annual production exceeding the 250 million<br />

micro-axles used in dashboards, Polydec parts are found in 5 out of 10 cars;<br />

electronics — Polydec manufactures contact probes, connectors and<br />

plungers; timepieces; and medical.<br />

Rofin Baasel Swiss AG, Biel<br />

C: Joachim Vogt<br />

T: +41 32 322 10 10<br />

E: joachim.vogt@rofin-baasel.ch<br />

W: www.rofin-baasel.ch<br />

For over 30 years ROFIN has been building laser sources and turnkey laser<br />

systems to address some of the most challenging material processing<br />

applications in the micro sector. With over 30,000 lasers installed around the<br />

world, ROFIN is a global company with extensive laser applications<br />

experience. Around 1,600 ROFIN employees communicate locally with<br />

customers wherever they are based. The headquarters of the ROFIN <strong>Micro</strong><br />

Division is in Starnberg, the heart of Europe. As well as solid state lasers,<br />

ROFIN manufactures CO2 lasers from 20W to 20,000W for processing plastics,<br />

paper and other organic materials. The StarPulse and StarFiber lasers can<br />

achieve fine welds with very low heat input — the laser is ideal for integrating<br />

into production automation for consumer electronics, medical devices,<br />

automotive or aerospace components. .<br />

SCHAEFER-TEC AG, Kirchberg<br />

C: Martin Bossard<br />

T: +41 34 423 70 70<br />

E: ch@schaefer-tec.com<br />

W: www.schaefer-tec.com<br />

The Schaefer group has offices in Germany, France, Italy, Switzerland, Poland,<br />

and Romania, and provides scientific instruments in the fields of nano<br />

technology, micro technology and surface inspection all over Europe.<br />

Customers benefit from the wealth of experience offered by Schaefer sales<br />

engineers, as well as from the broad product portfolio, which ensure that<br />

individual needs are identified and met. Instruments such as atomic force<br />

microscopes, optical profilers (interferometer, confocal), tribometers, as well as<br />

x-ray tomography devices and vacuum, gasflow, deposition rate and magnetic<br />

field measuring devices are supplied by Schaefer.<br />

MW Programmation SA, Malleray<br />

C: Patrick Duvanel<br />

T: +41 32 491 65 30<br />

E: pduvanel@mwprog.ch<br />

W: www.mwprog.ch<br />

MW Programmation specialises in CNC programming and data transfer, and<br />

has more than 1,000 customers in the watch, mechanical, medical, swisscutting<br />

and joinery sectors. Products include: alphacam CAD/CAM, including<br />

a mill/turn module, as well as Milling 2-5 simultaneously controlled,<br />

turning/Swiss-cutting 2-18 axis, stone setting, sequential numbering, wire,<br />

laser and 3D engraving; alphacam Partmodeler: CAD module in volumique;<br />

alphacut — simulates NC code on a defined machine.<br />

NUM, Teufen<br />

T: +41 71 3350411<br />

E: sales.ch@num.com<br />

W: www.num.com<br />

NUM CNC solutions provide machine builders with a competitive advantage.<br />

Its market strategy is to help the current and future customers to construct a<br />

better machine and thereby securing them a competitive advantage on the<br />

market. It perceives itself as a CNC High-End Application company and it is<br />

focusing on selected market niches, where it undeniably has something extra<br />

to offer, and it has a proven track record to back up this statement.<br />

Polyservice SA, Lengnau<br />

C: Francis Muller<br />

T: +41 32 653 04 44<br />

E: info@polyservice.ch<br />

W: www.polyservice.ch<br />

A market leader in the field of high-precision mass finishing of small precision<br />

parts, Polyservice offers a customer process engineering service and state-ofthe-art<br />

machines and consumables. For more than 40 years, the company has<br />

been offering customers complete solutions involving all aspects of deburring<br />

and burnishing precision parts in bulk. An especially important step in the<br />

development chain for customers takes place in process analysis and in<br />

Polyservice’s experimental laboratory where it subjects the products to be<br />

finished to detailed analysis. This service is free of charge. Due to the fact that<br />

industrial deburring and burnishing in bulk requires more than just a machine<br />

and consumables, the company also offers solutions for separation and drying<br />

of the parts after treatment, and provides handling accessories.<br />

ROLLOMATIC SA, Le Landeron<br />

C: Damien Wunderlin<br />

T: +41 32 7521700<br />

E: d.wunderlin@rollomatic.ch<br />

W: www.rollomaticsa.com<br />

Rollomatic offers a range of grinding machines dedicated to the manufacturing<br />

of cutting tools, punches and other precision ground parts. Rollomatic<br />

represents the professional approach to designing and manufacturing grinding<br />

centres, ranging from 3-axis CNC tool grinders to highly sophisticated 8-axis<br />

machines. In addition, Rollomatic also builds single purpose machines such<br />

as blank preparation machines, flute & relief grinders, point grinders, shankpreparation<br />

