data sheet - COMEVAL

data sheet - COMEVAL

data sheet - COMEVAL

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

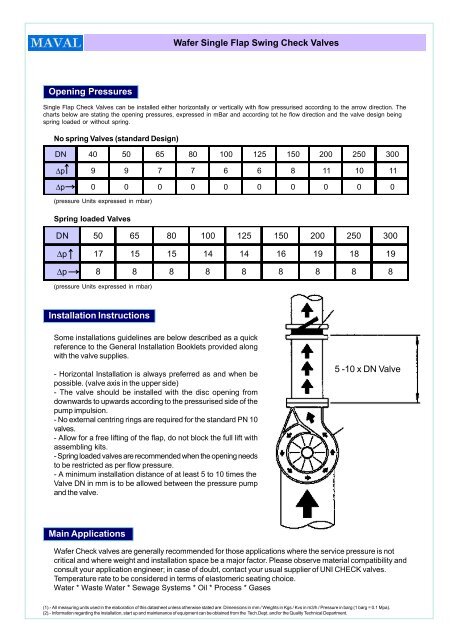

Wafer Single Flap Swing Check ValvesOpening PressuresSingle Flap Check Valves can be installed either horizontally or vertically with flow pressurised according to the arrow direction. Thecharts below are stating the opening pressures, expressed in mBar and according tot he flow direction and the valve design beingspring loaded or without spring.No spring Valves (standard Design)DN 40 50 65 80 100 125 150 200 250 300∆p 9 9 7 7 6 6 8 11 10 11∆p 0 0 0 0 0 0 0 0 0 0(pressure Units expressed in mbar)Spring loaded ValvesDN 50 65 80 100 125 150 200 250 300∆p 17 15 15 14 14 16 19 18 19∆p 8 8 8 8 8 8 8 8 8(pressure Units expressed in mbar)Installation InstructionsSome installations guidelines are below described as a quickreference to the General Installation Booklets provided alongwith the valve supplies.- Horizontal Installation is always preferred as and when bepossible. (valve axis in the upper side)- The valve should be installed with the disc opening fromdownwards to upwards according to the pressurised side of thepump impulsion.- No external centring rings are required for the standard PN 10valves.- Allow for a free lifting of the flap, do not block the full lift withassembling kits.- Spring loaded valves are recommended when the opening needsto be restricted as per flow pressure.- A minimum installation distance of at least 5 to 10 times theValve DN in mm is to be allowed between the pressure pumpand the valve.5 -10 x DN ValveMain ApplicationsWafer Check valves are generally recommended for those applications where the service pressure is notcritical and where weight and installation space be a major factor. Please observe material compatibility andconsult your application engineer; in case of doubt, contact your usual supplier of UNI CHECK valves.Temperature rate to be considered in terms of elastomeric seating choice.Water * Waste Water * Sewage Systems * Oil * Process * Gases(1).- All measuring units used in the elaboration of this <strong>data</strong><strong>sheet</strong> unless otherwise stated are: Dimensions in mm / Weights in Kgs / Kvs in m3/h / Pressure in barg (1 barg = 0.1 Mpa).(2).- Information regarding the installation, start up and maintenance of equipment can be obtained from the Tech.Dept. and/or the Quality Technical Department.