Nevamar® Laminate Floor Tiles - Panolam

Nevamar® Laminate Floor Tiles - Panolam

Nevamar® Laminate Floor Tiles - Panolam

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

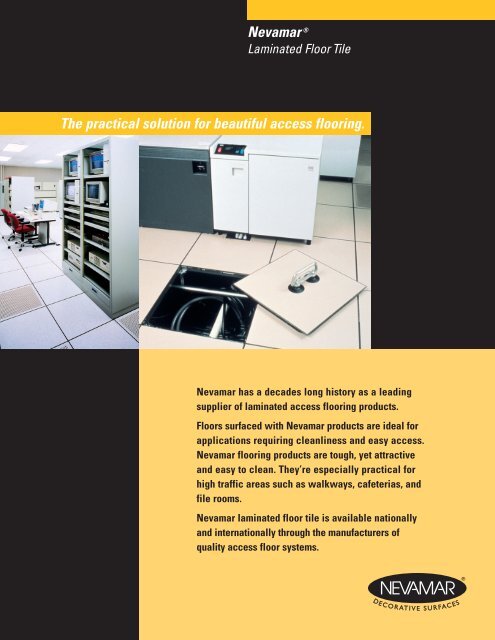

Nevamar ®<strong>Laminate</strong>d <strong>Floor</strong> TileThe practical solution for beautiful access flooring.Nevamar has a decades long history as a leadingsupplier of laminated access flooring products.<strong>Floor</strong>s surfaced with Nevamar products are ideal forapplications requiring cleanliness and easy access.Nevamar flooring products are tough, yet attractiveand easy to clean. They’re especially practical forhigh traffic areas such as walkways, cafeterias, andfile rooms.Nevamar laminated floor tile is available nationallyand internationally through the manufacturers ofquality access floor systems.D E C O R ATI V E S U R FAC E S

