Download pdf - MAPAL Dr. Kress KG

Download pdf - MAPAL Dr. Kress KG

Download pdf - MAPAL Dr. Kress KG

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

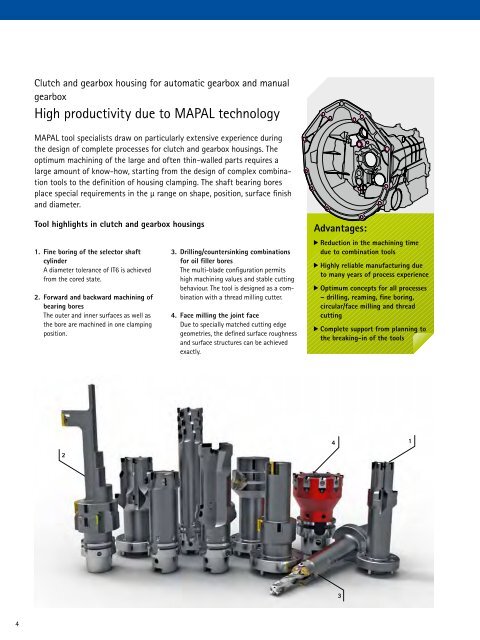

Clutch and gearbox housing for automatic gearbox and manualgearboxHigh productivity due to <strong>MAPAL</strong> technology<strong>MAPAL</strong> tool specialists draw on particularly extensive experience duringthe design of complete processes for clutch and gearbox housings. Theoptimum machining of the large and often thin-walled parts requires alarge amount of know-how, starting from the design of complex combinationtools to the definition of housing clamping. The shaft bearing boresplace special requirements in the µ range on shape, position, surface finishand diameter.Tool highlights in clutch and gearbox housings1. Fine boring of the selector shaftcylinderA diameter tolerance of IT6 is achievedfrom the cored state.2. Forward and backward machining ofbearing boresThe outer and inner surfaces as well asthe bore are machined in one clampingposition.3. <strong>Dr</strong>illing/countersinking combinationsfor oil filler boresThe multi-blade configuration permitshigh machining values and stable cuttingbehaviour. The tool is designed as a combinationwith a thread milling cutter.4. Face milling the joint faceDue to specially matched cutting edgegeometries, the defined surface roughnessand surface structures can be achievedexactly.Advantages:Reduction in the machining timedue to combination toolsHighly reliable manufacturing dueto many years of process experienceOptimum concepts for all processes– drilling, reaming, fine boring,circular/face milling and threadcuttingComplete support from planning tothe breaking-in of the tools4 1234