machines and peripheral equipment such as dressing/balancing<br />

units and precision gage systems.<br />

Schläfli Engineering AG, Bueren an der Aare<br />

C: Marlene Spätig<br />

T: +41 32 351 50 70<br />

E: info@schlafli.com<br />

W: www.schlafli.com<br />

In association with<br />

Schläfli Engineering is an independent enterprise specialising in the<br />

development and manufacture of highly precise machines for processing small<br />

parts. These machines are for the handling of hard to very hard materials, like<br />

ruby, sapphire, zirconium, ceramic(s) and tungsten carbide. The machine lineup<br />

consists of: a honing machine for the handling of small cylindrical throughholes,<br />

in the areas of hole dia. 0.04 to 2.0 mm; centreless grinding machines<br />

for the exact centric outside diameter of tubes, nozzles and cases with<br />

diameters from 0.5 to approx. 8 mm; brush polishing machines for surface<br />

polishing and edges processing; and machines to process concave and<br />

convex forms on various parts. These machines are used worldwide for the<br />

handling and checking of ruby and sapphire clocks, as well as industry<br />

bearings, ceramic couplings for the fibre-optics industry, tungsten carbide<br />

guide parts and high-precision tubes.<br />

cmm 3/7 www.micromanu.com 19

Swiss FOCUS<br />

In association with<br />

<strong>Micro</strong>narc: The Entry Point for <strong>Micro</strong> and Nano Technologies in Western Switzerland<br />

<strong>Micro</strong>. Nano. Arc. Three key<br />

concepts condensed into a<br />

single name that today<br />

represents the innovative force of Western<br />

Switzerland: its outstanding competencies<br />

in micro technology, its unparalleled<br />

position in nano technology research, and<br />

its privileged location encompassed by the<br />

twin mountainous arcs of the Jura and the<br />

Alps. <strong>Micro</strong>narc is a communication<br />

platform devoted to promoting these<br />

advantages and to encouraging seamless<br />

interaction between research facilities,<br />

educational structures and industry.<br />

Developing potential and attracting<br />

creative forces<br />

<strong>Micro</strong>narc is an initiative of seven cantons<br />

(the states of the Swiss Confederation):<br />

Berne, Fribourg, Vaud, Neuchâtel, Geneva,<br />

Valais and Jura. Nestled between the lakes<br />

and mountains of Western Switzerland,<br />

they share a strategic location and<br />

outstanding competencies in micro and<br />

nano technology. <strong>Micro</strong>narc’s mission is to<br />

develop and promote the skills, expertise<br />

and potential of the region on the national<br />

and international levels. It also seeks to<br />

integrate all participants in a network for<br />

the exchange of<br />

information and<br />

knowledge. This twoway<br />

approach aims<br />

to attract creative<br />

talent from outside<br />

the region, and to<br />

generate the<br />

framework conditions<br />

that will allow local<br />

innovative forces to<br />

realise their potential.<br />

<strong>Micro</strong>narc is also a<br />

news portal,<br />

informing the public<br />

about micro and<br />

nano technologies in<br />

Western Switzerland.<br />

Education and<br />

training: a unique<br />

hub of competence<br />

The <strong>Micro</strong>narc<br />

network represents<br />

an exceptional range<br />

of competencies in<br />

education, R&D and<br />

manufacturing. Its<br />

higher education<br />

institutions include<br />

the Federal Institute<br />

of Technology in<br />

Lausanne (EPFL),<br />

four universities<br />

(Fribourg, Geneva,<br />

Lausanne and Neuchâtel) and the two<br />

universities of applied sciences (UAS) of<br />

Bern (HTI) and Western Switzerland (HES<br />

SO). The UAS offer Bachelor’s and<br />

Master’s degrees in numerous disciplines,<br />

including micro technology.<br />

Research: industry is the driving force<br />

In parallel with their educational function,<br />

EPFL, the universities and the UAS are<br />

involved in cutting-edge research projects,<br />

often working in partnership with industry.<br />

Other institutions provide more specific<br />

inputs. The CSEM (Swiss Centre for<br />

Electronics and <strong>Micro</strong>technology Inc.) is a<br />

private R&D company specialised in micro<br />

and nano technology, systems engineering<br />

and IT. The FSRM (Swiss Foundation for<br />

Research in <strong>Micro</strong>technology) is a private<br />

foundation for the promotion of micro<br />

technology. It is very active in continuing<br />

education. The new Adolfe Merkle Institute<br />

(AMI) in Fribourg is a dedicated, state-ofthe-art,<br />

nano science research centre.<br />

Encouraging networking, today and for<br />

the future<br />

<strong>Micro</strong>narc manages and operates the<br />

Internet portal www.micronarc.ch. This<br />

mine of information offers access to all<br />

micro and nano technology participants in<br />

Western Switzerland.<br />

<strong>Micro</strong>narc<br />

C: Edward Byrne<br />

T: +41 32 7200990<br />

E: info@micronarc.ch<br />

W: www.micronarc.ch<br />

cmm 3/7 www.micromanu.com 21