Nevamar <strong>Laminate</strong> <strong>Floor</strong> Tile Technical InformationDESCRIPTIONInterior Use — Nevamar floor tile is specially formulated,high-pressure laminate manufacturedfor surfacing access flooring panels. Conductiveflooring should be used where permanent staticdissipation properties are required.Basic Use — It is recommended for accessflooring systems where cleanliness, ease ofmaintenance and long wear is of major concern.Conductive laminate is recommended for controlof static electricity and should be used whereelectric apparatus is sensitive to static electricity.Potential applications are clean rooms, hospitalintensive care rooms and computer rooms, orareas where a clean and dust free environmentis critical. They comply with requirements forlow static generation and retention, coupled witha washable surface requiring no waxing.Limitations — Nevamar laminated access flooringproducts are not recommended for exterioruse. <strong>Laminate</strong> should not be bonded to plasterboard,gypsum board, plaster, concrete blocks orsimilar materials. The internal bond strength ofthe substrate and adhesive line is not sufficientfor this type of application.Composition and Materials — Nevamar laminatedflooring products are manufactured to orderusing a specially formulated surface sheet overa melamine impregnated print pattern sheet. Thecore layers of phenolic impregnated kraft papershave been designed to control dimensional stability.The Conductive Grade laminate core materialconsists of several sheets of black conductivepaper impregnated with a thermosettingresin system. The laminate composition ispressed under closely controlled pressures andtemperatures. The back of the laminate compositionis sanded to maintain uniform thickness andto facilitate bonding.Standard Grades Nominal Thickness:Grade HDH .118” (3 mm) ± .005 (.12 mm)Grade HDM .059” (1.5 mm) ± .005 (.12 mm)Conductive Grades Nominal Thickness:Grade CHDH .118” (3 mm) ± .005” (.12 mm)Grade CHDM .059” (1.5 mm) ± .005” (.12 mm)Proper grade of product needed is dependenton the total flooring requirements. When specifyingan access floor, we recommend thatthe floor manufacturer be contacted for properspecification.Size Availability:All grades may be purchased in either full sizesheets 4’ X 10’ (1219 mm X 3048 mm) nominal, orcut to size 24” X 24” (610 mm X 610 mm) nominal.Cutting Tolerance:Precision Cutting ± .010” (0.25 mm)Rough Cutting ± .032” (0.8 mm)Diagonal within .045” (1.15 mm)Finish: Textured, a low sheen, matte finish.Gloss Specifications:Nevamar Spec 6-12 (60° Gloss Meter)Colors and Patterns:Nevamar flooring products are offered in patternsselected to meet most design and aestheticrequirements for initial installation and futureadditions. The standard patterns are manufacturedto comply with light reflectance values asrecommended by leading computer manufacturers.Other items in the Nevamar laminate line areavailable as <strong>Laminate</strong>d <strong>Floor</strong> Tile on a specialorder basis. Contact your Nevamar representativefor information.Conductive Grades flooring laminate is availablein two designs only, Graphite Gray and GraphiteBeige. Both colors have random patterns and thinblack lines throughout the surface. The product ismanufactured in textured finish and colors canvary from lot to lot.Applicable Standards:Material shall meet or exceed performance standardsset by ANSI (American National StandardsInstitute) NEMA (National Electrical ManufacturersAssociation) Publication LD3-2005 for high-pressuredecorative plastic laminate.INSTALLATIONSuitable Subsurfaces — Nevamar laminatedflooring must be bonded to substrates such asaluminum castings, fabricated steel or aluminumsections to provide the rigidity and load-bearingrequirements of access flooring installations.The laminate should be bonded using professionalfabricating techniques and procedures. Conductiveadhesives, contact glues and thermosetting rigidtypeadhesives are acceptable when followingadhesive manufacturer’s instructions.Conductive laminate flooring must be properlygrounded by utilizing a variety of terminals andgrounding cords properly attached to the laminateand a suitable earth ground. Groundingsystems should be checked periodically.Methods — Fabrication of Nevamar floor tilescan be done generally with conventional woodworkingor metalworking equipment, either handoperated or power driven. Sawing, drilling, edgefiling,sanding and routing should be done withthe decorative side up to prevent cracking orchipping of the surface. Curved edges should becut slightly oversize and finished by sanding,filing or routing for smooth edges. Carbide tippedcutting edges should be used on saws, drillsand routers to produce chip free edges and toavoid frequent resharpening of tools. The productshould be drilled with a wood backing to prevent“breakout” at the bottom of the drilled hole.AVAILABILITY AND PRICINGVaries according to grade, quantity and locale.All items are manufactured to order. Nevamarrepresentatives will quote on request.Call 1-800-638-4380 to place your order.MAINTENANCENevamar laminate access flooring is designed forminimum maintenance. Dry mop, sweep, vacuum,or damp mop with a mild detergent as requiredfor proper housekeeping. Stubborn stains may beremoved with a non-flammable organic cleaner.Do not permit the cleaner to get into the cracksbetween the support panel and the laminate asit could adversely affect the bond.Tack rugs are recommended at entrances toavoid abrasives being tracked in from adjacentareas. Do not clean floor surface with steel wool,nylon pads or abrasives of any kind, manually orwith power equipment. Don’t flood the floor withwater or cleaning agents. Don’t buff, wax, oil orpolish; they are unnecessary and may interferewith the conductive properties of the laminate.TECHNICAL SERVICESNevamar maintains a technical staff and trainedpersonnel to assist you. For technical supportcall 800-845-4790 or write toNevamarOne Nevamar PlaceHampton, SC 29924IMPORTANT NOTICEThe information and statements herein arebelieved to be reliable but are not to be construedas a warranty or representation for whichwe assume legal responsibility. Users shouldundertake sufficient verification and testing todetermine the suitability for their own particularpurpose of any information or products referredto herein. NO WARRANTY OF FITNESS FOR APARTICULAR PURPOSE IS MADE.D E C O R ATI V E S U R FAC E S800-638-4380 www.nevamar.com© 2006 Nevamar ® is a registered trademark of <strong>Panolam</strong> Industries Printed in U.S.A. N0410